High-expansion-rate water-blocking yarn and production process thereof

A production process, water-blocking yarn technology, applied in yarn, liquid/gas/steam fiber/sliver/roving treatment, liquid/gas/steam removal, etc. Water yarn has a lot of glue on it, etc., to achieve the effect of good water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

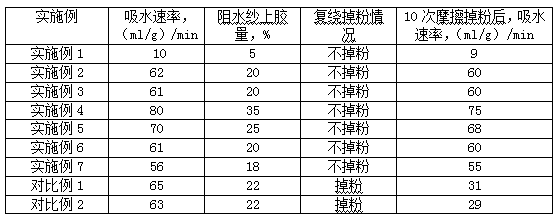

Examples

Embodiment 1

[0033] A production process of high expansion rate water-blocking yarn, the steps are as follows:

[0034] A Preparation of aramid water-blocking yarn: impregnate the unrolled 1500D aramid fiber into the binder solution, and pass the impregnated fiber through double rollers to remove excess binder solution;

[0035] B. Process the fiber obtained in step A through a heat channel, the temperature of the heat channel is 120°C, and the heat treatment time is 1 min;

[0036] C impregnating the fibers obtained in step B with water-soluble resin glue and removing excess glue through double rollers;

[0037] D. Process the fiber obtained in step C through a heat channel to cross-link the water-soluble resin glue into a superabsorbent resin. The temperature of the heat channel is 195°C, and the heat treatment time is 1.5 minutes;

[0038] E, rewinding the fiber obtained in step D to obtain aramid water-blocking yarn with high expansion rate;

[0039] Among them, the adhesive solution...

Embodiment 2

[0041] The difference between this embodiment and embodiment 1 is:

[0042] Adhesive solution is to mix and stir 5 parts of polyvinyl alcohol, 0.25 parts of glutaraldehyde, and 95 parts of deionized water evenly; water-soluble resin glue is made of sodium polyacrylate post-crosslinking water-absorbing resin solution 50 parts, polyethylene glycol 2 parts were mixed with 48 parts of deionized water and stirred evenly.

Embodiment 3

[0044] A production process of high expansion rate water-blocking yarn, the steps are as follows:

[0045] A Preparation of aramid water-blocking yarn: impregnate the unrolled 1500D aramid fiber into the binder solution, and pass the impregnated fiber through double rollers to remove excess binder solution;

[0046]B. Process the fiber obtained in step A through a heat channel, the temperature of the heat channel is 125° C., and the heat treatment time is 2 minutes;

[0047] C impregnating the fibers obtained in step B with water-soluble resin glue and removing excess glue through double rollers;

[0048] D. Process the fiber obtained in step C through a heat channel to cross-link the water-soluble resin glue into a superabsorbent resin. The temperature of the heat channel is 200°C, and the heat treatment time is 0.5 min;

[0049] E, rewinding the fiber obtained in step D to obtain aramid water-blocking yarn with high expansion rate;

[0050] Among them, the adhesive solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com