Metal lithium battery

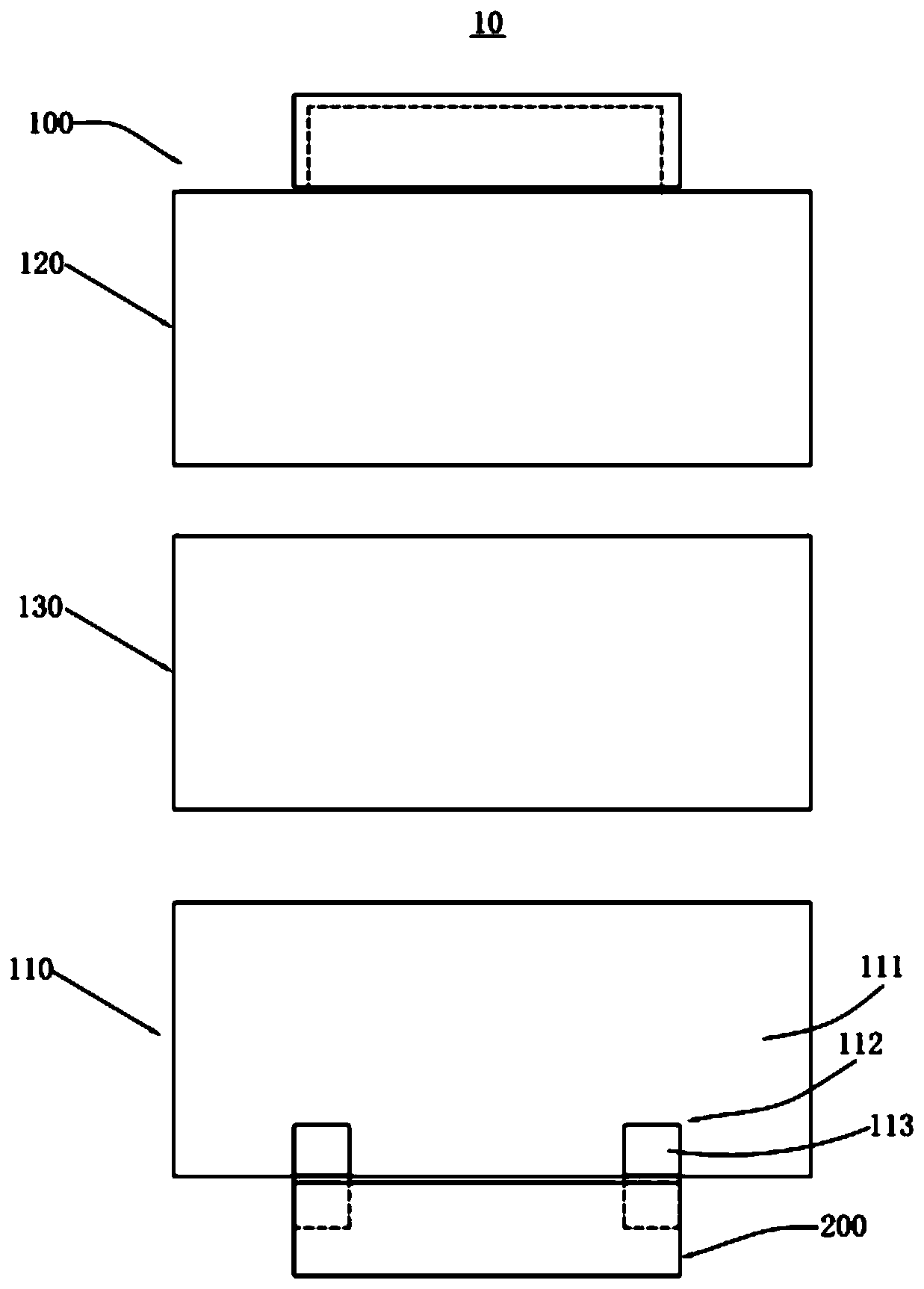

A metal lithium and battery technology, applied in the field of metal lithium batteries, can solve the problems of reducing the utilization rate of negative electrode active materials, reducing battery capacity, etc., achieving high electrical effect and heat dissipation effect, increasing reaction area, and increasing the effect of utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

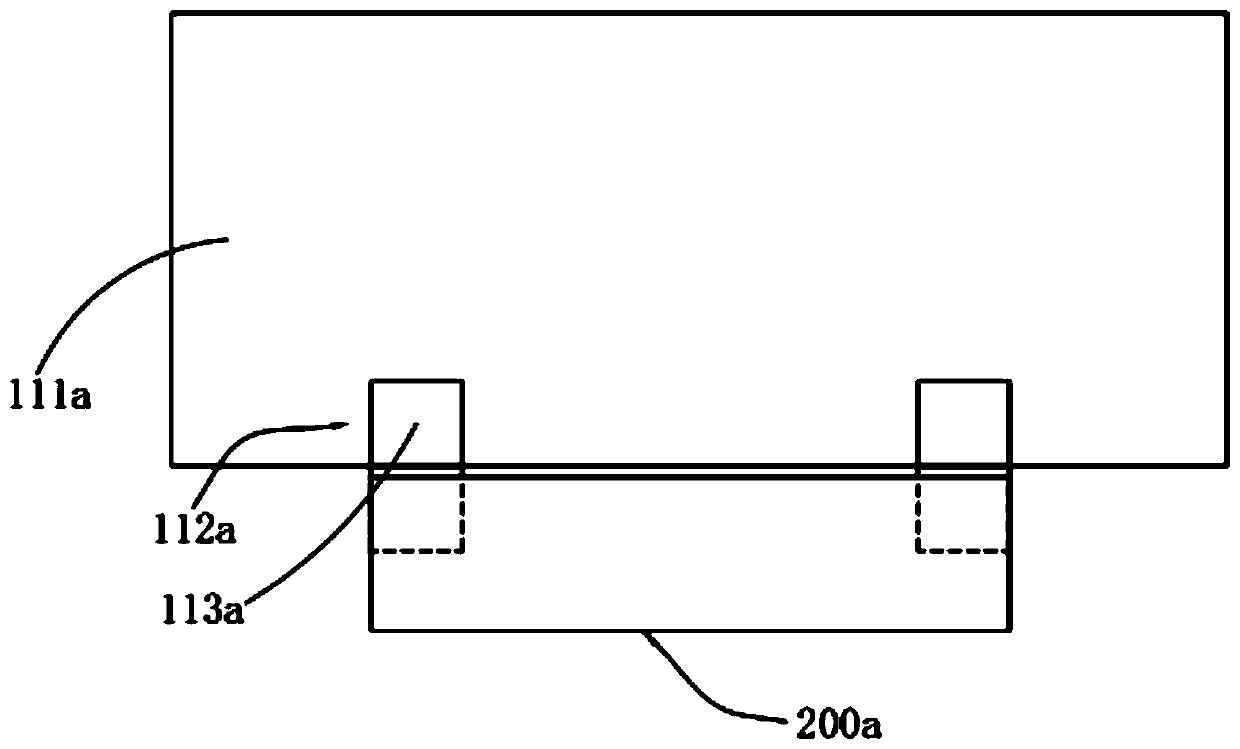

[0054] see figure 2 , is a schematic diagram of a partial structure of a metal lithium battery according to Example 1 of the present invention, the current collector 112a includes two current collectors 113a, and the two current collectors 113a are located on the opposite side edges of the negative electrode tab 200a In this way, the distance between the two current collectors 113a can be maximized, and the heat generation is at the intersection of the current collectors 113a, lithium pole pieces 111a and negative electrode tabs 200a, so that the two current collectors The fluid 113a is located at the opposite side edges of the negative tab 200a, thereby maximizing the distance between the two heat sources, effectively reducing local overheating, and improving battery safety and electrical performance.

[0055] Further, the two current collectors are arranged symmetrically with respect to the central axis of the lithium pole piece, so that the transfer path of the charge of t...

Embodiment 2

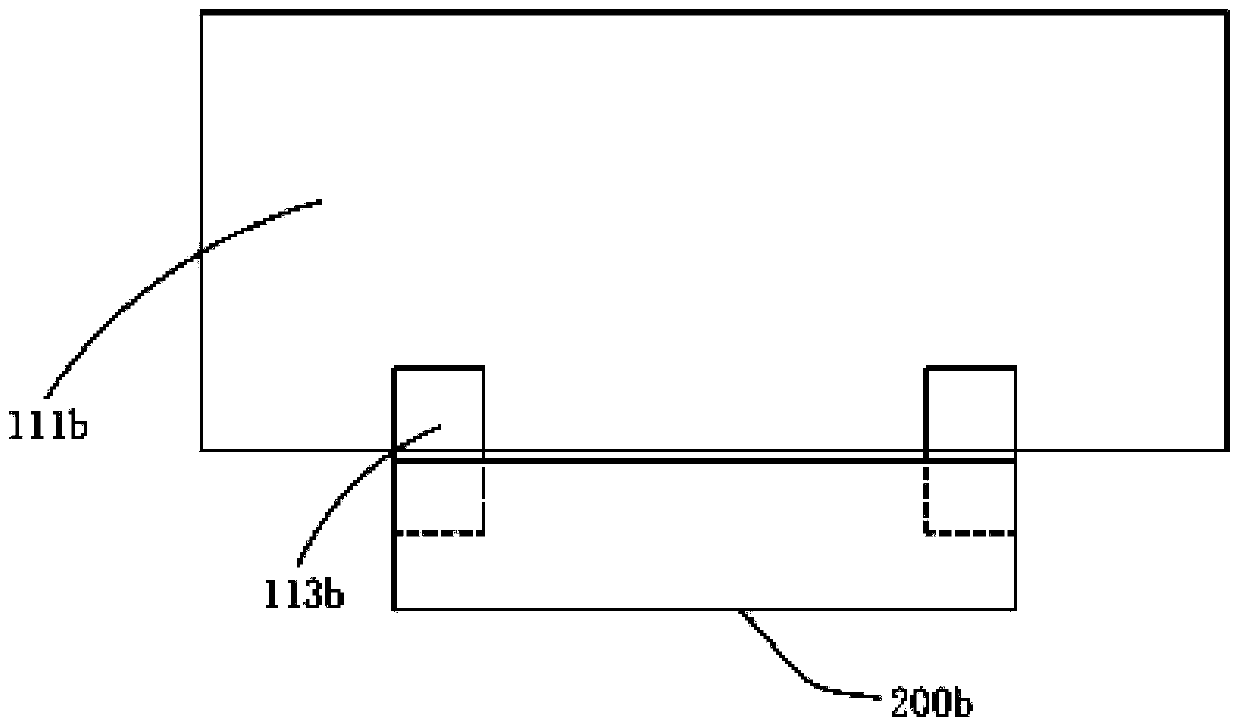

[0061] see image 3 , is a schematic diagram of a partial structure of a metal lithium battery in Example 2 of the present invention, the lithium pole piece 111b has a long side and a short side, and each of the current collectors 113b is electrically connected to the long side of the lithium pole piece 111b, respectively, The distance between the current collector 113b and the active material on the lithium pole piece 111b can be reduced, so that the active material of the lithium pole piece 111b can be fully utilized, the utilization rate of the negative electrode active material is improved, the battery capacity is improved, and the charge of the battery The transmission path is more reasonable, which can reduce the internal resistance of the battery and reduce the heating problem.

Embodiment 3

[0063] see Figure 4 , is a schematic diagram of a partial structure of a metal lithium battery according to Example 3 of the present invention, the current collector 112c includes two current collectors 113c, and the two current collectors 113c are located on the opposite side edges of the negative electrode tab 200c The current collector 112c includes an angled piece 114c and a main piece 115c, and the angled piece 114c is connected to the main piece 115c. In actual processing, the angled piece 114c and the main piece 115c are integrally formed; the two current collectors 112c, the extension direction of the angled piece 114c forms an included angle, and the degree of the included angle is between 0 degrees and 180 degrees. In this way, the distance between the two positions that generate heat sources can be further increased, and the heat can be more effectively alleviated. Local overheating problem, improve battery safety performance and electrical performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com