Metal complex catalyst for catalyzing acetylene hydrochlorination reaction and preparation method and application thereof

A metal complex, acetylene hydrochlorination technology, applied in the direction of organic compound/hydride/coordination complex catalyst, catalytic reaction, hydrogen halide addition preparation, etc., can solve the problem of low reactivity and short catalyst life of non-metallic catalysts and other problems, to achieve the effect of improving catalytic activity and stability, not easy to be lost and agglomerated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The preparation method of the metal complex catalyst for catalyzing the hydrochlorination of acetylene is as follows:

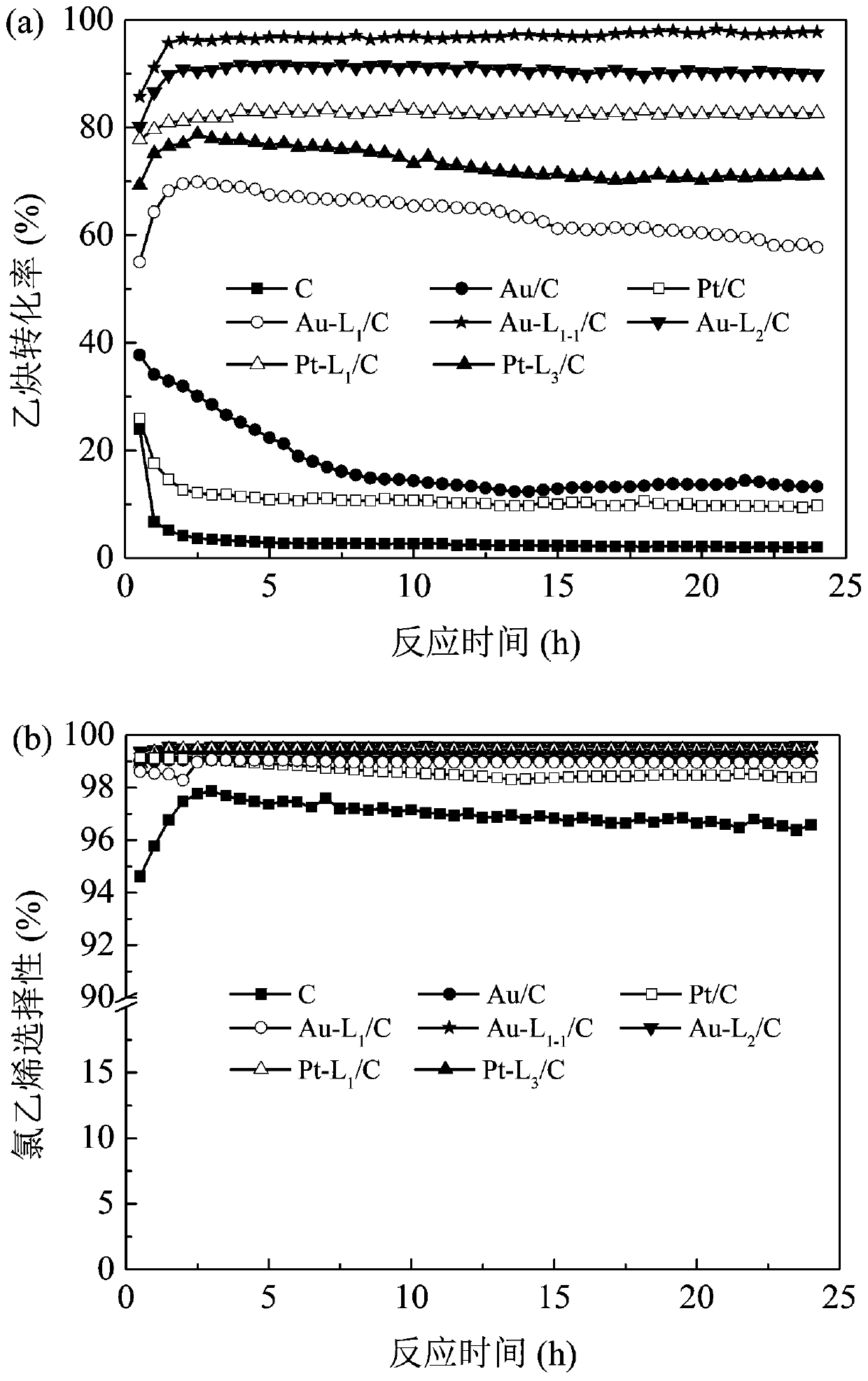

[0066] Step 1. Synthesis of gold complex: Weigh 0.0014976g of phthalimide, add it to 30mL of deionized water, stir at 80℃ for 2h, then add 0.000571g of KOH, continue to stir for 12h; finally add 0.00419 gHAuCl 4 ·XH 2 O was added to it and stirred at room temperature for 12 hours to obtain a gold complex solution.

[0067] Step 2. Loading of gold complexes and thermal activation of the catalyst: Add 2g of activated carbon support to the gold complex solution and stir for 12h at 70°C; then transfer it to a tube furnace and thermally activate it at 140°C in a nitrogen flowing atmosphere 24h, get the supported gold complex catalyst, denoted as Au-L 1 / C.

Embodiment 2

[0069] The preparation method of the metal complex catalyst for catalyzing the hydrochlorination of acetylene is as follows:

[0070] Step 1. Synthesis of gold complex: Weigh 0.0471689g of phthalimide, add it to 30mL of deionized water, stir at 80℃ for 2h, then add 0.025645g of NaOH, continue to stir for 12h; finally add 0.044012 gHAuCl 4 ·XH 2 O was added to it and stirred at room temperature for 12 hours to obtain a gold complex solution.

[0071] Step 2. Loading of gold complexes and thermal activation of the catalyst: Add 2g of activated carbon support to the gold complex solution and stir for 12h at 70°C; then transfer it to a tube furnace and thermally activate it at 140°C in a nitrogen flowing atmosphere 16h, get the supported gold complex catalyst, denoted as Au-L 1-1 / C.

Embodiment 3

[0073] The preparation method of the metal complex catalyst for catalyzing the hydrochlorination of acetylene is as follows:

[0074] Step 1. Synthesis of gold complex: Weigh 0.03152g of succinimide, add it to 30mL of deionized water, stir at room temperature for 4h, then add 0.025449g of NaOH, continue to stir for 12h; finally add 0.04368g of HAuCl 4 ·XH 2 O was added to it and stirred at room temperature for 12 hours to obtain a gold complex solution.

[0075] Step 2. Loading of gold complexes and thermal activation of the catalyst: Add 2g of activated carbon support to the gold complex solution and stir for 12h at 70°C; then transfer it to a tube furnace and thermally activate it at 140°C in a nitrogen flowing atmosphere 16h, get the supported gold complex catalyst, denoted as Au-L 2 / C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com