Sampling storage box material for egg quality detection and preparation method thereof

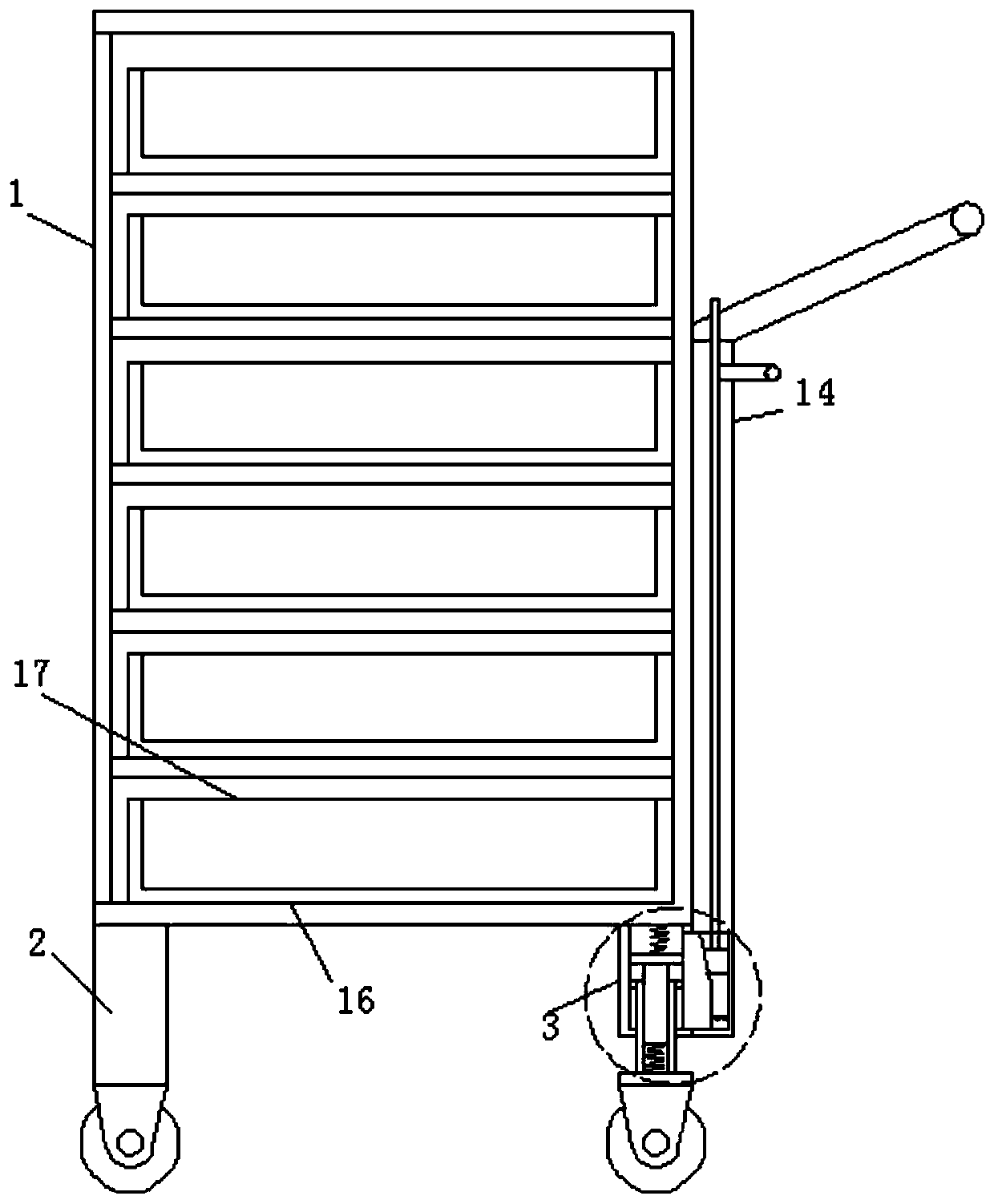

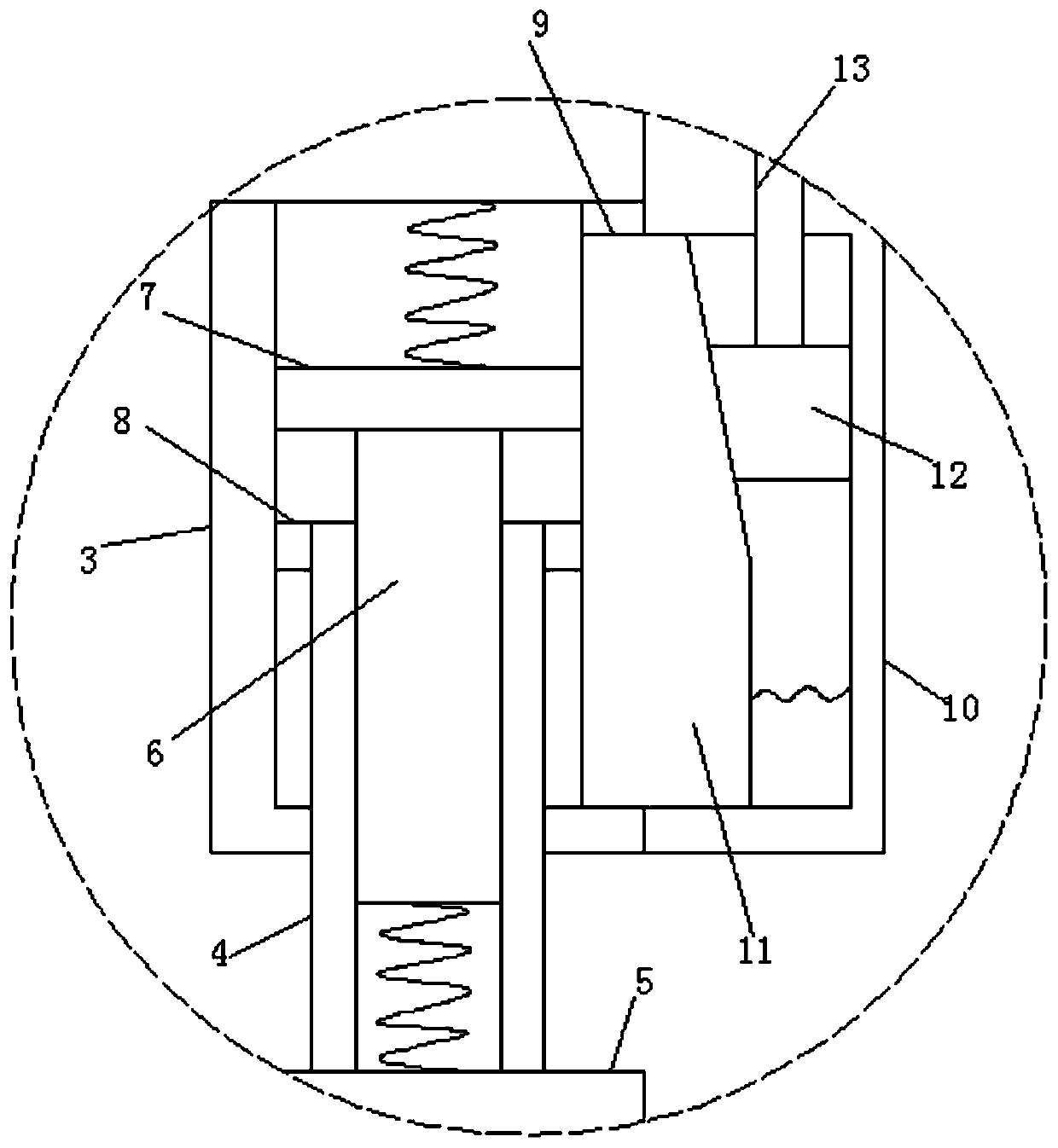

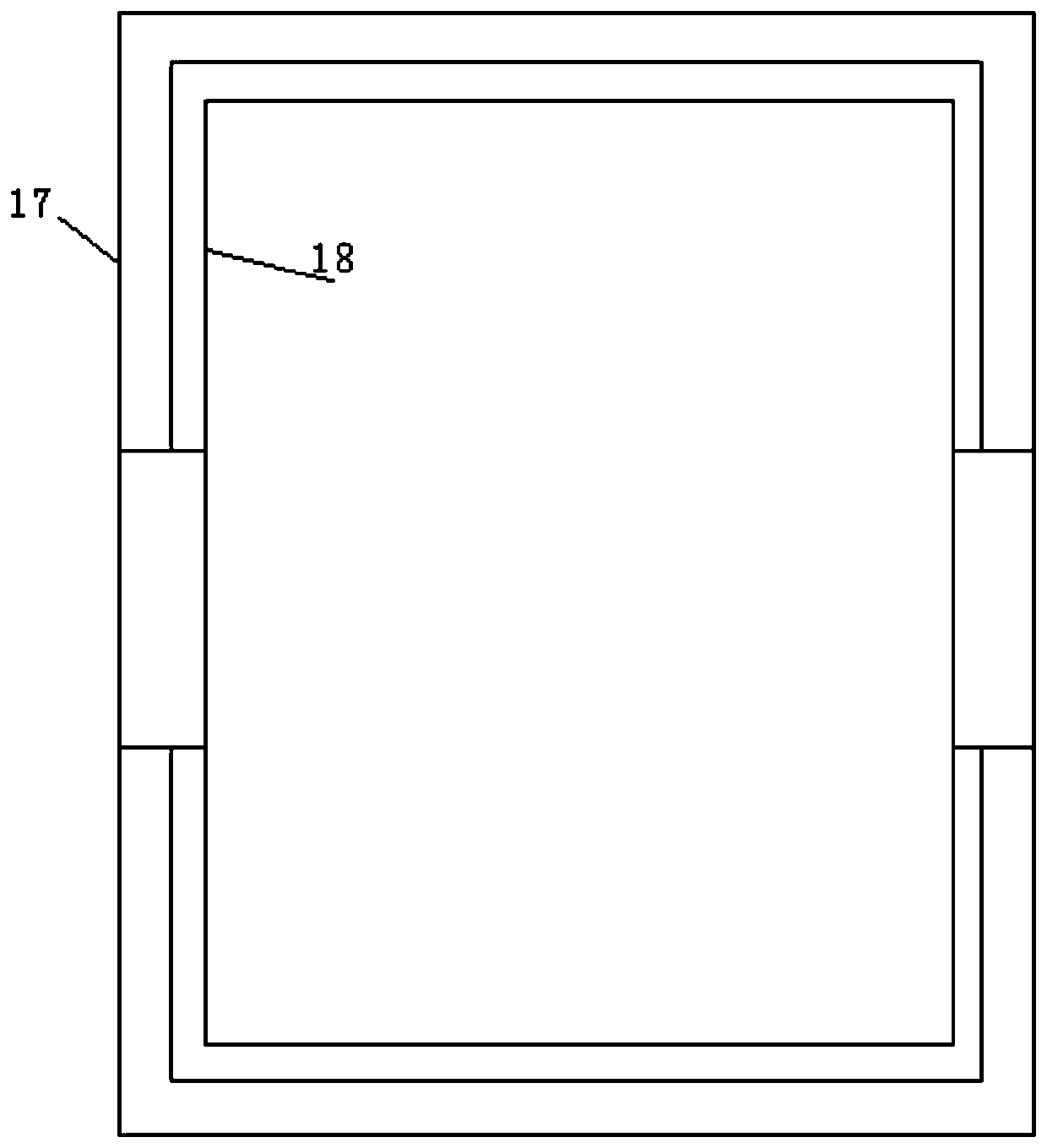

A quality inspection and storage box technology, applied in the field of egg storage boxes, can solve the problems affecting the accuracy of test measurement, low structural strength of square carton, and eggs are easily broken, so as to protect the safety of samples, enhance mechanical properties and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing a sampling storage box material for egg quality testing, comprising the following steps:

[0046] S1. Mix 5kg of carbon nanotubes, 40kg of concentrated sulfuric acid, and 5kg of concentrated nitric acid, adjust the temperature to 135°C and stir for 2 hours, wash with deionized water, dry at 90°C, add 50kg of N,N-dimethylformamide, and stir Add 10kg of lactide, stir at 65°C for 15min, add 0.01kg of stannous octoate for ultrasonic treatment for 40min, the ultrasonic frequency is 40kHz, then microwave for 40min, the microwave temperature is 145°C, the microwave power is 750W, cool to room temperature, filter, wash, Dry at 70°C and pulverize to obtain a toughening treatment agent;

[0047] S2. Add 100kg of expandable polystyrene particles into the mixer, adjust the temperature to 50°C and stir for 15 minutes, then bake in an oven with a temperature of 88°C until stickiness occurs, stop baking, then wrap with gauze, send Put it into a steam oven, adju...

Embodiment 2

[0050] A method for preparing a sampling storage box material for egg quality testing, comprising the following steps:

[0051] S1. Mix 15kg of carbon nanotubes, 20kg of concentrated sulfuric acid, and 15kg of concentrated nitric acid, adjust the temperature to 125°C and stir for 4 hours, wash with deionized water, dry at 80°C, add 60kg of N,N-dimethylformamide, and stir Add 4kg of lactide, stir at 75°C for 5min, add 0.015kg of stannous octoate for ultrasonic treatment for 20min, the ultrasonic frequency is 45kHz, then microwave for 30min, the microwave temperature is 155°C, the microwave power is 650W, cool to room temperature, filter, wash, Dry at 80°C and pulverize to obtain a toughening treatment agent;

[0052] S2. Add 60kg of expandable polystyrene particles into the mixer, adjust the temperature to 60°C and stir for 5 minutes, then bake in an oven with a temperature of 95°C until stickiness occurs, stop baking, then wrap with gauze, send Put it into a steam oven, adjus...

Embodiment 3

[0055] A method for preparing a sampling storage box material for egg quality testing, comprising the following steps:

[0056] S1. Mix 8 kg of carbon nanotubes, 35 kg of concentrated sulfuric acid, and 8 kg of concentrated nitric acid, adjust the temperature to 132°C and stir for 2.5 hours, wash with deionized water, dry at 88°C, add 53kg of N,N-dimethylformamide, and stir Add 8kg of lactide at low temperature, stir at 68°C for 12min, add 0.011kg of stannous octoate for ultrasonic treatment for 35min, the ultrasonic frequency is 42kHz, then microwave for 37min, the microwave temperature is 148°C, the microwave power is 720W, cool to room temperature, filter, wash , dried at 73°C, and pulverized to obtain a toughening treatment agent;

[0057] S2. Add 90kg of expandable polystyrene particles into the mixer, adjust the temperature to 52°C and stir for 12 minutes, then bake in an oven with a temperature of 90°C until stickiness occurs, stop baking, then wrap with gauze, send Pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com