Deployable Mechanism of Spaceborne Antenna

A technology for deploying mechanisms and space-borne antennas, applied to antennas, folding antennas, antenna parts, etc., can solve the problems of increasing the weight of the mechanism, high manufacturing cost, and low rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

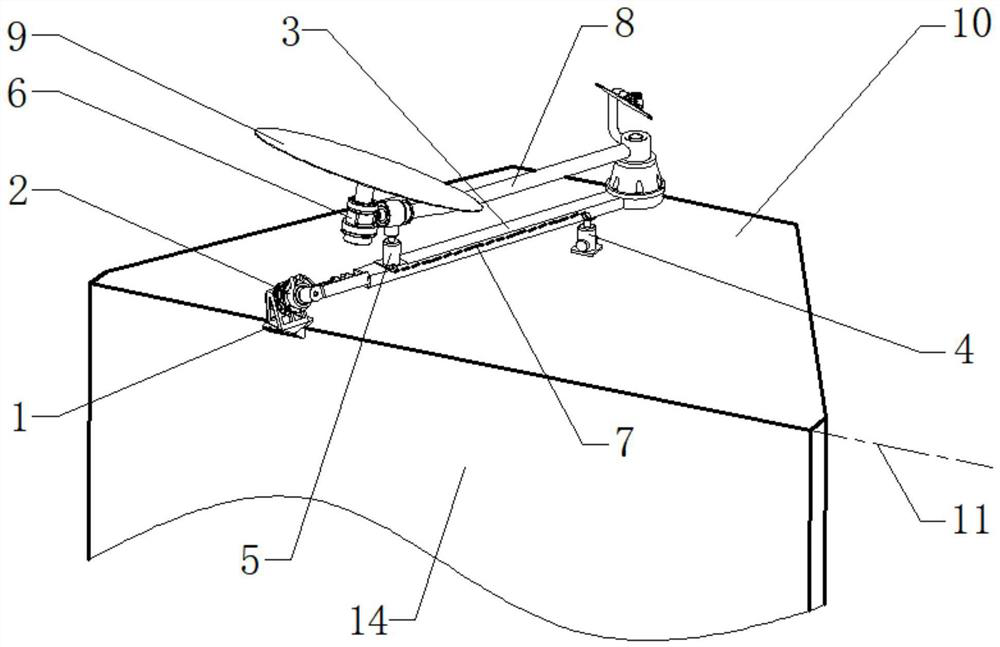

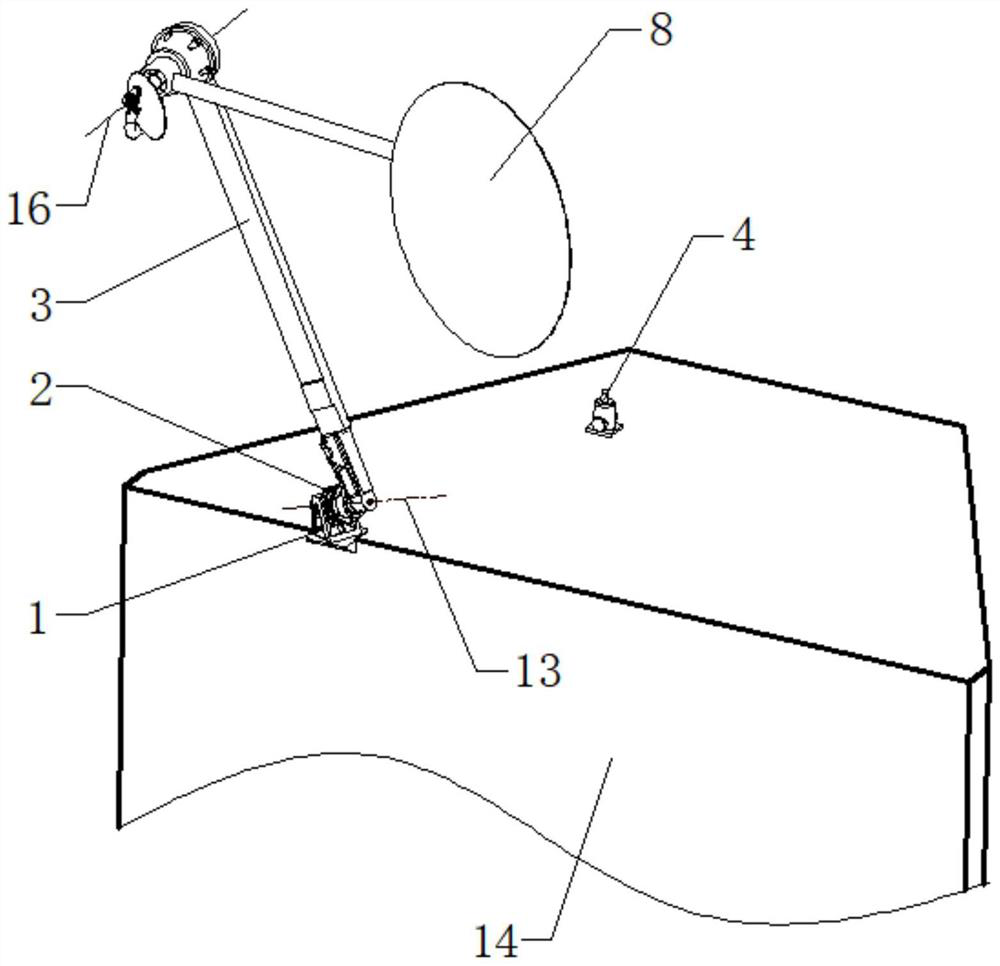

[0028] see figure 1 figure 2 . In the preferred embodiment described below, an on-board antenna deployable mechanism includes a passively driven synchronous gear drive joint hinge 2 mounted on the satellite body 14 and one end hingedly fixed to the satellite body through the synchronous gear drive joint hinge 2 The extension arm 3 on 14, the antenna 8 connected at the other end through the antenna rotating shaft 16, and the passive drive hinge 6 installed on the antenna reflector 9 at the free end of the connecting rod of the antenna 8, it is characterized in that: installed on the extension arm 3 There is an unlocking mechanism 5 corresponding to the passive driving hinge 6 and a locking mechanism 4 located under the extension arm 3 corresponding to the passive driving hinge 2. When in the transmitting and retracting state, the antenna reflector 9 is connected to the joint through the passive driving hinge 6 After rotation, it is fixed on the extension arm 3 by the unlocki...

Embodiment 2

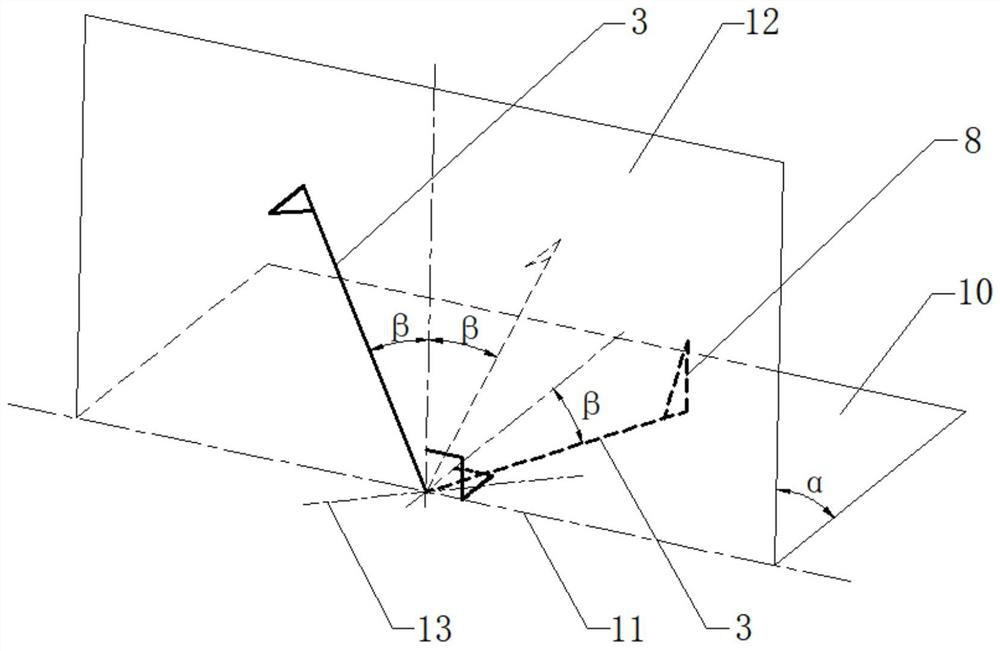

[0034] combine image 3 . The deployable mechanism of the spaceborne antenna of this embodiment is to maximize the space utilization. When the antenna is stored, the antenna needs to be arranged on the fixed surface 10 of the antenna storage state of the satellite body 14, and the antenna 8 on the end of the extension arm 3 is turned over to a specific angle during operation. When the extension arm 3 rotates along the fixed surface 10 of the antenna in the storage state to the fixed surface 12 of the antenna in the unfolded state by any angle α, the angle between the vertical line of the extension arm 3 and the initial connection axis of the extension arm is β, and the space angle β is 0°< When β≤90° is arranged, the rotation axis of the antenna 8 is always kept perpendicular to the fixed surface 12 in the unfolded state of the antenna, and at the same time, the direction of the rotation axis 13 of the hinge 2 is formed by the plane method formed by the axis of the extension ...

Embodiment 3

[0036] see Figure 4 . In the deployable mechanism of the spaceborne antenna of this embodiment, the locking mechanism 4 and the unlocking mechanism 5 have a linkage unlocking structure. The locking mechanism 4 and the unlocking mechanism 5 realize flexible linkage through the cable 7 . A hinge device is provided at both ends of the cable 7, and a torsion spring (or only a hinge near the unlocking mechanism 5) is provided on the rotation nodes of the two hinges. The driving force direction of the torsion spring is shown by the rotation arrow in the figure. When the locking mechanism 4 is unlocked, the right slider moves upward, and the pull cable 7 is driven by the elastic potential energy of the torsion spring, moves along the unlocking movement direction 15, and pulls the left slider to move downward, thereby completing the unlocking of the unlocking mechanism 5 and realizing the locking The linkage between the mechanism 4 and the unlocking mechanism 5 is unlocked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com