Production method of frozen surimi product

A production method and a technology for freezing surimi products, which are applied in the field of processing and production of frozen surimi products, can solve the problems of decreased gel strength, elasticity and water-holding capacity of surimi products, affecting the quality of surimi products, etc. The effect of no decrease in gel strength, improved juiciness and flavor quality, and avoidance of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

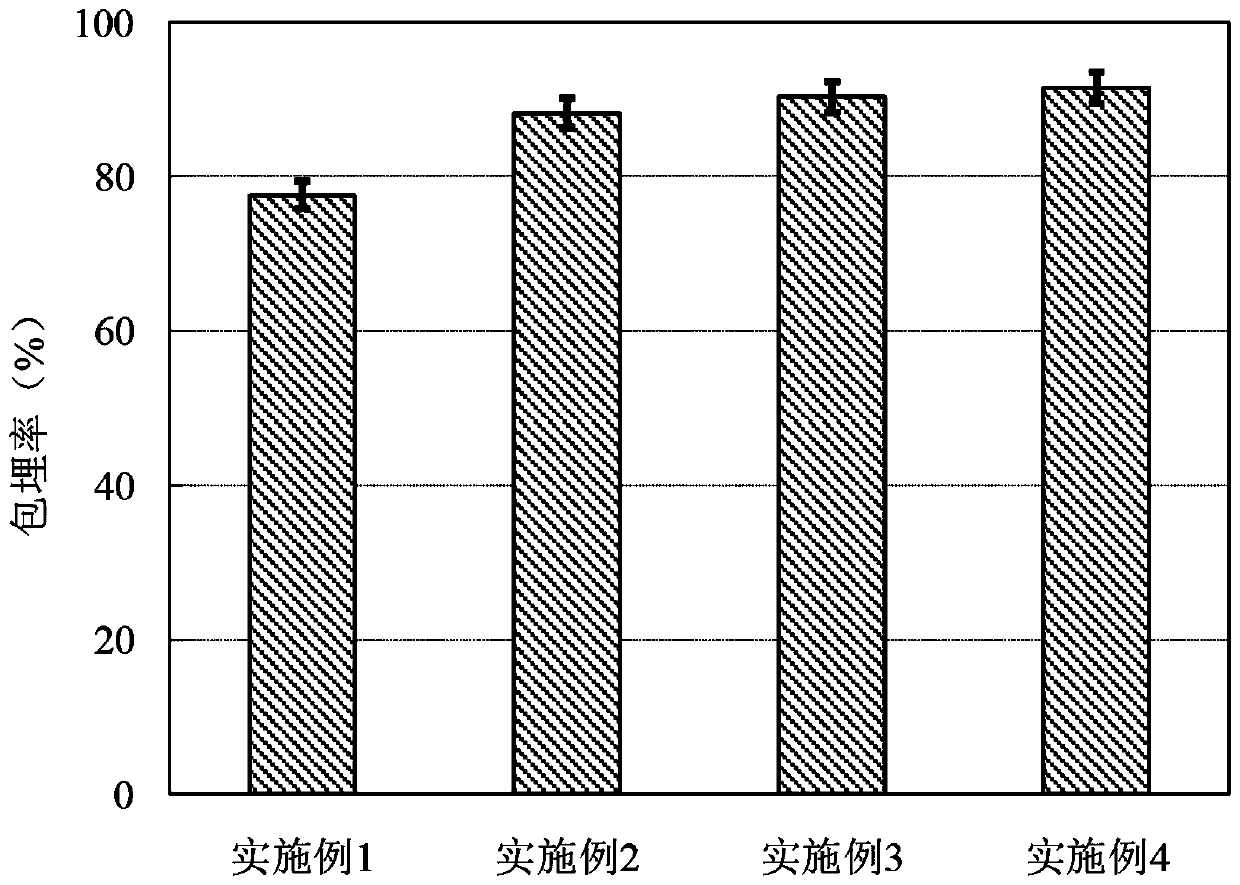

Embodiment 1

[0023] Add 6.5 kg of pure water to 1 kg of gelatin hydrolyzate with an average molecular weight of 40 kDa and 0.5 kg of soybean protein isolate to dissolve, add 2 kg of soybean oil, mash and disperse evenly through the tissue, heat at 70 °C for 40 min, and use The high-pressure homogenizer was emulsified three times at 80 MPa, and then the emulsified oil was prepared by spraying with a spray dryer at an inlet air temperature of 160°C and an outlet air temperature of 80°C.

[0024] Add 2 g of soybean protein isolate and 4 g of transglutaminase to 2 kg of surimi semi-thawed at -5~-1°C, chop and beat at 6°C to mix evenly, then add 40 g of salt and beat for 30 minutes , add 200 g of the above-prepared emulsified oil and grind it for 8 minutes. After the crushed surimi is formed, heat it at 40°C for 40 minutes, and then heat it at 92°C for 12 minutes to prepare a surimi product. After the surimi products were cooled rapidly with ice water, they were then transferred to -20°C freeze...

Embodiment 2

[0026] Add 6.5 kg of purified water to 1 kg of gelatin hydrolyzate with an average molecular weight of 50 kDa and 0.5 kg of soybean protein isolate to dissolve, add 2 kg of soybean oil, mash and disperse evenly through the tissue, heat at 70°C for 40 min, and use The high-pressure homogenizer was emulsified three times at 80 MPa, and then the emulsified oil was prepared by spraying with a spray dryer at an inlet air temperature of 160°C and an outlet air temperature of 80°C.

[0027] Add 2 g of soybean protein isolate and 4 g of transglutaminase to 2 kg of surimi semi-thawed at -5~-1°C, chop and beat at 6°C to mix evenly, then add 40 g of salt and beat for 30 minutes , add 200 g of the above-prepared emulsified oil and grind it for 8 minutes. After the crushed surimi is formed, heat it at 40°C for 40 minutes, and then heat it at 92°C for 12 minutes to prepare a surimi product. After the surimi products were cooled rapidly with ice water, they were then transferred to -20°C fre...

Embodiment 3

[0029] Add 6.5 kg of pure water to 1.5 kg of gelatin hydrolyzate with an average molecular weight of 75 kDa and 1 kg of soybean protein isolate to dissolve, add 1 kg of lard, mash and disperse evenly through the tissue, heat at 90°C for 60 min, use The high-pressure homogenizer was emulsified three times at 150 MPa, and then sprayed with a spray dryer at an inlet air temperature of 170°C and an outlet air temperature of 90°C to prepare emulsified oil.

[0030] Add 5 g of porcine blood protein and 10 g of transglutaminase to 2 kg of surimi half-thawed at -5~-1°C, chop and beat at 10°C to mix evenly, then add 80 g of salt and beat for 10 minutes , add 300 g of the above-prepared emulsified oil and grind it for 10 minutes. After the crushed surimi is formed, heat it at 50°C for 30 minutes, and then heat it at 95°C for 10 minutes to prepare a surimi product. After the surimi products were cooled rapidly with ice water, they were then transferred to -20°C freezer for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com