Fuel cell stack modeling method with fluid non-uniform distribution effect

A fuel cell stack and uniform distribution technology, applied in fuel cells, fuel cell additives, fuel cell control, etc., can solve the problems of small intake manifold size, low computing efficiency, and high computing resource requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

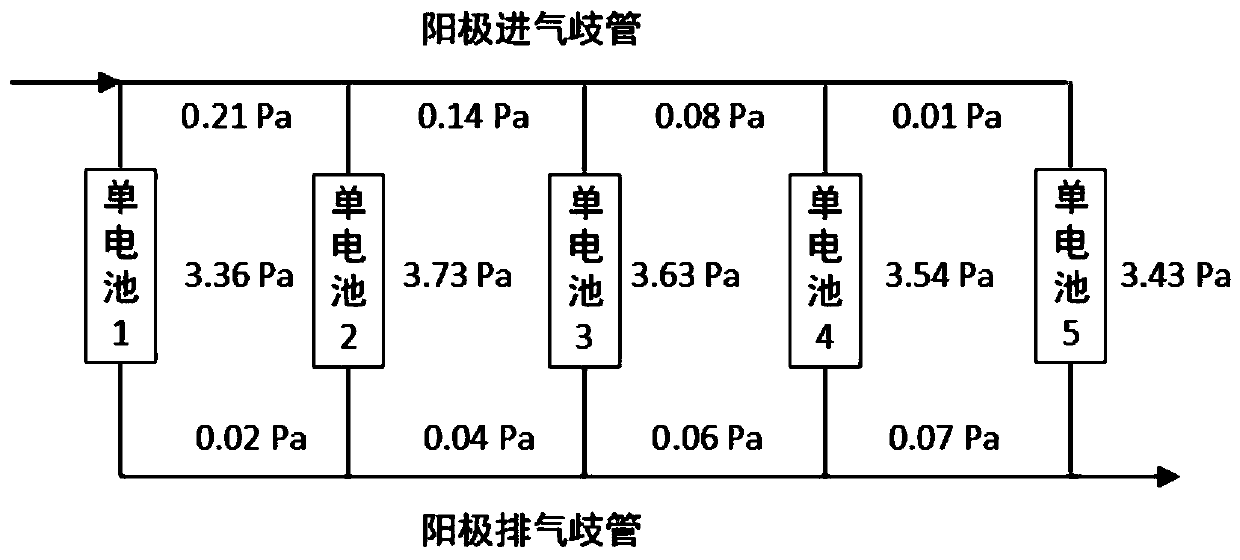

[0106] The method of the invention and the specific steps of building the model will be described in detail below through specific calculation examples.

[0107] Stack structure parameters:

[0108] Single battery quantity: 5; Gas manifold size: 10×6mm; Coolant manifold size: 10×5mm.

[0109] Single battery structural parameters:

[0110] Effective reaction area: 120cm 2 ;Coolant effective heat transfer area: 60cm 2 .

[0111] Plate thickness: 2mm; channel thickness: 1mm; gas diffusion layer thickness: 0.2mm; microporous layer thickness: 0.03mm; catalytic layer thickness: 0.01mm; membrane thickness: 0.0508mm; channel length: 0.1m; Height: 1mm; ratio of runner to rib width: 1.

[0112] Proton exchange membrane density: 1980kg m -3 ;Catalytic layer density: 1000kg m -3 ;Microporous layer density: 1000kg m -3 ;Diffusion layer density: 1000kg m -3 ;Plate density: 1000kg m -3 .

[0113] Proton exchange membrane specific heat capacity: 833J kg -1 K -1 ; Specific heat ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com