Preparation method of low biological amine fermentation bacon

A biogenic amine, biofilm technology, applied in food science, preservation of meat/fish with protective coating, preservation of meat/fish with chemicals, etc. The problem of poor heat resistance of enzymes, etc., can prevent the reduction of bacon gel performance and water holding capacity, overcome the loose texture of the product, and reduce the activity of microorganisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

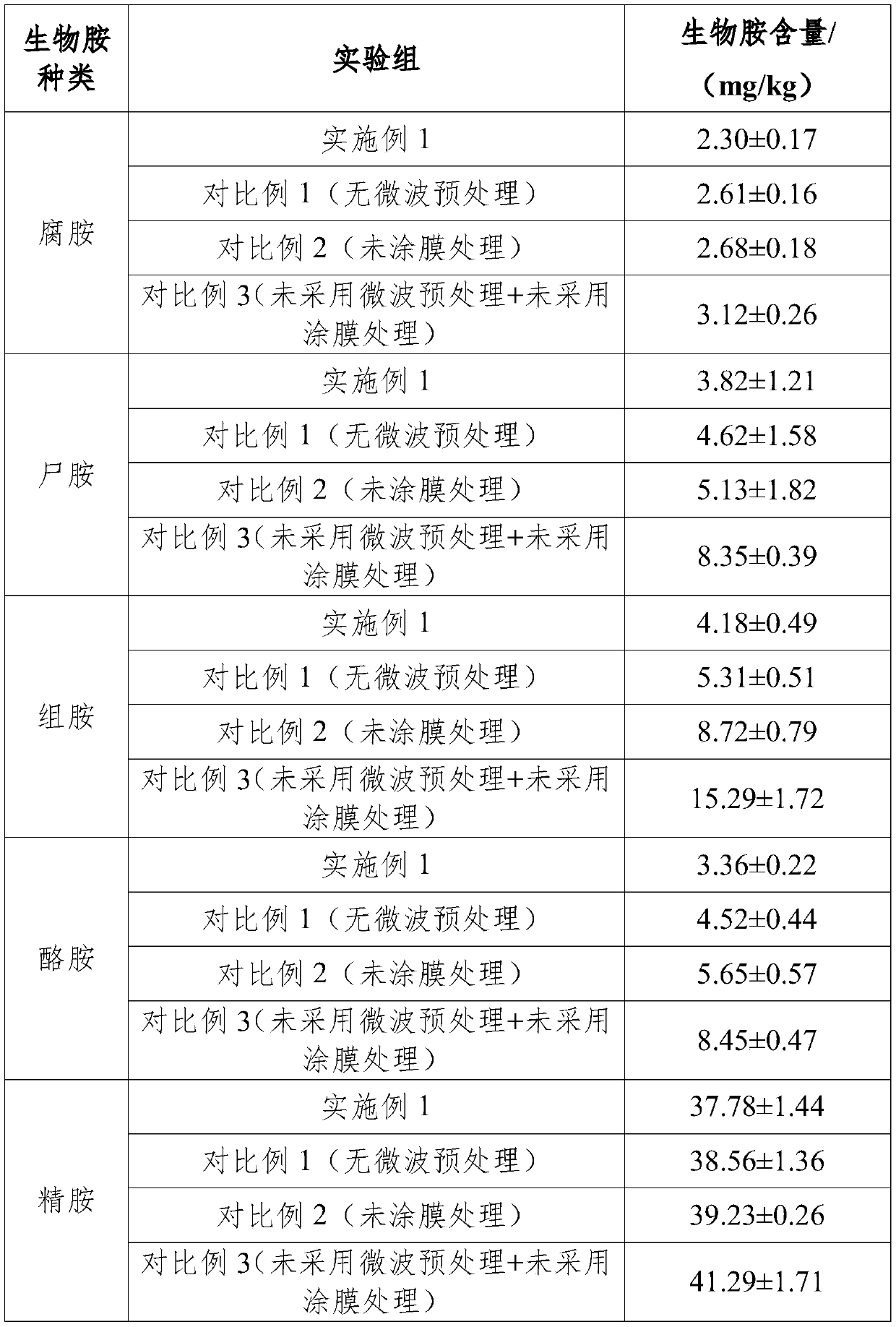

[0029] A preparation method for fermented bacon with low biogenic amine, which comprises the following steps carried out in sequence:

[0030] S1 The raw meat is microwaved for 0.5-1.5 minutes;

[0031] S2 injecting raw meat with a mixture containing protein isolate, TG enzyme, Lactobacillus and Staphylococcus xylosus;

[0032] S3 smears the raw meat surface with a biofilm solution containing chitosan, tea polyphenols and gingerol;

[0033] S4 fermenting the raw meat in a fermentation environment at 25-35° C. for 20-24 hours to obtain fermented bacon.

[0034] In this embodiment, after the raw meat is treated with microwaves, the protein structure and fat structure in the raw meat are destroyed, the action site of TG enzyme and the utilization rate of the liquid strain fermentation are increased, and the raw meat can be recovered from the meat in a short time. Heating evenly from the inside to the surface to 38°C inactivates endogenous muscle enzymes and prevents the product...

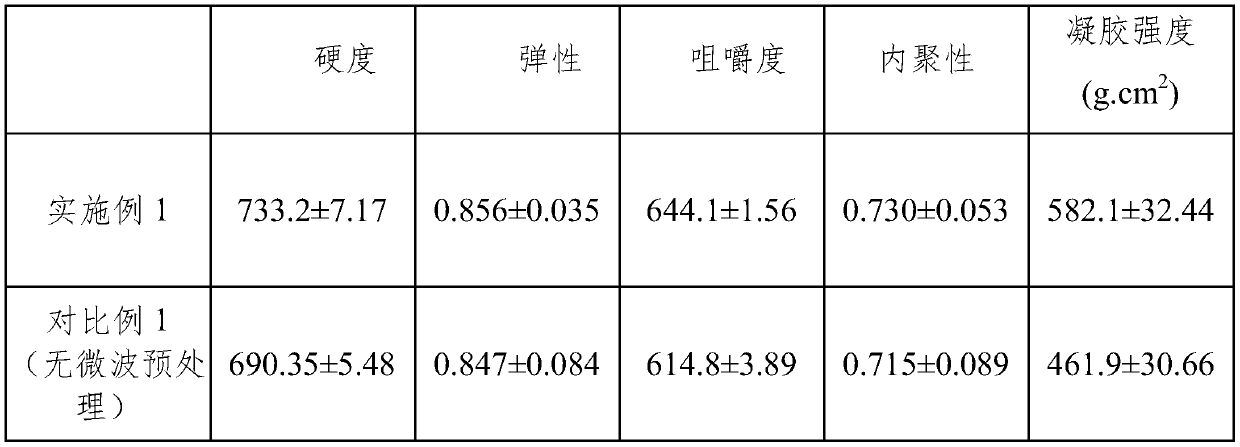

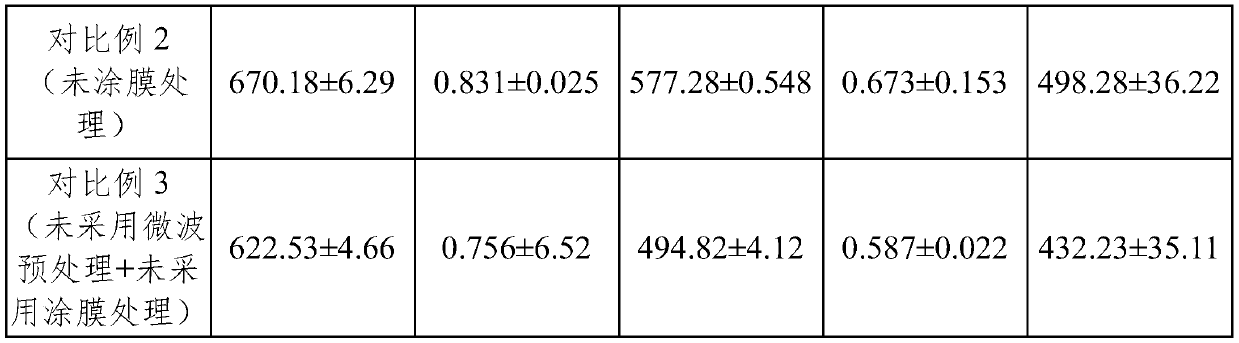

Embodiment 1

[0048] A preparation method for fermented bacon with low biogenic amine, comprising the following steps:

[0049] S1 Raw meat preparation: Wash the fresh pork foreleg and pork belly with water, remove the blood, lymph, cartilage, fur and impurities, and then cut it into slices. The thickness should be controlled at about 0.8cm, and the thickness of the fat part should be controlled At 0.9cm, put the processed fat and lean meat into the chopping machine, chop and mix evenly for 7 minutes, add ice cubes with 14% of the total weight of pork foreleg and pork belly during the chopping process to keep the meat warm When the temperature exceeds 5°C, the raw meat is obtained, and the ice cubes can be added in multiple times instead of at one time;

[0050] S2 Microwave treatment: Microwave the raw meat at a constant frequency of 3.0GHz for 1min, and the microwave power is 100W;

[0051] S3 Injecting the mixed solution: injecting the microwaved raw meat into the mixed solution, and in...

Embodiment 2

[0056] A preparation method for fermented bacon with low biogenic amine, comprising the following steps:

[0057] S1 Raw meat preparation: Wash the fresh pork foreleg and pork belly with water, remove the blood, lymph, cartilage, fur and impurities, and then cut it into slices. The thickness should be controlled at about 0.8cm, and the thickness of the fat part should be controlled At 0.8cm, put the processed fat and lean meat into the chopping machine, chop and mix for 8 minutes, add ice cubes with 10% of the total weight of the pork foreleg and pork belly during the chopping process to keep the meat warm If the temperature exceeds 5°C, raw meat can be obtained;

[0058] S2 microwave treatment: microwave the raw meat at a constant frequency of 3.0GHz for 1.5min, and the microwave power is 70W;

[0059] S3 Inject the mixed solution: the raw meat after microwave is injected into the mixed solution according to the mass ratio of 50:1. The mixed solution contains the following r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com