Patents

Literature

39results about How to "Resource" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

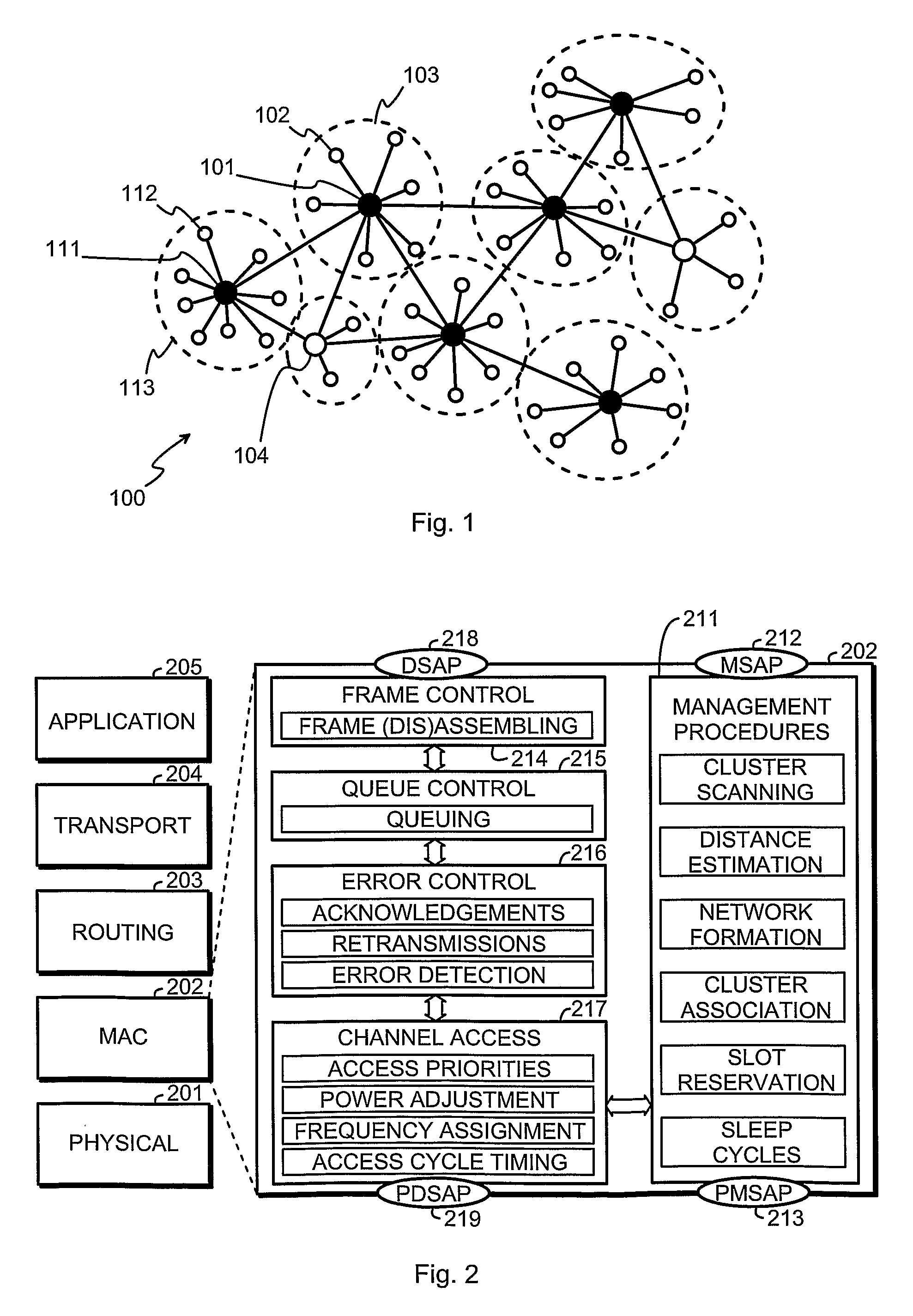

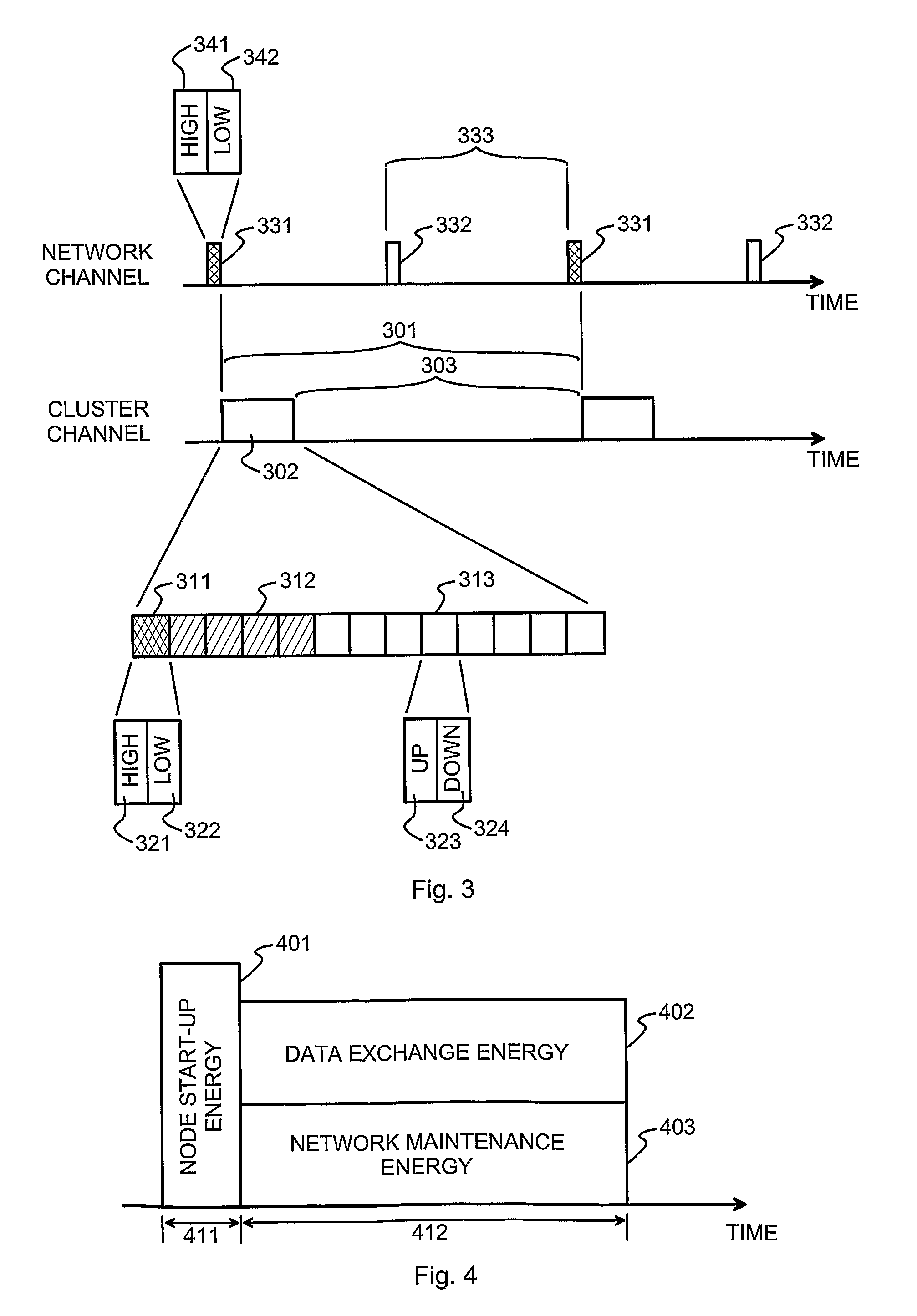

Energy Efficient Wireless Sensor Network, Node Devices for the Same and a Method for Arranging Communications in a Wireless Sensor Network

ActiveUS20080253327A1Reduce power consumptionAvoiding prohibitively network scanning timeEnergy efficient ICTPower managementLine sensorTelecommunications

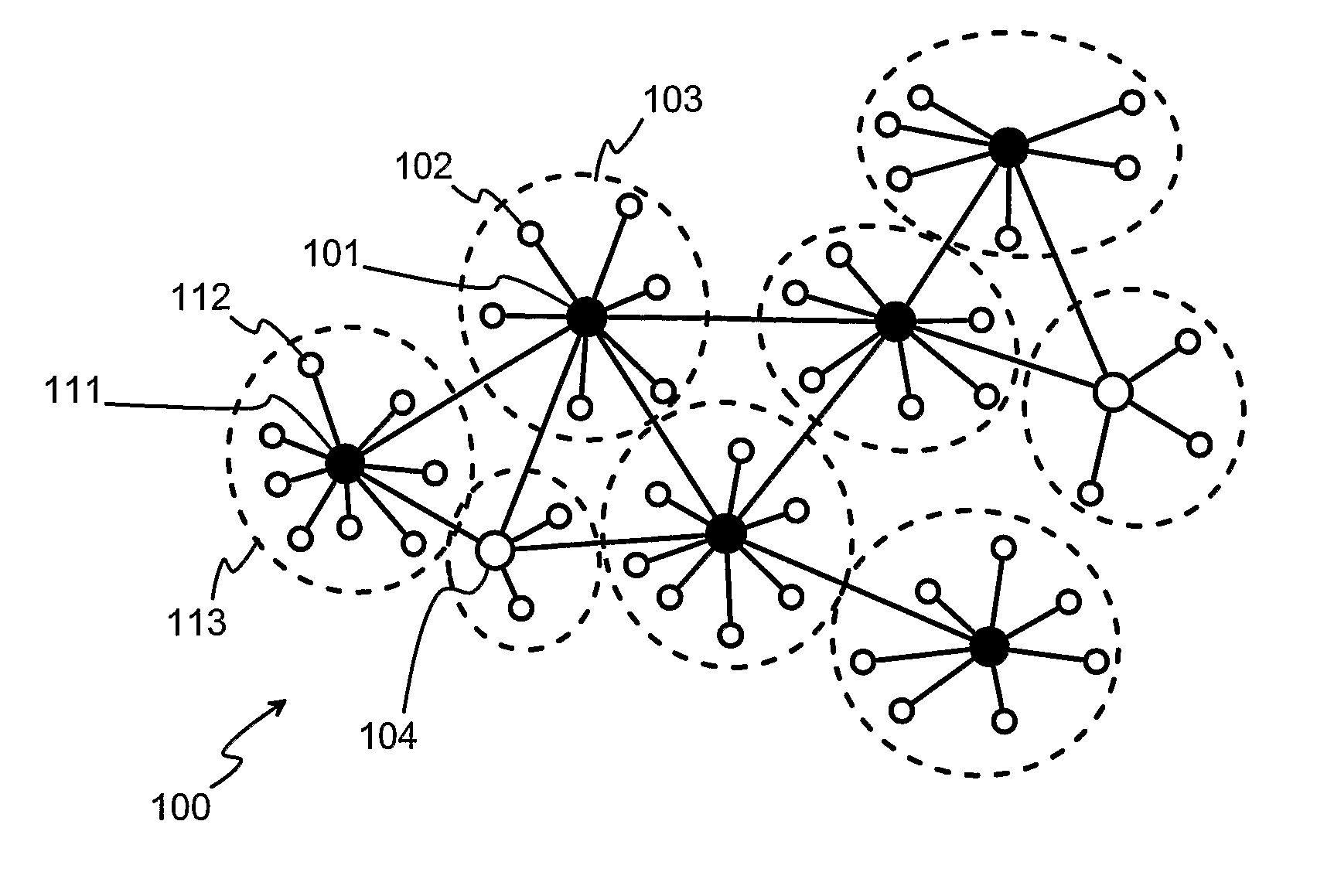

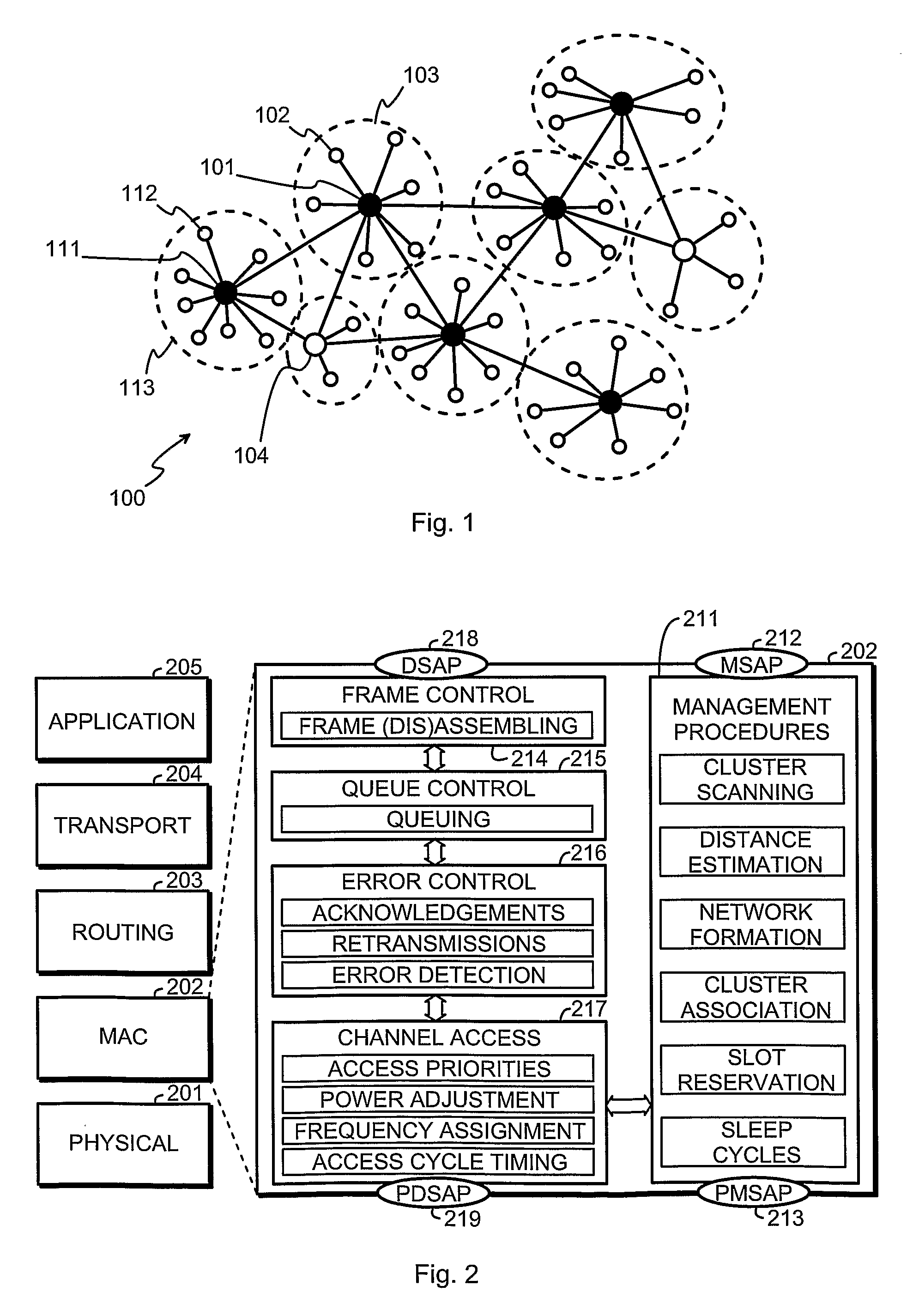

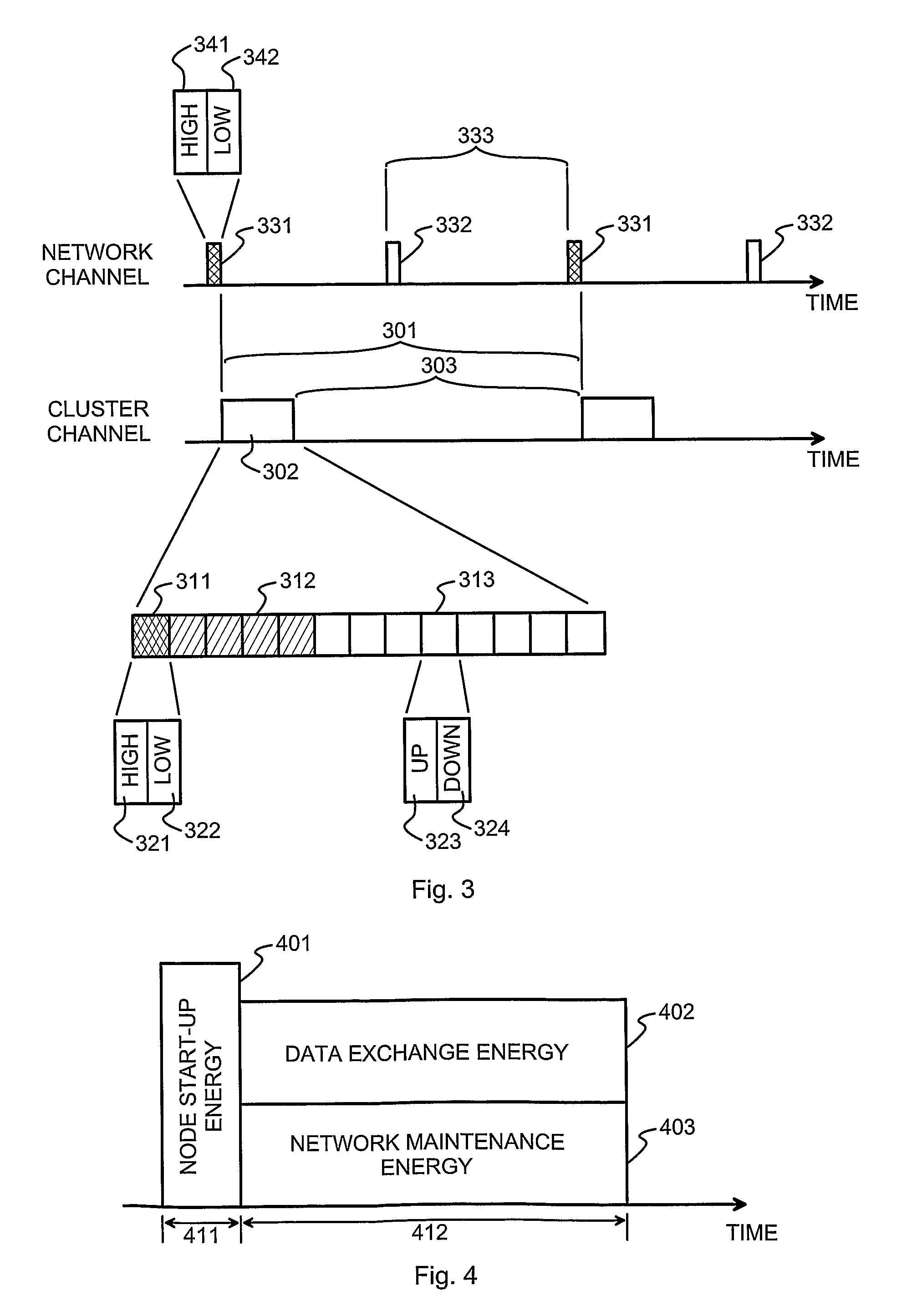

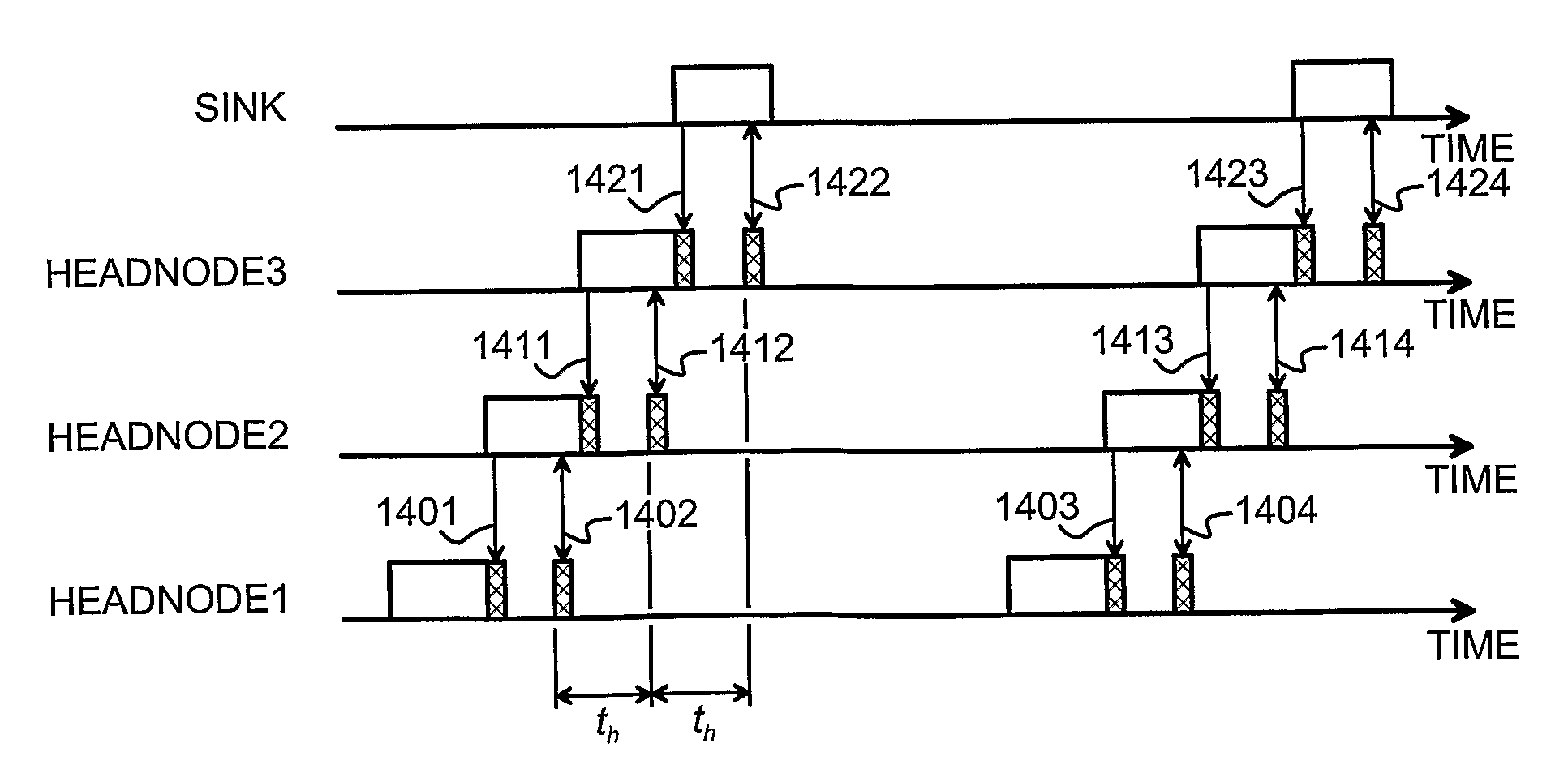

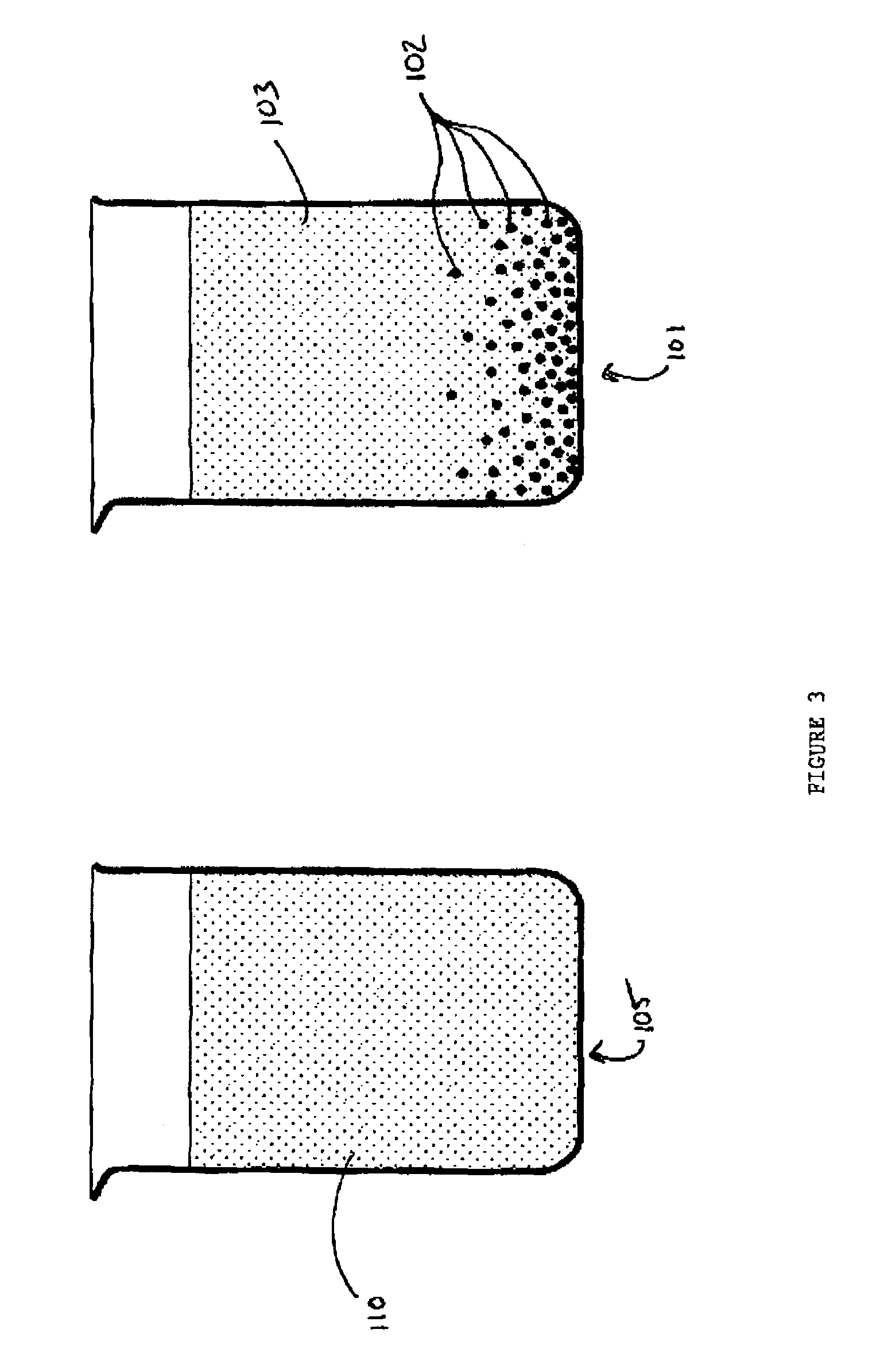

A wireless sensor network, a node device thereof and a method for arranging communications therein are presented. A first frequency is used in wireless communication of information between a headnode and subnodes of a first cluster (103) using a time slotted channel access scheme. A headnode of a second cluster (113) known the first frequency and selects a second, different frequency for use in wireless communication of information within said second cluster (113) using a time slotted channel access scheme. The headnode of the first cluster (103) is informed about the second frequency selected for the second cluster (113). Information from the headnode of said first cluster (103) to the headnode of said second cluster (113) is communicated on said second frequency, using the same time slotted channel access scheme as other nodes in said second cluster (113).

Owner:WIREPAS

Energy efficient wireless sensor network, node devices for the same and a method for arranging communications in a wireless sensor network

ActiveUS7830838B2Reduce power consumptionAvoiding prohibitively network scanning timeEnergy efficient ICTPower managementLine sensorTelecommunications

Owner:WIREPAS OY

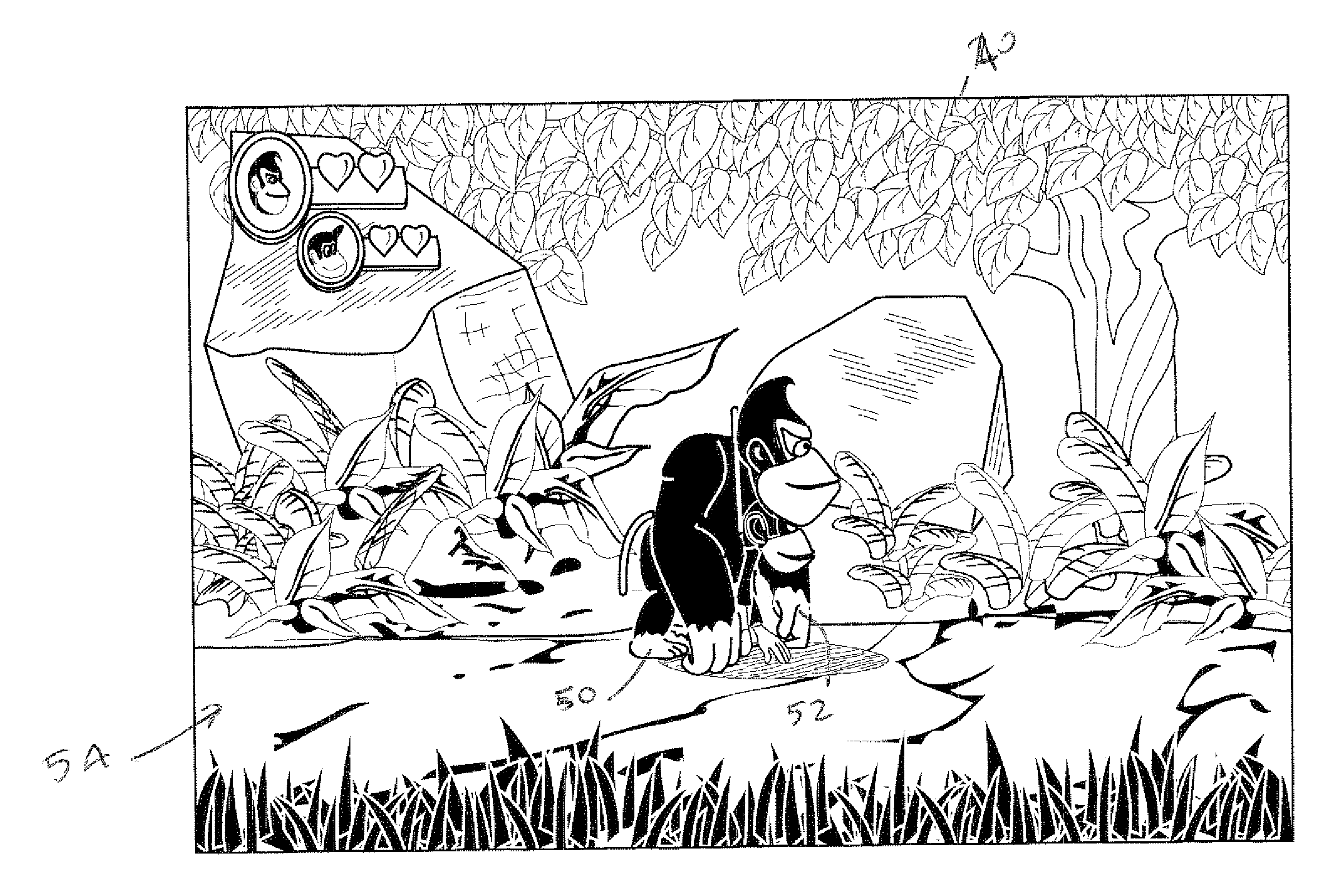

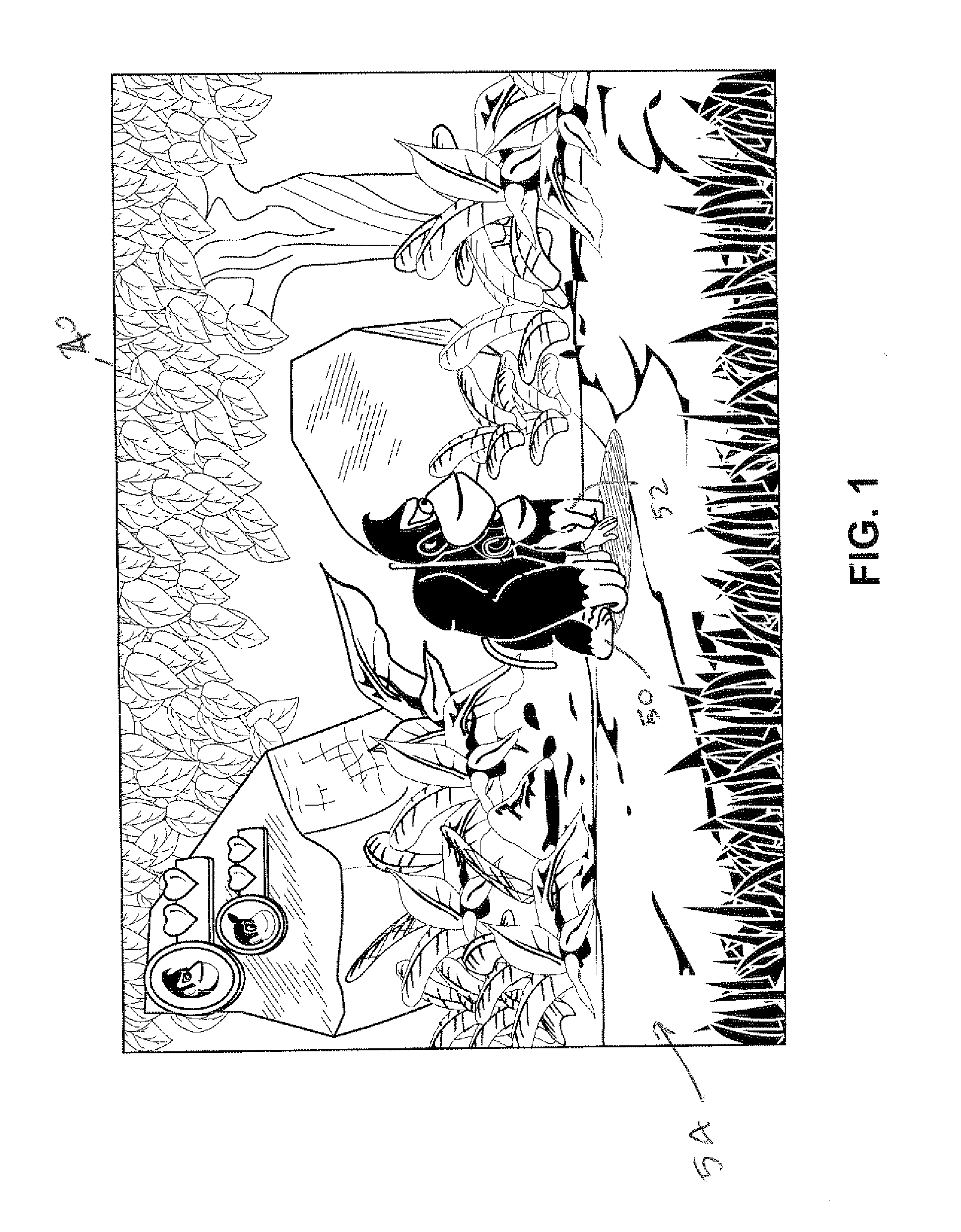

2d imposters for simplifying processing of plural animation objects in computer graphics generation

ActiveUS20110306417A1Reduce process complexityReduce memory loadAnimationVideo gamesGraphicsViewpoints

The technology herein involves use of 2D imposters to achieve seemingly 3D effects with high efficiency where plural objects such as animated characters move together such as when one character follows or carries another character. A common 2D imposter or animated sprite is used to image and animate the plural objects in 2D. When the plural objects are separated in space, each object can be represented using its respective 3D model. However, when the plural objects contact one another, occupy at least part of the same space, or are very close to one other (e.g., as would arise in a situation when the plural objects are moving together in tandem), the animation system switches from using plural respective 3D models to using a common 2D model to represent the plural objects. Such use of a common 2D model can be restricted in some implementations to situations where the user's viewpoint can be restricted to be at least approximately perpendicular to the plane of 2D model, or the 2D surface on which the combined image is texture mapped can be oriented in response to the current virtual camera position.

Owner:NINTENDO CO LTD

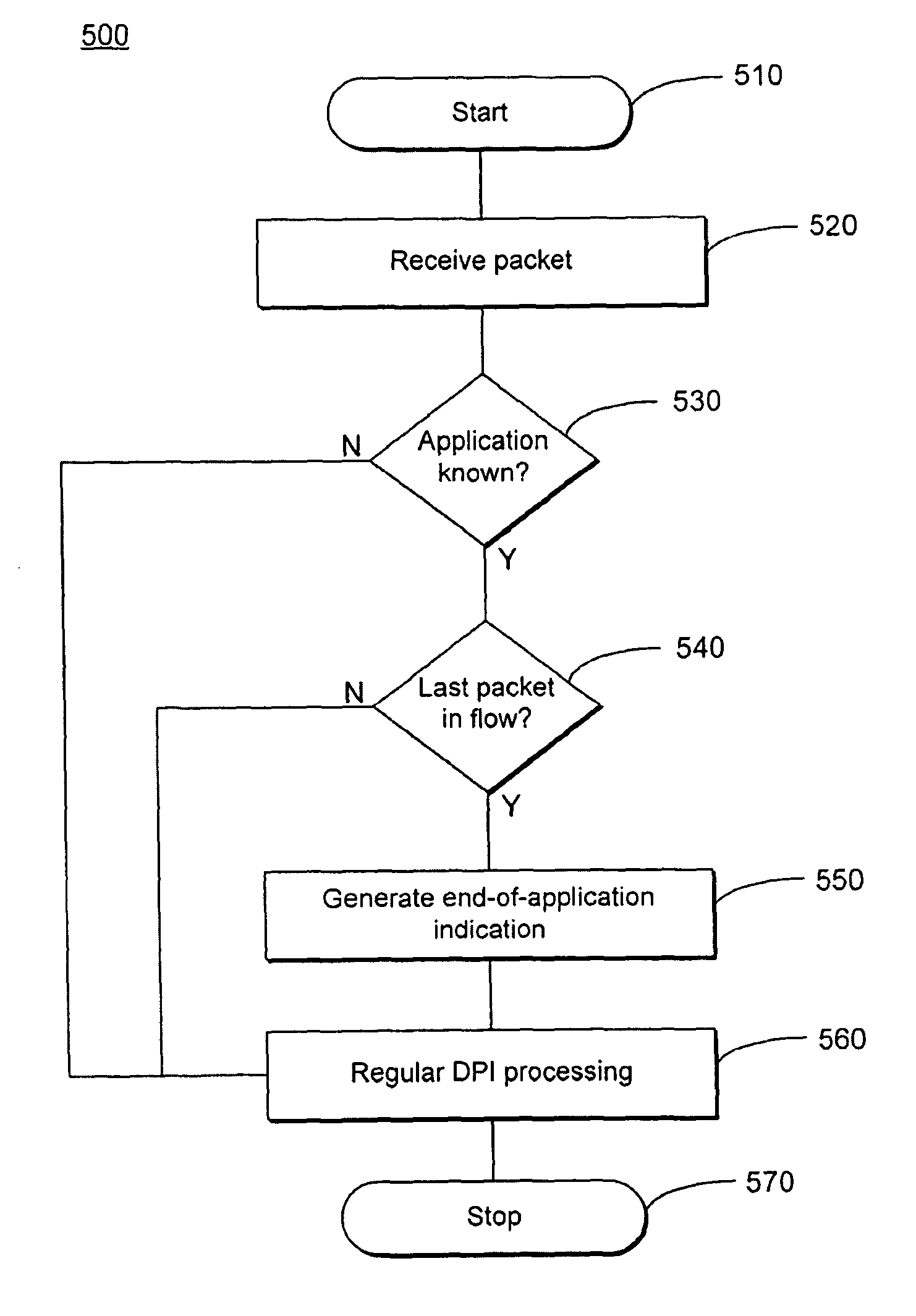

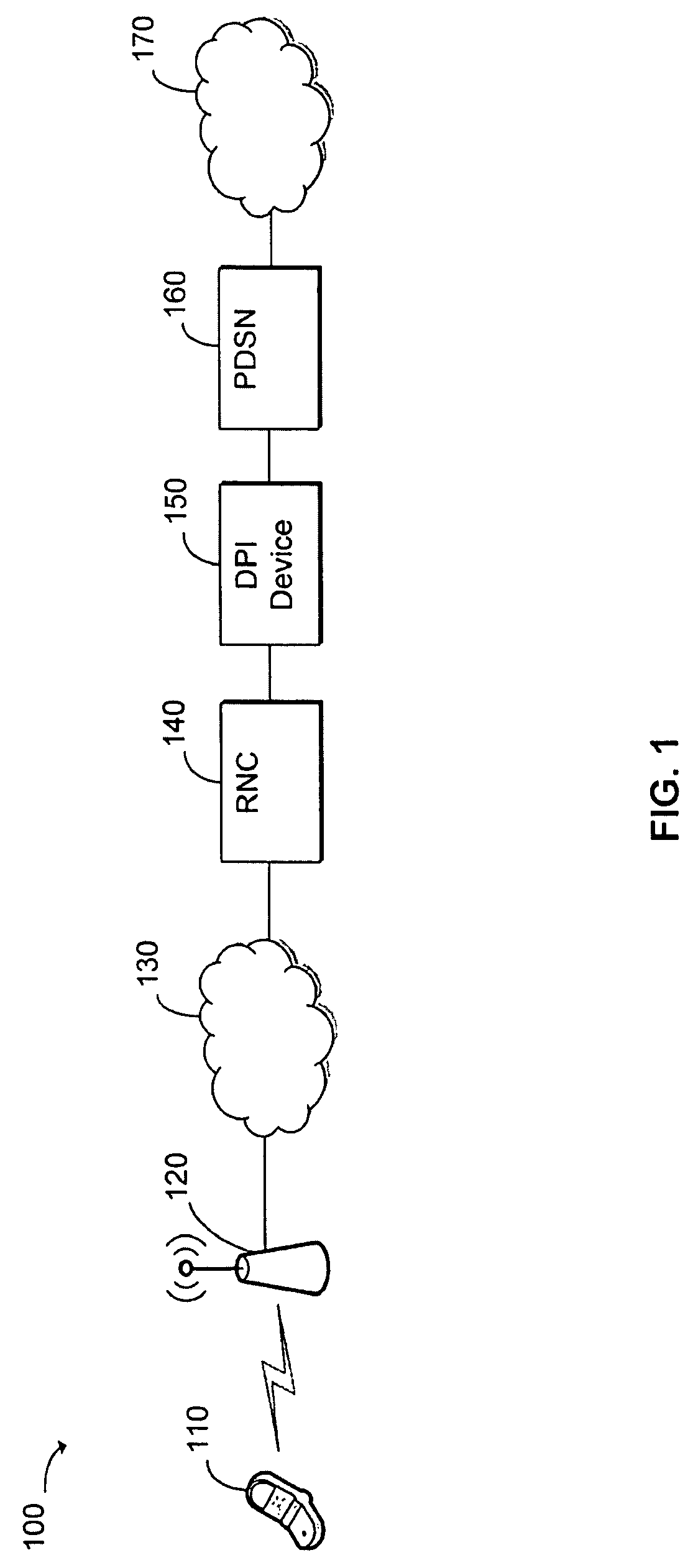

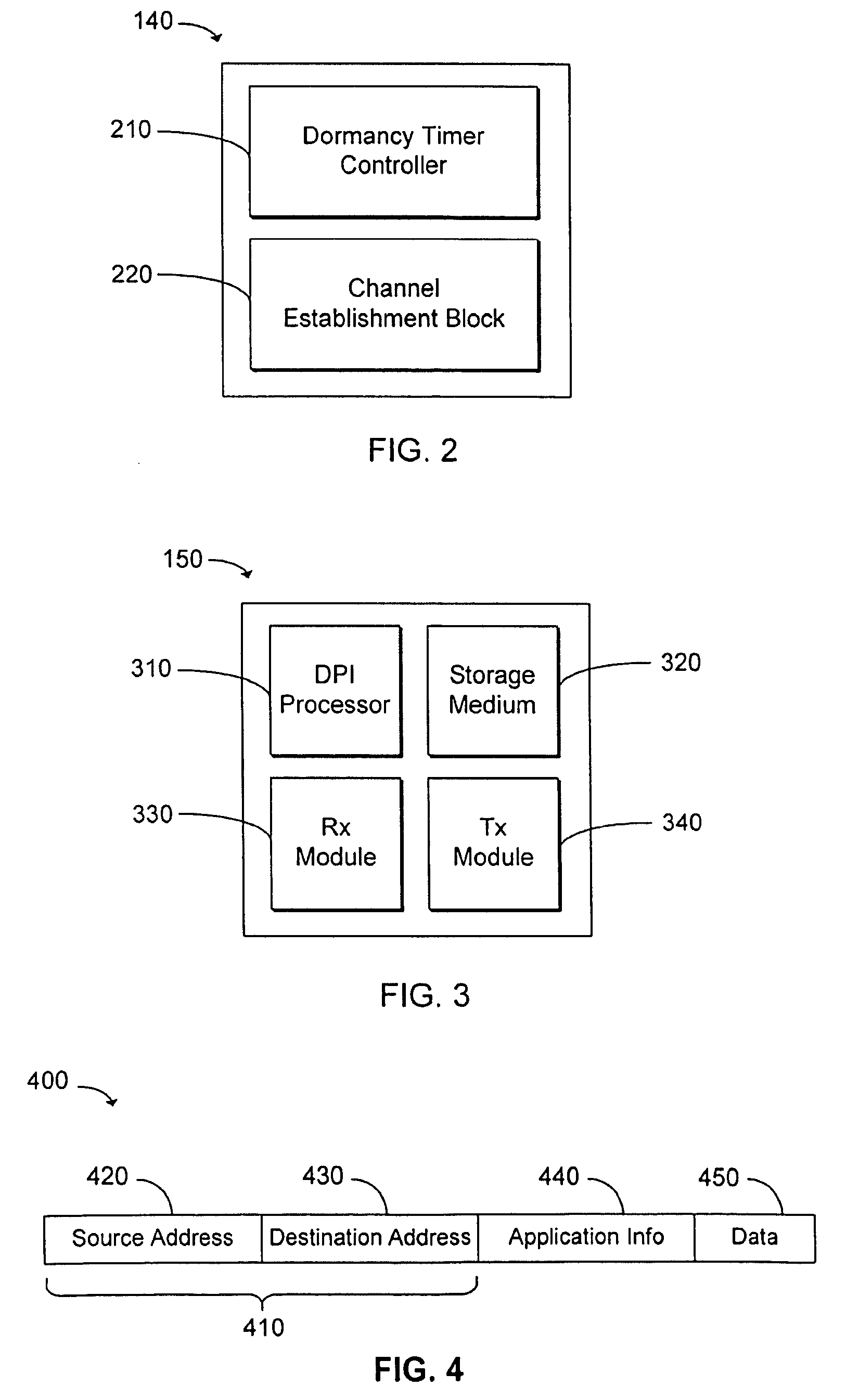

DPI-driven bearer termination for short-lived applications

InactiveUS8179846B2ResourceEasy to implementConnection managementWireless commuication servicesTelecommunicationsRadio networks

Based on application information received from a DPI device, a downstream device, such as a Radio Network Controller (RNC), optimally implements a dormancy timer policy for short-lived applications, such as email and MMS. In particular, the RNC may initially use a large value for the dormancy timer for these applications. When the RNC receives an indication of the end of the application from the DPI device, the RNC may terminate the connection, thereby immediately freeing up resources. Alternatively, should the DPI device fail to recognize the end of the application, the initial dormancy timer serves as a fail-safe, such that the radio network resources are still released for allocation to another device in the radio network.

Owner:WSOU INVESTMENTS LLC

Distributed scheduler

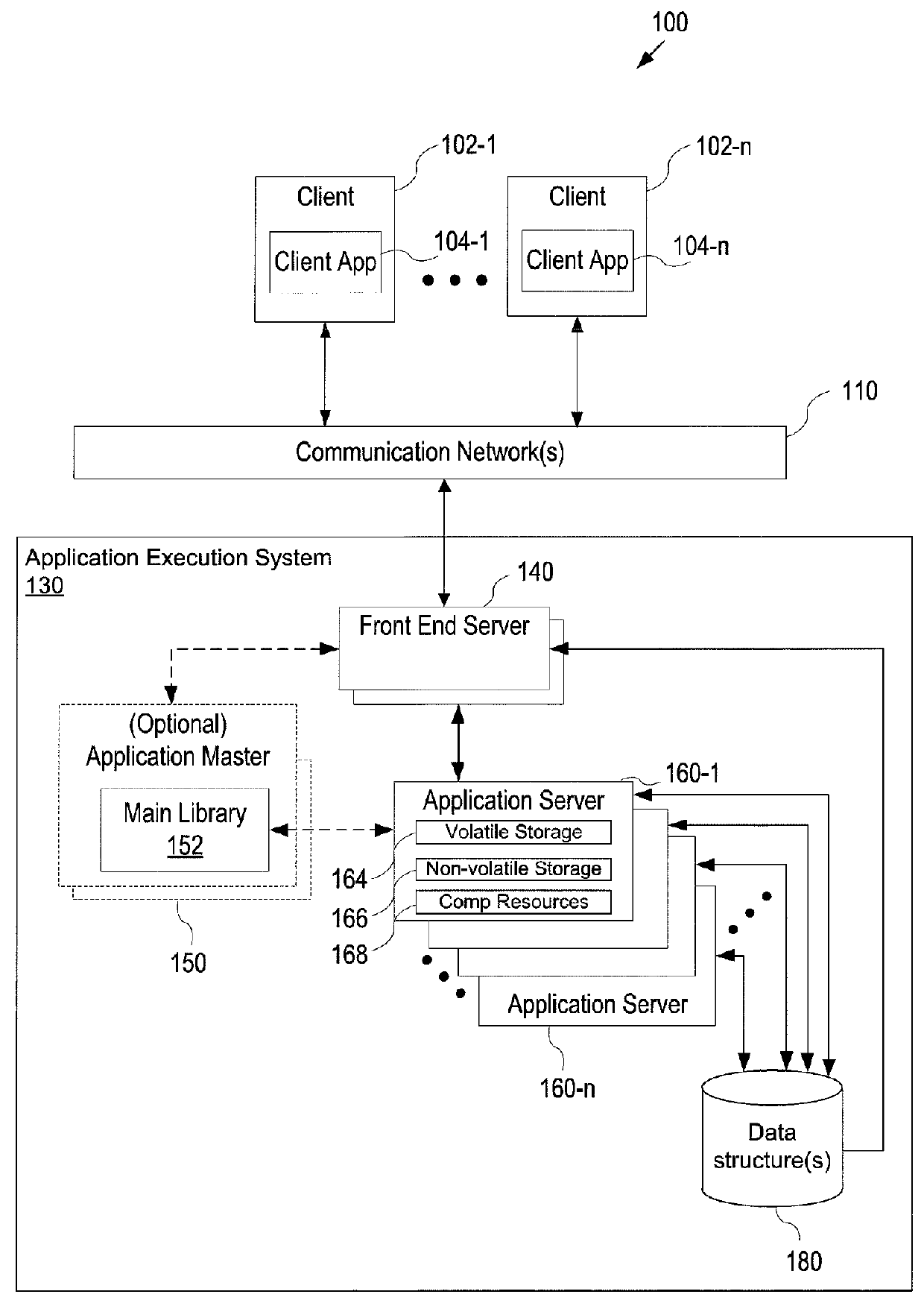

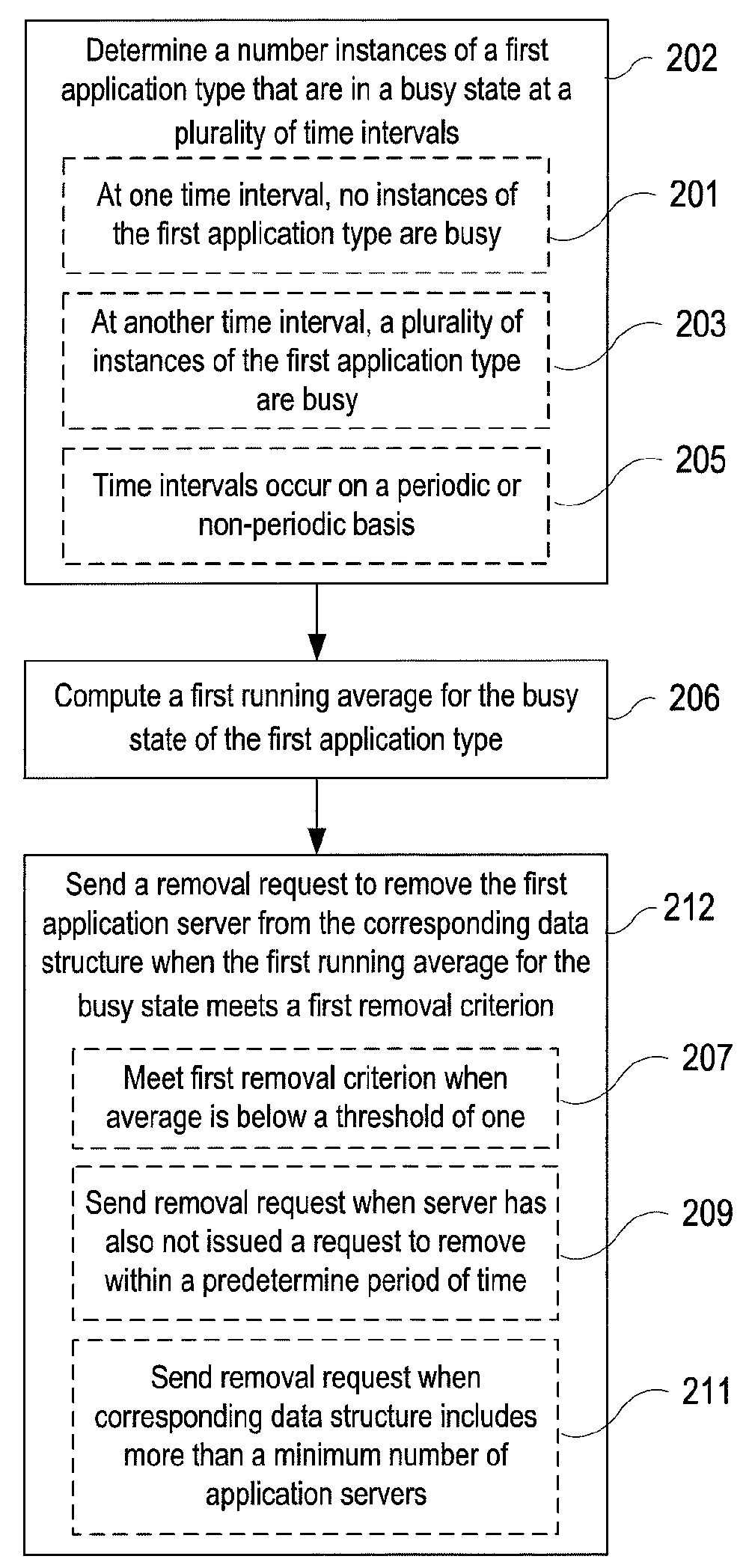

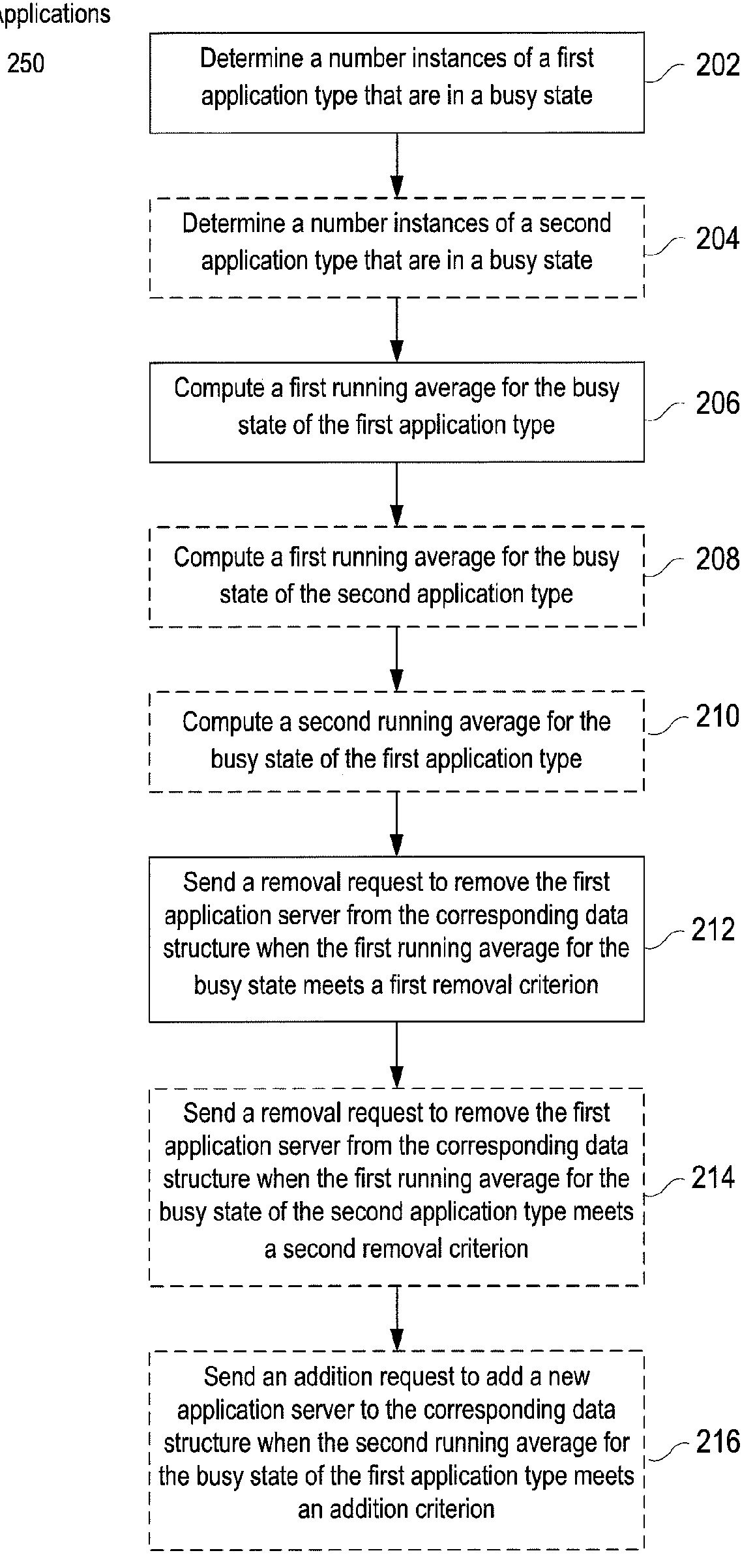

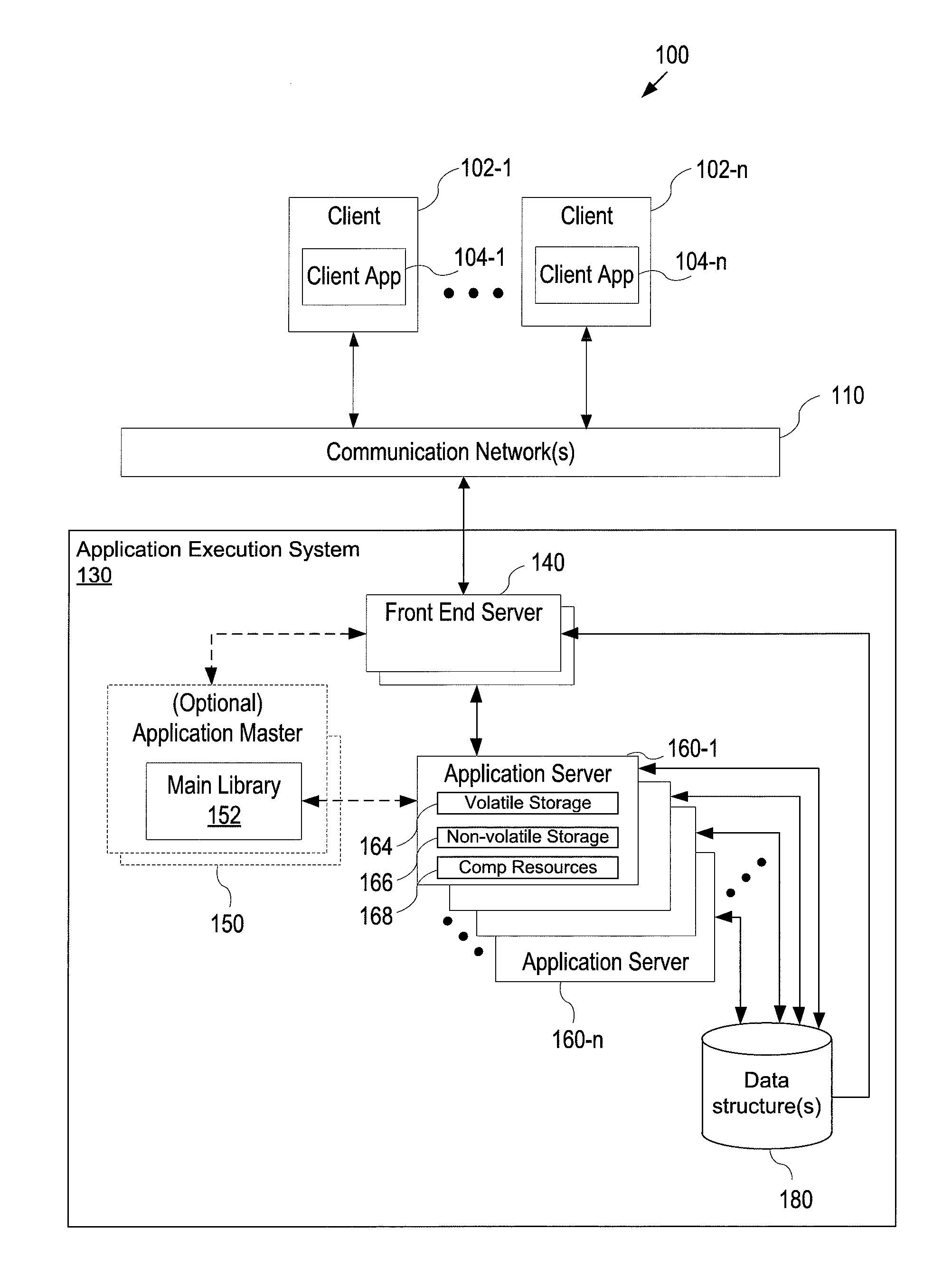

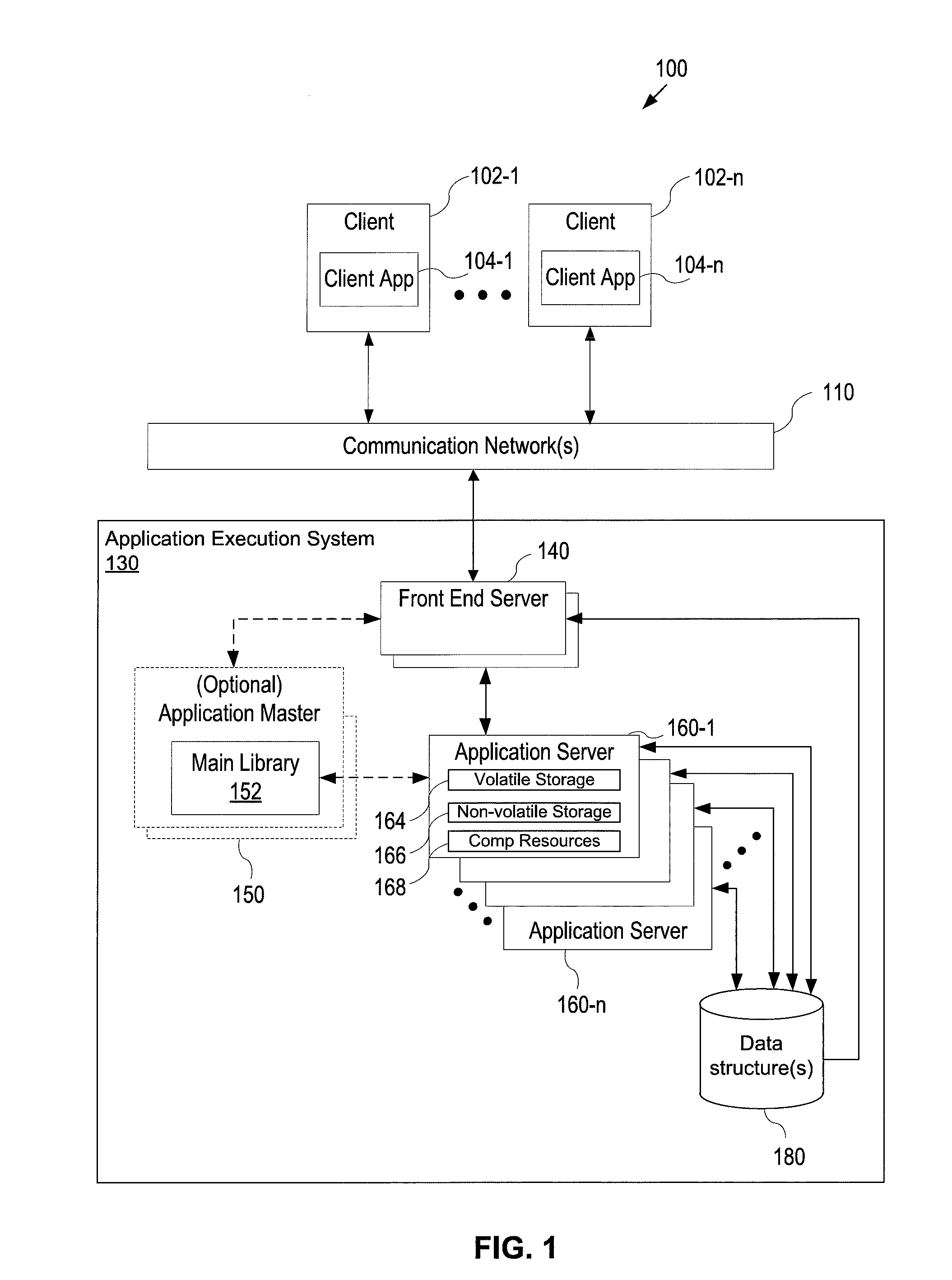

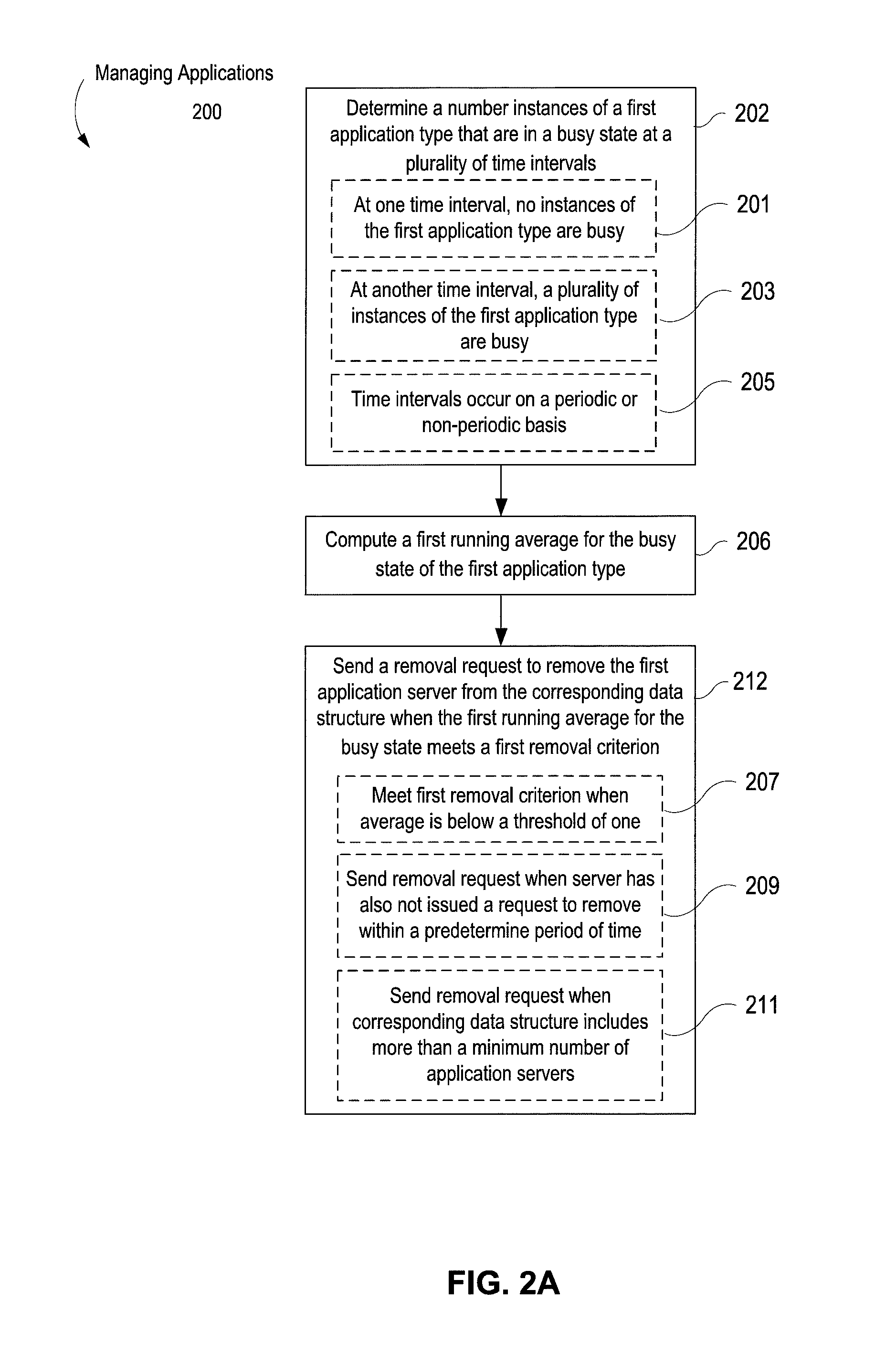

ActiveUS9379903B1Freeing resourceResourceError detection/correctionDigital computer detailsApplication serverApplication software

A method, system, and computer readable medium for managing applications on an application execution system are disclosed. On an application server the number of instances of a first application type that are in a busy state is determined. This determination is performed at each respective time interval in a plurality of time intervals. Then, a first running average for the busy state of the first application type is computed based upon the number of instances of the first application type that are in a busy state, at the application server, at each respective time interval. A removal request is sent when the first running average for the busy state meets a first removal criterion. The removal request is a request to remove the application server from a data structure that specifies which of a plurality of application servers accept service requests for the first application type.

Owner:GOOGLE LLC

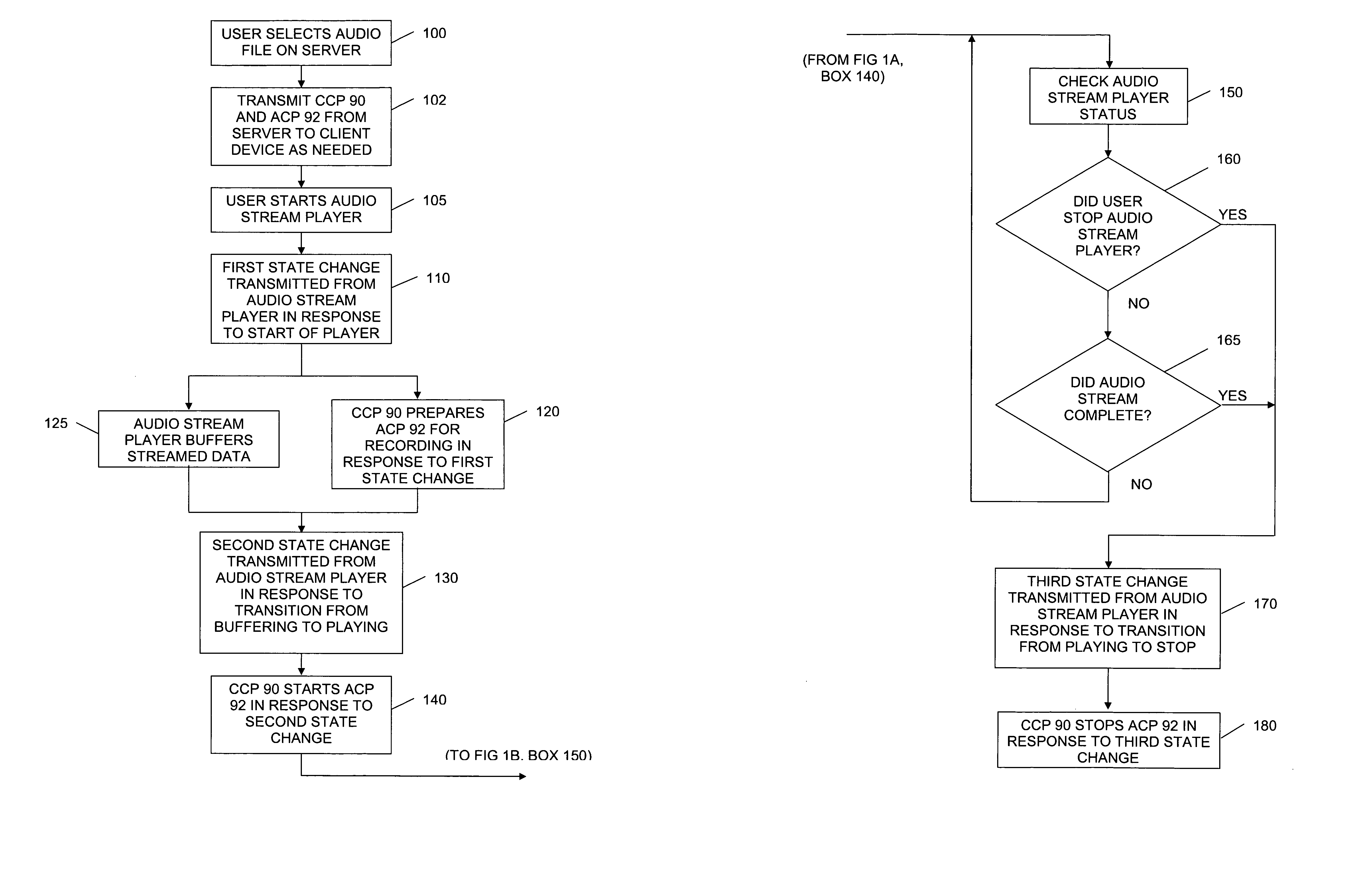

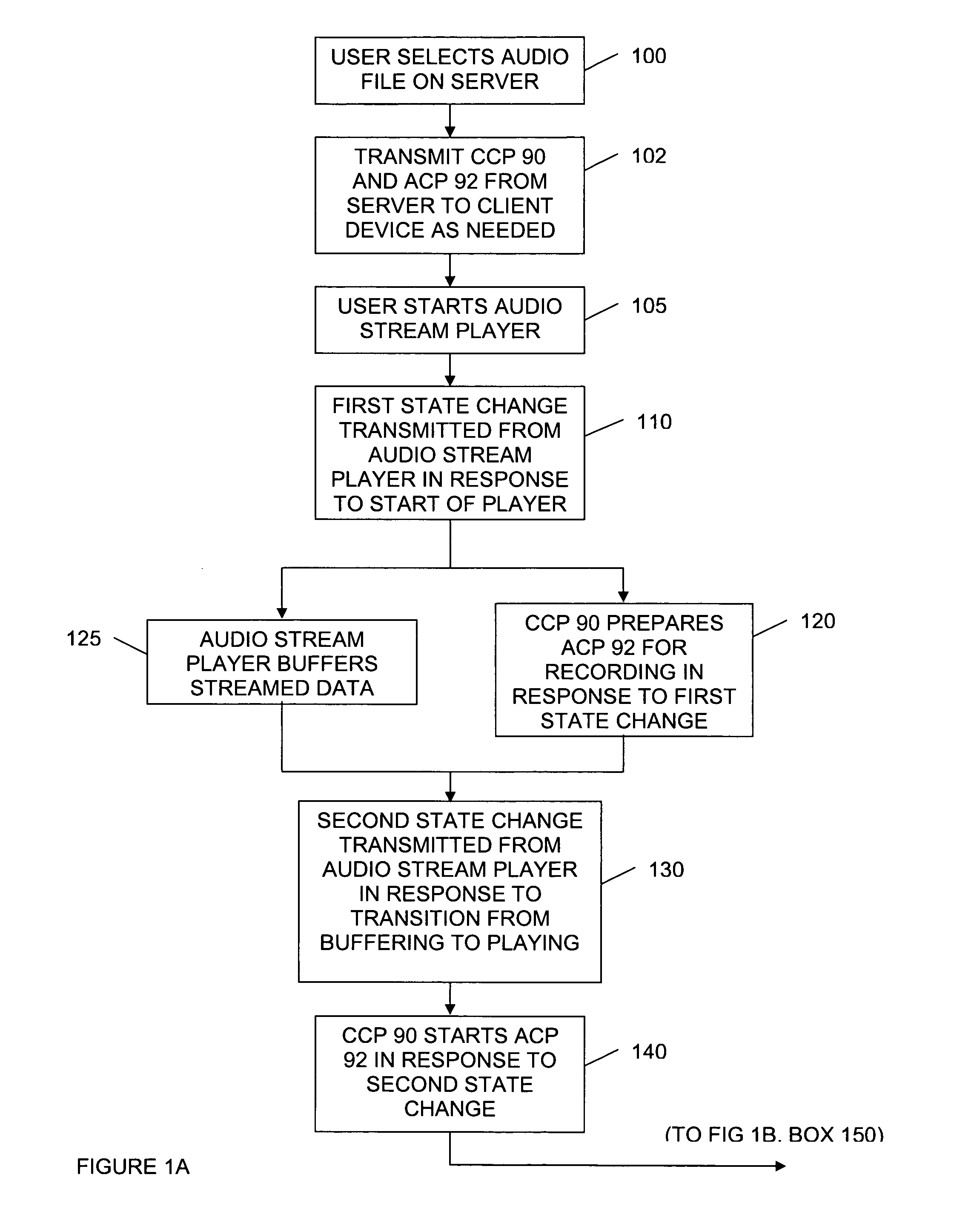

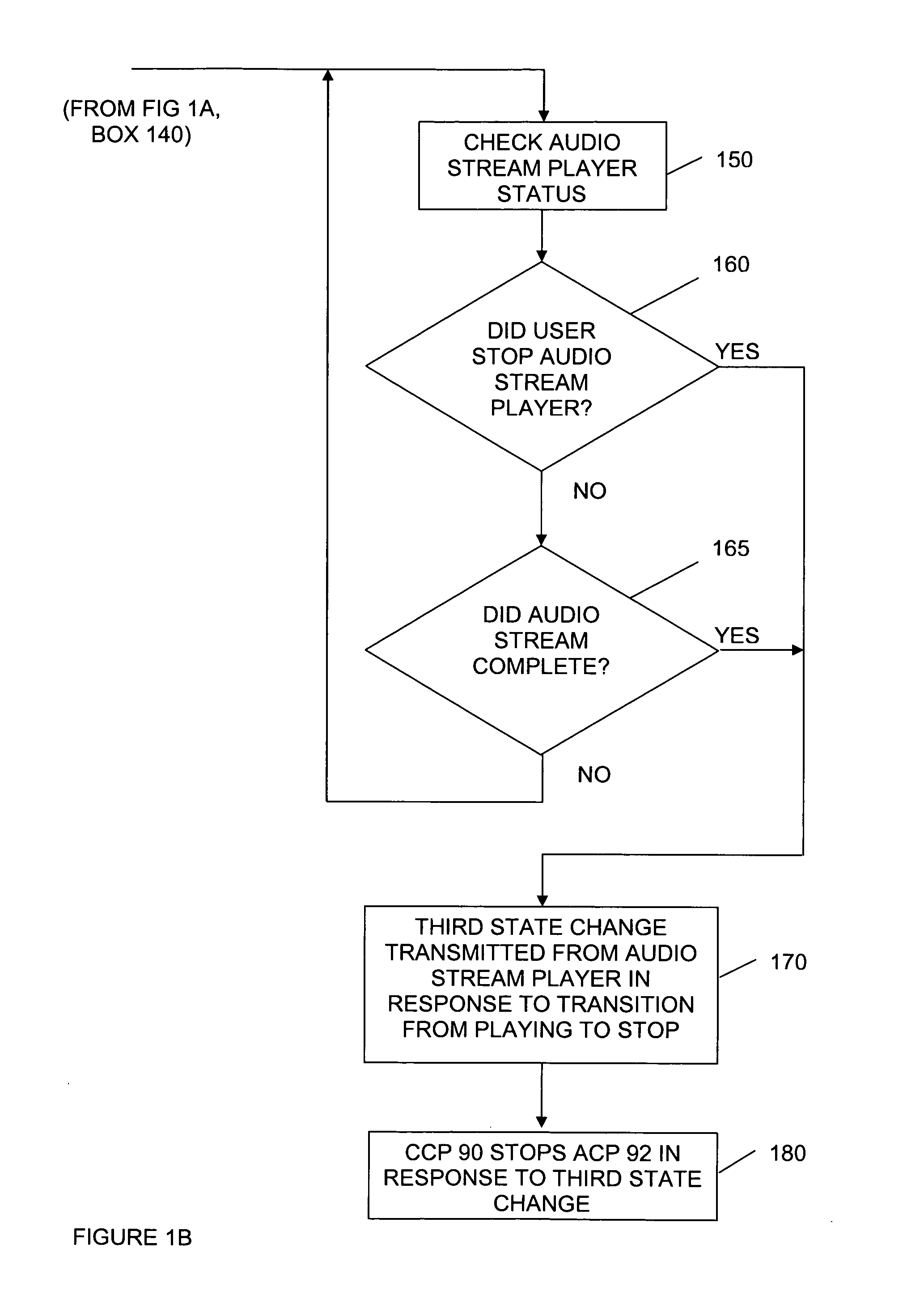

Synchronized streamed playback and recording for personal computers

InactiveUS7228189B1Eliminate needResourceProgram loading/initiatingElectrical appliancesClient-sidePersonal computer

A method is provided for synchronizing an audio capture program with a streamed audio file. The method comprises receiving at least one selection request from a user connected to a server device, the transmission of a program from the server device to the user client device, the streaming of digital audio data from the server device to the client device, and the detection of state changes associated with an audio stream player disposed within the client device. The transmitted program prepares an audio capture program on the client device in response to state changes associated with the audio stream player and initiates audio capture at a fixed time interval from when the playback state change is detected.

Owner:GADDY JOHN C

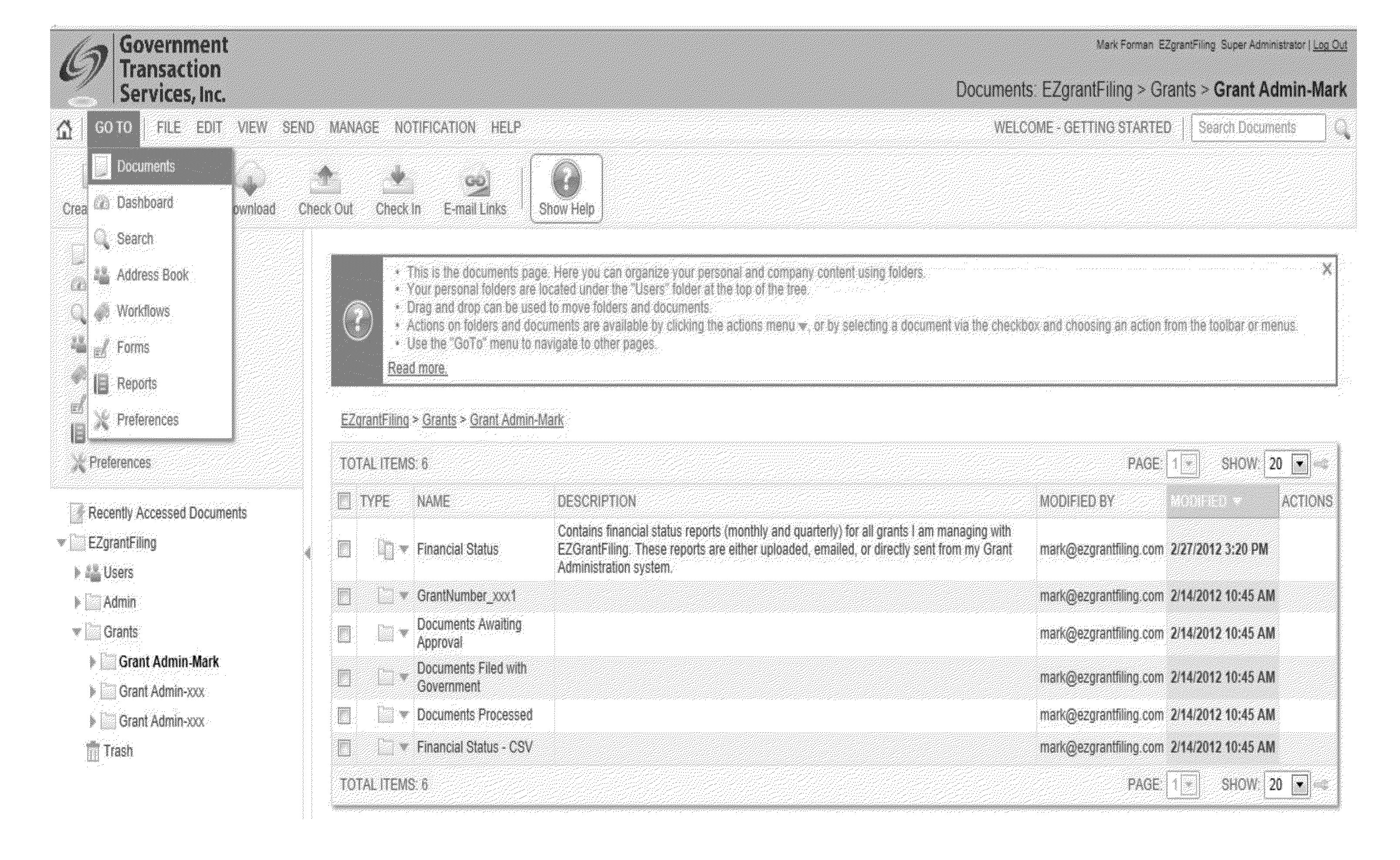

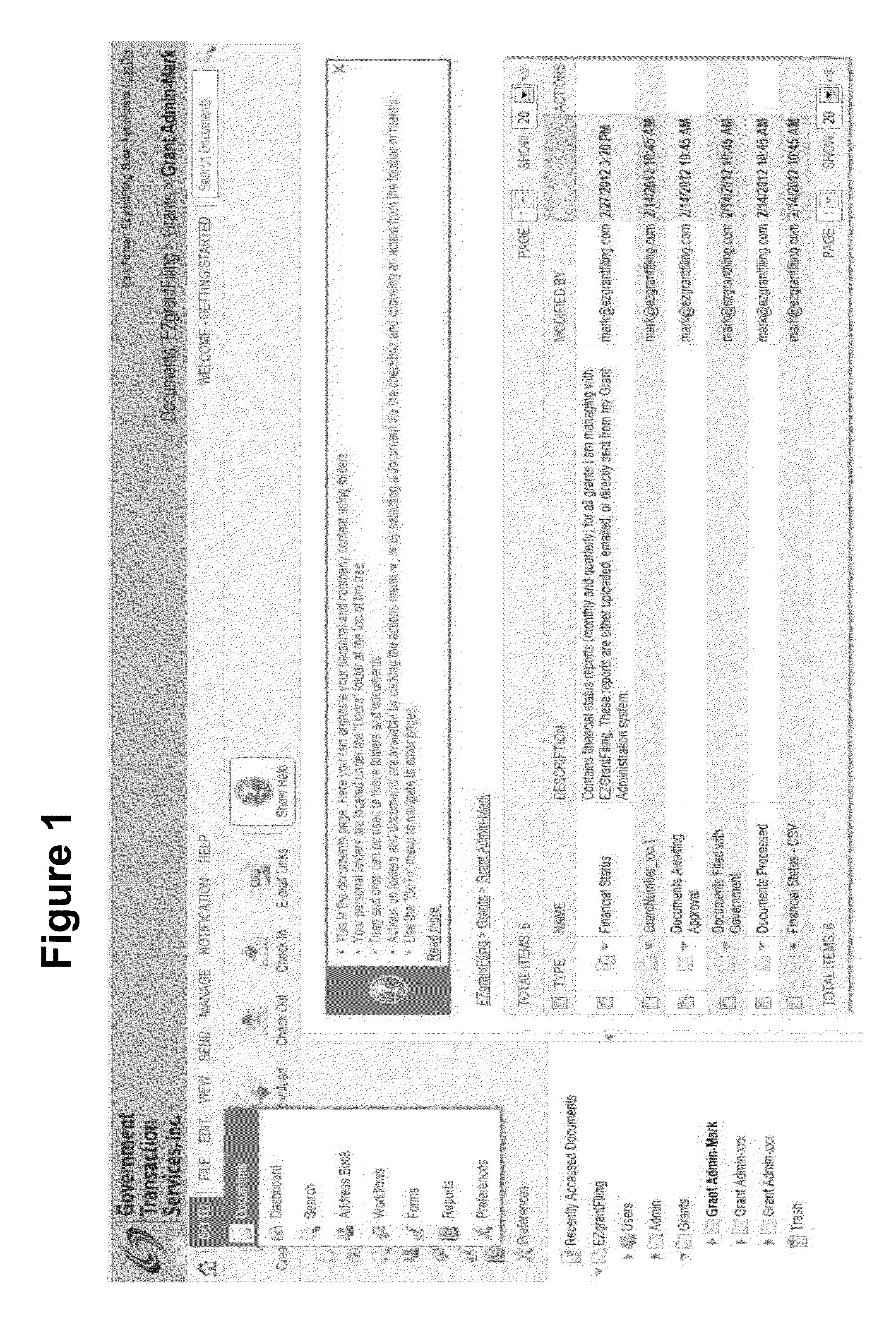

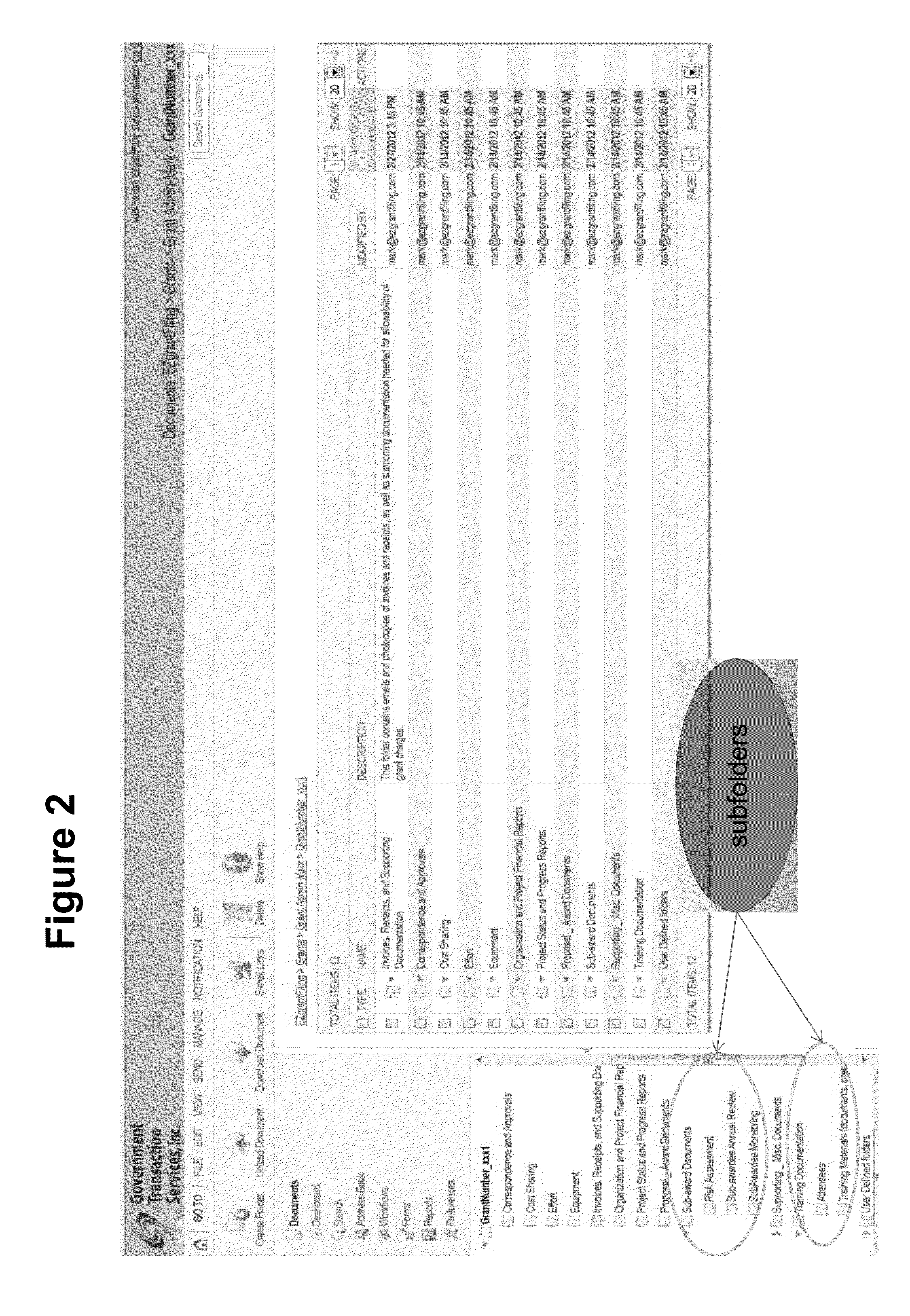

System and Method for Integrated Use of Shared Hardware, Software and Storage Resources Communicating Through a Network to Standardize and Simplify Transactions Between an Organization and Entities That Do Business With The Organization

InactiveUS20130054431A1Low costReduce complexityComplete banking machinesFinanceDocumentation procedureProgram planning

Systems and methods that use “cloud” technologies to standardize and simplify transactions between the Federal government and entities that do business with it. The system may include cloud storage containing data files for account user data, grant reporting documentation and grant results / products; secure storage for user account / e-commerce data and USASPENDING archival data on the grant; and regulatory decision support tools for use among administrators, principal investigators, and program directors. The system may include a grant decision support engine for optimizing use of grant funds and a regulatory assistance engine for grant regulatory compliance, reporting, and approval requirements specific to Federal agencies.

Owner:GOVERNMENT TRANSACTION SERVICES

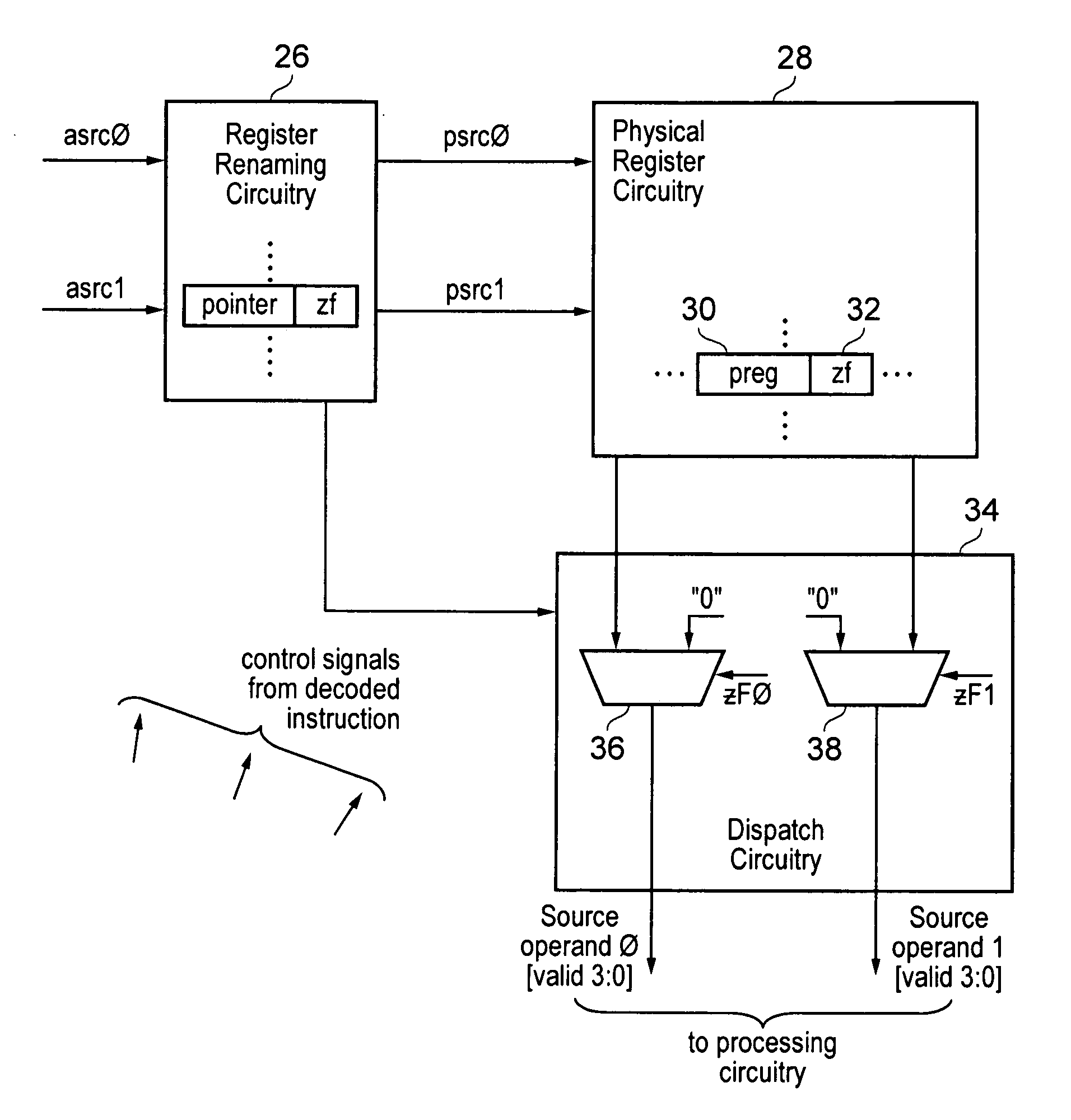

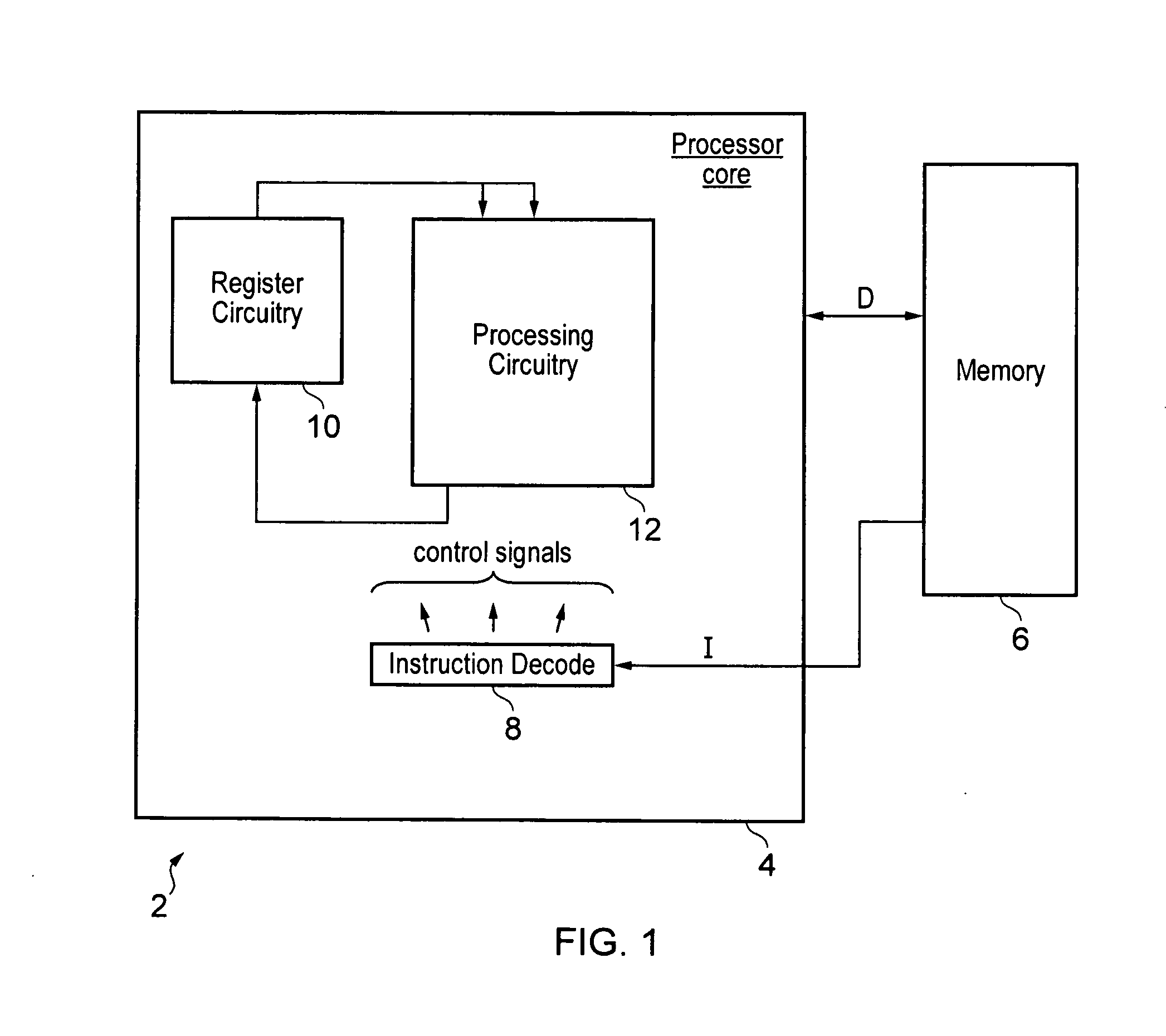

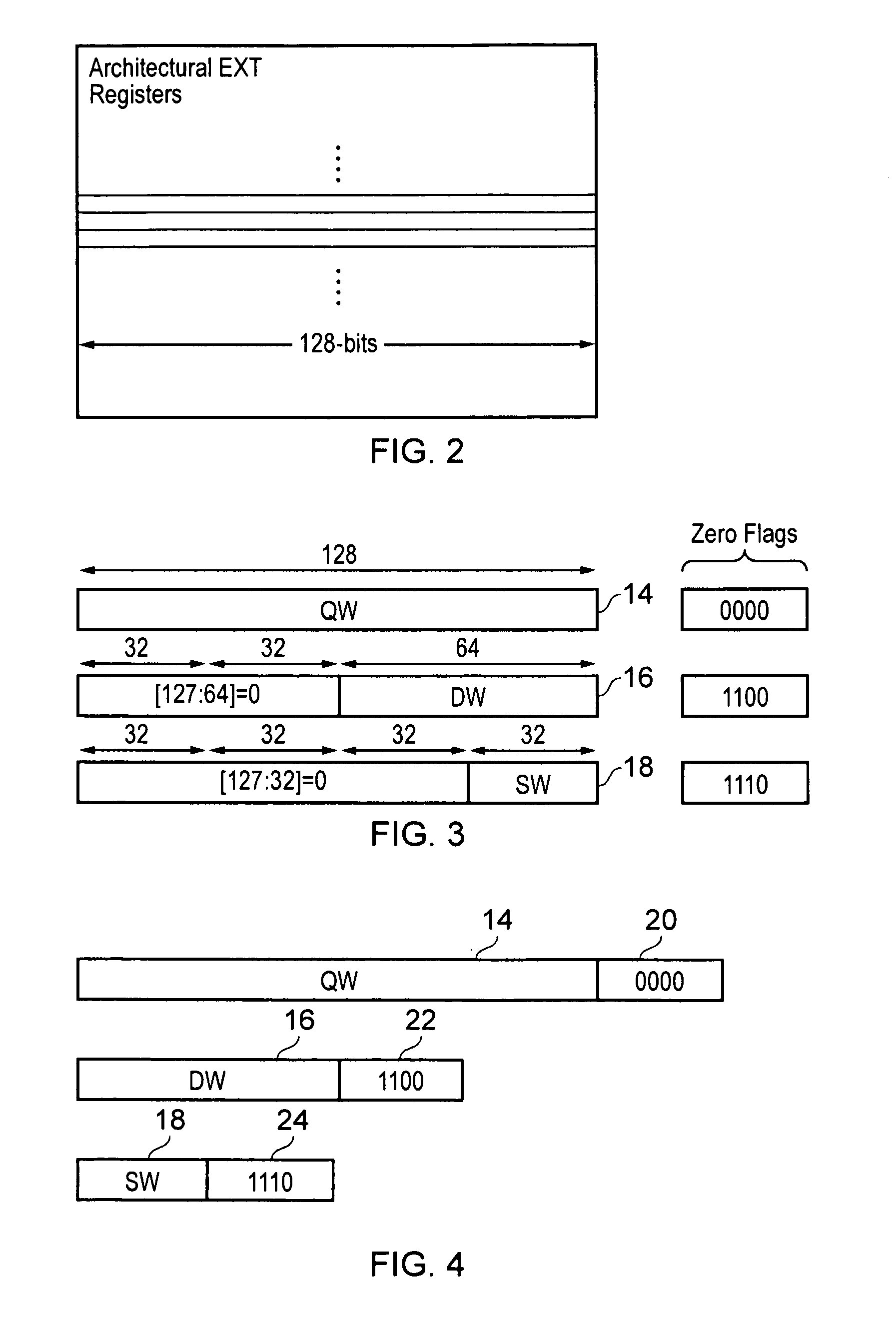

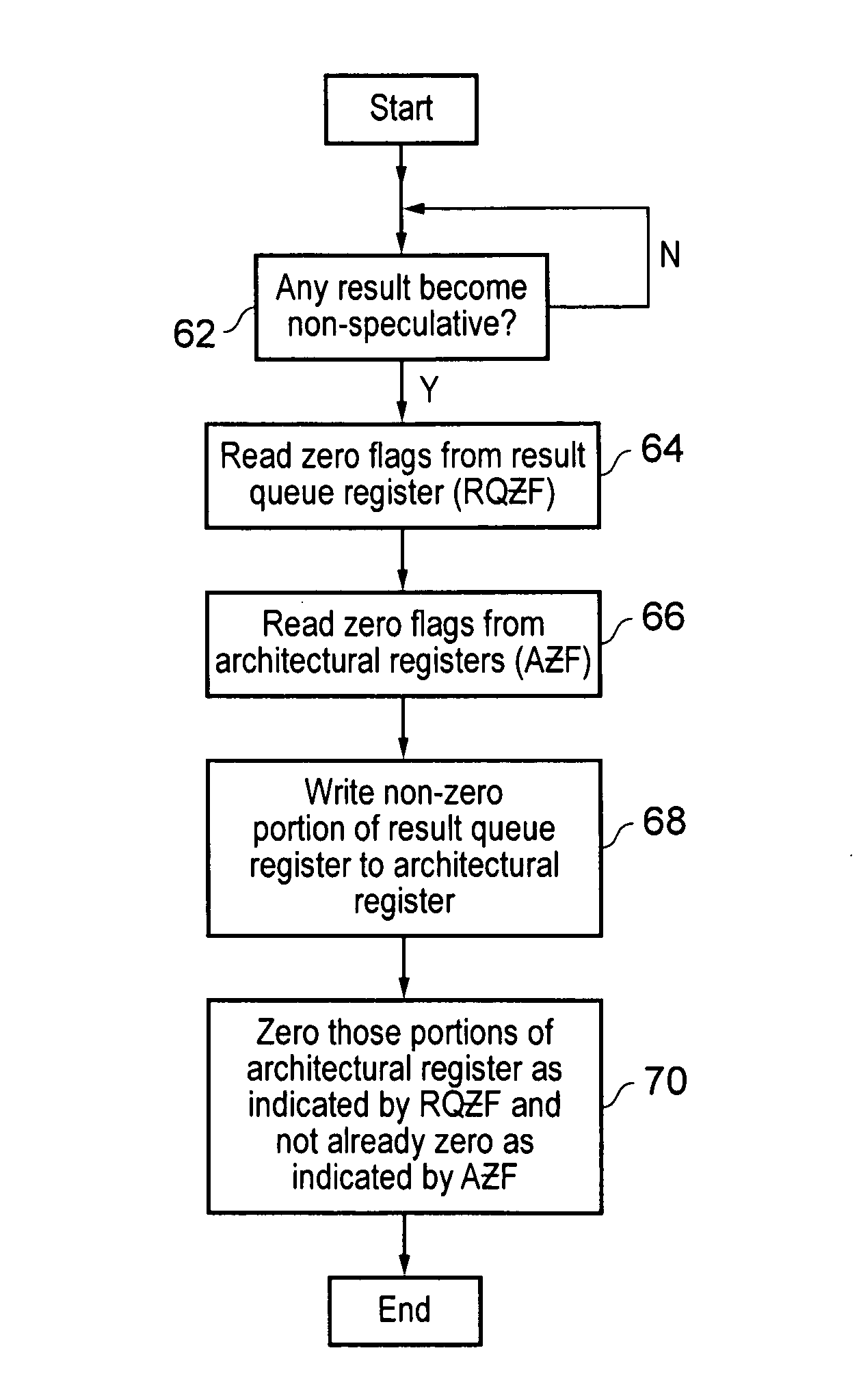

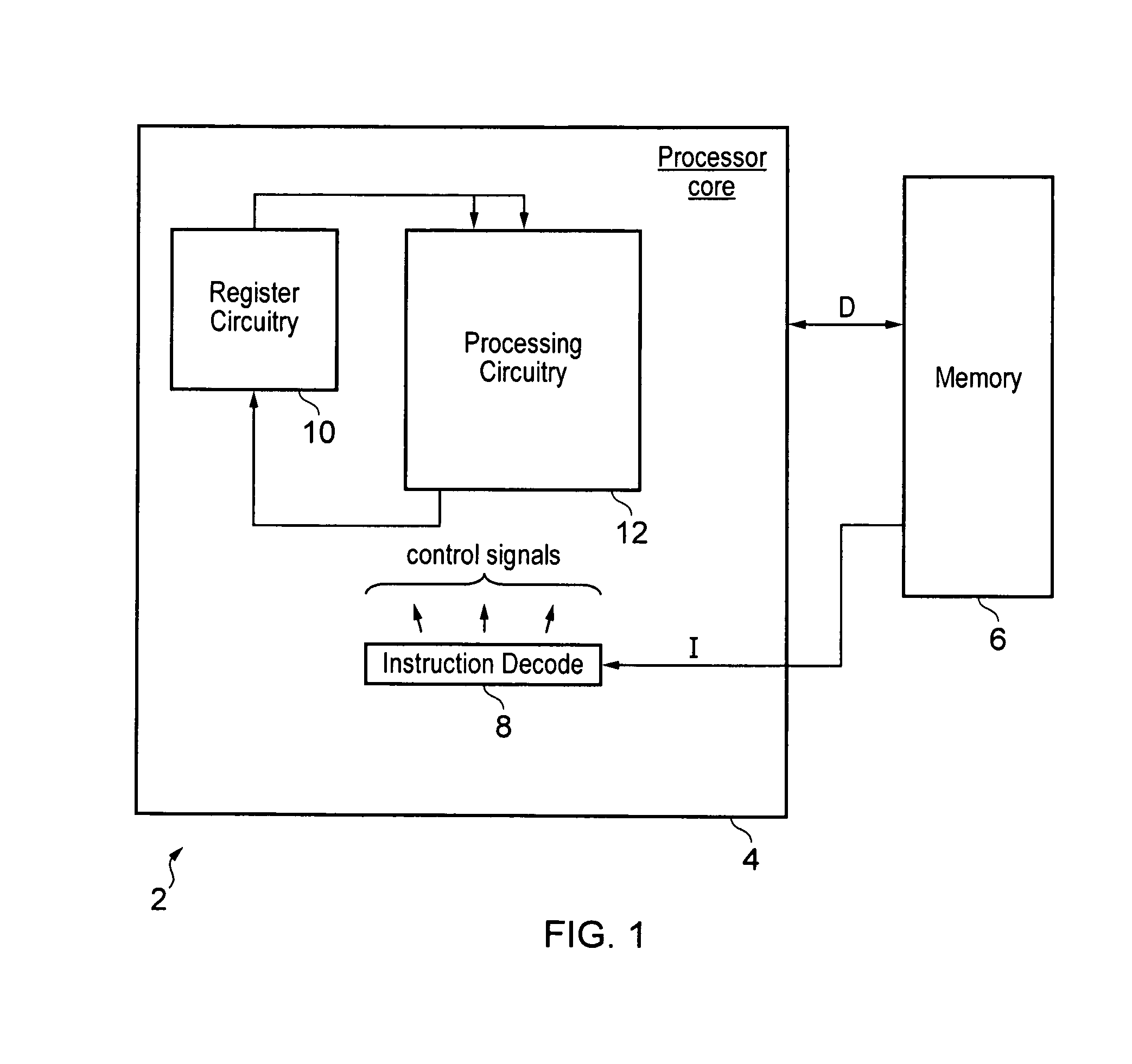

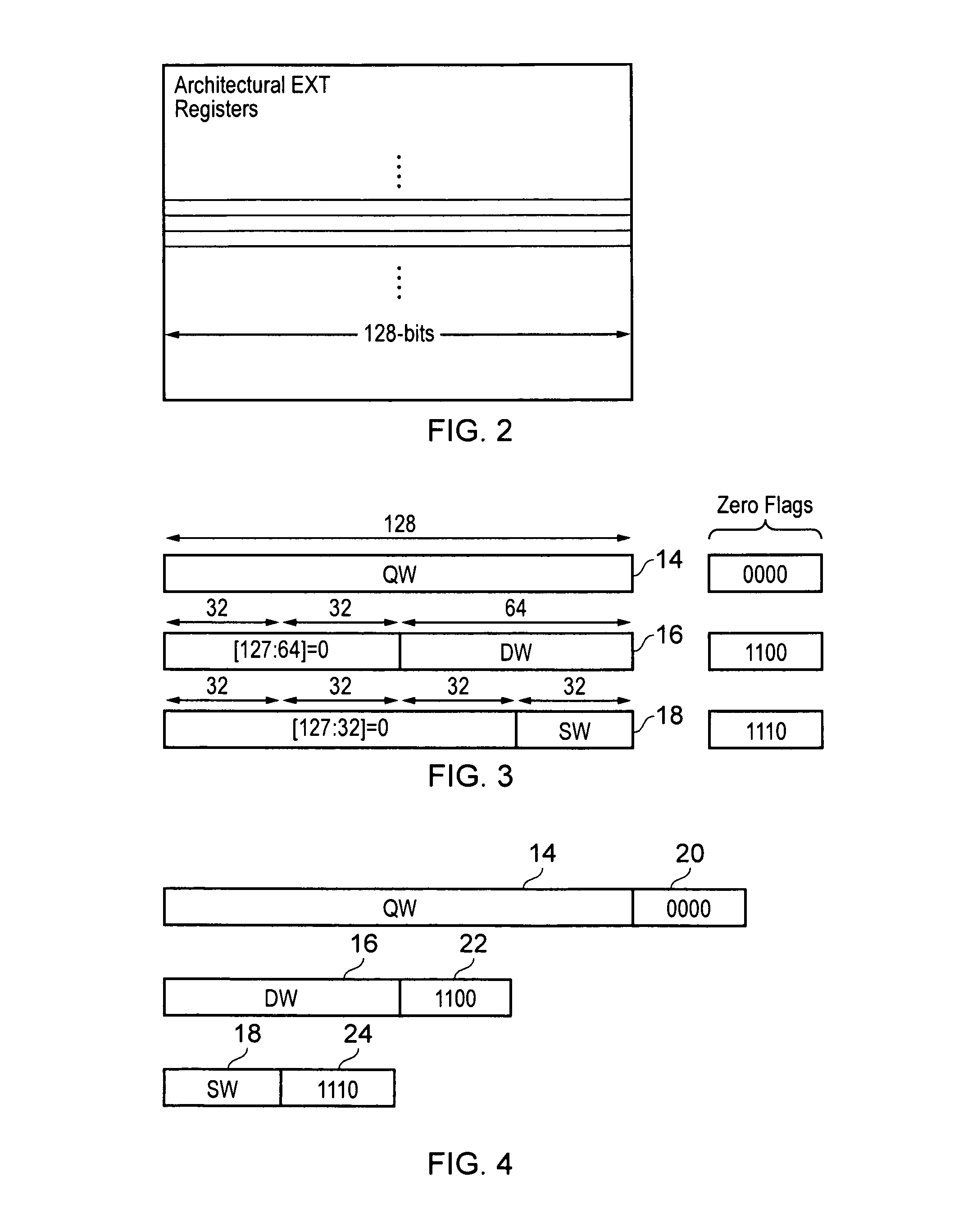

Zero value prefixes for operands of differing bit-widths

ActiveUS20130145127A1Saving energy and circuitry resourceAvoiding adding additional delayDigital data processing detailsDigital computer detailsEnergy consumptionRegister file

A data processing system is provided in which destination operands to be stored within architectural registers are constrained to have zero values added as prefixes in order that the architectural register value has a fixed bit width irrespective of the bit width of the destination operand being written thereto. Instead of adding these zero values everywhere in the data path, they are instead represented by zero flags in at least the physical registers utilised for register renaming operations and in the result queue prior to results being written to the architectural register file. This saves circuitry resources and reduces energy consumption.

Owner:ARM LTD

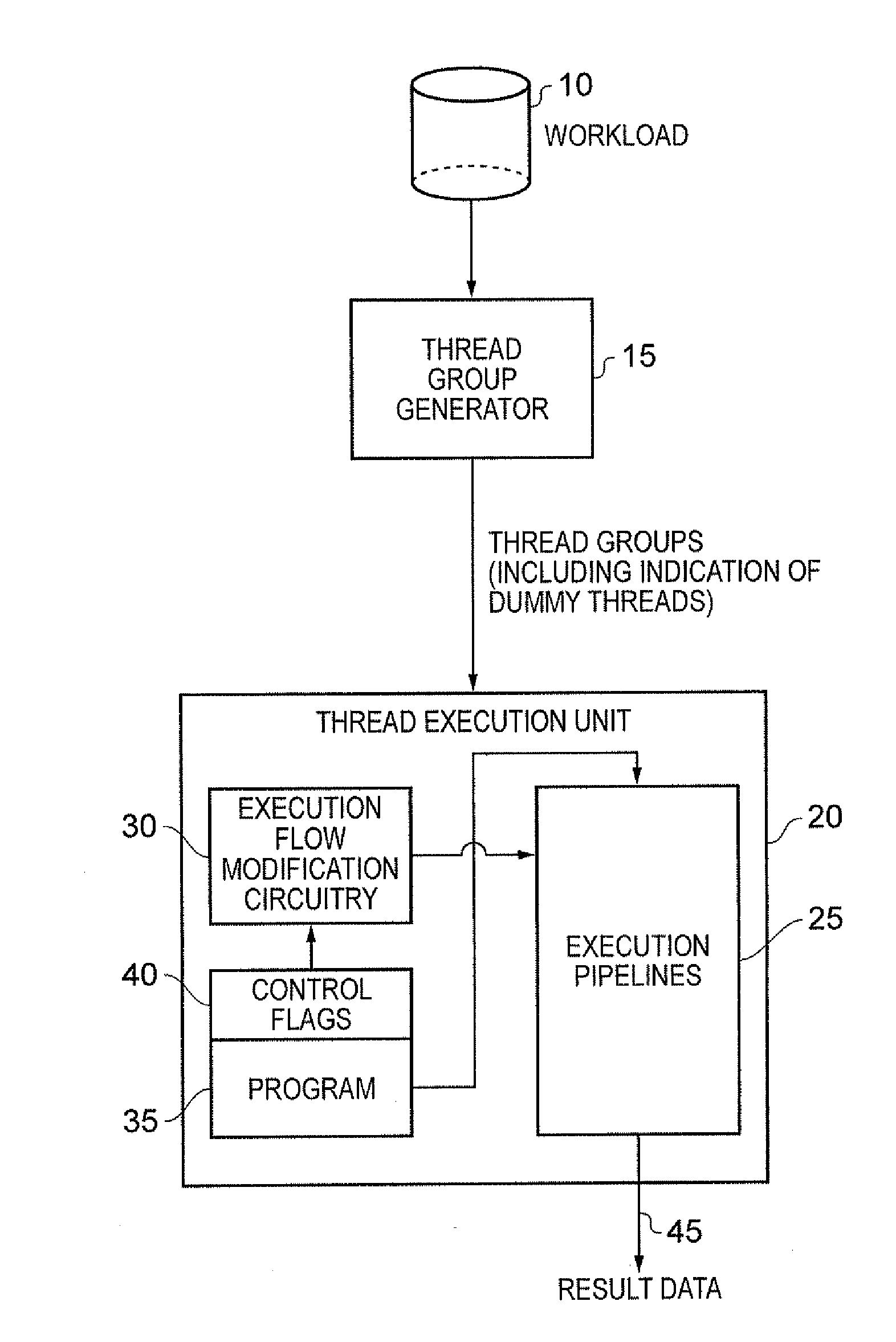

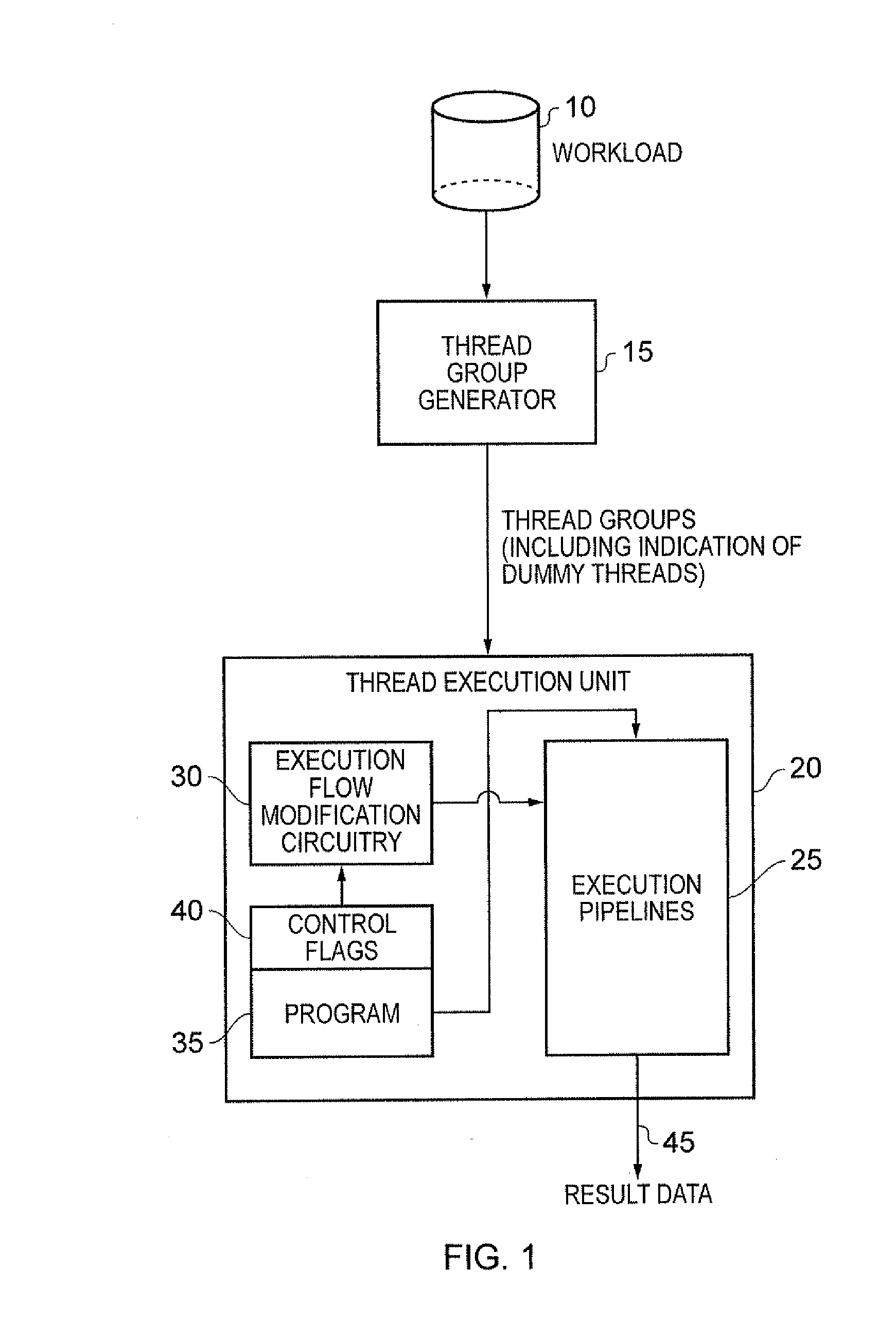

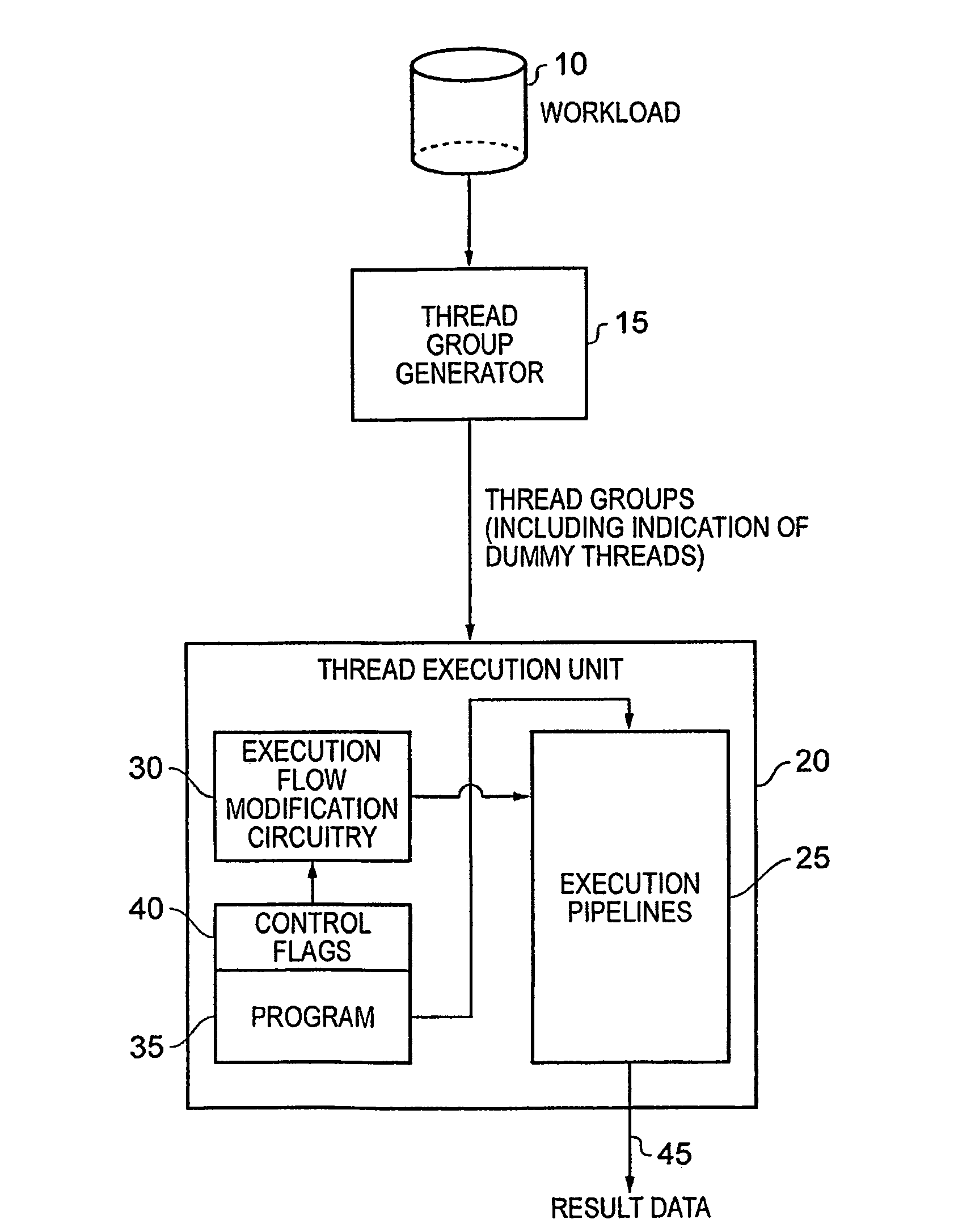

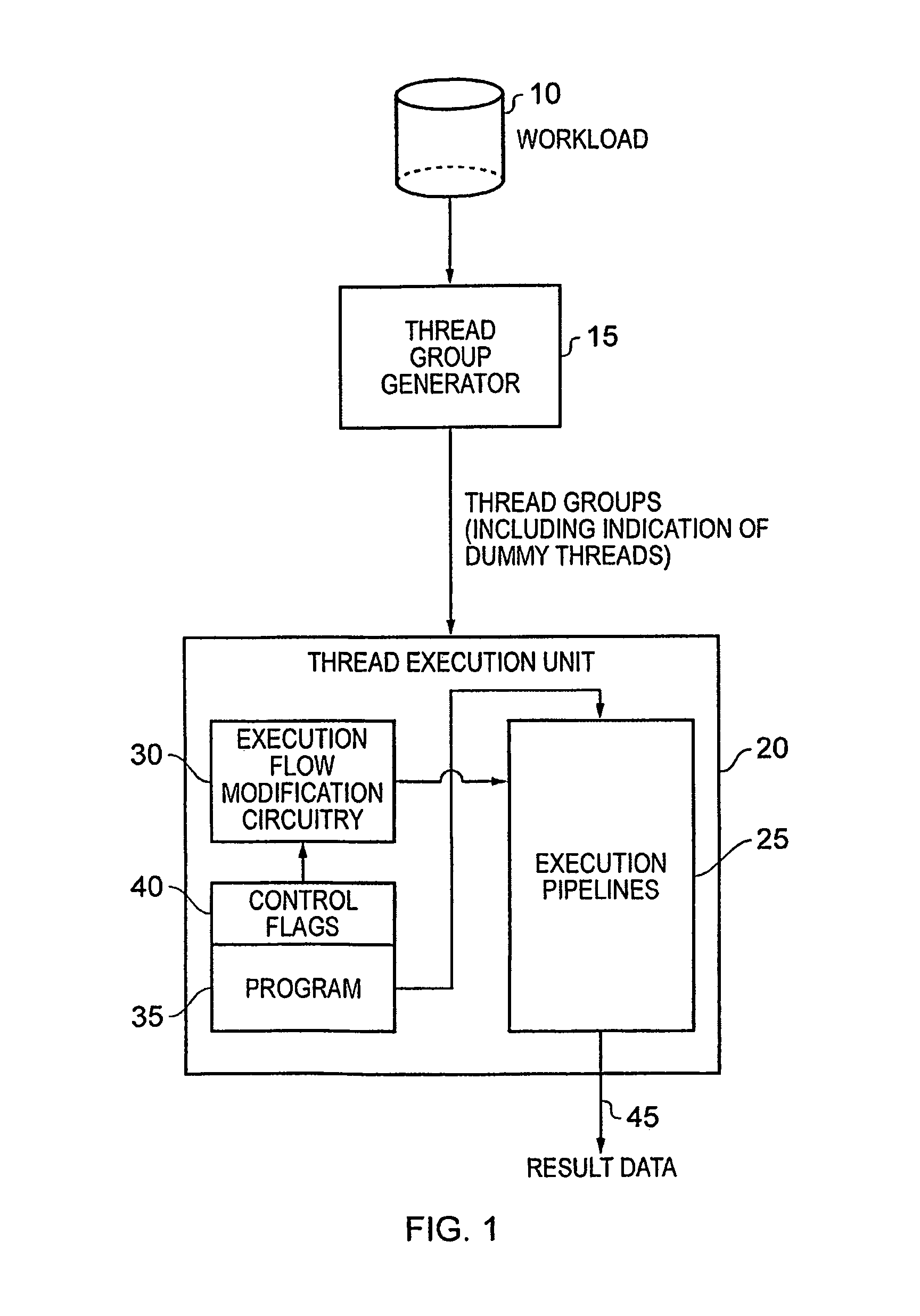

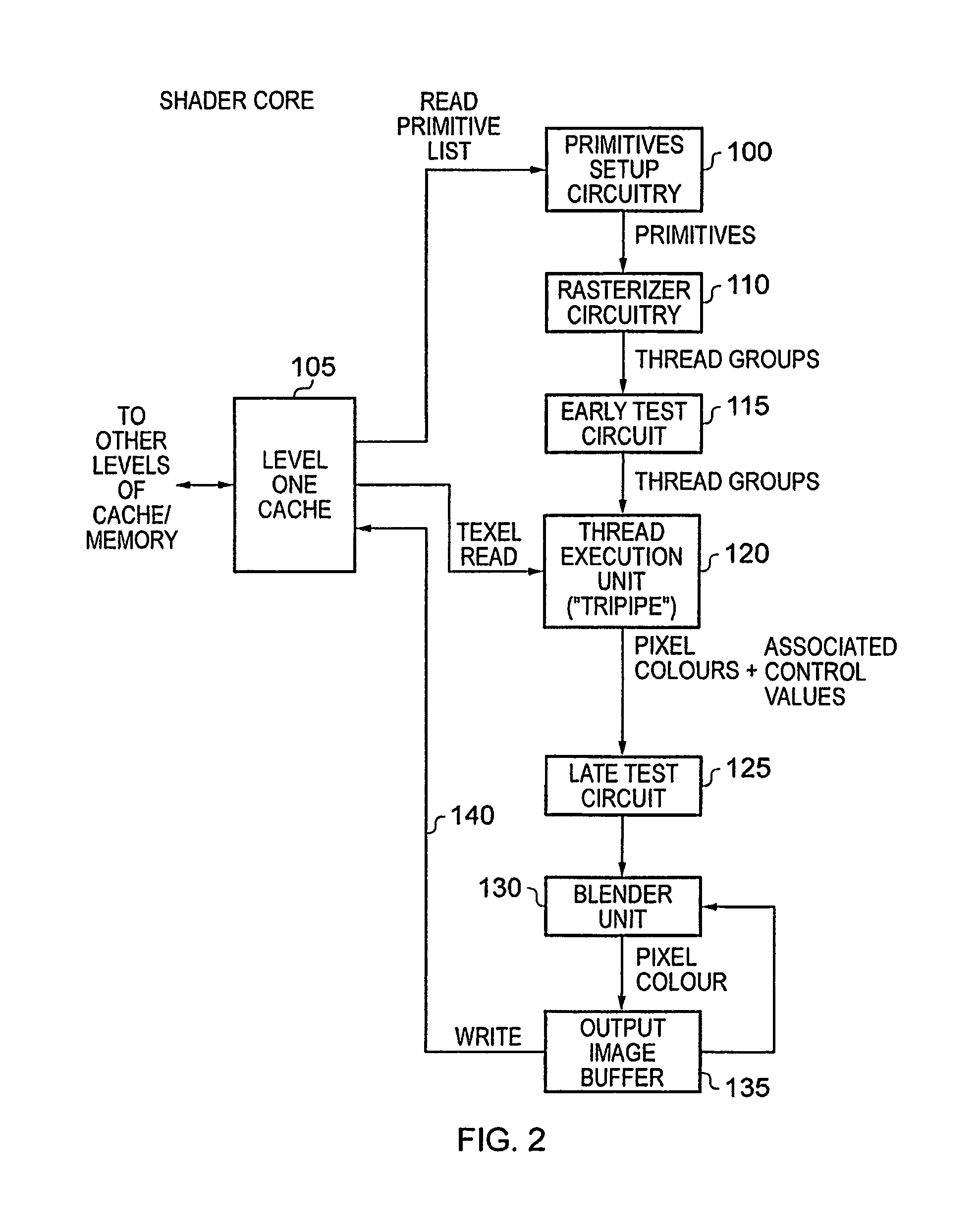

Data processing apparatus and method for processing a received workload in order to generate result data

ActiveUS20130332939A1Reduce consumptionImprove data processing capabilitiesMultiprogramming arrangementsProcessor architectures/configurationGraphicsProgram instruction

A data processing apparatus and method are provided for processing a received workload in order to generate result data. A thread group generator generates from the received workload a plurality of thread groups to be executed to process the received workload. Each thread group consists of a plurality of threads, and at least one thread group has an inter-thread dependency existing between the plurality of threads. Each thread may be either an active thread whose output is required to form the result data, or a dummy thread required to resolve the inter-thread dependency for one of the active threads but whose output is not required to form the result data. The thread group generator identifies for each thread group any dummy thread within that thread group. A thread execution unit then executes each thread within a thread group received from the thread group generator by executing a predetermined program comprising a plurality of program instructions. Execution flow modification circuitry is responsive to the received thread group having at least one dummy thread, to cause the thread execution unit to selectively omit at least part of the execution of at least one of the plurality of instructions when executing each dummy thread, in dependence on control information associated with the predetermined program. In one particular embodiment the received workload is a graphics rendering workload and the thread execution unit performs graphics rendering operations in order to generate as the result data pixel values and associated control values. Such an approach can yield significant improvements in performance, as well as reducing power consumption.

Owner:ARM LTD

Edible nanocrystal cellulose ink and preparation method thereof

The invention discloses edible nanocrystal cellulose ink and a preparation method thereof. The preparation method of the edible nanocrystal cellulose ink comprises the steps that nanocrystal cellulose is mixed with water, ultrasonic treatment is performed, the water, a sweetening agent, coloring materials, a thickening agent and connecting materials are added in batches under the constant temperature and stirring conditions, and then the edible nanocrystal cellulose ink is prepared, wherein the nanocrystal cellulose is selected from natural plant fiber. According to the edible nanocrystal cellulose ink and the preparation method thereof, the nanocrystal cellulose is adopted to prepare the edible ink, the fibrous components are added in the ink, functionalization is achieved, the health care function is achieved, and meanwhile the color and luster of the edible ink is enhanced; especially, if the nanocrystal cellulose is selected from agricultural wastes (such as corn stalks, wheat straw and rice straw), recycling of the agricultural wastes is facilitated. The edible nanocrystal cellulose ink has the advantages of being environmentally friendly, free of public hazards, good in color and luster and the like and can be applied to the fields of baby food, drugs, edible packaging materials and the like.

Owner:DALIAN POLYTECHNIC UNIVERSITY

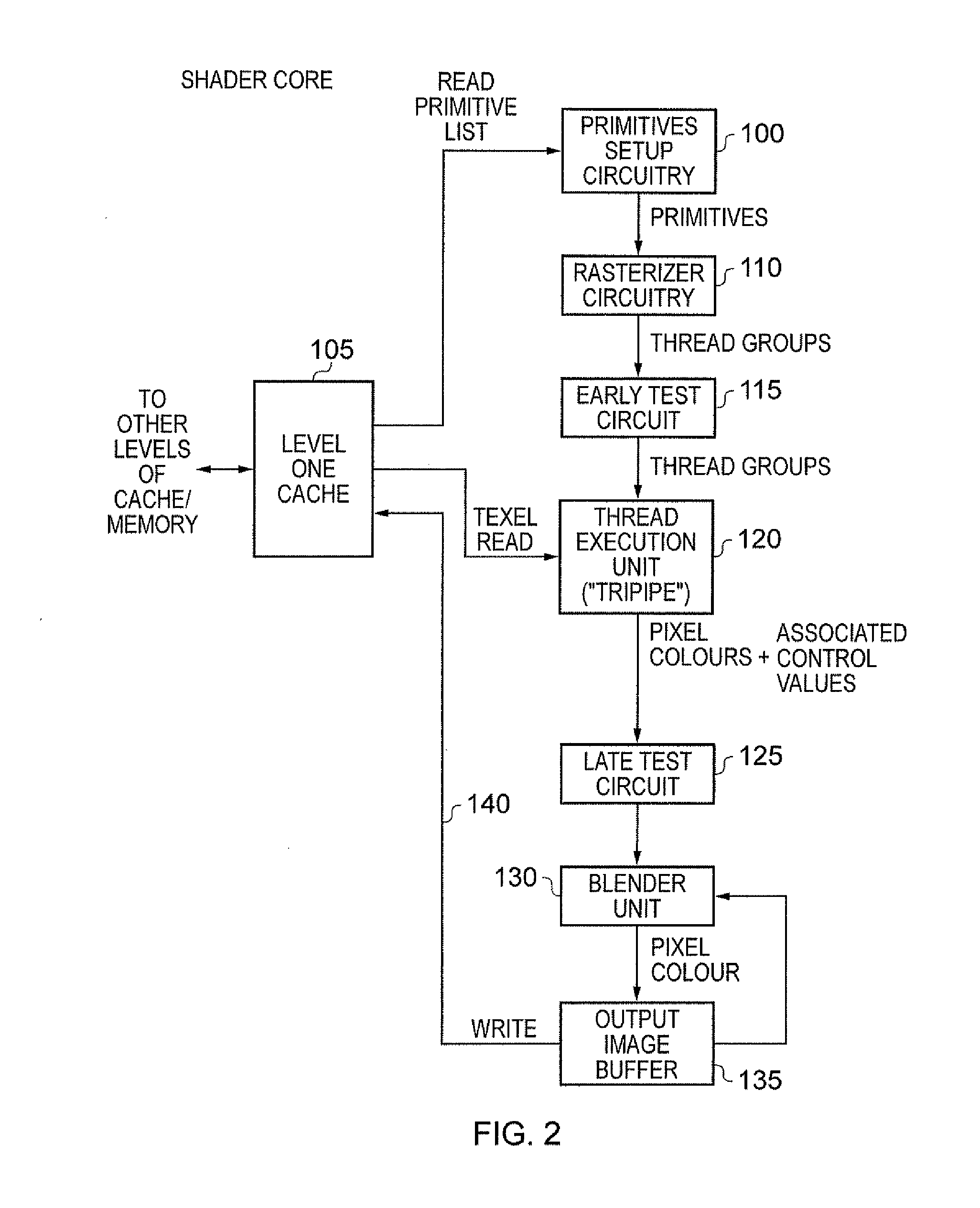

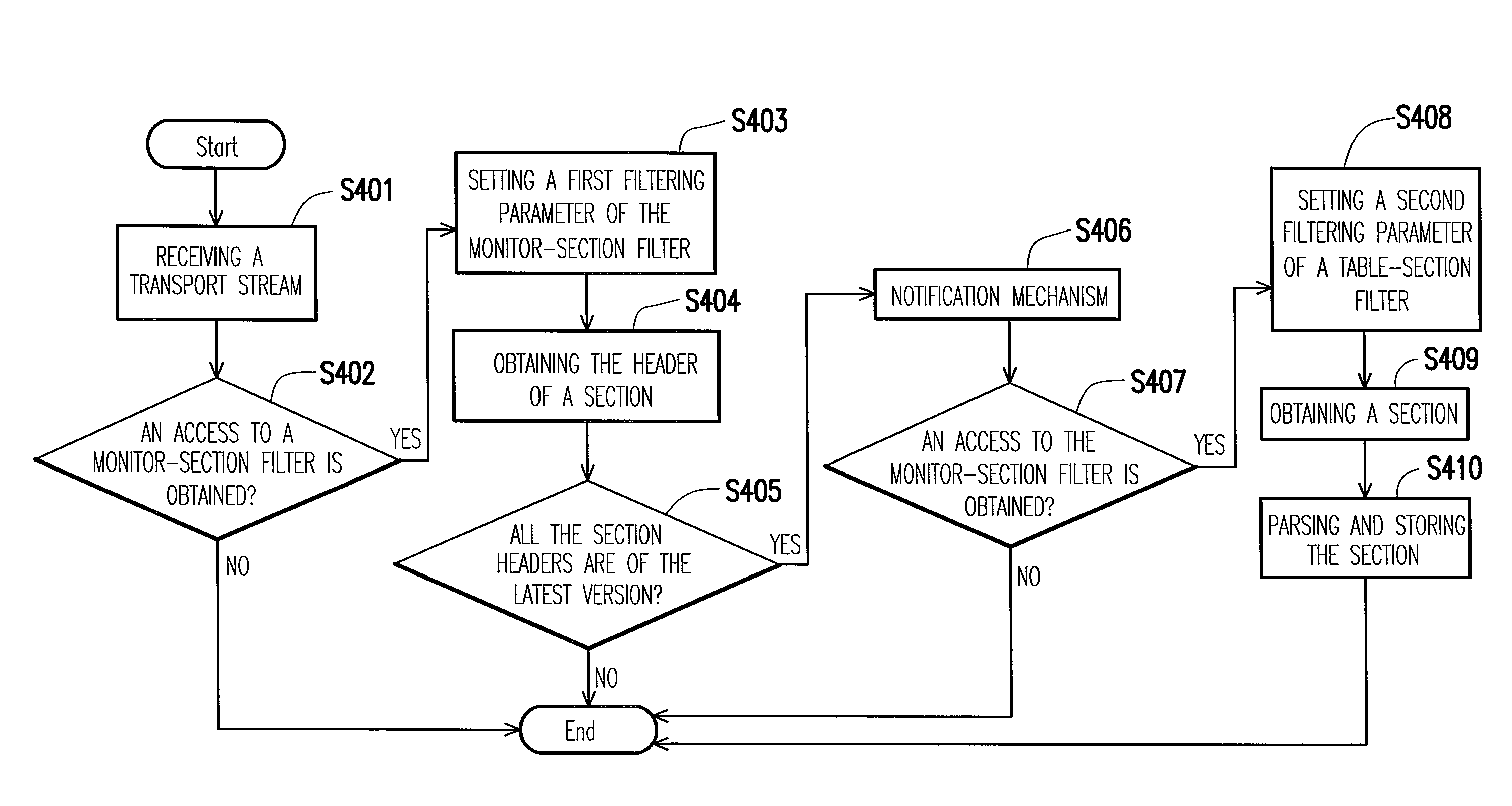

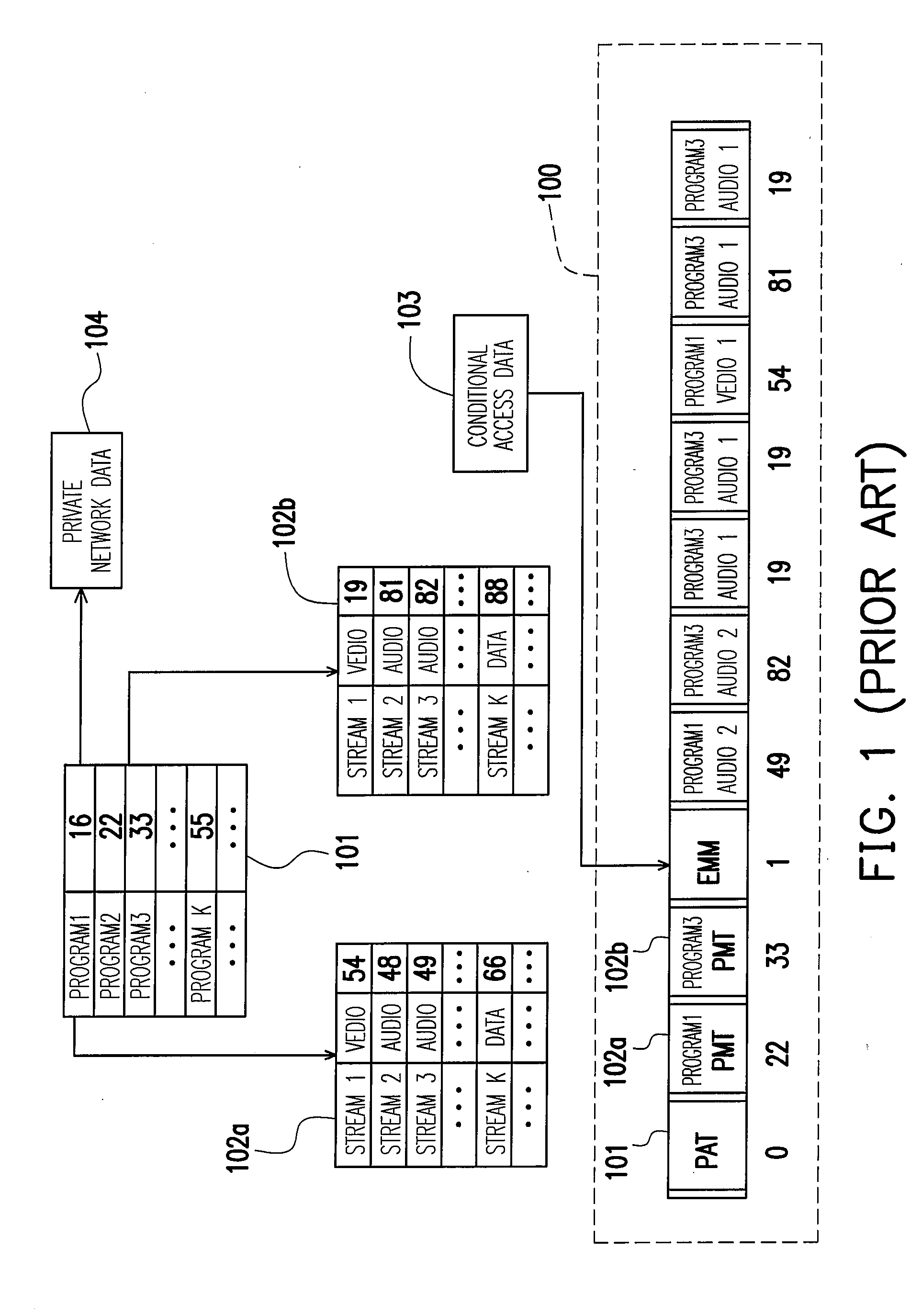

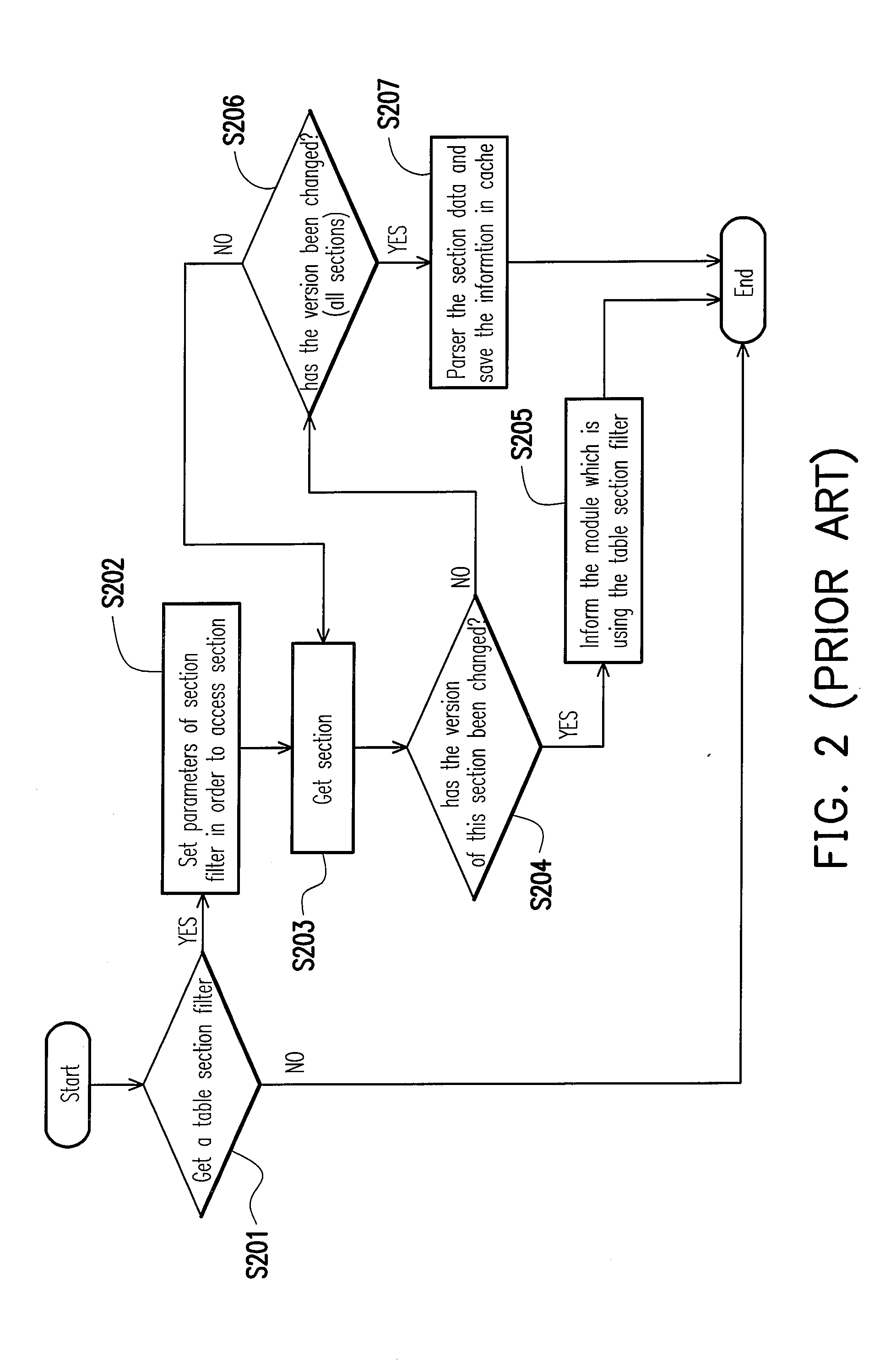

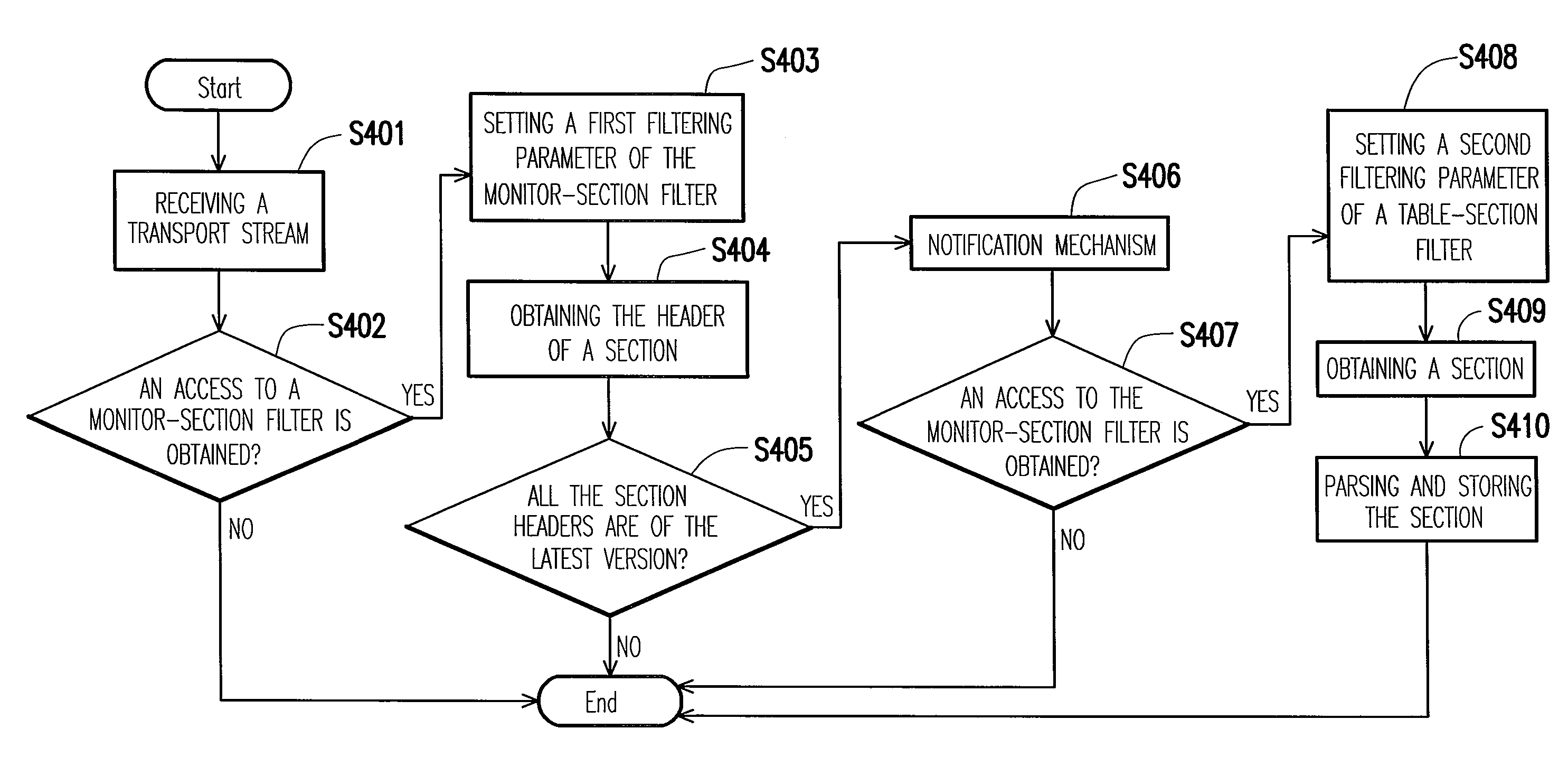

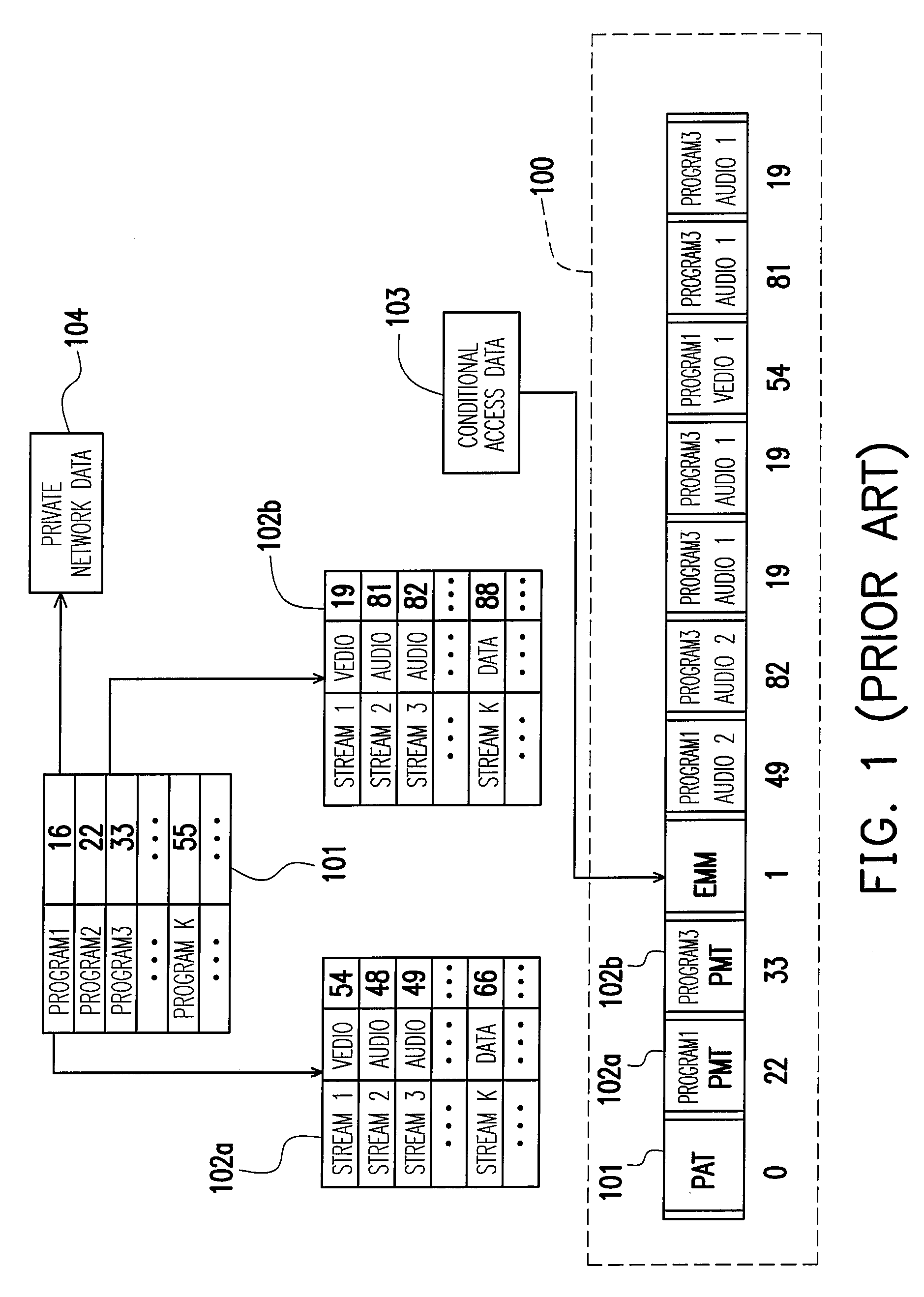

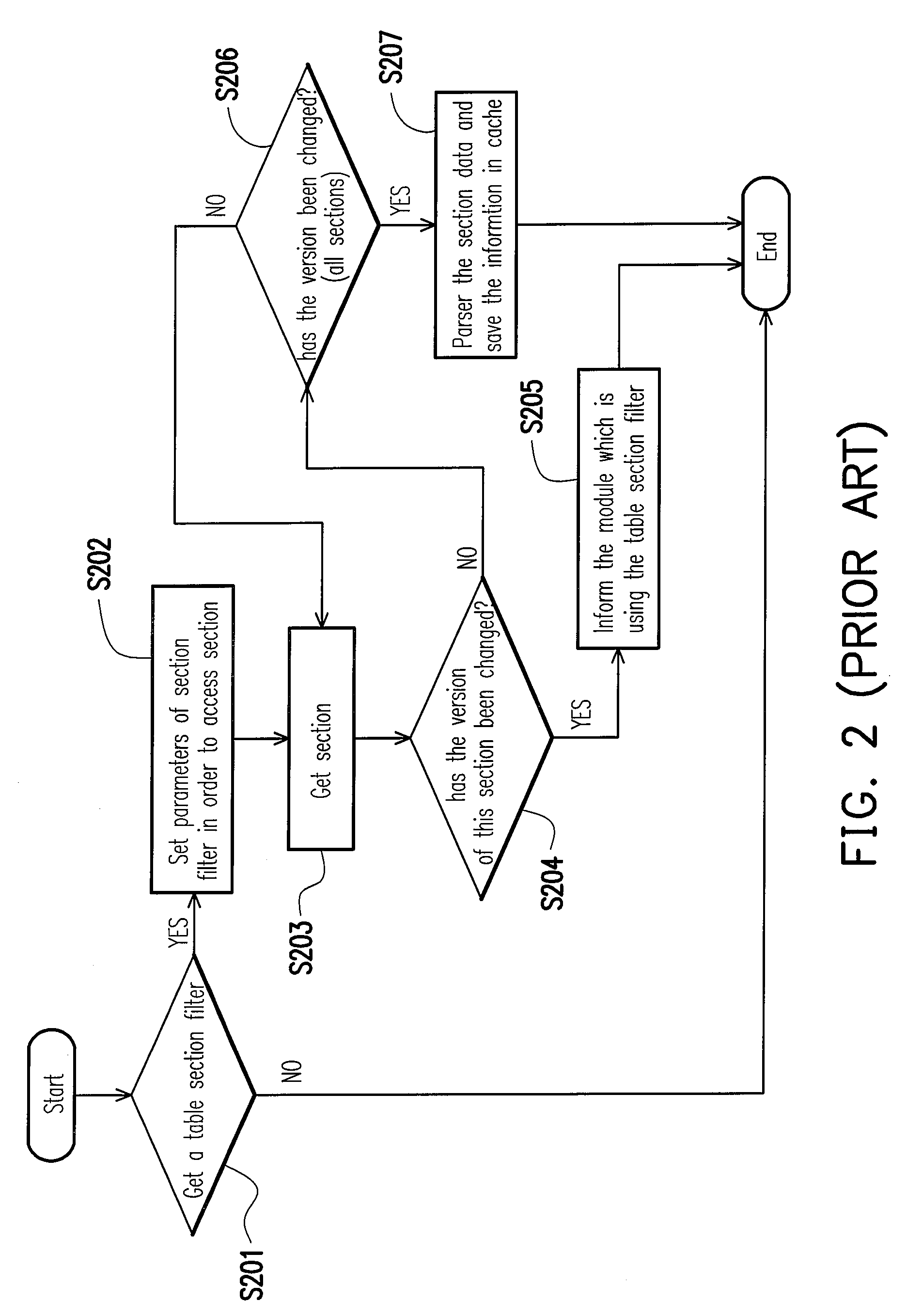

Information monitoring and updating method and system for transport stream

InactiveUS20080184325A1Reduce memory spaceImprove receiver performanceTelevision system detailsPulse modulation television signal transmissionComputer scienceInformation monitoring

An information monitoring and updating method and system for a transport stream is provided. First, a transport stream is received. The transport stream includes a program specific information (PSI) table, and the PSI table is divided into a plurality of sections. Next, by setting a first filtering parameter of a monitor-section filter, the header of each section of the PSI table is filtered out and is then checked whether to be a latest version or not. When all the section headers of the PSI table are of the latest version, each section of the PSI table is filtered by setting a second filtering parameter of a table-section filter.

Owner:IND TECH RES INST

Data processing apparatus and method for processing a received workload in order to generate result data

ActiveUS8601485B2Reduce consumptionImprove data processing capabilitiesEnergy efficient ICTMultiprogramming arrangementsParallel computingExecution unit

A data processing apparatus and method are provided for processing a received workload in order to generate result data. A thread group generator generates from the received workload a plurality of thread groups to be executed to process the received workload. Each thread may be either an active thread whose output is required to form the result data, or a dummy thread required to resolve the inter-thread dependency for one of the active threads but whose output is not required to form the result data. Execution flow modification circuitry is responsive to the received thread group having at least one dummy thread, to cause the thread execution unit to selectively omit at least part of the execution of at least one of the plurality of instructions when executing each dummy thread, in dependence on control information associated with the predetermined program.

Owner:ARM LTD

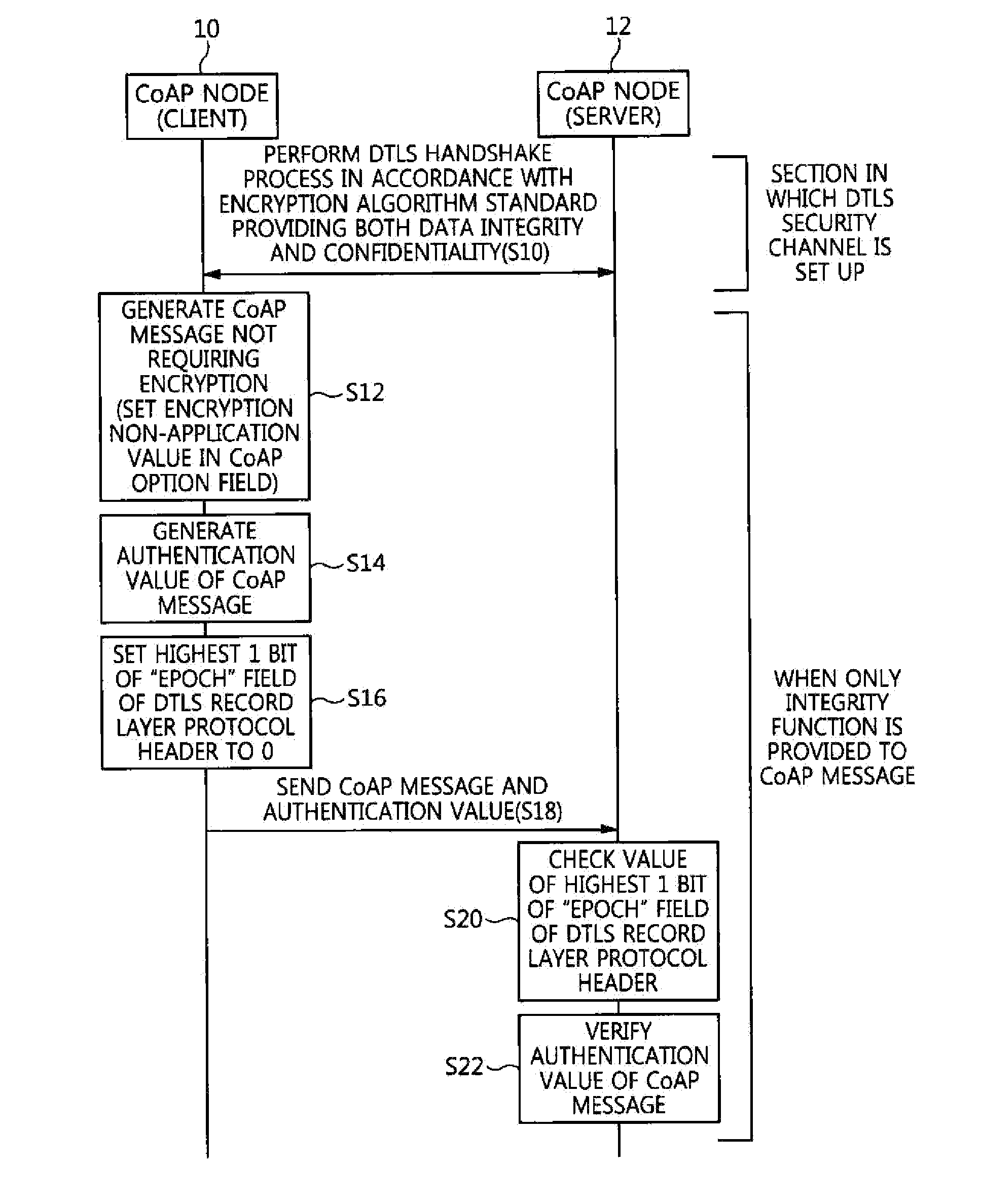

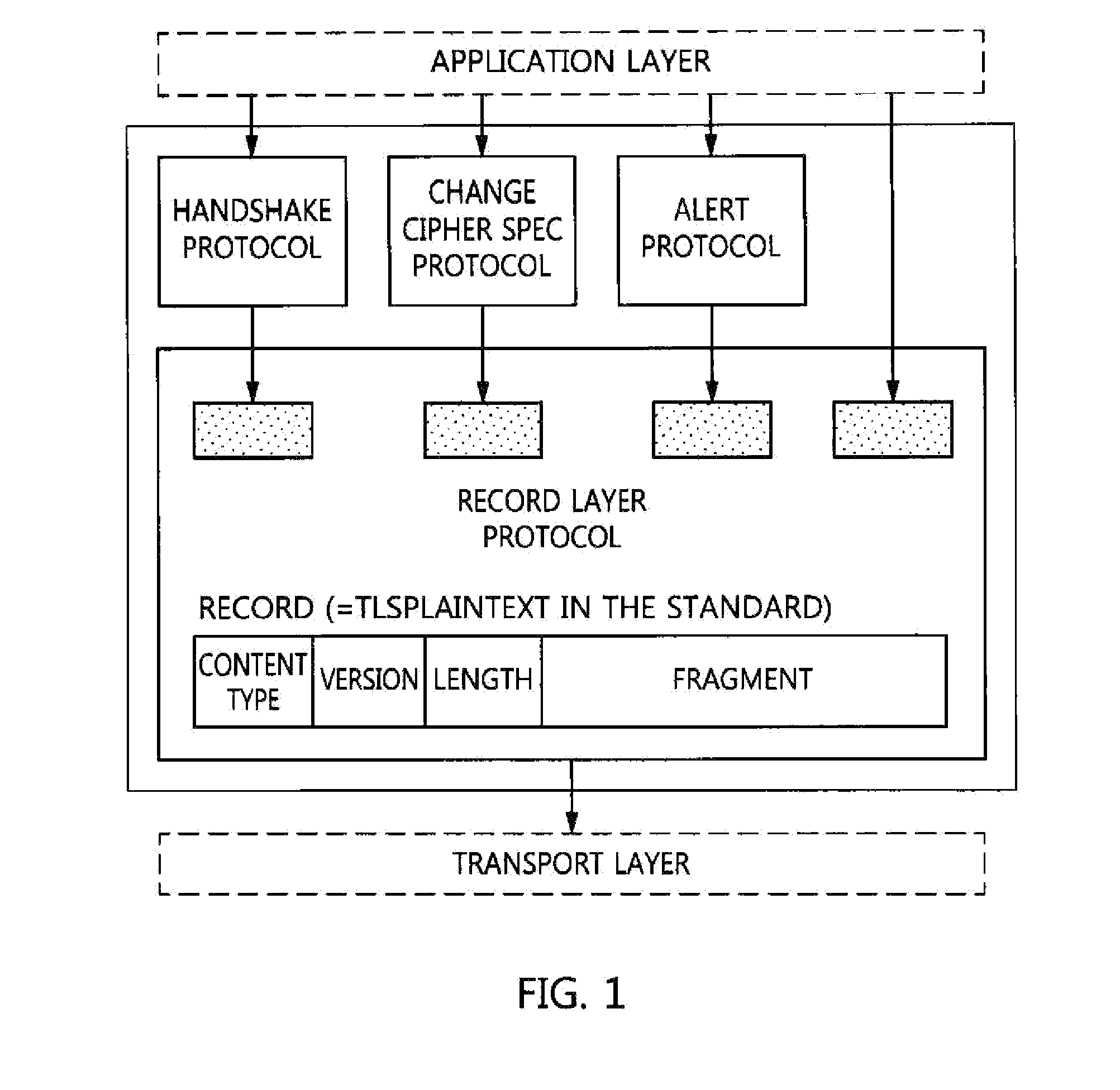

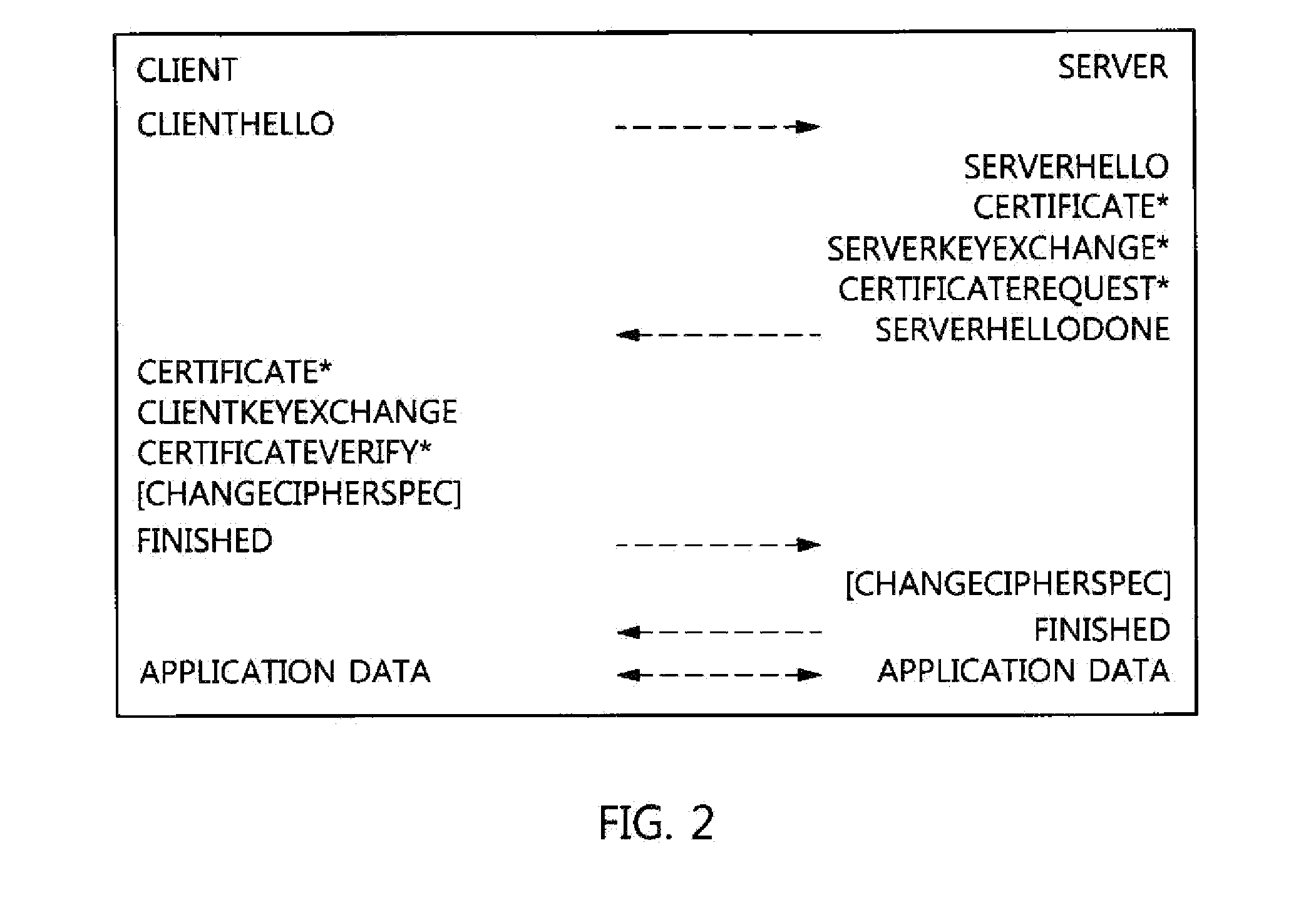

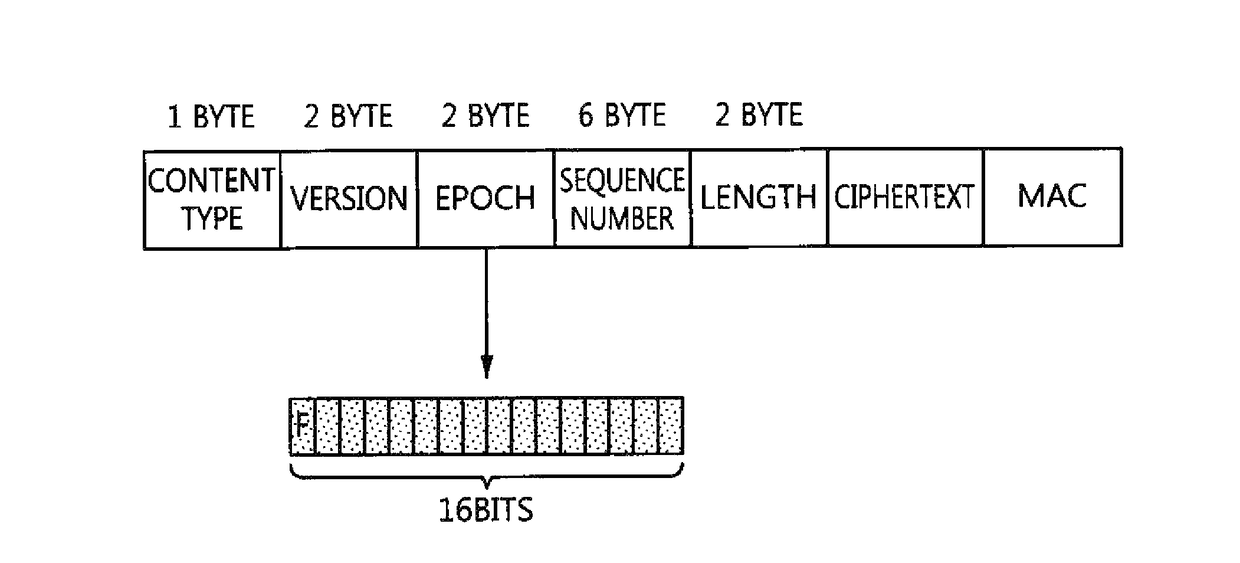

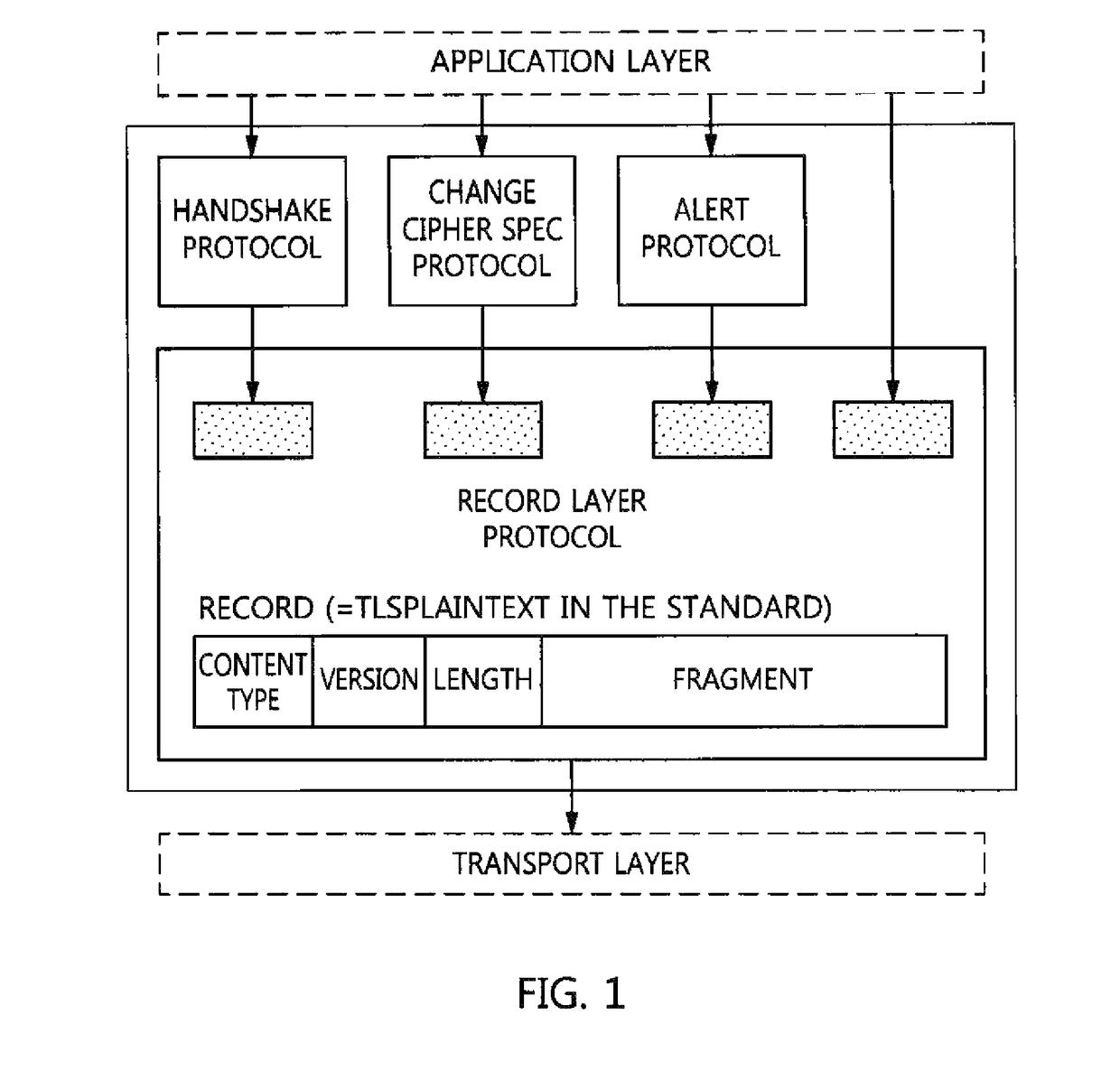

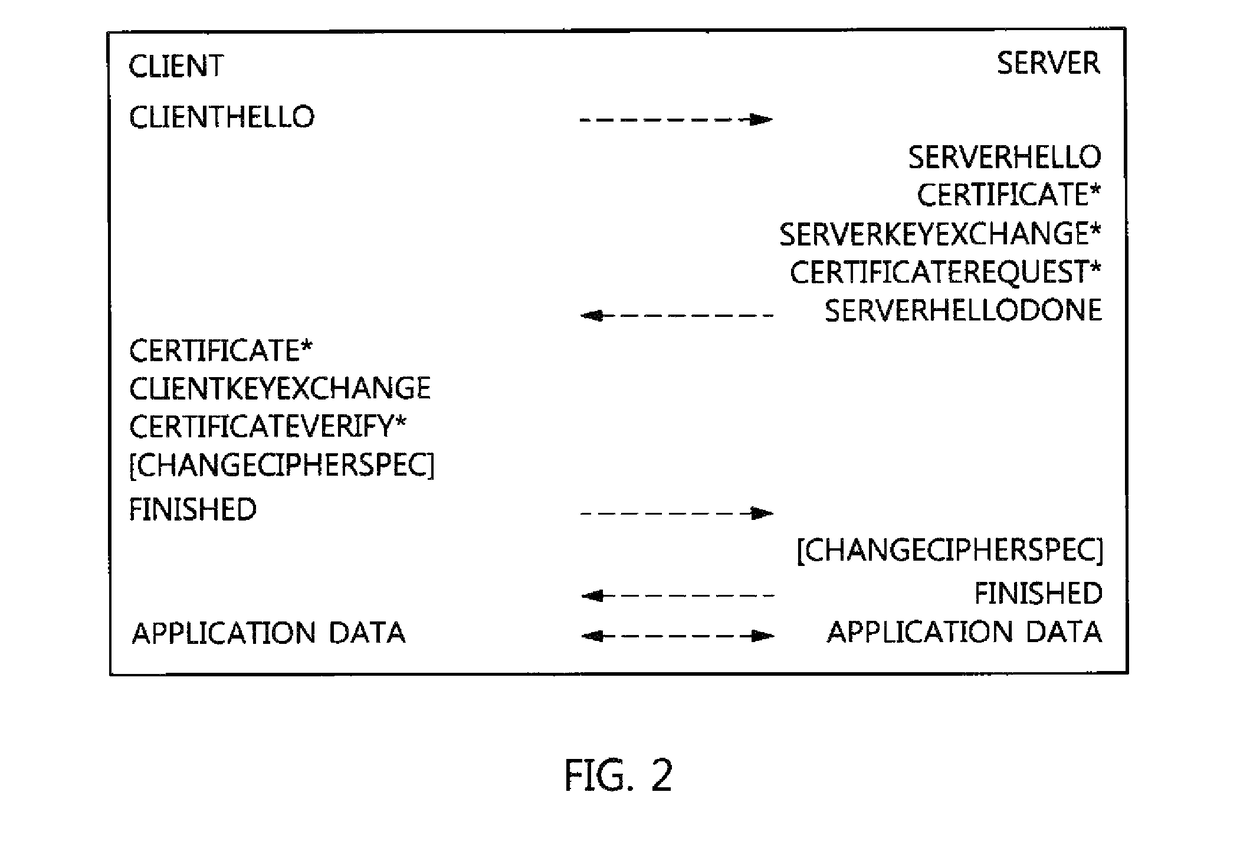

Method of selectively applying data encryption function

In a method of selectively applying a data encryption function, a CoAP client and a CoAP server perform a DTLS handshake process. The CoAP client generates a CoAP message when the DTLS handshake process has been completed, and then indicates that encryption does not need to be applied to the CoAP message. The CoAP client generates only the authentication value of the CoAP message via a DTLS record layer protocol. The CoAP client sets the value of the specific field of a DTLS record layer protocol header to a specific value via the DTLS record layer protocol. The CoAP client sends the CoAP message and the authentication value to the CoAP server.

Owner:ELECTRONICS & TELECOMM RES INST

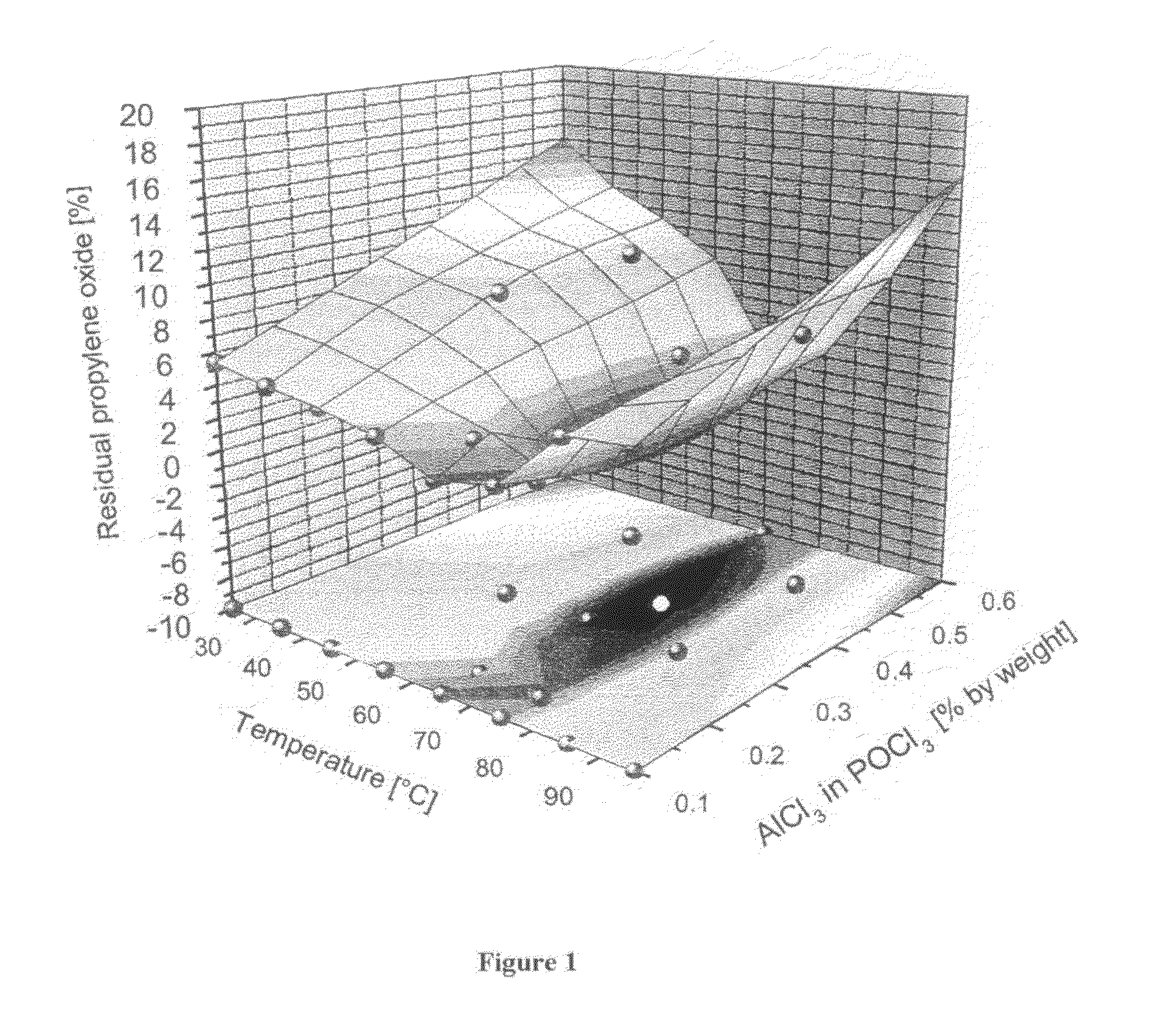

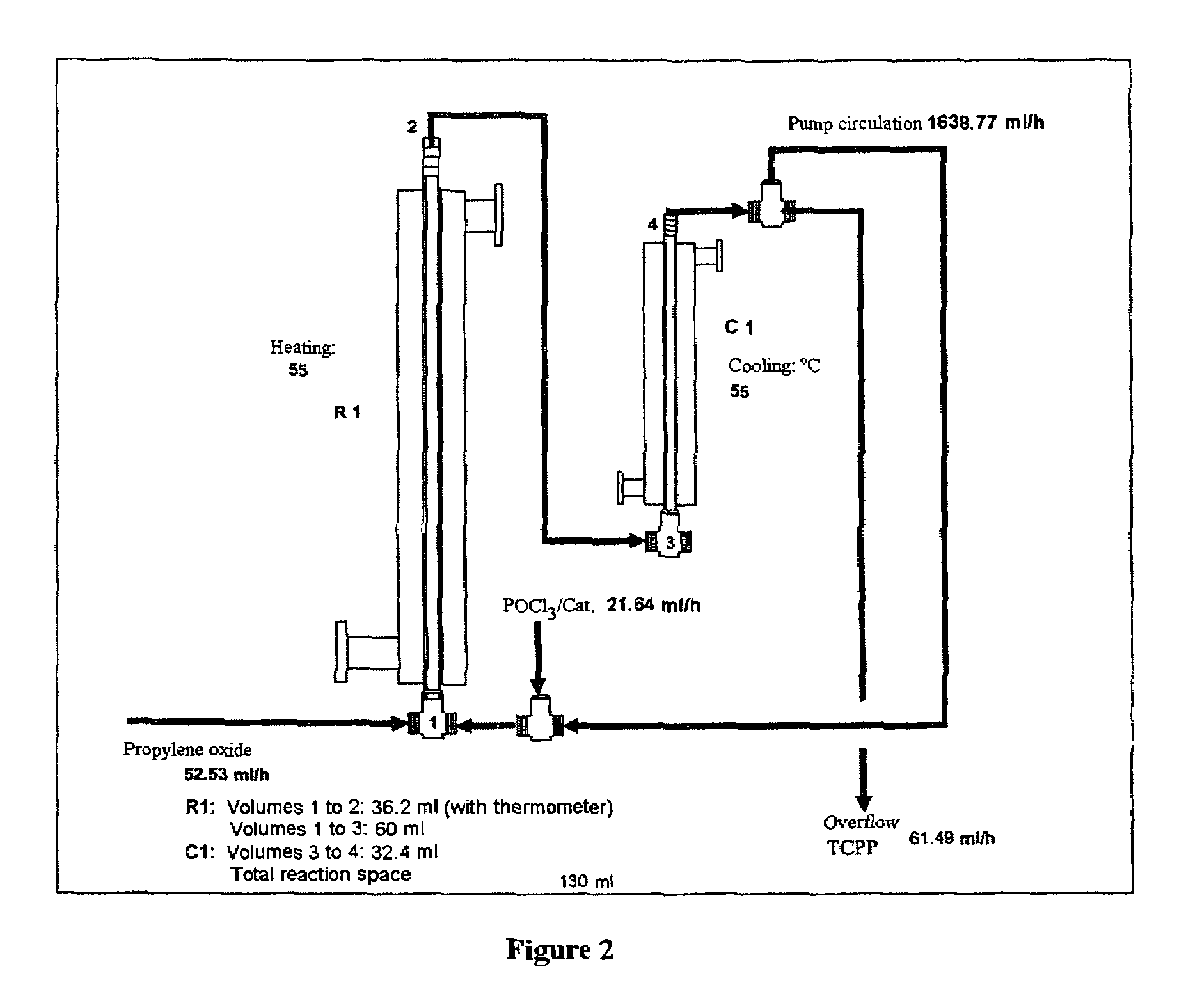

Preparation of phosphorus-containing propoxylation products by using aluminium trichloride

InactiveUS7820845B2Inhibition formationResourcePhosphorus organic compoundsAluminium chloridePtru catalyst

The invention describes a process for preparing propoxylated, phosphorus-containing compounds using aluminium chloride catalyst.

Owner:LANXESS DEUTDCHLAND GMBH

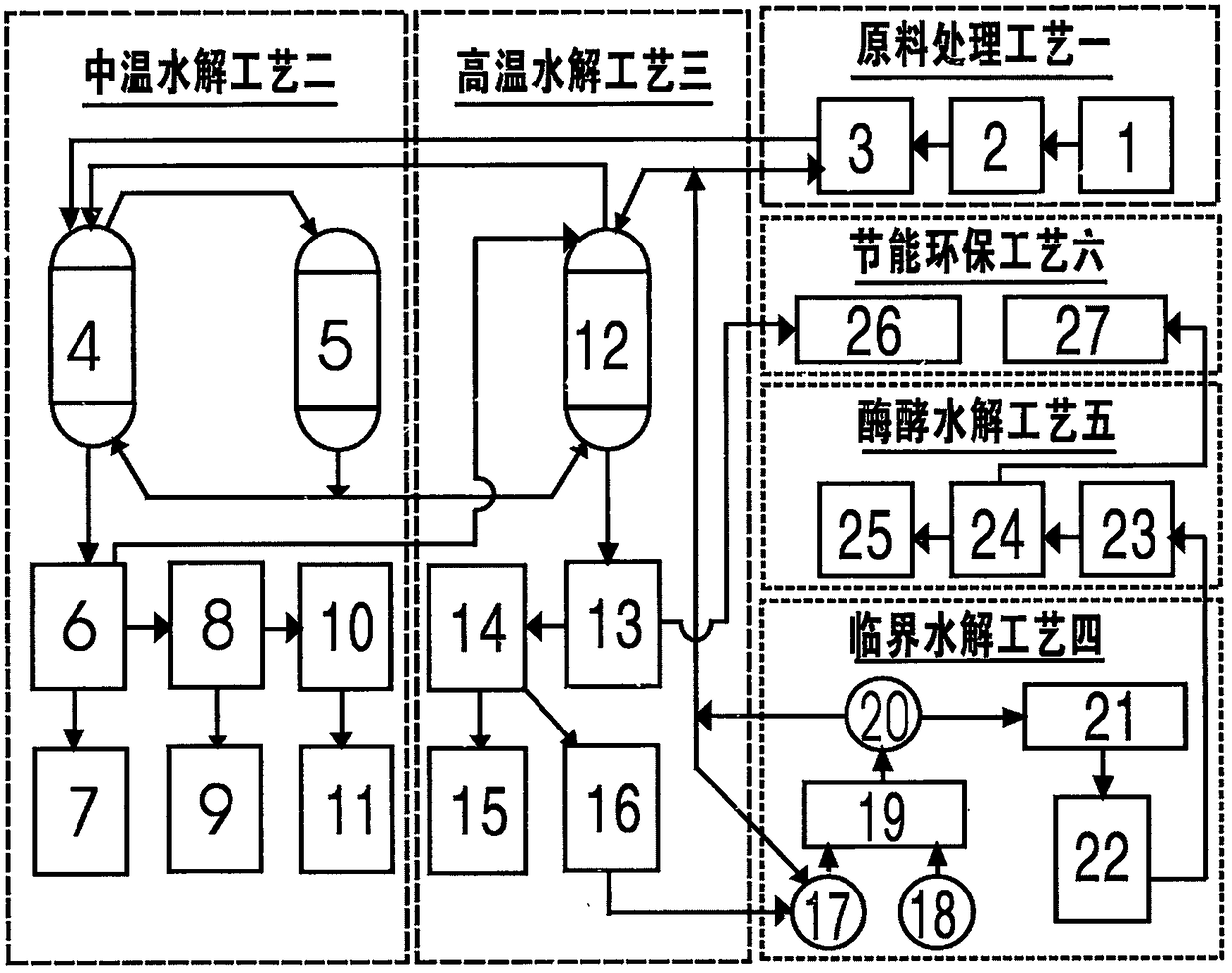

Industrial thermo-operated monosaccharide and alcohol ester hydrolysis technology system for plant straw

PendingCN108823071AResourceHelps scaleBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseEnzyme digestion

The invention discloses an industrial thermo-operated monosaccharide and alcohol ester hydrolysis technology system for plant straw. The system is mainly composed of a straw cutting machine, a wind power dust collector, a steam explosion device, an intermediate-temperature hydrolyzer, a hot water catalyst system, a first solid-liquid separator, a paper pulp preparing system, a concentrating and crystallizing system, a first lignin system, a distilling and drying system, a pentose system, a high-temperature hydrolyzer, a second solid-liquid separator, a crystallizing and separating system, a second lignin system, a cellulose system, an intermediate preheater, a critical heat source system, a critical hydrolyzer, a flashing desuperheater, a purifying and concentrating system, a hexose system, a hexosidase yeast system, a distilling rectifying system, an ethyl alcohol or grease system, a system of fertilizer fuel prepared with residues and a heat energy solvent and catalyst recovering system. In the system, a first composing raw material treatment technology, a second intermediate-temperature hydrolysis technology, a third high-temperature hydrolysis technology, a fourth critical hydrolysis technology, a fifth enzyme yeast hydrolyzing technology and a sixth energy-saving environmentally-friendly technology are involved. The system has the advantages that monosaccharide and alcoholester are prepared industrially from the straw, and in this way, straw recycling is performed easily on a large scale and with a low cost; in the straw thermo-operated hydrolysis technology, traditional acid-bases and the pollution and a low effect during enzyme digestion are abandoned.

Owner:北京鑫泽清源植物秸秆技术有限公司

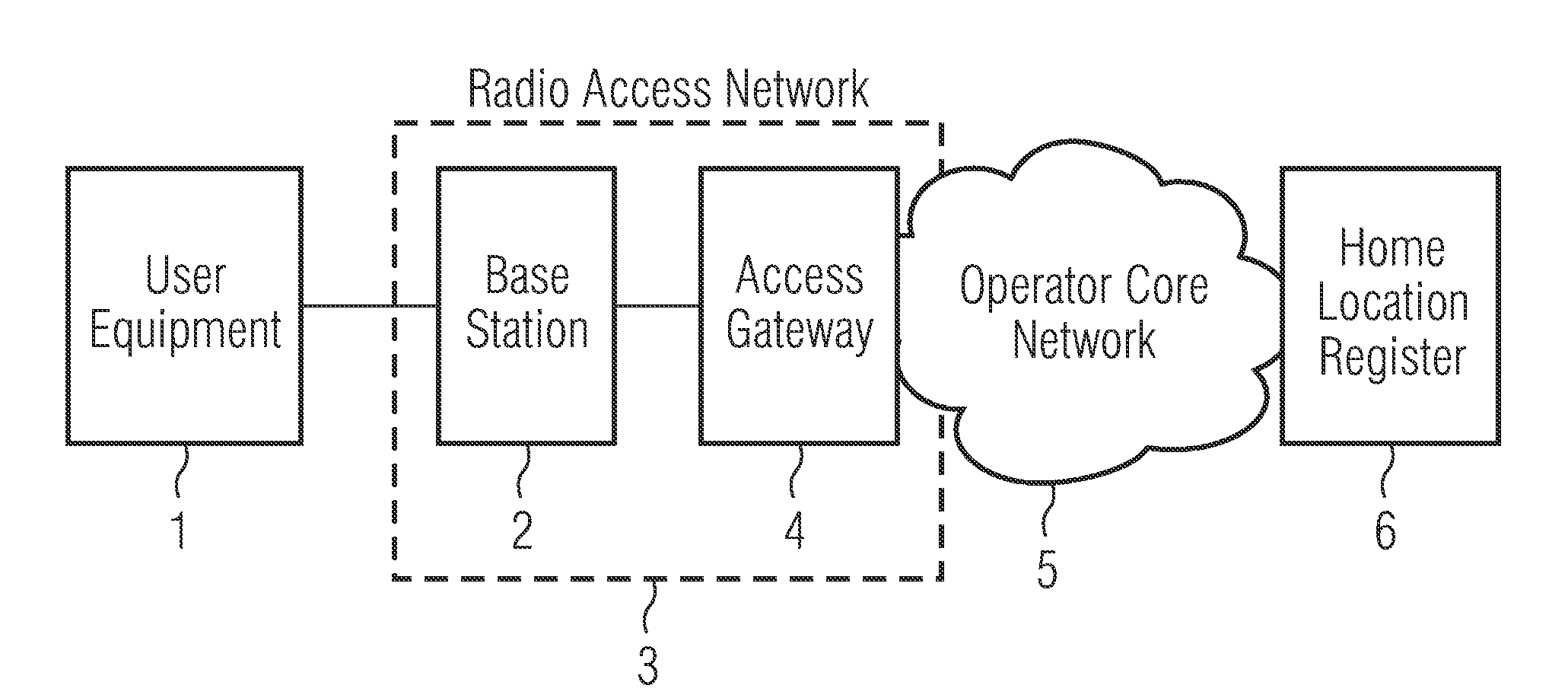

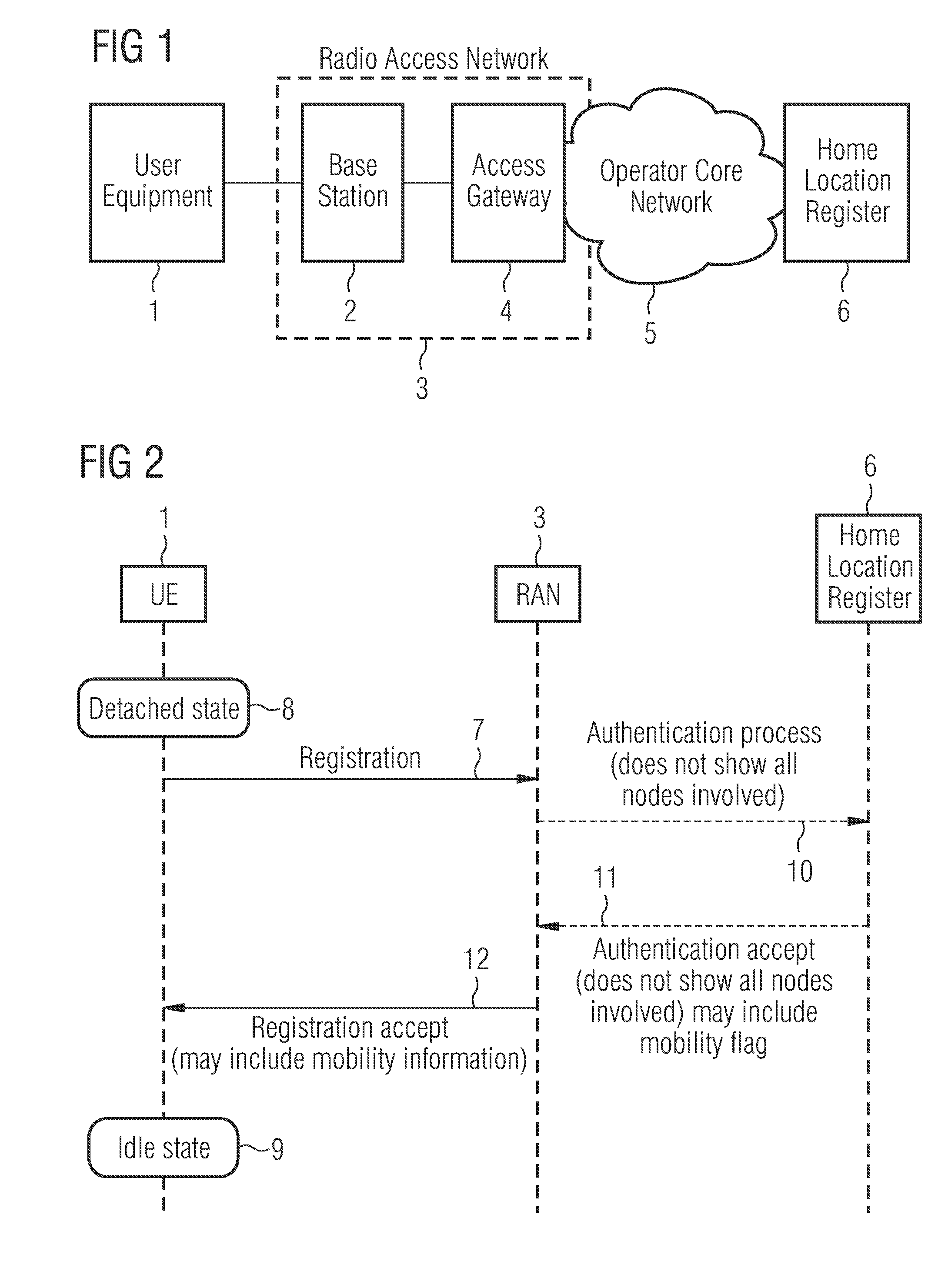

Method of providing mobility information in a communication system

InactiveUS20090221270A1ResourceSpecial service for subscribersWireless commuication servicesCommunications systemMobile communication systems

A method of providing mobility information in a mobile communication system comprises setting a mobility flag on initiation of a user subscription representing (5) mobility type in a network (3) for each subscriber. On receiving a request (7) from a subscriber to operate in the network, the mobility flag (10) of the subscriber is checked (12) and the subscriber is instructed to use an appropriate configuration for communication on the network according to the mobility flag set for that subscriber

Owner:NOKIA SIEMENS NETWORKS GMBH & CO KG

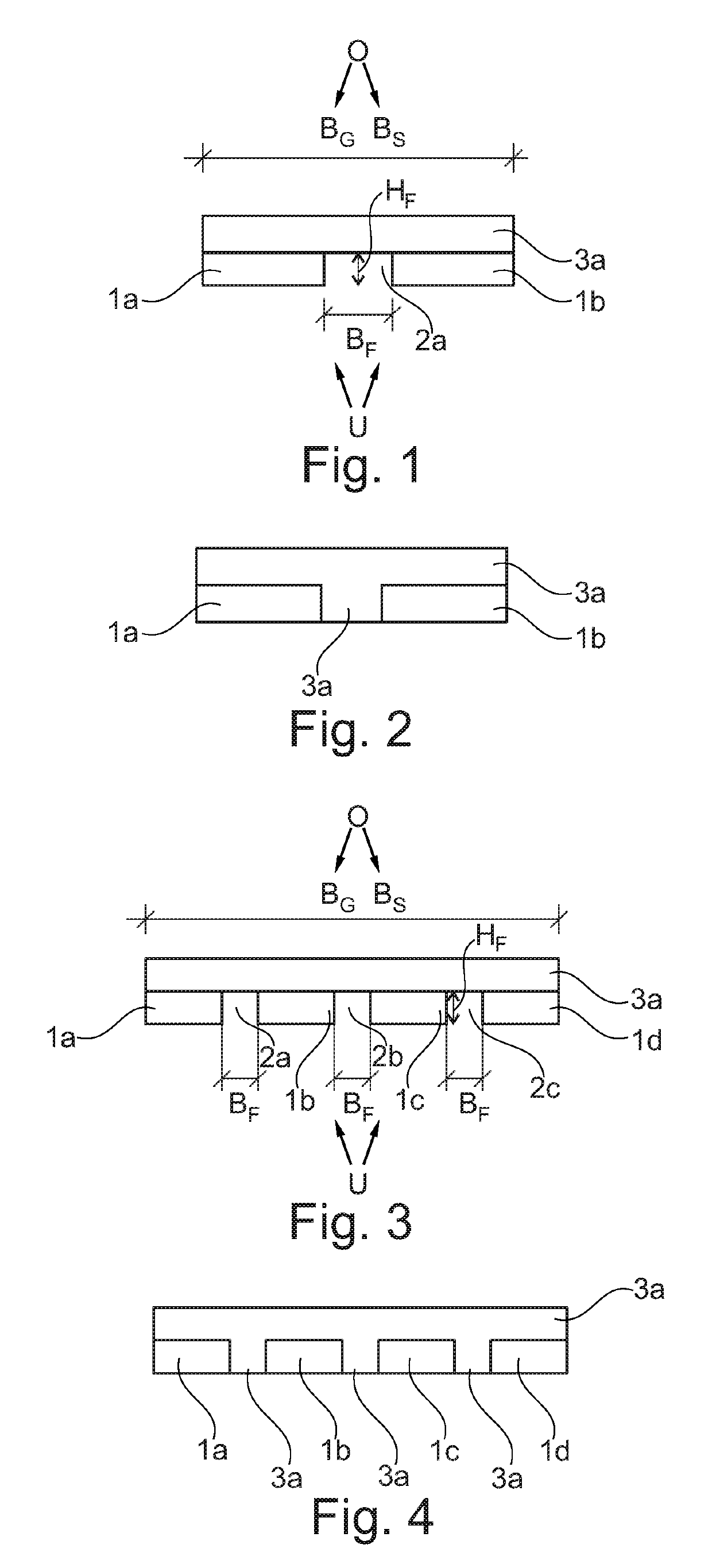

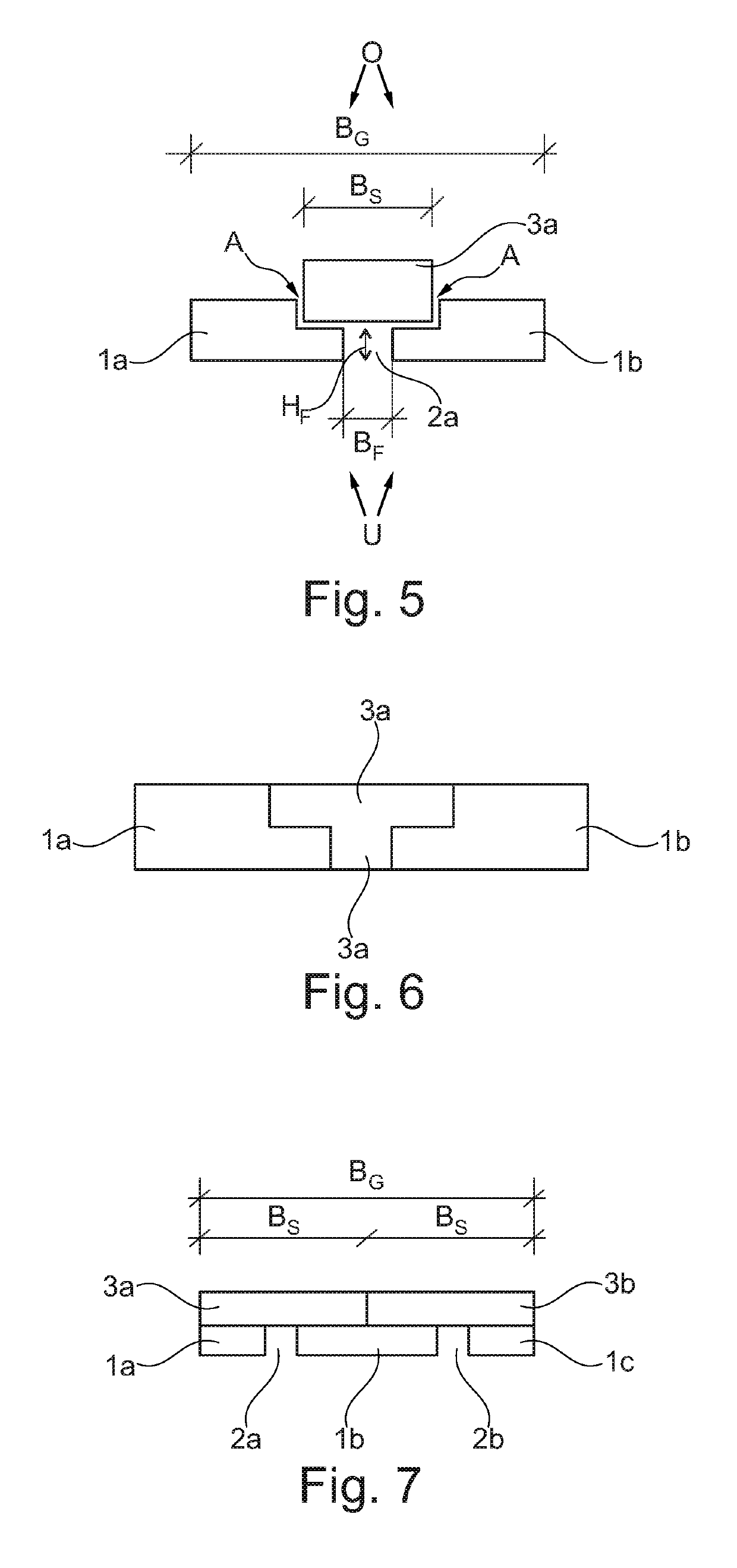

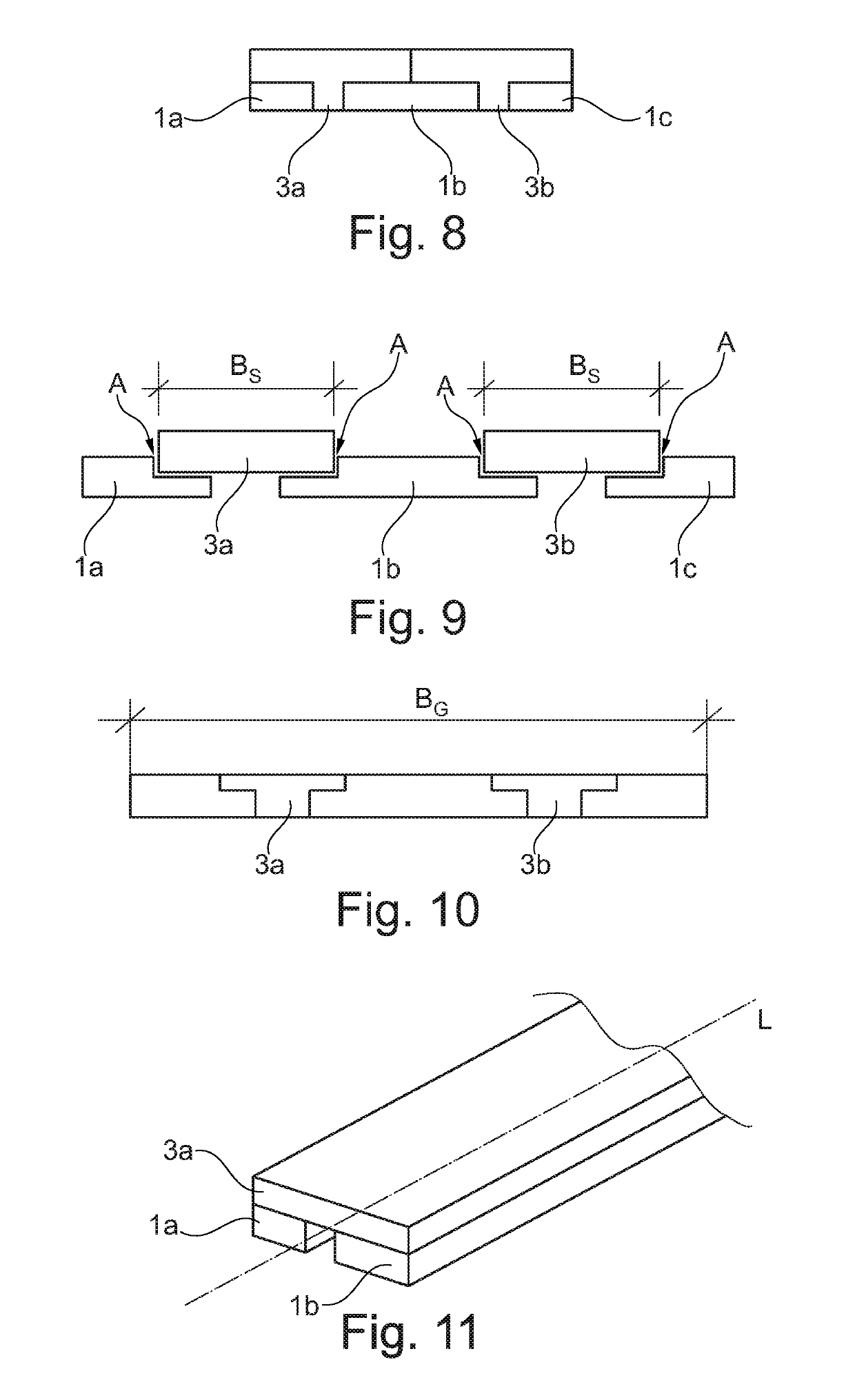

Method for producing a composite material, and composite material

ActiveUS20190321870A1Expand the scope of expressionSmall widthDomestic articlesMetal working apparatusBand shapeElectroplating

A method for producing a composite material by plating a band arrangement with a top side (O) and a bottom side (U), wherein the band arrangement comprises at least a first strip and a second strip, which form between them a filling channel, wherein the band arrangement comprises at least one filler strip, wherein the abovementioned band arrangement is plated, wherein a part of the filler strip, during the plating, is extruded into the filling channel; and a composite material, characterized in that it has been produced according to the method as disclosed.

Owner:WICKEDER WESTFALENSTAHL

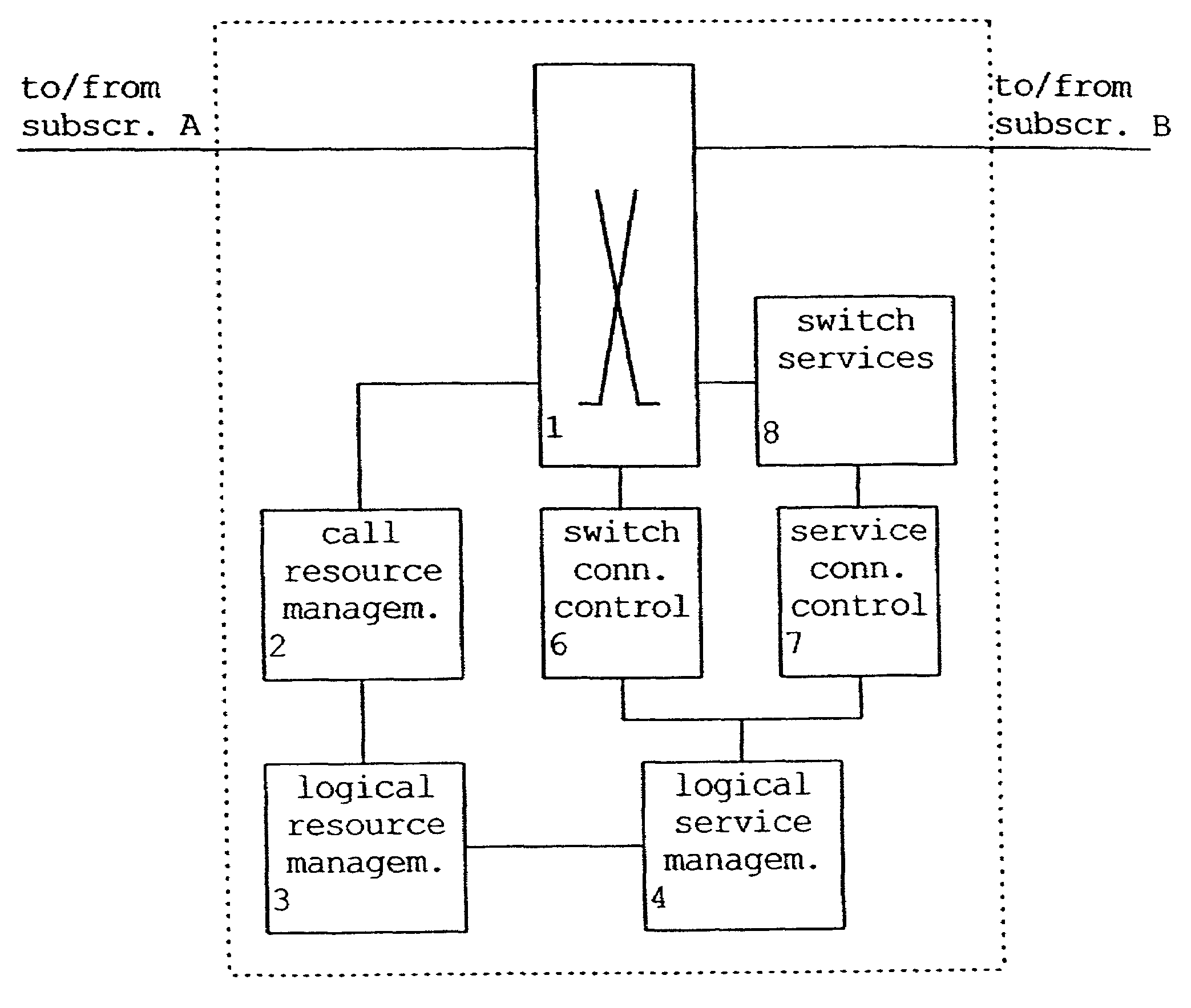

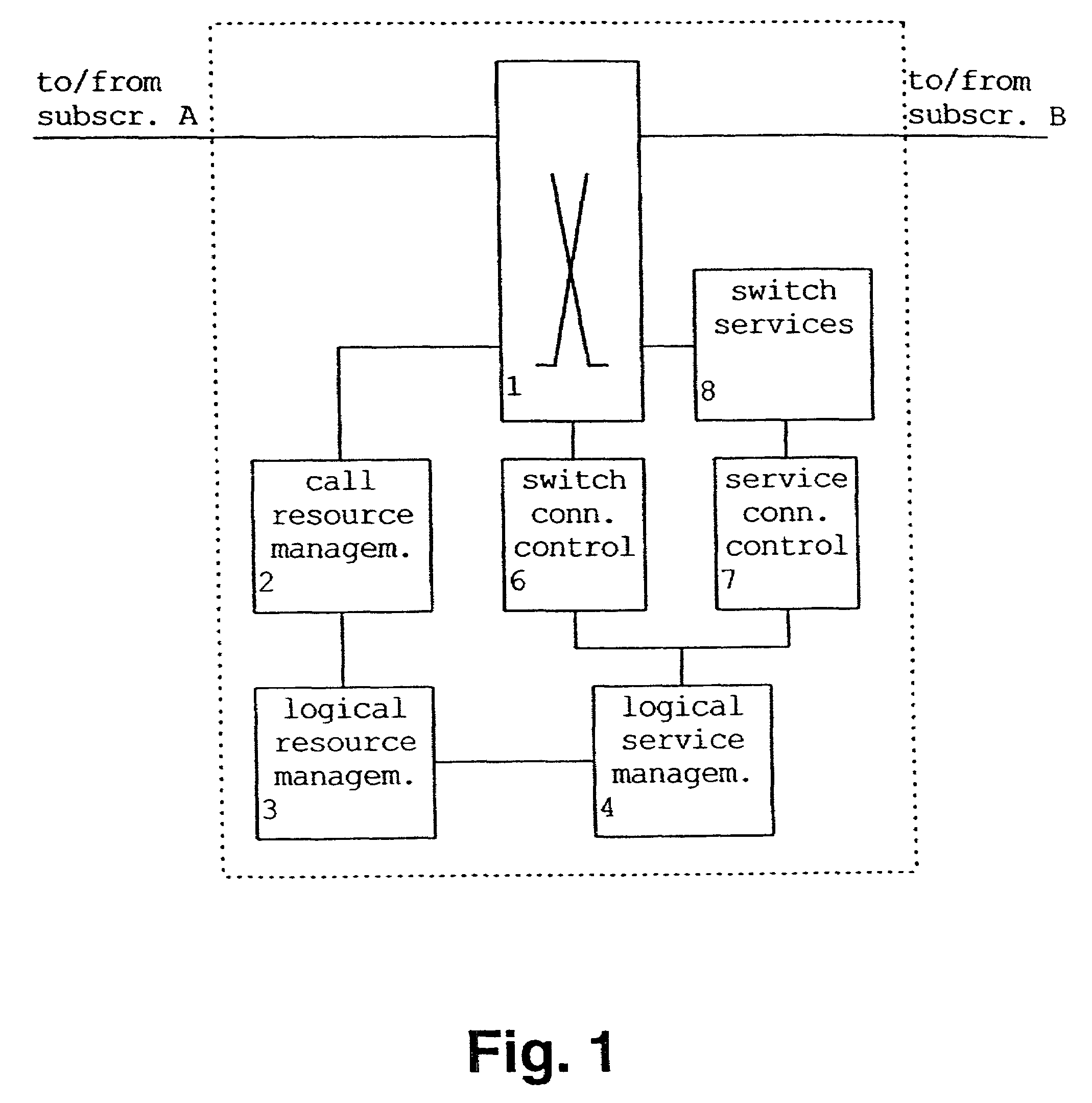

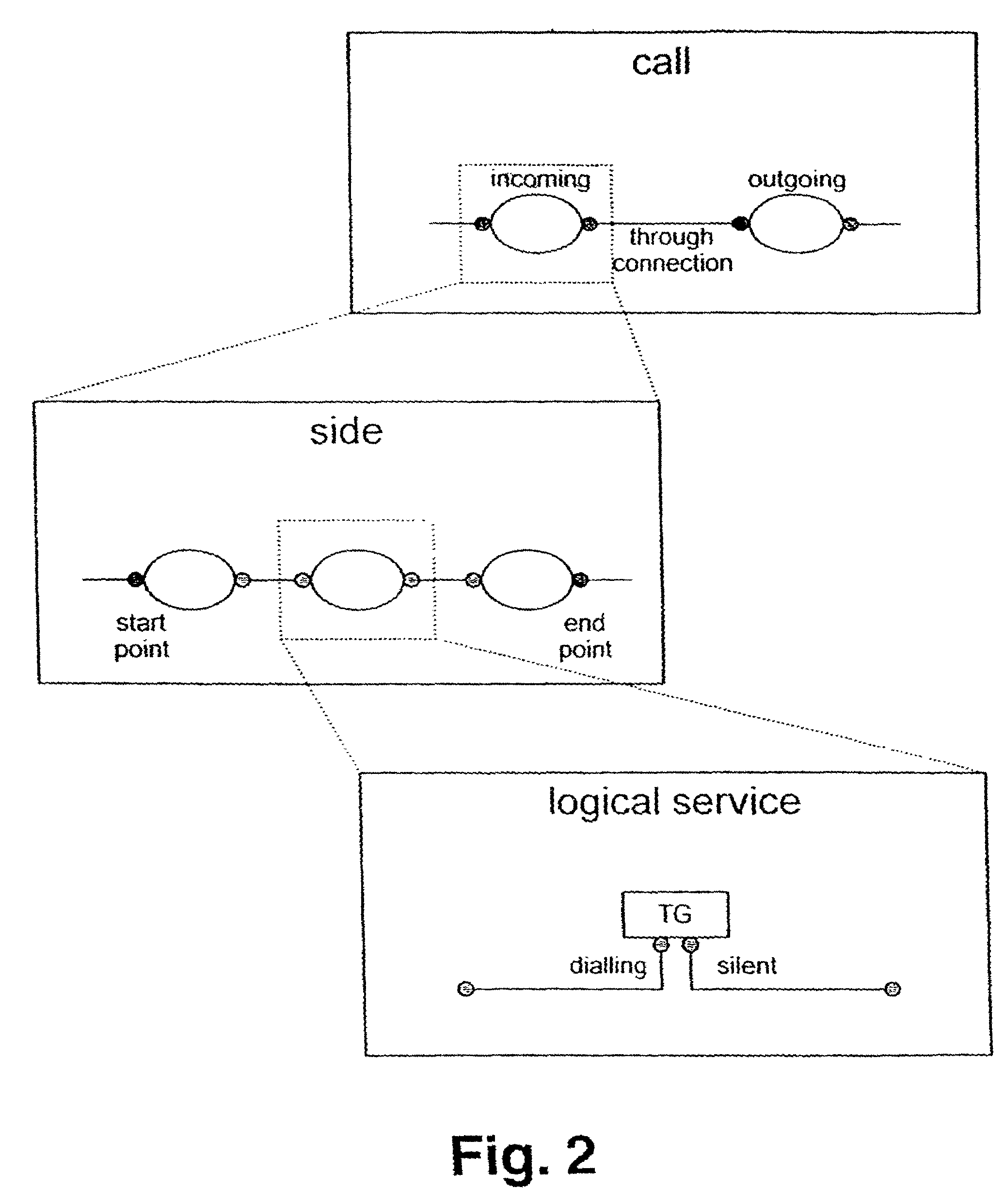

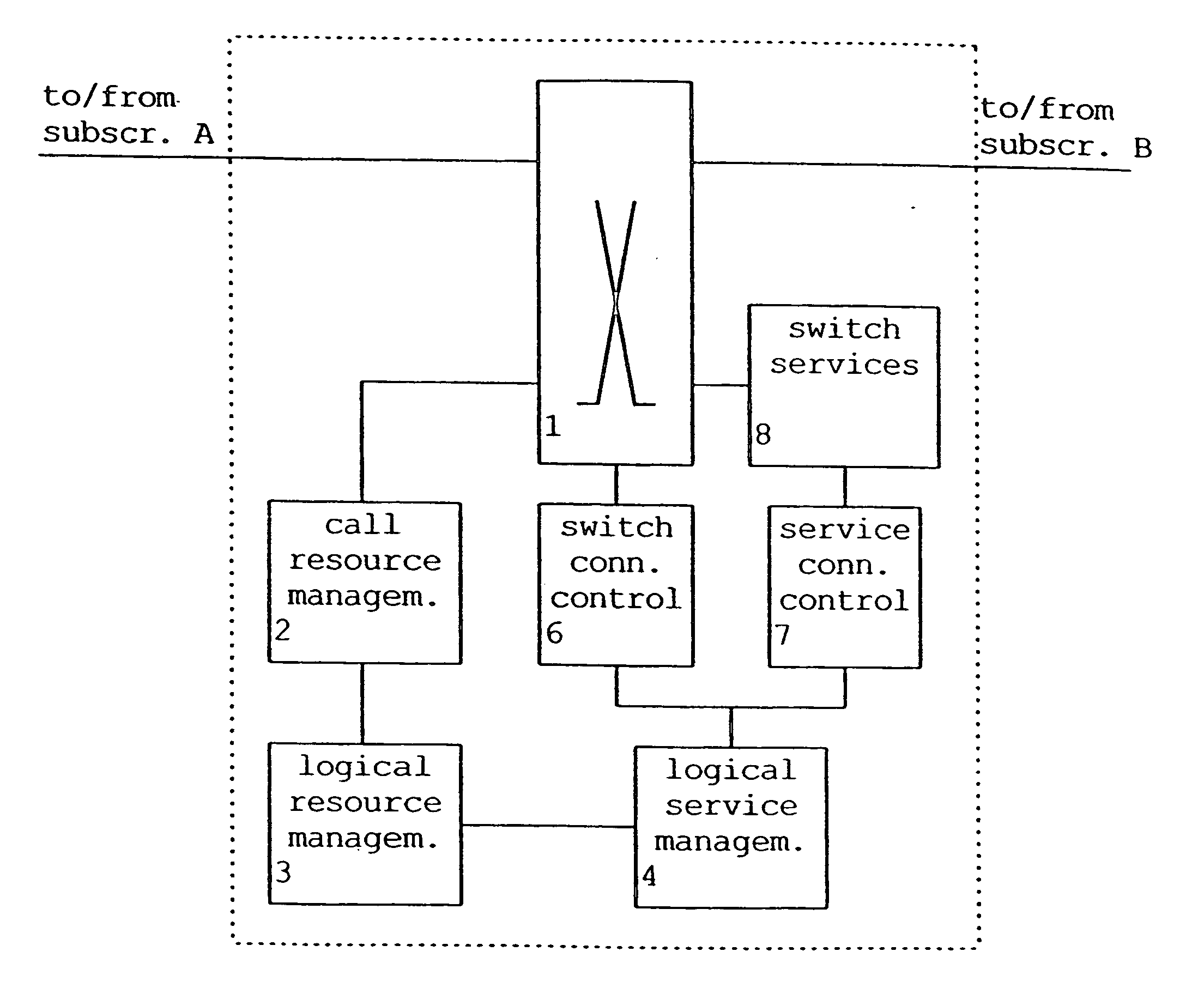

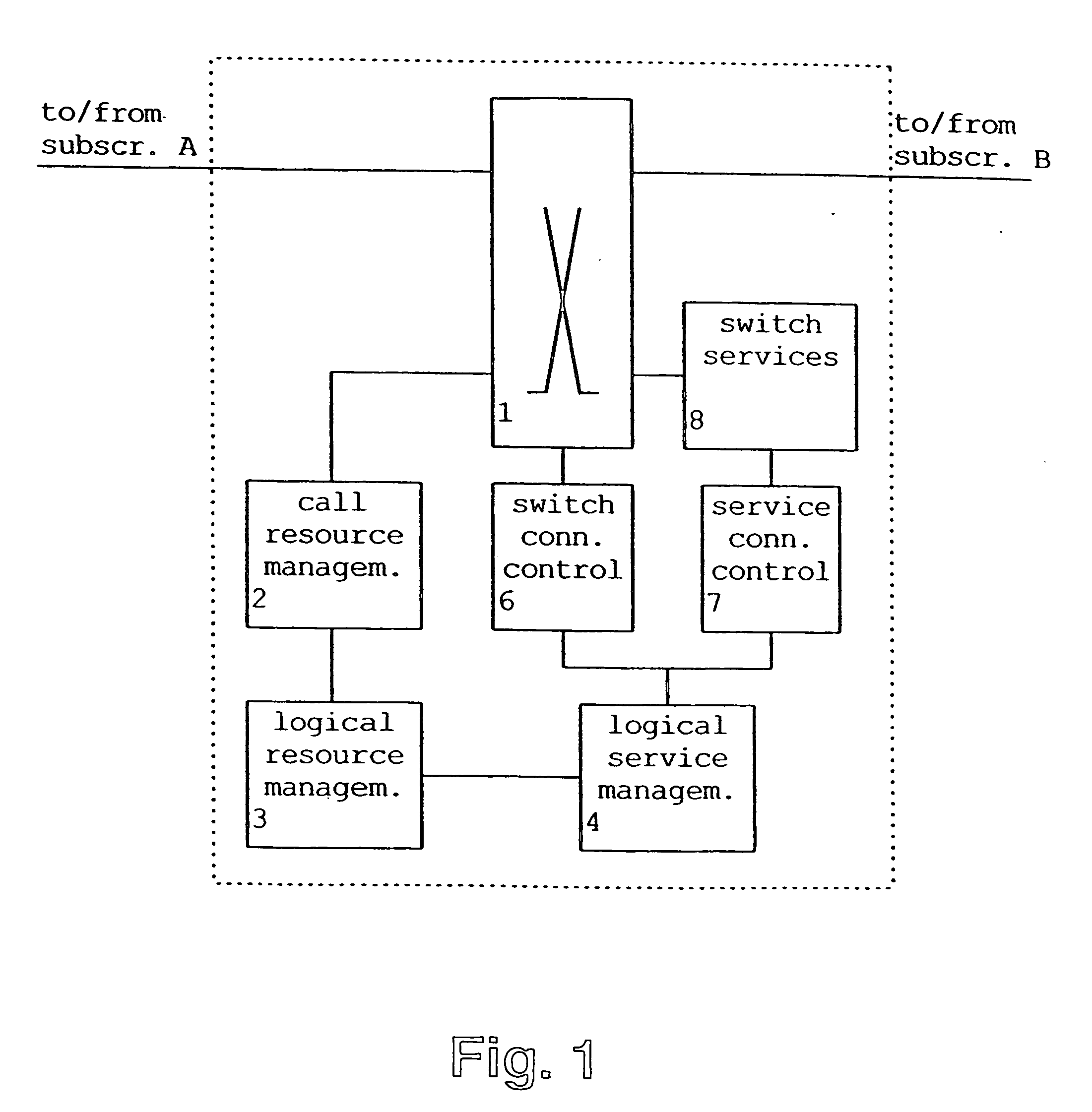

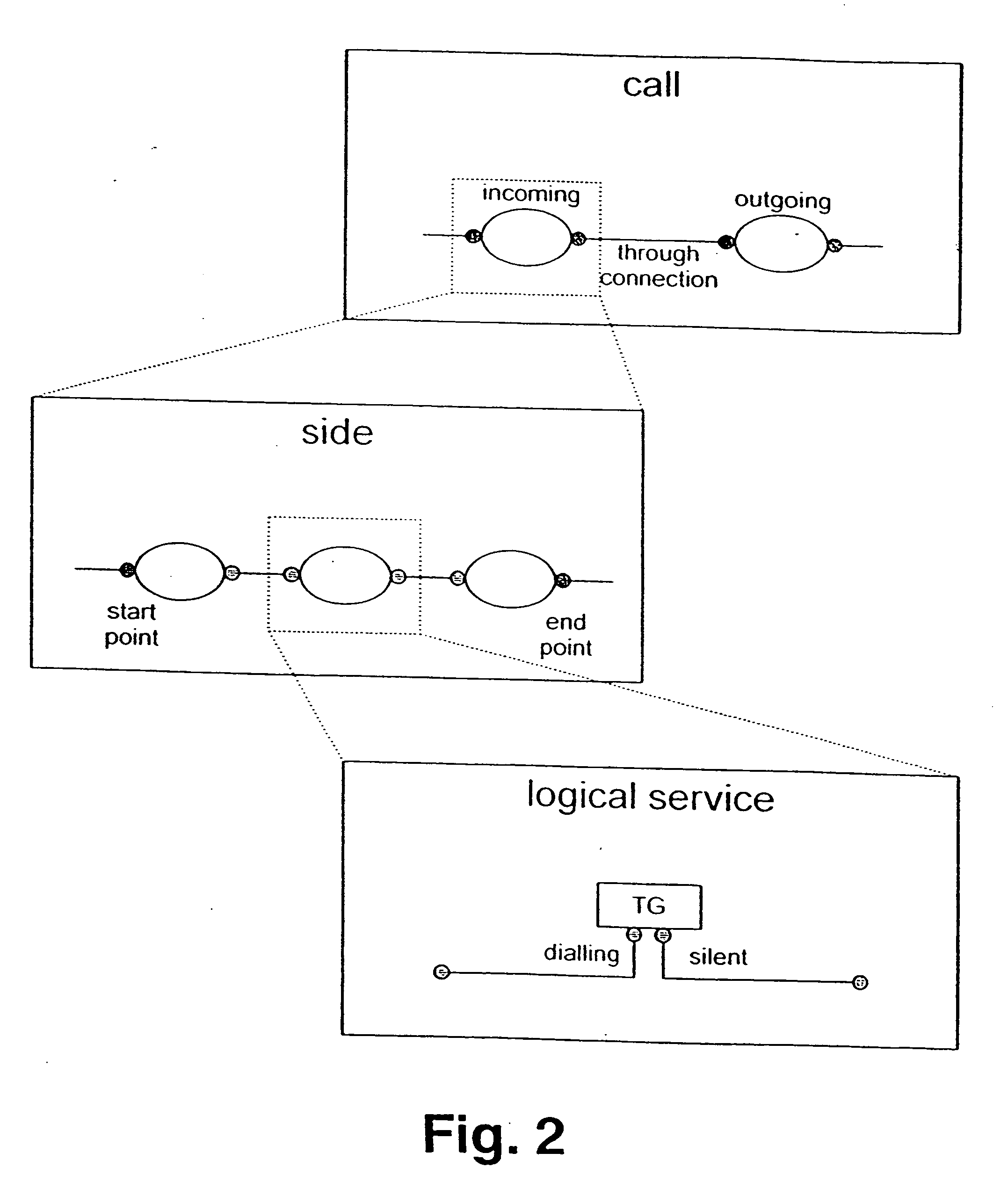

Switching method and apparatus

InactiveUS7035268B2Internal structure be simplifyIncrease performanceSpecial service provision for substationTime-division multiplexService informationTerminal point

The present invention relates to a switching method and apparatus for performing a switching operation in a telecommunication network, wherein a side information and a service information generated based on a received call is converted into a switching technology independent identification information for identifying a start point and an end point of a connection to be switched in said switching apparatus. Thus, the physical resources of the switch are abstracted to a logical model which provides a clear interface for call control and signaling applications. Logical resources are controlled by resource managers, such that the physical resources are hidden by the switching technology independent identification information of the start point and end point of the connection. Thereby, problems with different switching technologies can be solved, and the complexity and maintenance of call control applications can be reduced, since they handle logical resources independent of the switching techniques.

Owner:NOKIA SOLUTIONS & NETWORKS OY

Distributed scheduler

ActiveUS20160301559A1ResourceEffective wayError detection/correctionData switching networksApplication serverDistributed computing

Owner:GOOGLE LLC

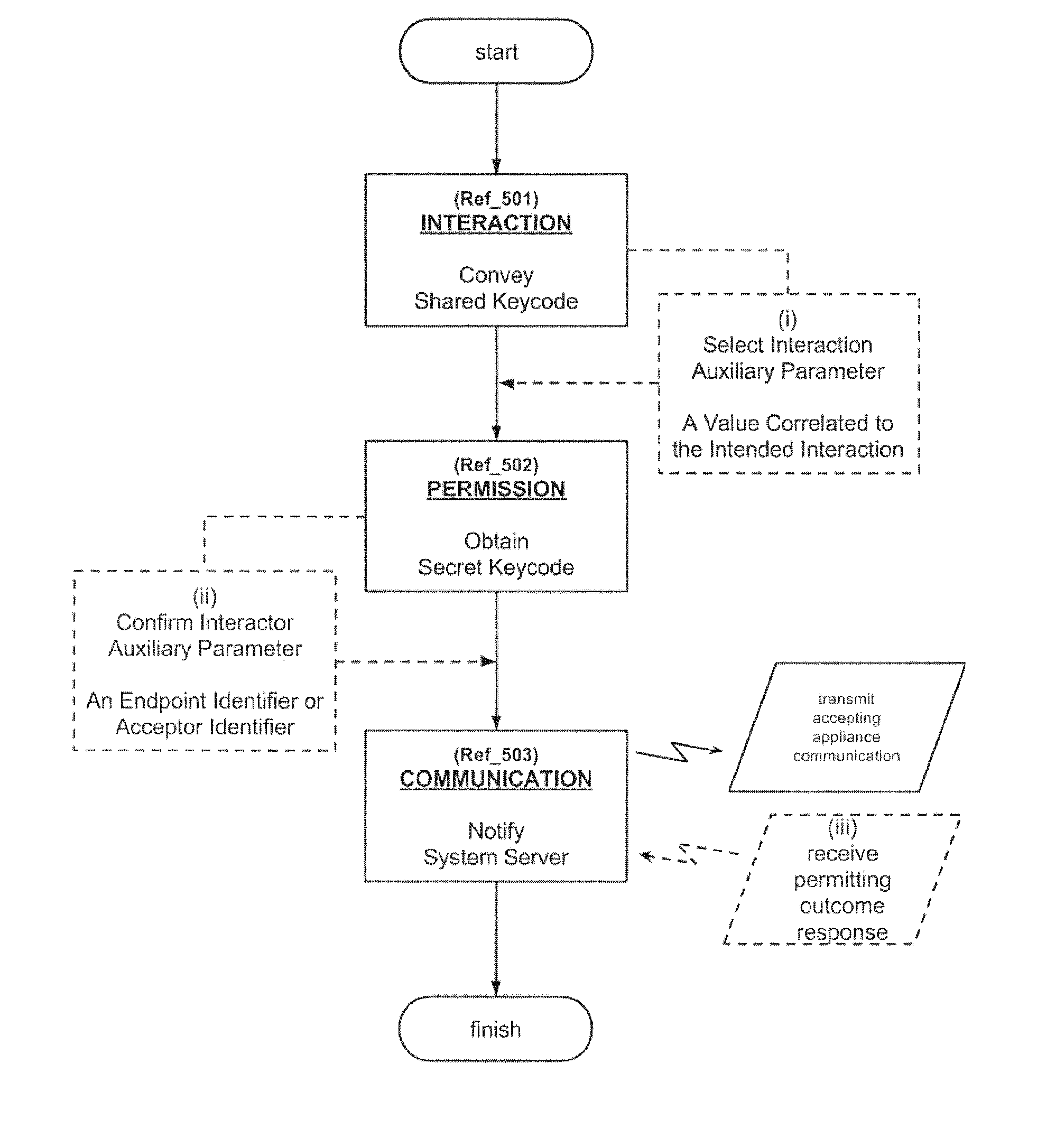

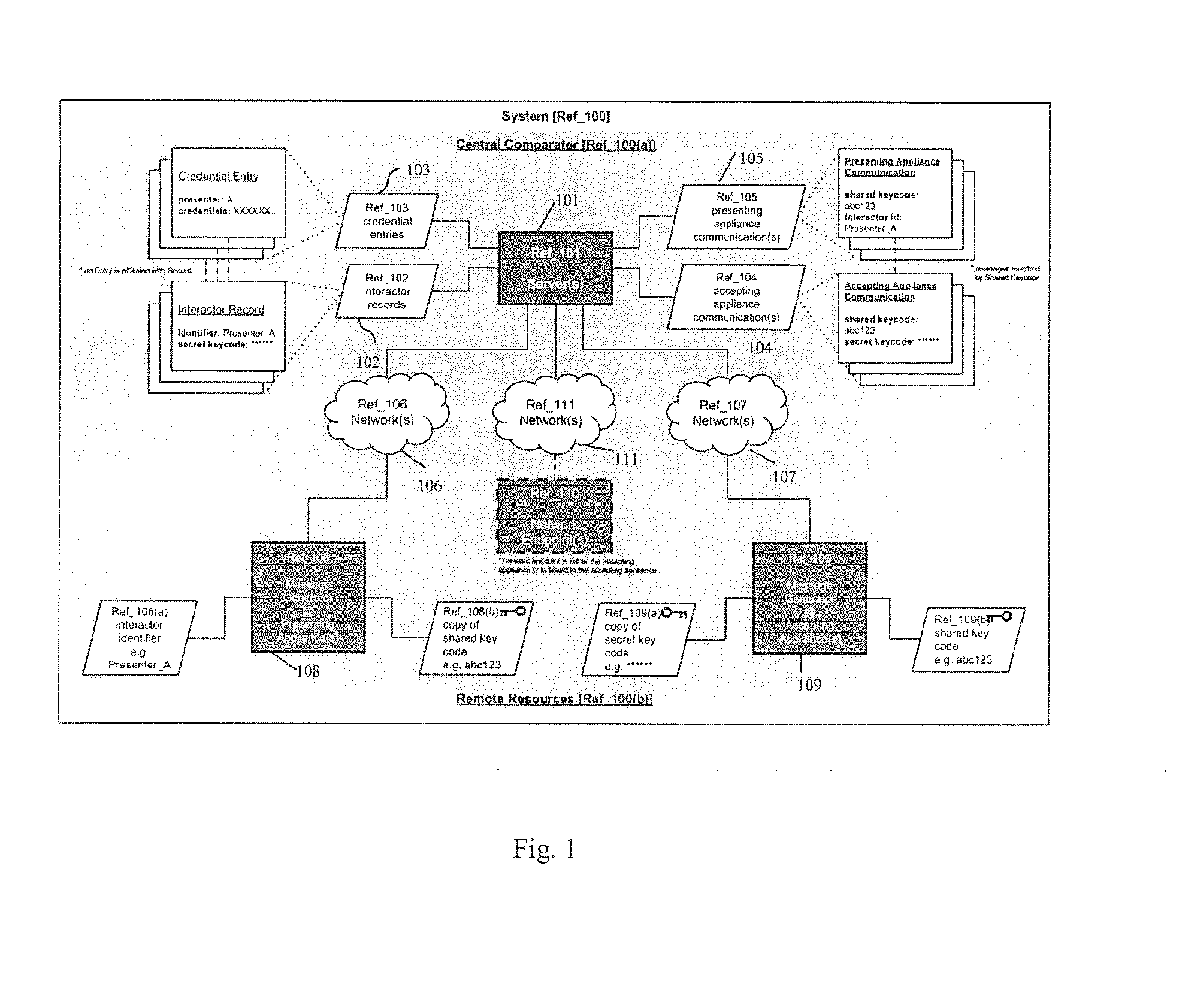

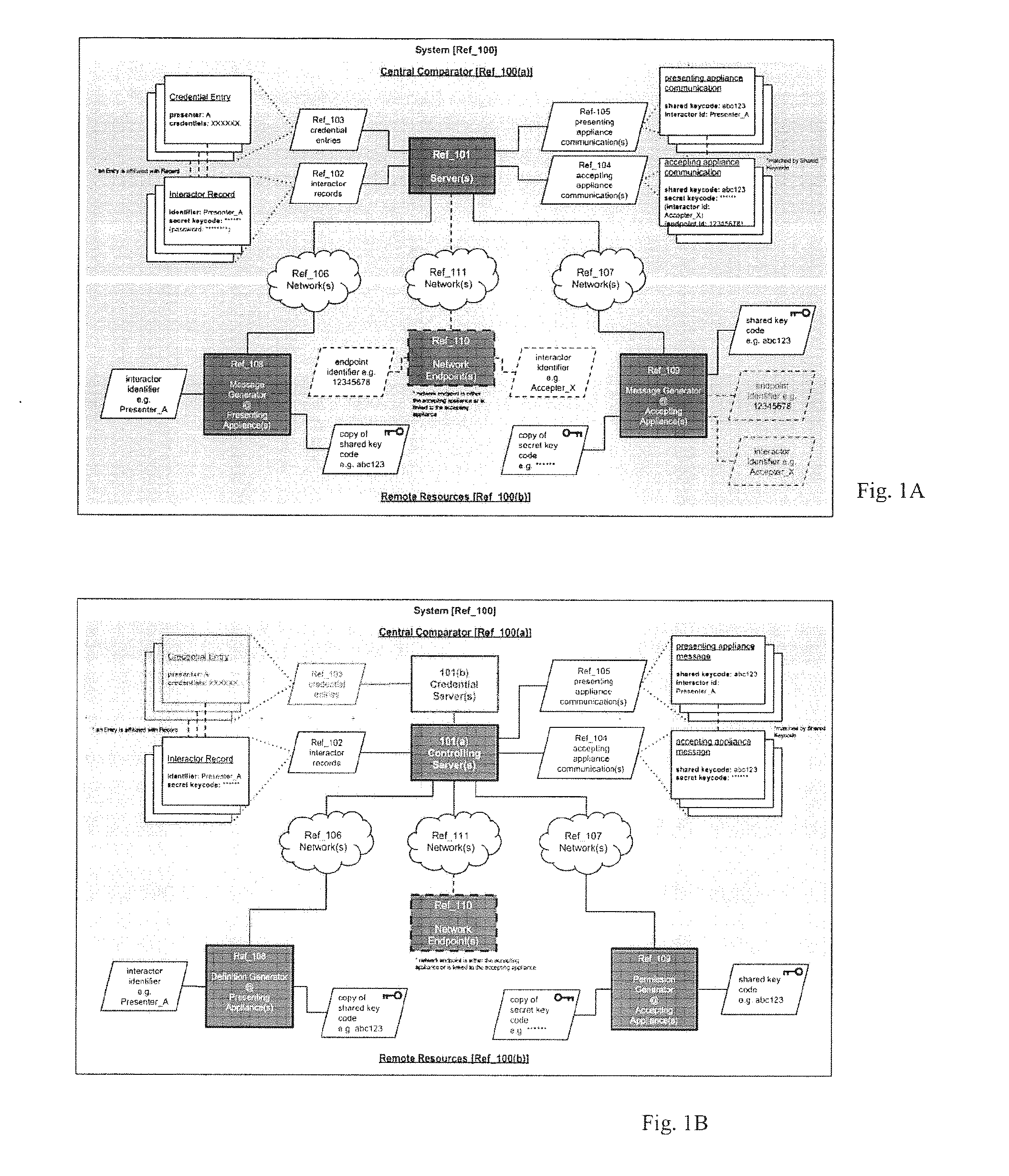

System and Method for Communicating Credentials

ActiveUS20160337345A1Simple methodResourceDigital data protectionTransmissionOperating systemNetwork Endpoint

A system and method for conducting transactions involving the communication of credentials connected to an entity or an individual, known as the presenter to a permitted destination, known as the network endpoint (110) following a request from an accepter while maintaining the privity in said credentials. The system includes presenting appliances (108) and accepting appliances (109) that communicate with a controlling server (101). The controlling server receives communication from the accepting and presenting appliances that contains a secret keycode exclusive to the individual or presenter, presenter identifiers and a shared keycode and if the communications are matched, credentials specific to presenter identifier is permitted to be released to a known network endpoint.

Owner:PRIVITI PTE LTD

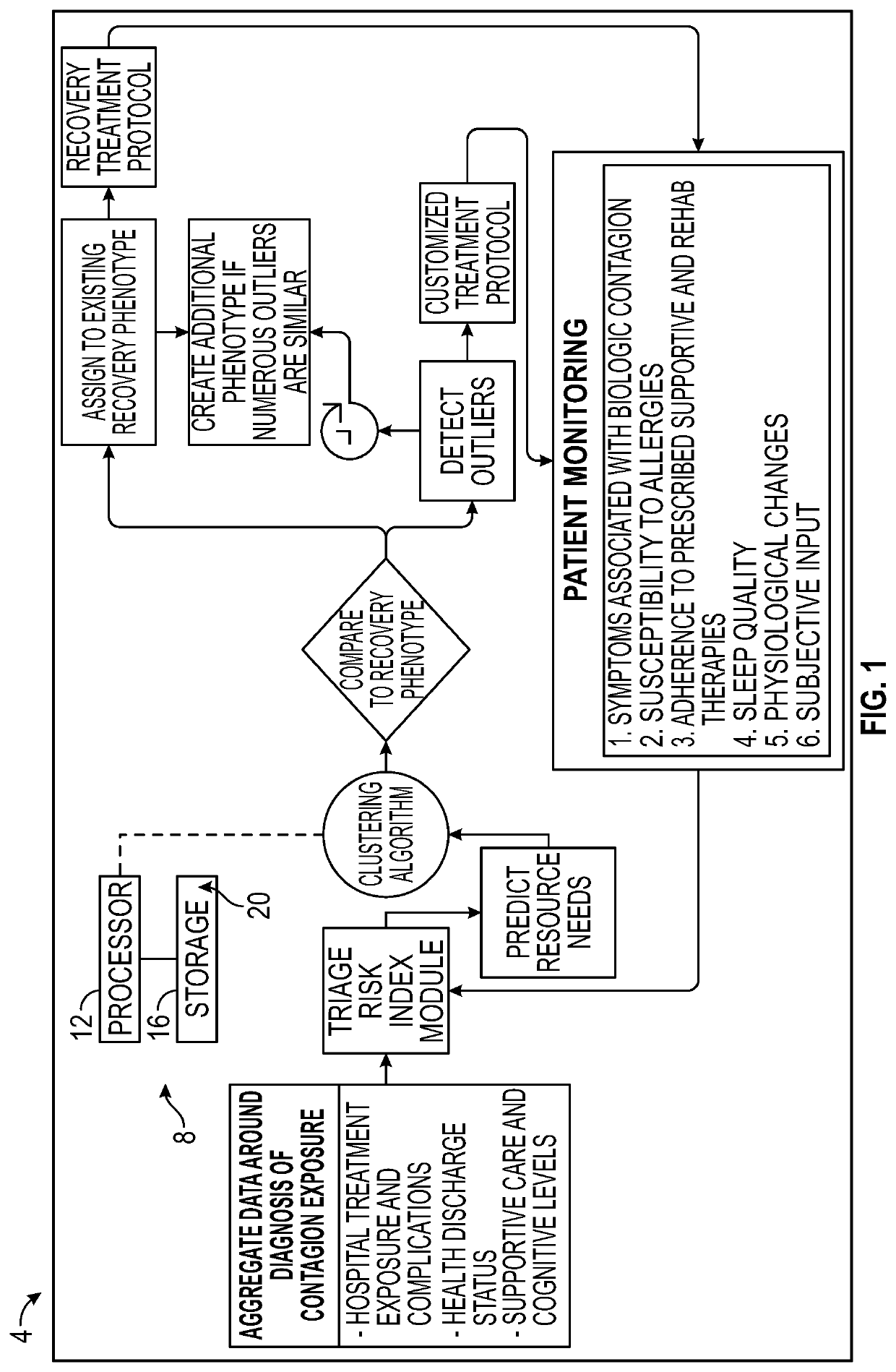

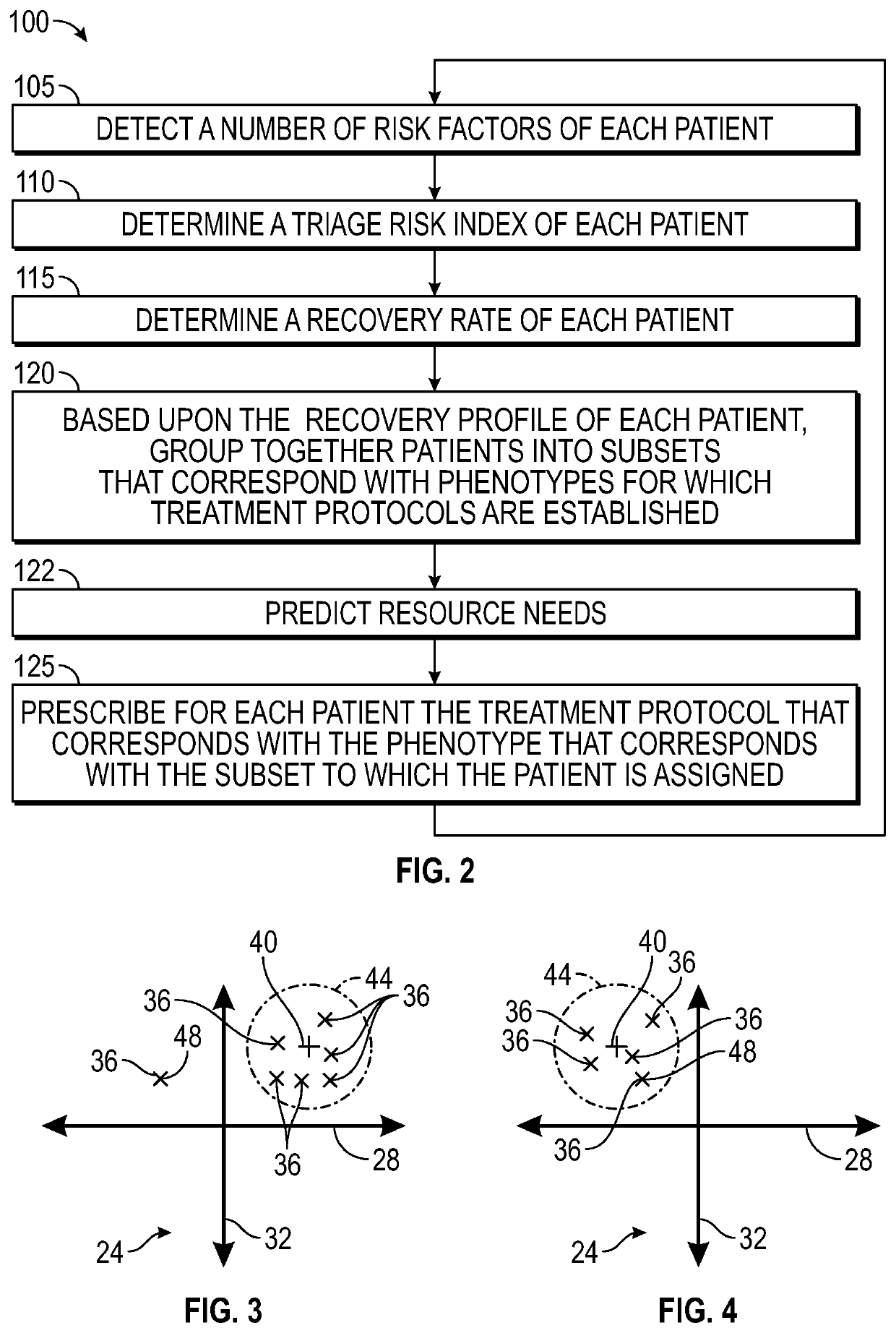

Recovery profile clustering to determine treatment protocol and predict resourcing needs

PendingUS20210366619A1Improve abilitiesResourceHealth-index calculationDrug and medicationsMedicineData mining

An apparatus and method involve not just comparing a patient's recovery but improving predications by grouping the patient into a phenotype to trend the patient's rate of progress compared to existing phenotype clusters to predict, based on a comparison of rate of progress of decline, and assess in order to benefit in the improvement of allocation and timing of future resource needs, including the economic impact.

Owner:KONINKLJIJKE PHILIPS NV

Recycled regenerated plastic

The invention relates to the technical field of recycled plastics, and provides a recycled regenerated plastic. The recycled regenerated plastic at least comprises, by weight, 50-80 parts of waste plastic, 5-15 parts of a functional material and 1-5 parts of an auxiliary agent; and the auxiliary agent is selected from at least one of a lubricant, a plasticizer, a dispersing agent and an antioxidant. The invention also provides a preparation method of the recycled regenerated plastic. The method can be suitable for preparing products in various fields, can also be suitable for the field of products with odor requirements, and is beneficial to recycling of waste plastics.

Owner:上海壹诚塑胶有限公司

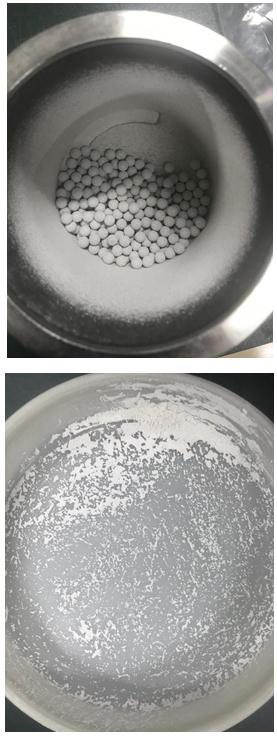

A kind of nanocrystalline cellulose edible ink and preparation method thereof

The invention discloses edible nanocrystal cellulose ink and a preparation method thereof. The preparation method of the edible nanocrystal cellulose ink comprises the steps that nanocrystal cellulose is mixed with water, ultrasonic treatment is performed, the water, a sweetening agent, coloring materials, a thickening agent and connecting materials are added in batches under the constant temperature and stirring conditions, and then the edible nanocrystal cellulose ink is prepared, wherein the nanocrystal cellulose is selected from natural plant fiber. According to the edible nanocrystal cellulose ink and the preparation method thereof, the nanocrystal cellulose is adopted to prepare the edible ink, the fibrous components are added in the ink, functionalization is achieved, the health care function is achieved, and meanwhile the color and luster of the edible ink is enhanced; especially, if the nanocrystal cellulose is selected from agricultural wastes (such as corn stalks, wheat straw and rice straw), recycling of the agricultural wastes is facilitated. The edible nanocrystal cellulose ink has the advantages of being environmentally friendly, free of public hazards, good in color and luster and the like and can be applied to the fields of baby food, drugs, edible packaging materials and the like.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Switching method and apparatus

InactiveUS20060193312A1Solve the real problemControl complexityData switching by path configurationCircuit switching systemsTelecommunications networkComputer architecture

The present invention relates to a switching method and apparatus for performing a switching operation in a telecommunication network, wherein a side information and a service information generated based on a received call is converted into a switching technology independent identification information for identifying a start point and an end point of a connection to be switched in the switching apparatus. Thus, the physical resources of the switch are abstracted to a logical model which provides a clear interface for call control and signaling applications. Logical resources are controlled by resource managers, such that the physical resources are hidden by the switching technology independent identification information of the start point and end point of the connection. Thereby, problems with different switching technologies can be solved, and the complexity and maintenance of call control applications can be reduced, since they handle logical resources independent of the switching techniques.

Owner:NOKIA SOLUTIONS & NETWORKS OY

Method of selectively applying data encryption function

Owner:GAUSS LAB CO LTD

Information monitoring and updating method and system for transport stream

InactiveUS8272005B2Reduce memory spaceImprove performanceTelevision system detailsPulse modulation television signal transmissionComputer scienceInformation monitoring

Owner:IND TECH RES INST

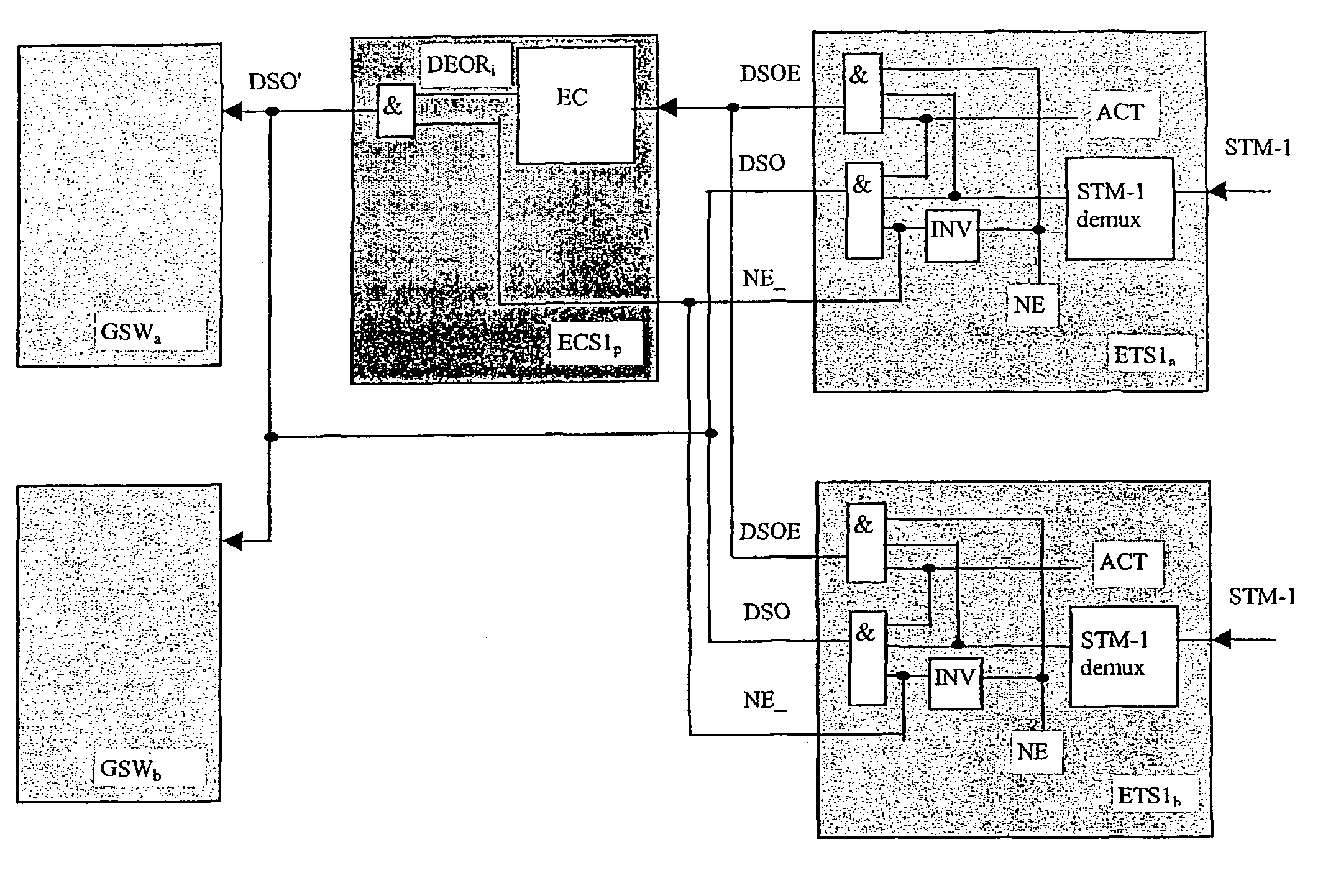

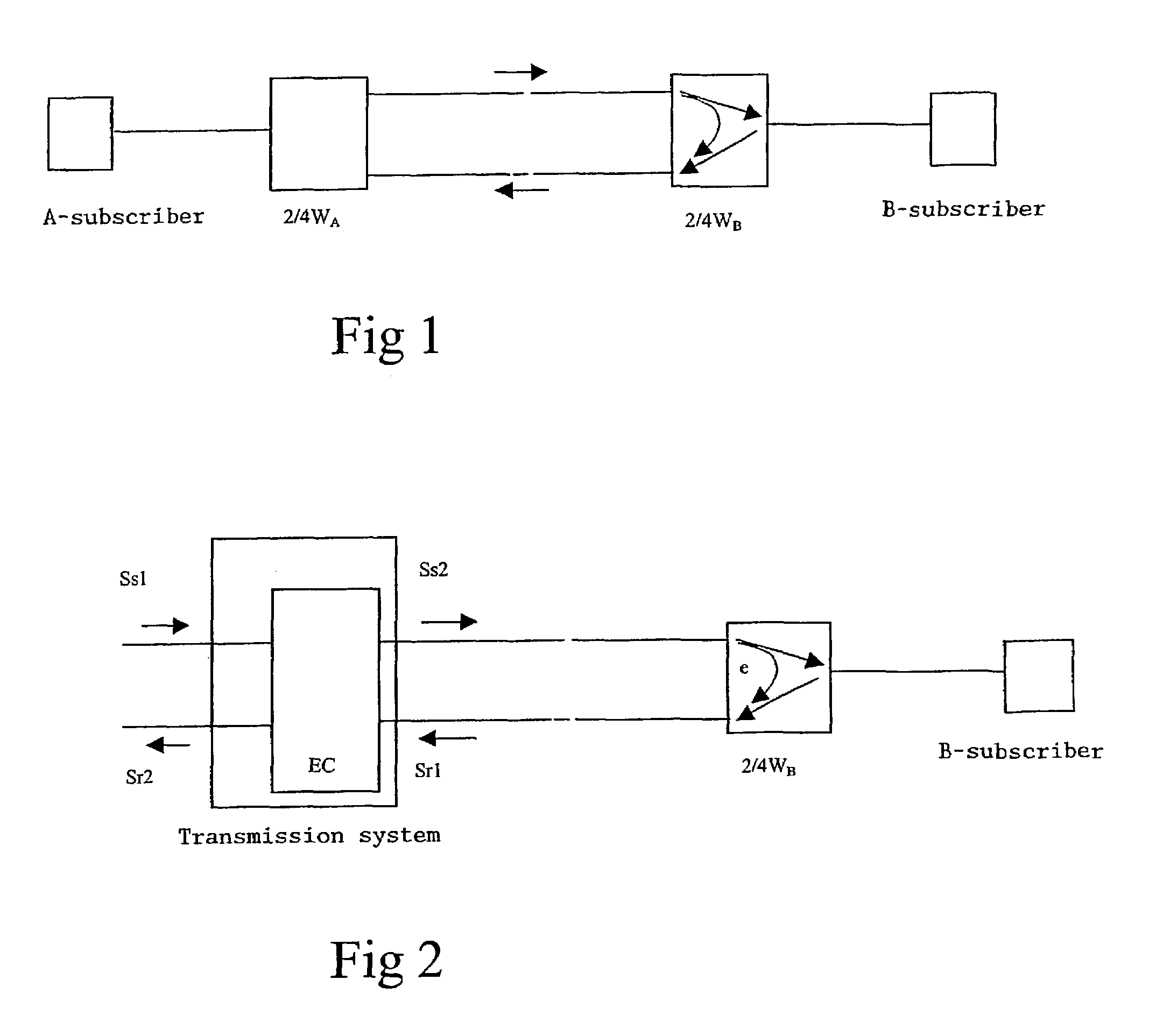

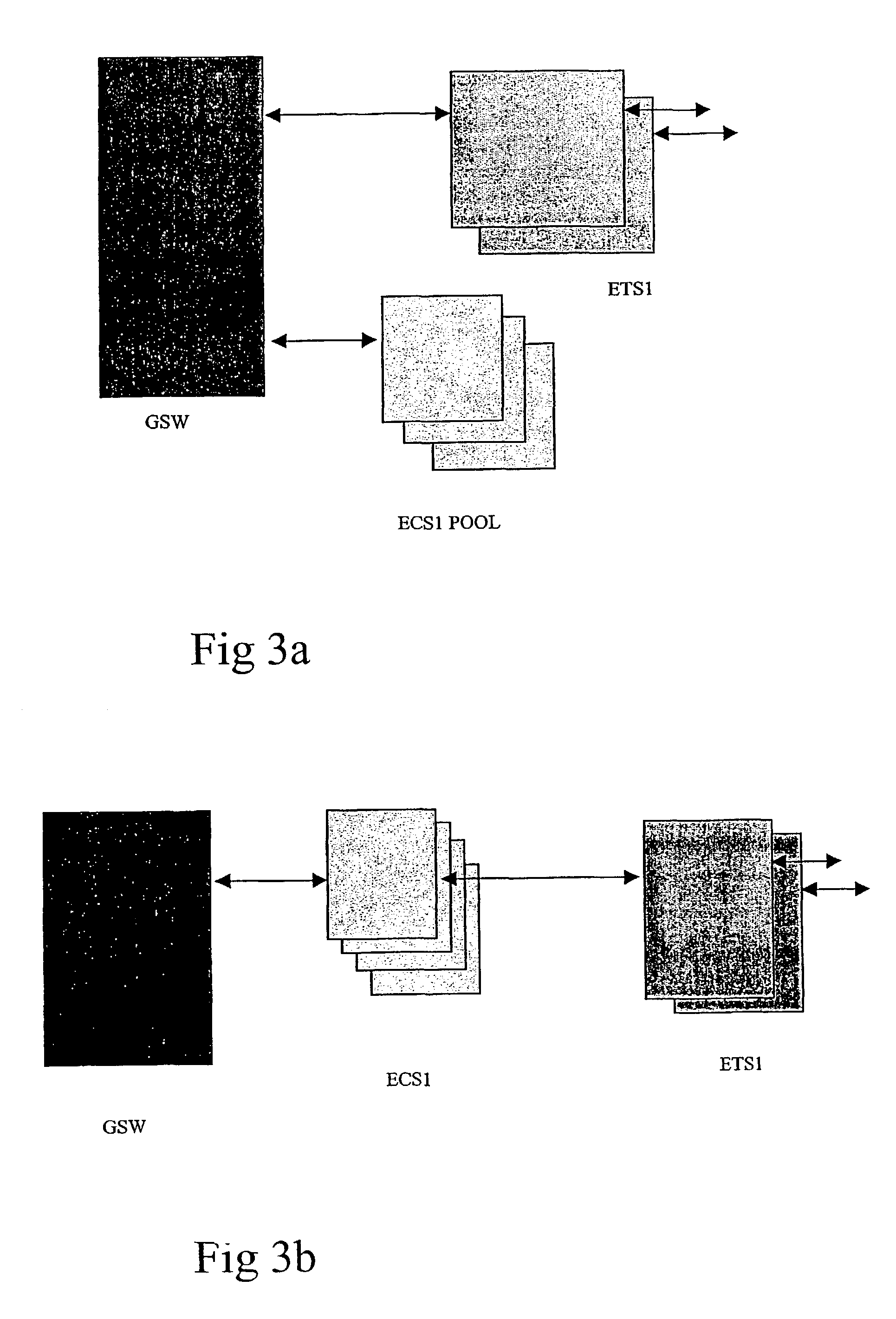

Method and system for processing telecommunication signals

InactiveUS7035205B2AdvantageouslyResourceError preventionTransmission systemsEmbedded systemSignal processing

The present invention relates to a method and a system of implementing a signal processing facility in a digital transmission system environment. In the invention, the signal between the switching field (GSW) and the interface unit ETS1 is divided into a first (DEOS, DSOE) and second signal (DGO, DSO). The first signal is directed through the signal processing unit and the second signal past it. Either one of the signals is selected and activated depending on the need of the signal processing and the operational status of the signal processing unit; this information the interface unit gets from the control unit.

Owner:INTELLECTUAL VENTURES I LLC

Setting zero bits in architectural register for storing destination operand of smaller size based on corresponding zero flag attached to renamed physical register

ActiveUS8972701B2The process is compact and efficientLess hardwareVolume/mass flow measurementDigital computer detailsData processing systemComputer architecture

A data processing system is provided in which destination operands to be stored within architectural registers are constrained to have zero values added as prefixes in order that the architectural register value has a fixed bit width irrespective of the bit width of the destination operand being written thereto. Instead of adding these zero values everywhere in the data path, they are instead represented by zero flags in at least the physical registers utilized for register renaming operations and in the result queue prior to results being written to the architectural register file. This saves circuitry resources and reduces energy consumption.

Owner:ARM LTD

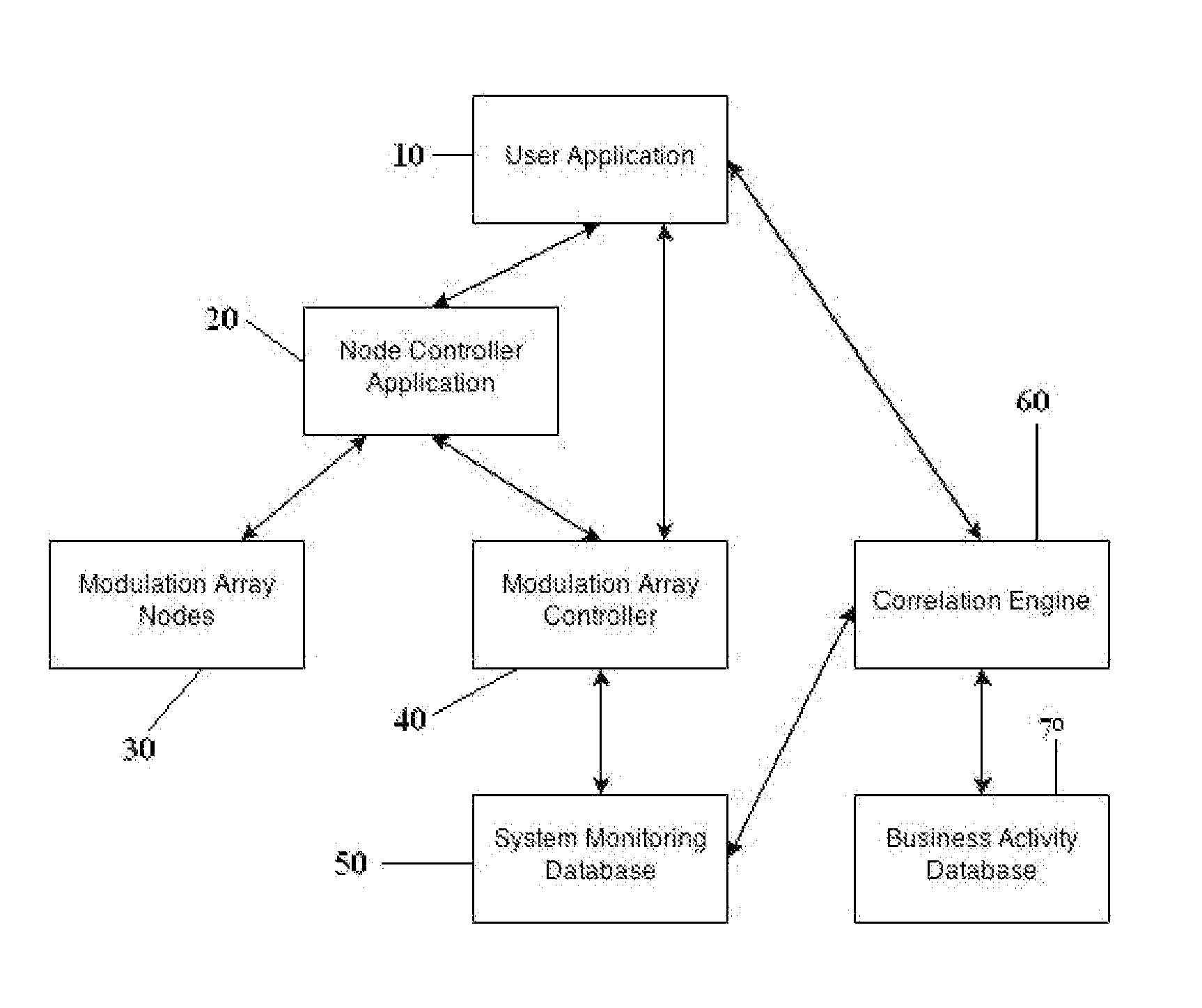

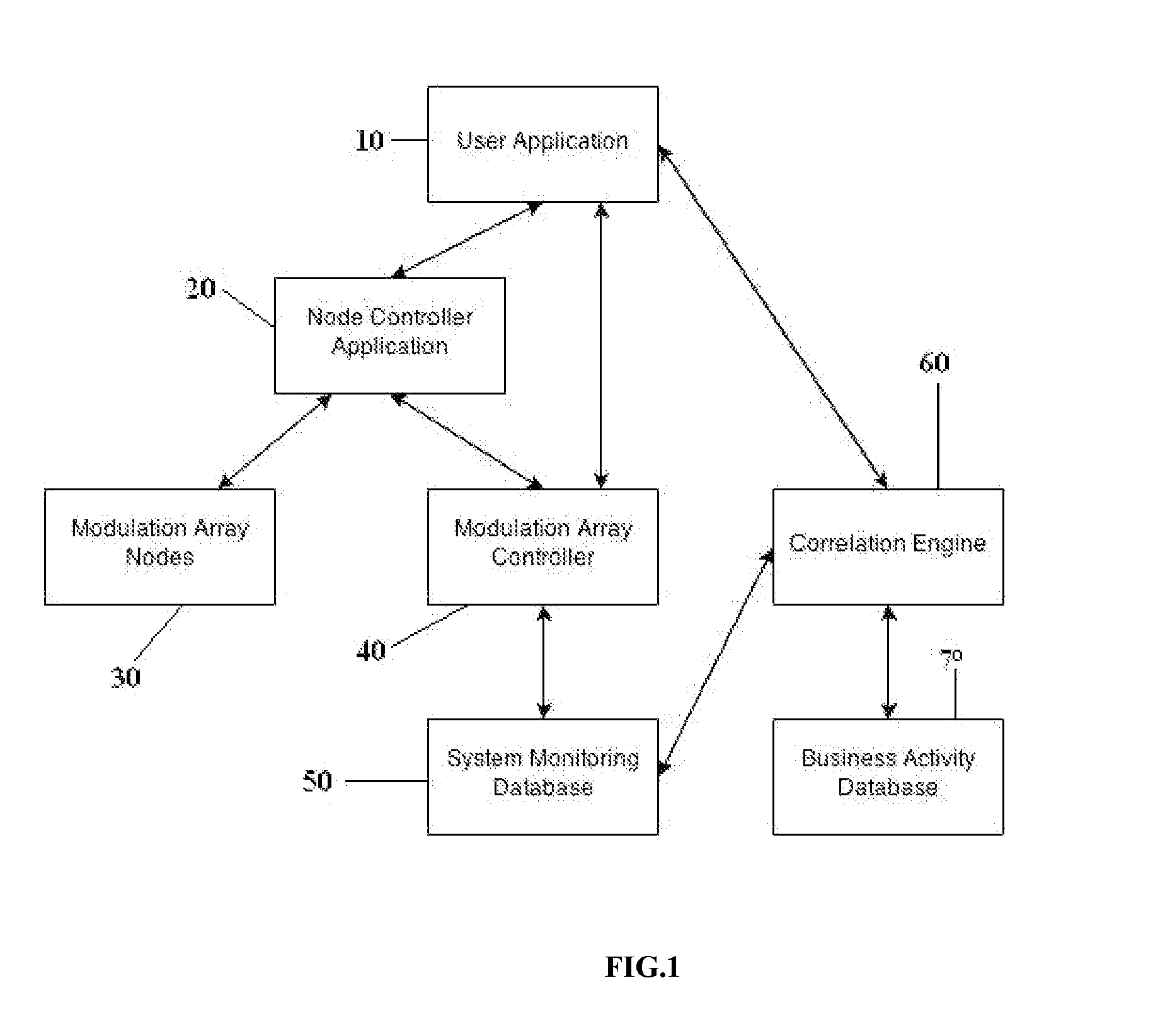

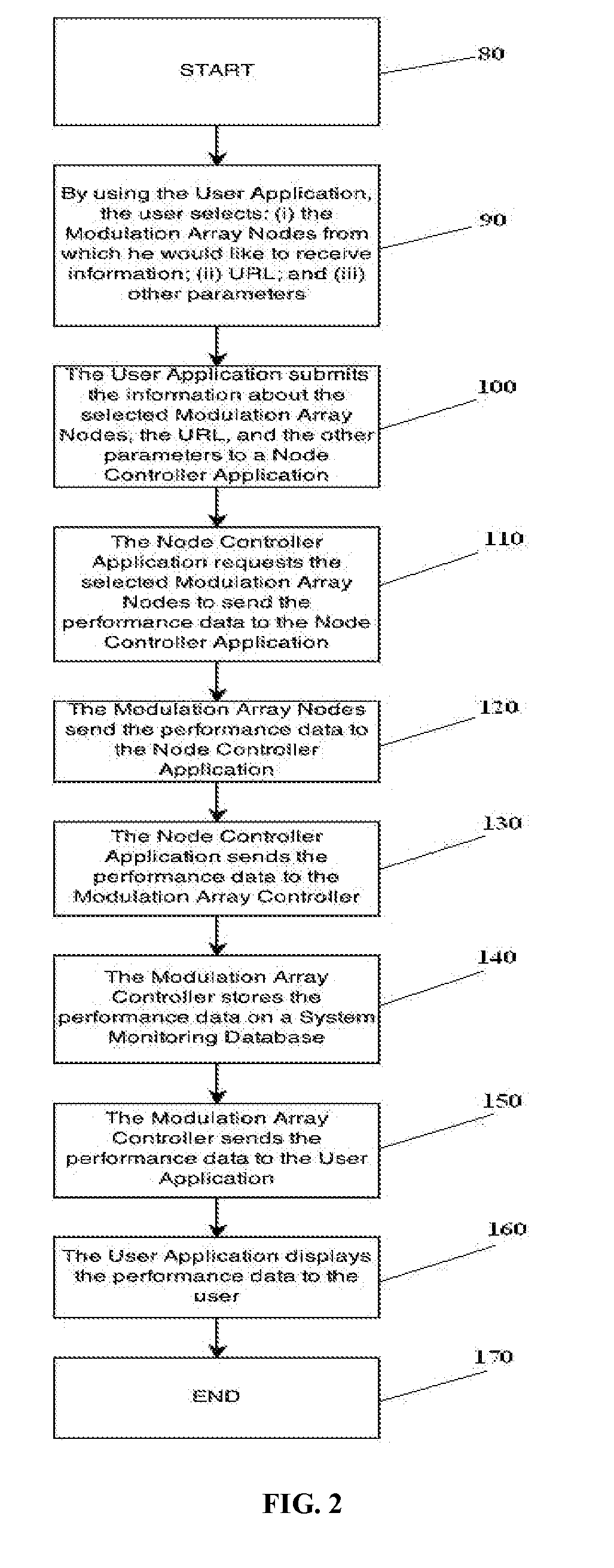

Software system which presents data about the used and the available hosting resources of a computing device as well as the pricing of hosting resources that need to be purchased for ensuring the proper operation of software applications installed on a computing device

InactiveUS20140379459A1ResourceDigital computer detailsHardware monitoringComputer deviceApplication software

A software system which visually presents data about the used and available hosting resources of the computing device or devices specified by the user of invention via an user application as well as data about the pricing of the hosting resources that need to be purchased for ensuring the proper operation of software applications installed on the computer device or devices specified by the user of invention via an user application.

Owner:WEISSMANN FEODOR

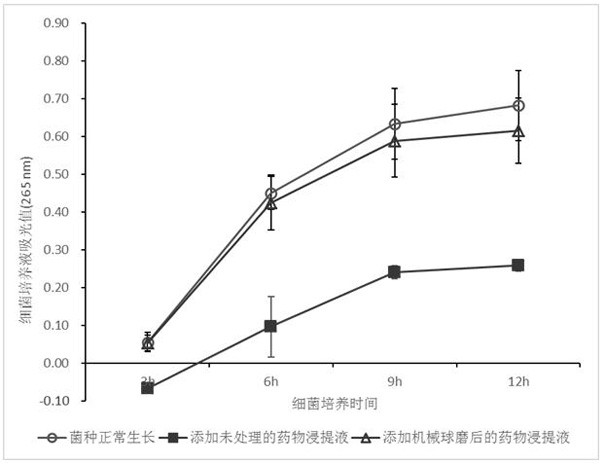

A kind of harmless treatment method for expired drugs

ActiveCN113102473BNo secondary pollutionReduce environmental stressSolid waste disposalTransportation and packagingExpired drugMedicine

Owner:QUANZHOU NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com