Water-stable large-thickness double-unit double-layer synchronous continuous laying and continuous pressing integral forming construction method

A technology of integral molding and construction method, applied in the direction of roads, road repair, roads, etc., can solve the problems that cannot be eliminated in time, time-consuming and labor-intensive secondary paving joints, prolonged construction period, etc., to simplify the interlayer bonding process and materials. , Eliminate hidden dangers of quality and improve the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

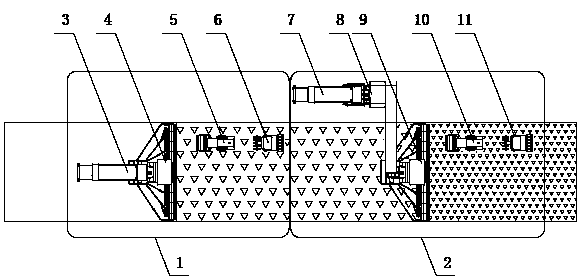

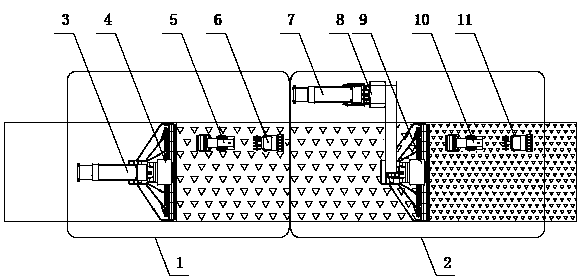

[0042] This embodiment provides a water-stable and large-thick double-unit double-layer synchronous continuous paving and pressing integral forming construction method. During the initial setting period, the dual units are synchronously paved and rolled in layers one after the other, and the two units are combined. Complete the total thickness of the base layer, with a distance of 45-55 meters;

[0043] Wherein, both units include an anti-segregation paver, a vibratory roller and a rubbing tire roller, the vibratory roller includes a single-drum vibratory roller and a double-drum vibratory roller, and the anti-segregation paver includes a cement slurry spraying device, During the paving process, the anti-segregation paver, vibratory roller, and rubbing tire roller are constructed sequentially. The anti-segregation paver sprays cement slurry while paving. The segregated paver continuously feeds materials, and the second unit 2 continuously feeds materials against the segregated...

Embodiment 2

[0050] On the basis of Example 1, this example provides a water-stable and large-thickness double-unit double-layer synchronous continuous paving and pressing integral forming construction method, and the rolling includes pre-pressing, re-pressing and final pressing.

[0051] During preloading, use a double-drum vibratory road roller to roll from low to high. If there is no shoulder soil or formwork, leave 30-50cm on the left and right sides without rolling. Roll directly along the road shoulder soil or the formwork side. The road roller moves forward and backward at a speed of 3.5km / h and performs static pressure. Each wheel overlaps by 30cm. The stop joint forms a 45-degree trapezoid and rolls once.

[0052] The repressurization process includes the following steps:

[0053] Step 1) Use a single-drum vibratory roller to move forward and backward respectively, and each wheel overlaps by 30cm. When there is no formwork and road shoulder soil, leave 30cm for the left and right ...

Embodiment 3

[0059] On the basis of Embodiment 1, this embodiment provides a water-stable and large-thickness dual-unit double-layer synchronous continuous paving and pressing integral forming construction method, which also includes compacting and sprinkling the roadbed in the construction section before paving.

[0060] Check the roadbed in the construction section in advance, and if the degree of compaction is insufficient, it needs to be reinforced with a 36T single-drum vibratory roller. Sprinkle water on the roadbed again before paving to ensure the humidity of the roadbed, prevent the roadbed from drying out and absorb water to stabilize the moisture in the lower layer, resulting in loosening of the lower layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com