Industrial thermo-operated monosaccharide and alcohol ester hydrolysis technology system for plant straw

A plant straw and process system technology, which is applied in biochemical cleaning devices, biochemical equipment and methods, biochemical instruments, etc., can solve the problems of high cost of lignocellulose enzymatic hydrolysis, unsatisfactory pentose fermentation, complex environmental protection treatment technology, etc. problems, to achieve the effect of helping straw resource utilization, solving pollution and inefficiency problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation

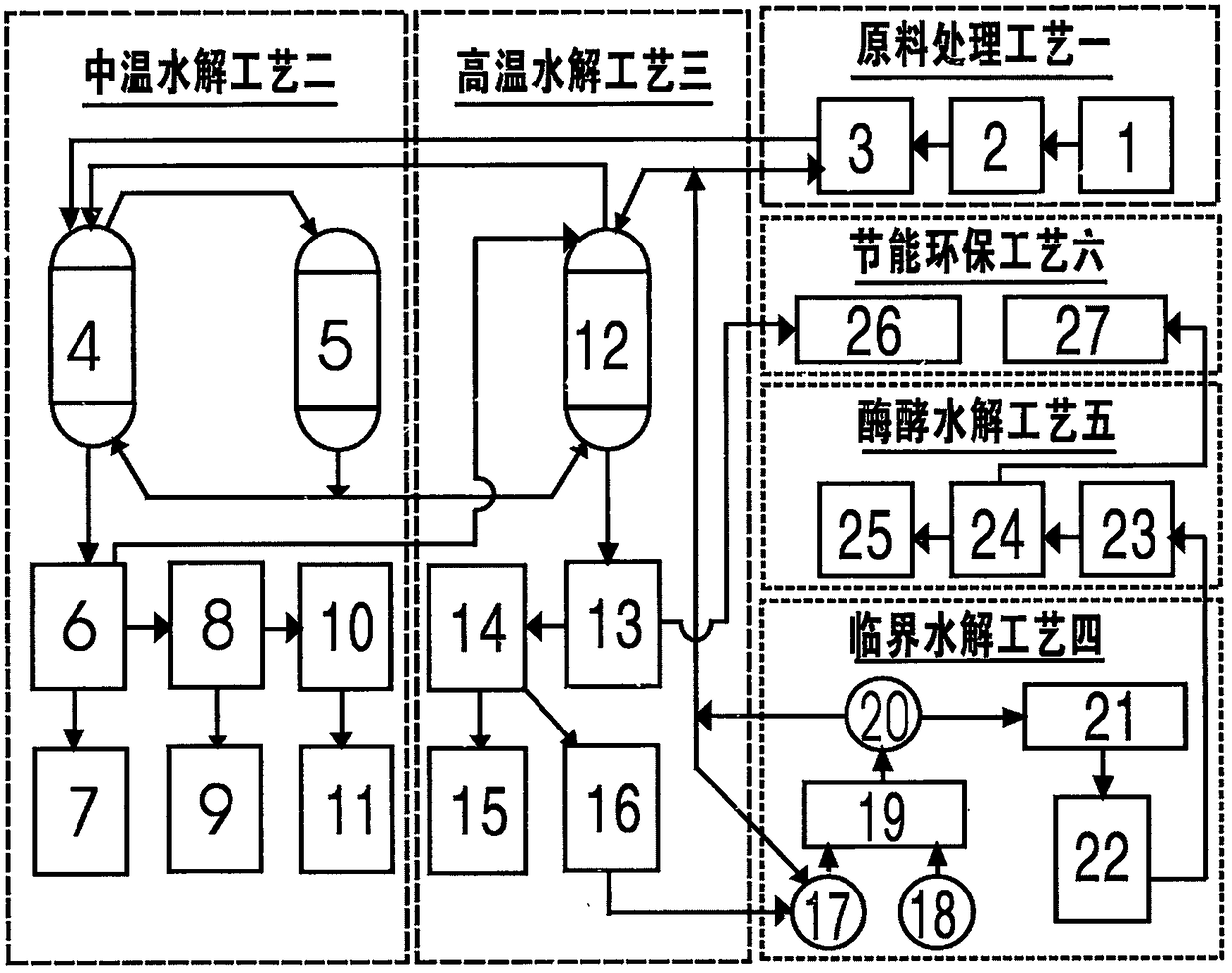

[0028] Attached below figure 1 , The present invention is further analyzed.

[0029] Such as figure 1 As shown, the plant straw industrialized thermodynamic hydrolysis monosaccharide and alcohol ester process system of the present invention consists of main equipment and devices: straw chopper 1, wind dust collector 2, steam explosion 3, medium temperature hydrolyzer 4, hot water catalyst Agent system 5, solid-liquid separator 6, pulp preparation system 7, concentrated crystallization system 8, lignin system 9, distillation drying system 10, pentose sugar system 11, high-temperature hydrolyzer 12, solid-liquid separator 13, crystallization separation system 14 , lignin system 15, cellulose system 16, intermediate preheater 17, critical heat source system 18, critical hydrolyzer 19, flash desuperheater 20, purification and concentration system 21, hexose system 22, hexase enzyme system 23 , Distillation and rectification system 24, ethanol or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com