MEMS device and manufacturing method thereof

A manufacturing method and device technology, applied in the manufacture of microstructure devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., to achieve good material compactness, ensure internal stress, and structure The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] It can be seen from the background art that the performance of MEMS devices in the prior art needs to be improved.

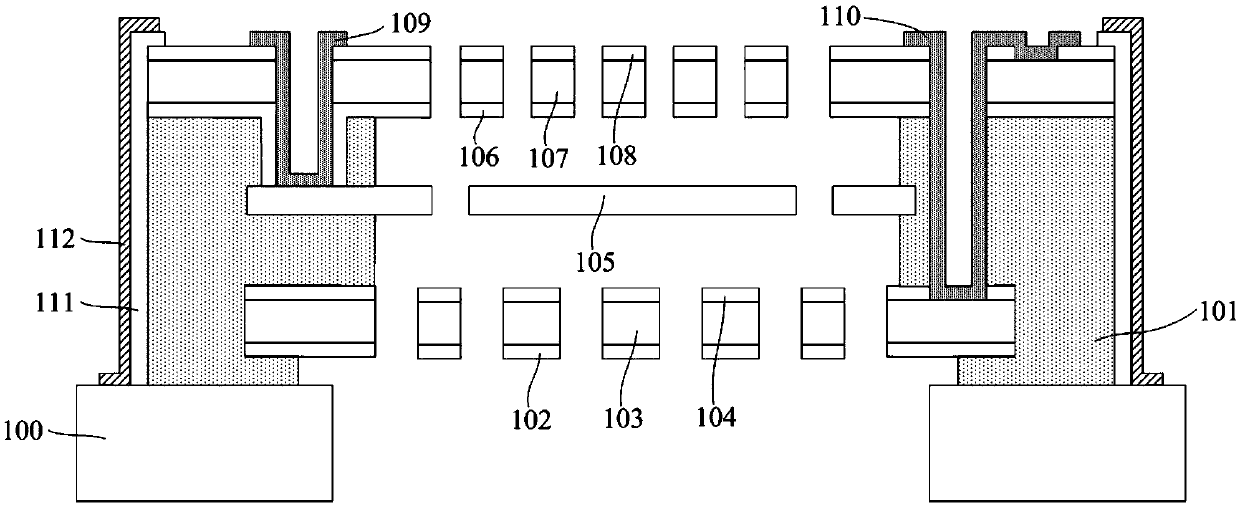

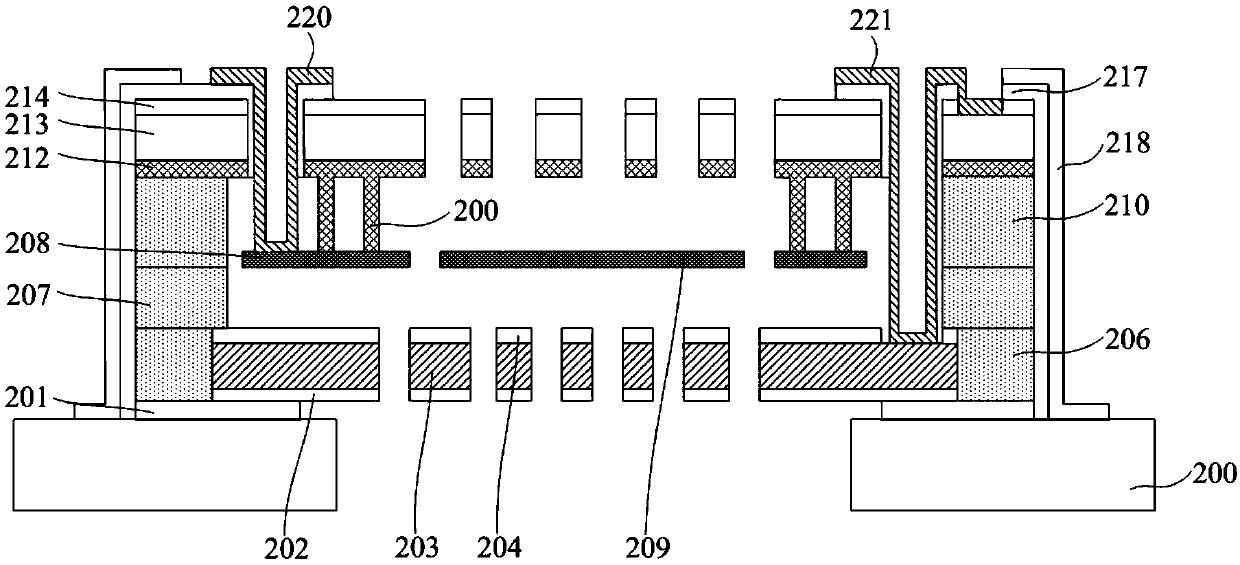

[0016] refer to figure 1 , figure 1 It is a schematic cross-sectional structure diagram of a double-back pole MEMS device, taking the double back pole MEMS device as a MEMS microphone as an example, and the MEMS device includes:

[0017] Substrate 100, the substrate 100 has a groove running through its thickness; a patterned first back plate located above the substrate 100, the first back plate includes a first lower plate 102, a first conductive electrode plate 103 and a first upper plate 104, the first back plate includes a first support area and a first vibration area, the first vibration area is located above the groove, and the first support area is located on the upper surface of the substrate 100 Above, and the first back plate of the first vibrating area has several openings through its thickness; the vibrating electrode located above the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com