A method for preparing high-strength supported semi-vitrified ceramsite by using low-siliceous red mud raw material

A red mud and siliceous technology, which is applied in the field of comprehensive utilization of metallurgical solid waste, can solve problems such as high alkali content, reduced ceramsite strength, and excessive addition of red mud, so as to increase the amount of red mud added and ensure Strength, the effect of solving the stockpiling problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

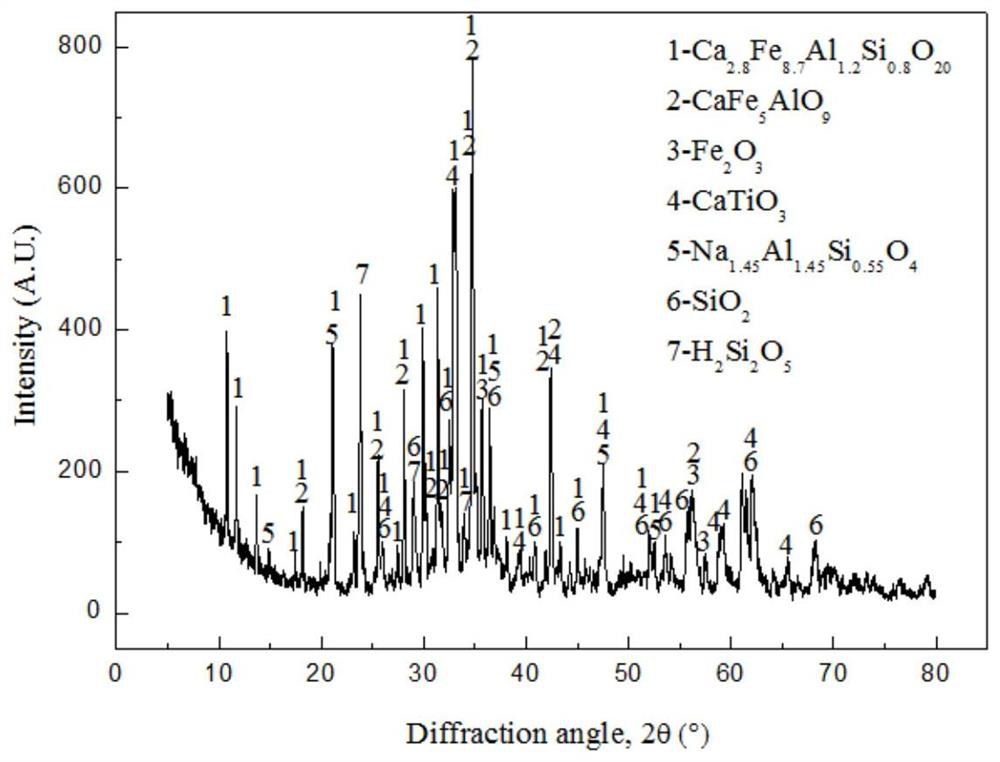

[0031] Red mud from an alumina plant in Guangxi was used to dealkalize (to Na 2 O content 2.8%), after drying, the main components and content are SiO 2 11%, Fe 2 o 3 29%, Al 2 o 3 15%, CaO 14%, H 2 O 15%. Grind the dried red mud to below 100 mesh, add 5% deionized water and mix well. Take the above-mentioned red mud material and put it into a pressure mold, shape it on the press with a pressure of 20MPa to make a cylindrical ceramsite green body with a diameter of 0.6cm and a height-to-diameter ratio of 0.8, dry it again and place it in a high-temperature furnace for sintering at 1150°C 1h, and then air-cooled to room temperature to obtain a high-strength red mud-based ceramsite product with a peak compressive strength of 335MPa. It can be seen from the XRD pattern of ceramsite products that a semi-vitrified ceramic body with high iron and low silicon multi-component eutectic is formed.

Embodiment 2

[0033] Red mud from an alumina plant in Guangxi was used to dealkalize (to Na 2 O content 2.8%), after drying, the main components and content are SiO 2 11%, Fe 2 o 3 29%, Al 2 o 3 15%, CaO 14%, H 2 O 15%. Grind the dried red mud to below 100 mesh, add 5% deionized water and mix well. Take the above-mentioned red mud material and put it into a pressure mold, shape it on the press with a pressure of 20MPa to make a cylindrical ceramsite green body with a diameter of 0.6cm and a height-to-diameter ratio of 0.8, dry it again and place it in a high-temperature furnace for sintering at 950°C 2h, and then air-cooled to room temperature to obtain a high-strength red mud-based ceramsite product with a peak compressive strength of 180MPa.

Embodiment 3

[0035] Red mud from an alumina plant in Shandong was used for dealkalization (to Na 2 O content 2.6%), after drying, the main component and content are SiO 2 17%, Fe 2 o 3 32%, Al 2 o 3 18%, CaO 10%, H 2 O 11%. Grind the dried red mud to below 100 mesh, add 10% bio-organic waste liquid and mix evenly. Take the above-mentioned red mud material and put it into a pressure mold, shape it on the press with a pressure of 10MPa to make a cylindrical ceramsite green body with a diameter of 0.6cm and a height-to-diameter ratio of 0.8, dry it again and place it in a high-temperature furnace for sintering at 1250°C 1h, and then air-cooled to room temperature to obtain a high-strength red mud-based ceramsite product with a peak compressive strength of 82MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com