Mineral separation method for separating calcium and magnesium in medium-low-grade phosphorite, urea ammonium nitrate calcium-magnesium fertilizer and ammonium magnesium sulfate nitrate fertilizer

A technology of urea ammonium nitrate and mineral processing method, which is applied in the mineral processing field, can solve the problems of reduced phosphorus yield, increased cost and high magnesium content, and achieves the effects of wide application, saving mineral processing cost and fast fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

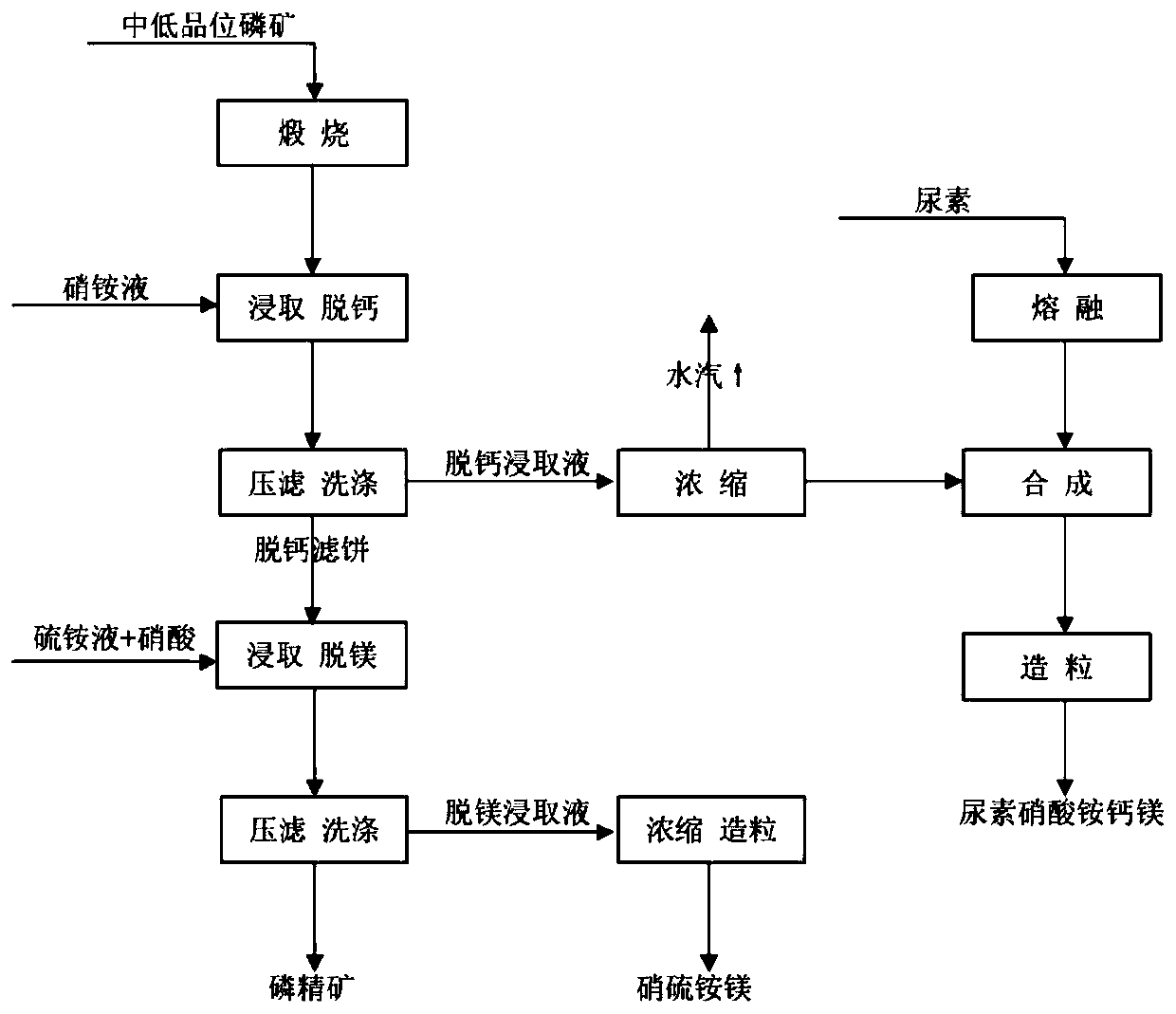

[0094] The beneficiation methods for separating calcium and magnesium from medium and low grade phosphate rock include:

[0095] The medium and low grade phosphate rock (P 2 o 5 24.34%, CaO 41.03%, MgO 4.79%, Fe 2 o 3 0.34%, Al 2 o 3 0.41%, F3.16%, SiO 2 3.38%, A.I4.50%, organic matter 0.46%) 349.73kg was calcined at 950°C for 2h to obtain 300kg of calcined ore, ground to 0.5mm, added 100kg of water for digestion, and then added 30% ammonium nitrate by mass 800kg of the solution was leached for 45min at a temperature of 17-19°C, filtered to obtain 844kg of decalcified leaching solution, concentrated to obtain 240kg of ammonium nitrate calcium magnesium, and then 360kg of urea melt was added for synthesis and granulation to obtain 580kg of urea calcium ammonium nitrate Magnesium products, products containing N39.41%, N 铵 4.94%, N 酰 27.62%, CaO3.73%, MgO0.29%.

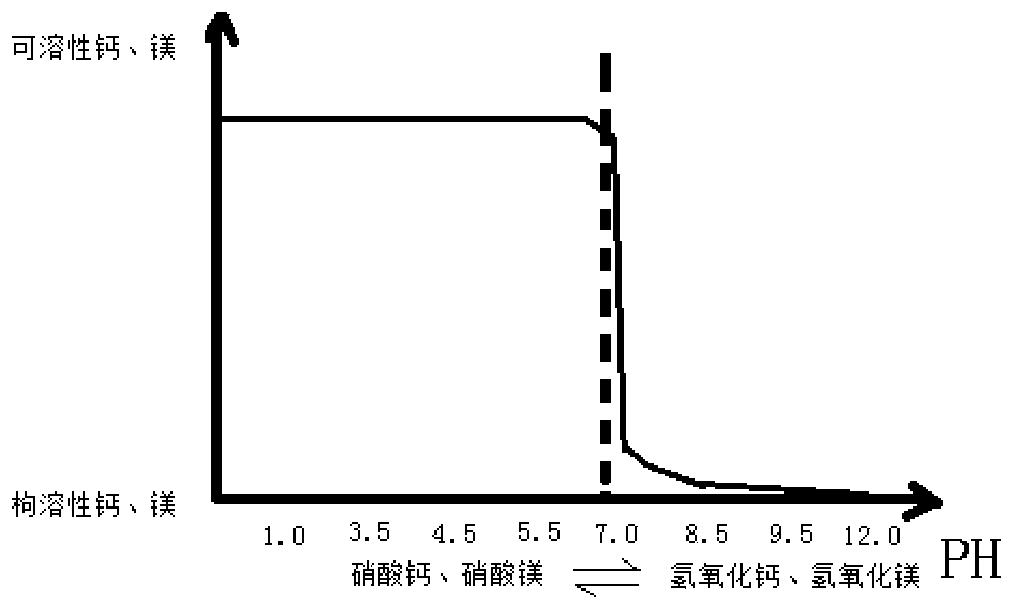

[0096] Add 320kg of water to the press-filtered decalcified filter cake for washing, add 420kg of 30% ammoniu...

Embodiment 2

[0098] The beneficiation method of separating calcium and magnesium in the middle and low grade phosphate rock is the same as embodiment 1, the difference is that the pH is adjusted to be 4 when leaching and removing magnesium; The specific composition is N14.16%, N 铵 9.64%, CaO0.73%, MgO20.16%, S22.14%.

Embodiment 3

[0100] The beneficiation method of separating calcium and magnesium in middle and low-grade phosphate rocks is the same as in Example 1, except that the pH is adjusted to be 6.5 during leaching and magnesium removal; The specific composition is N13.53%, N 铵 10.78%, CaO0.76%, MgO20.14%, S22.83%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com