Seven-stage preheating system for cement kiln tail and work method

A cement kiln heating technology, applied in the field of seven-stage preheating system at the end of the cement kiln, can solve the problems of energy waste, ineffective utilization, waste of water resources, etc., to reduce heat consumption, reduce heat, and reduce outlet temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

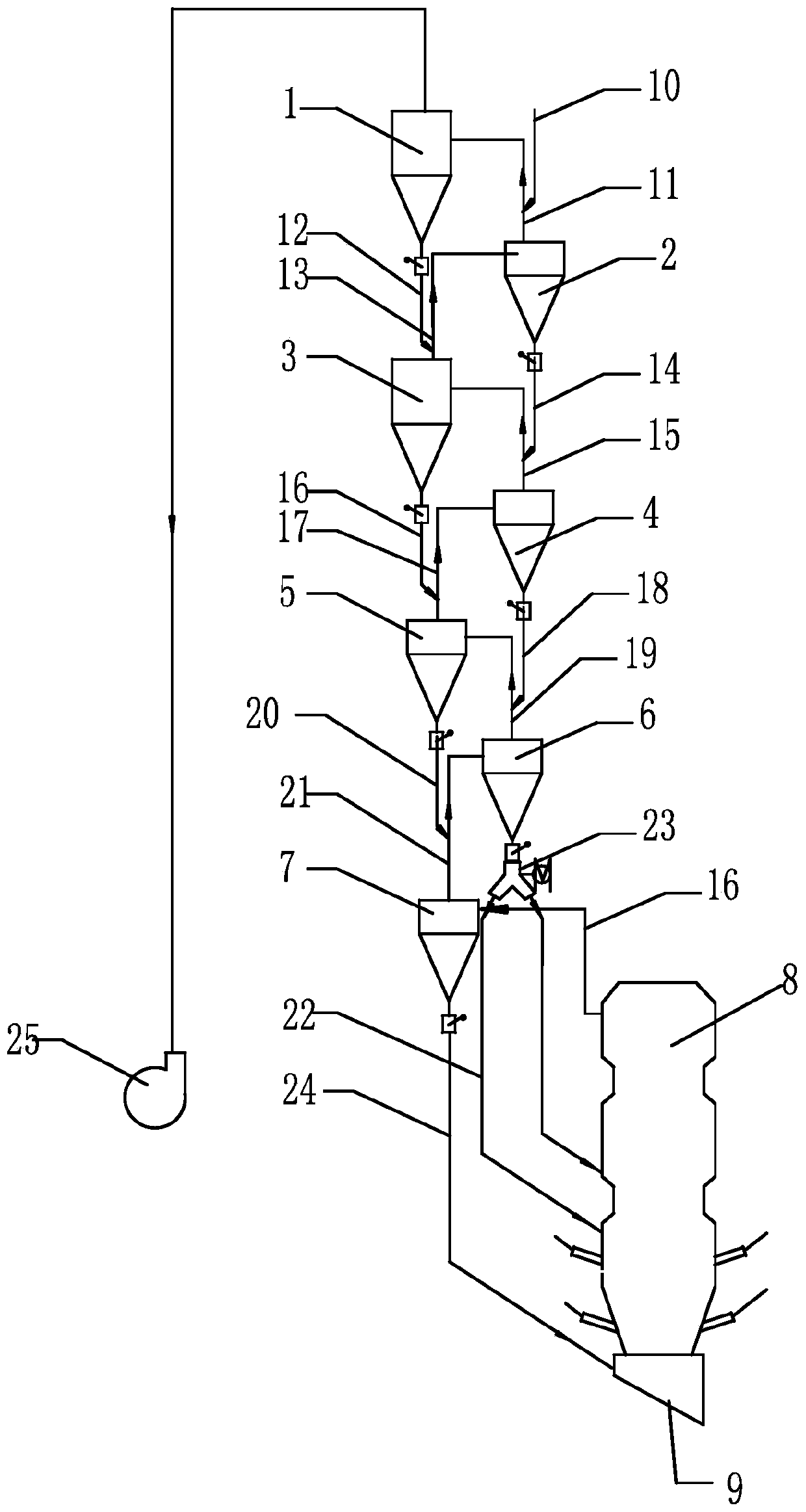

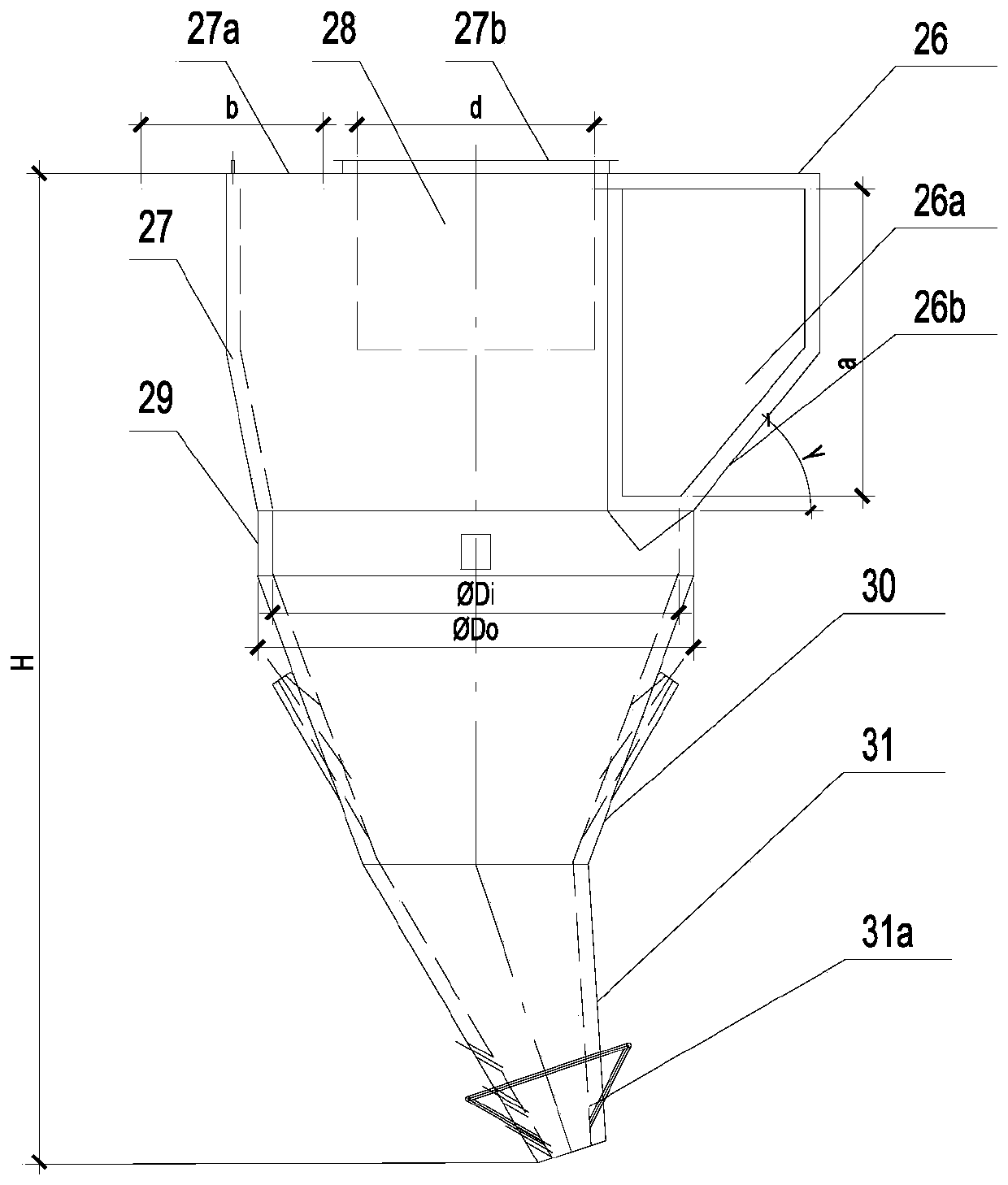

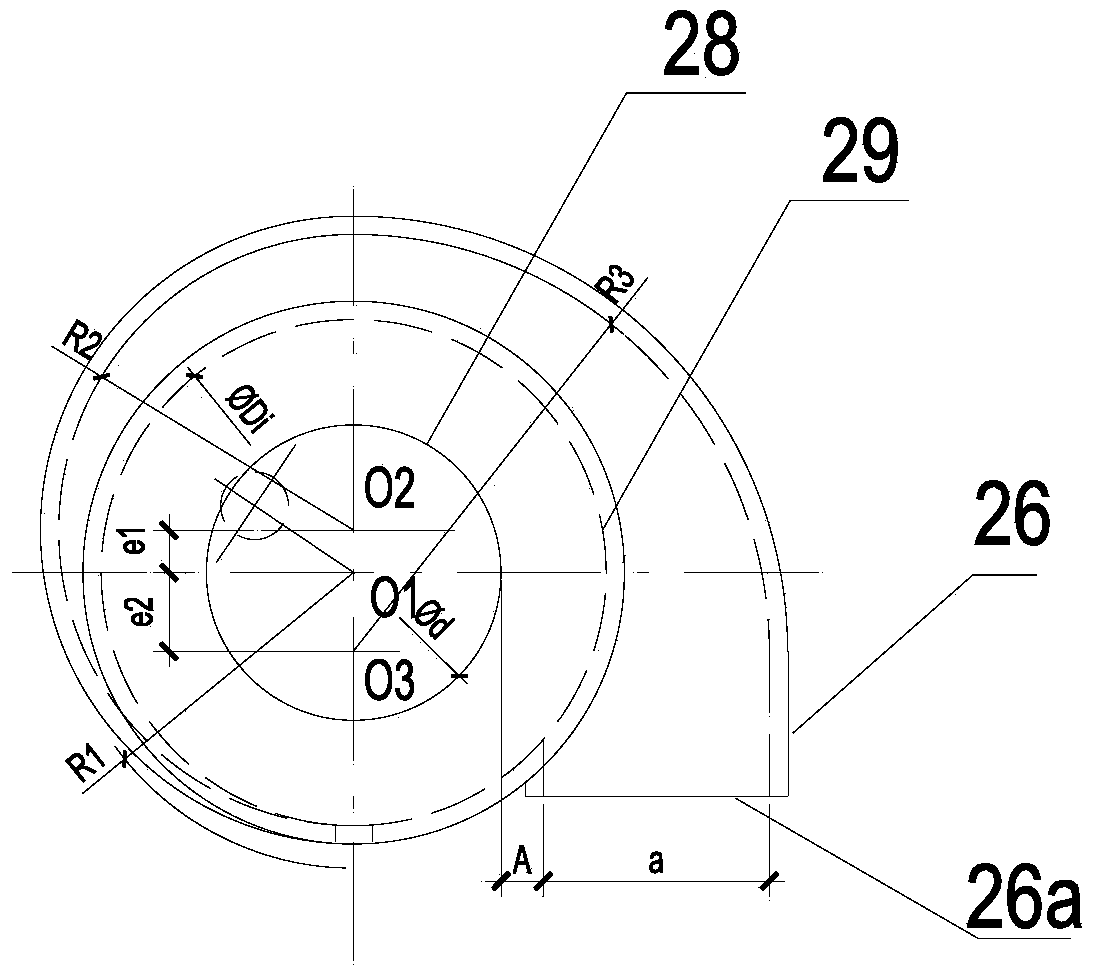

[0034] Such as figure 1 As shown, the present invention discloses a seven-stage preheating system at the end of a cement kiln, which includes a seven-stage cyclone, an air duct, a feeding pipe, and a decomposition furnace 8; the seven-stage cyclone includes a set from top to bottom C1 cyclone 1, C2 cyclone 2, C3 cyclone 3, C4 cyclone 4, C5 cyclone 5, C6 cyclone 6 and C7 cyclone 7; each cyclone has an air outlet on the top and a side The air inlet is provided with a discharge port at the bottom; in all adjacent cyclones, the air inlet of the upper cyclone is connected with the air outlet of the lower cyclone through the air pipe; all the discharge ports are connected with the discharge pipe; The feeding pipe is provided with an air lock valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com