Manufacturing method of fan blade self-power generation photovoltaic fan

A self-generating and fan technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of long charging time, poor use of light, inconvenient movement and other daily needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

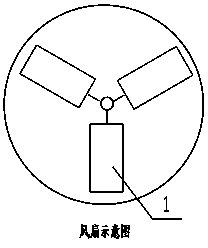

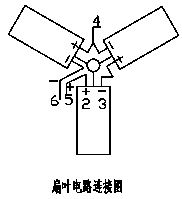

[0018] specific implementation plan

[0019] composition and structure

[0020] How to make fan blades:

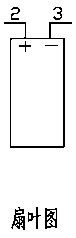

[0021] The thin-film photovoltaic battery chip is deposited on a stainless steel substrate by a PVD magnetron sputtering method to deposit a copper indium gallium selenide power generation film layer, and the upper and lower layers are plated with positive and negative electrodes and cut to form a fan blade type thin film battery chip. The thickness of the chip is Thin and flexible, and the mass-to-power ratio is small to meet the fusion with the fan blades. The fan-blade thin-film battery chip and the copper wire winding are heat-pressed and packaged by leading out wires. The encapsulated thin film chip is hot-pressed with the fan blade receiving piece by hot melt adhesive to form a image 3 The shown fan blades, 2 and 3 are the positive and negative poles of the lead wires.

[0022] The fan blade self-generating photovoltaic fan consists of 3 pieces image 3 The fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com