Spectrum dimming packaging structure and manufacturing method thereof

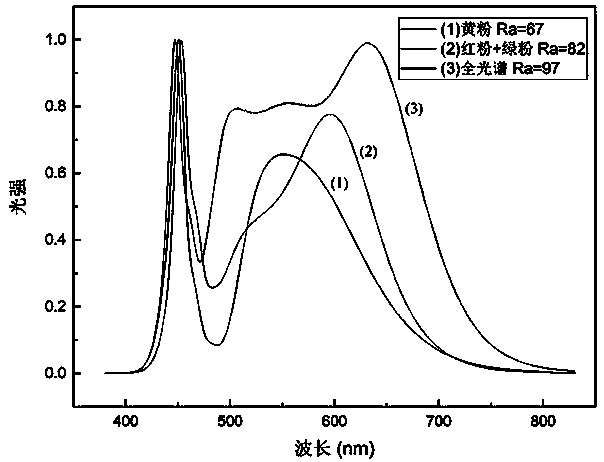

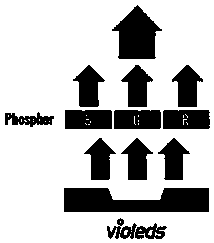

A packaging structure and dimming technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of mixed phosphor secondary absorption, low color rendering index, narrow luminous spectrum, etc., to avoid reabsorption, high quantum Efficiency, improve the effect of light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Make a spectral dimming package structure with a color temperature of 4000K:

[0101] The specification of the first wavelength blue-ray chip is 14*30mil, the wavelength λA is 465nm, the peak wavelength of the long-wavelength phosphor in the long-wavelength phosphor colloid layer and the colloid powder in the long-wavelength phosphor colloid layer is 620nm, and the glue weight The ratio is 1.7:1; the thickness of the long-wavelength phosphor colloid layer on the top surface of the first-wavelength blue-ray chip is 200 microns, and the thickness on the side of the first-wavelength blue-ray chip is 120 microns;

[0102] The specification of the second wavelength Blu-ray chip is 14*30mil, and the wavelength λB is 452nm;

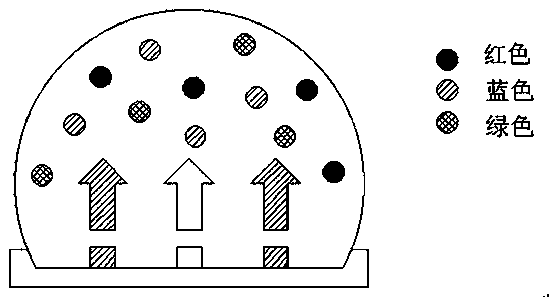

[0103] The total number of chips in the entire spectral dimming package structure is 40 to 50. In this embodiment, the number of red powder packages is 22, and the number of second-wavelength blue light chips is 23. On the CIE chromaticity diagram, the re...

Embodiment 2

[0106] Make a spectrum dimming package structure with a color temperature of 3000K, which can be applied to the lighting of meat such as beef:

[0107] The specification of the first wavelength blue light chip is 14*30mil, and the wavelength λA is 465nm. The long-wavelength phosphor in the colloidal layer of the long-wavelength phosphor adopts mixed phosphor, among which, the weight of the red phosphor with a wavelength of 658-660nm is more than 70%, and the rest is For red phosphor with a wavelength of 627nm, the weight ratio of the long-wavelength phosphor to the colloid in the long-wavelength phosphor colloid layer is 3:1; the thickness of the long-wavelength phosphor colloid layer on the top surface of the first-wavelength blue chip is 200 microns, The thickness of the side of the blue light chip at the first wavelength is 120 microns;

[0108] The specification of the second wavelength Blu-ray chip is 14*30mil, and the wavelength λB is 452nm;

[0109] The total number of...

Embodiment 3

[0112] Make a spectrum dimming package structure with a color temperature of 6500K, which is applied to the lighting of seafood:

[0113] The specification of the first-wavelength blue light chip is 14*30mil, the wavelength λA is 465nm, and the long-wavelength phosphors in the long-wavelength phosphor colloid layer are all red powders with a peak wavelength of 620nm.

[0114] The weight ratio of the long-wavelength phosphor to the colloid in the colloidal layer of the long-wavelength phosphor is 0.2:1; The thickness is 120 microns;

[0115] The specification of the second wavelength Blu-ray chip is 14*30mil, and the wavelength λB is 452nm;

[0116] The total number of chips in the entire spectrum dimming package structure is about 30. In this embodiment, the number of red powder packages is 8, and the number of second-wavelength blue light chips is 20. On the CIE chromaticity diagram, the red powder package corresponds to the red The coordinates of the point are (0.43, 0.21)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com