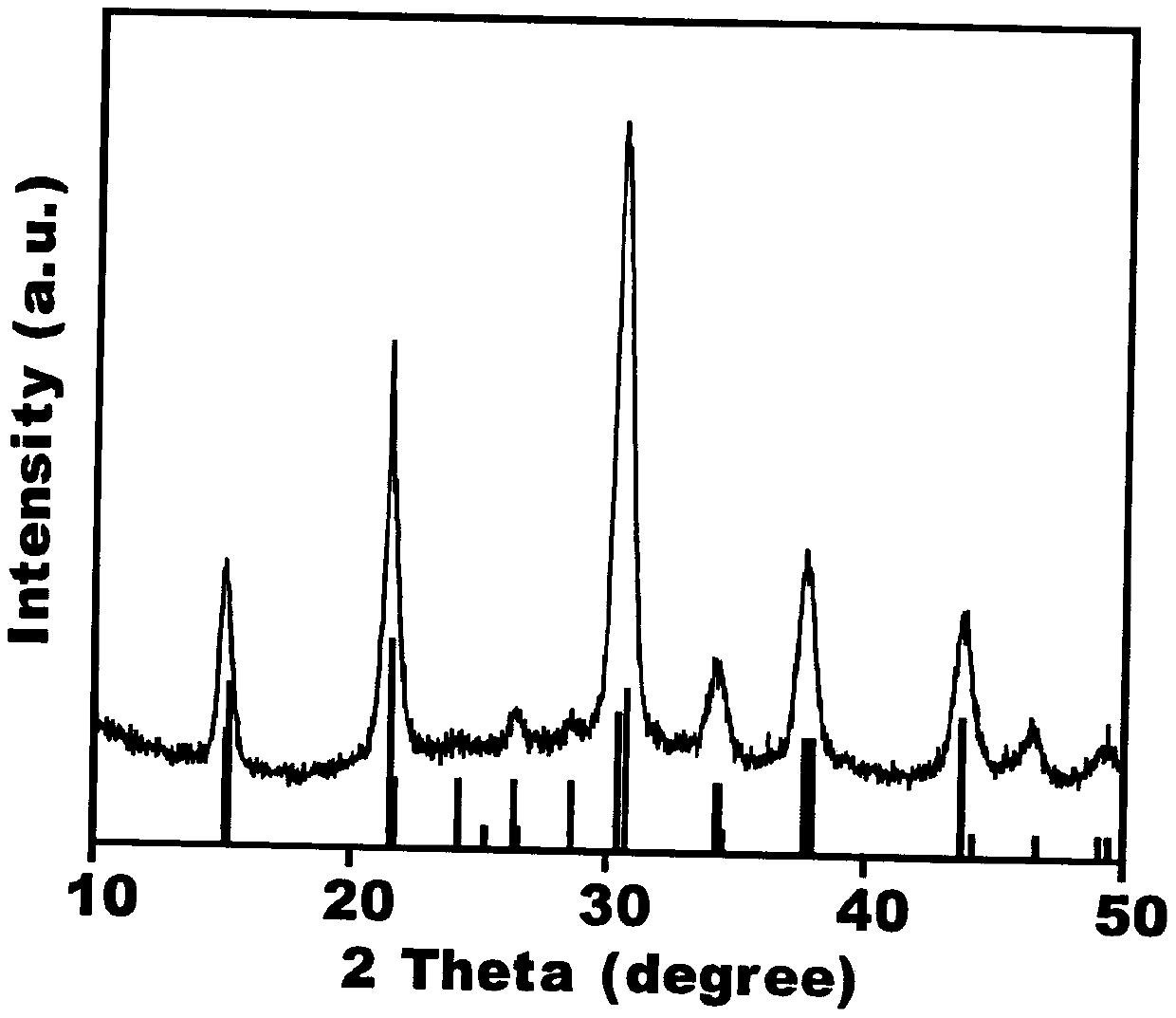

Preparation method of all-inorganic CsPbBr3 perovskite nanocrystal with controllable morphology

A nanocrystal and perovskite technology, applied in the field of inorganic nanoluminescent material preparation, can solve the problems of great influence on luminescence color, short lifespan of perovskite materials, poor material stability, etc., and achieves excellent optical properties, simple preparation method, The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

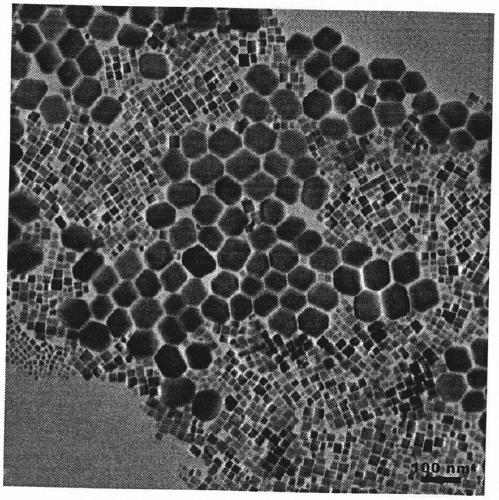

Embodiment 1

[0019] (1) Add 0.15g of cesium carbonate, 10ml of octadecene, and 0.5ml of oleic acid into a 50ml round-bottomed flask, heat up to 130°C under nitrogen protection, stir to make the whole solution clear and transparent, and set aside;

[0020] (2) Add 0.1g of lead bromide, 10ml of octadecene, 1ml of oleylamine, and 0.5ml of 5-hexynoic acid into a 50ml round bottom flask, raise the temperature to 100°C under the protection of nitrogen, keep stirring for 20min to ensure that the solid The drug is completely dissolved, and then continue to heat up to 140°C, take 0.8ml of the solution obtained in step (1) and quickly inject it into it, stir and react for 10 seconds, and then cool to room temperature with an ice-water bath;

[0021] (3) Add the cooled stock solution into a 50ml centrifuge tube, add 10ml of absolute ethanol to it for washing and ultrasonication for 1min to make the solution uniform, then put it in a centrifuge and centrifuge at 10,000 rpm for 5 minutes, discard the su...

Embodiment 2

[0024] (1) Add 0.2g of cesium carbonate, 10ml of octadecene, and 1ml of oleic acid into a 50ml round-bottomed flask, heat up to 140°C under the protection of nitrogen, stir to make the whole solution clear and transparent, and set aside;

[0025] (2) Add 0.2g of lead bromide, 15ml of octadecene, 2ml of oleylamine, and 1ml of 5-hexynoic acid into a 50ml round-bottom flask, raise the temperature to 110°C under the protection of nitrogen, and keep stirring for 30min to ensure that the solid drug Dissolve it completely, then continue to heat up to 155°C, take 1.2ml of the solution obtained in step (1) and quickly inject it into it, stir and react for 7s, then cool to room temperature with an ice-water bath;

[0026] (3) Add the cooled stock solution into a 50ml centrifuge tube, add 15ml of absolute ethanol to it for washing and ultrasonication for 2 minutes to make the solution uniform, then put it in a centrifuge and centrifuge at 8000 rpm for 5 minutes, discard the supernatant s...

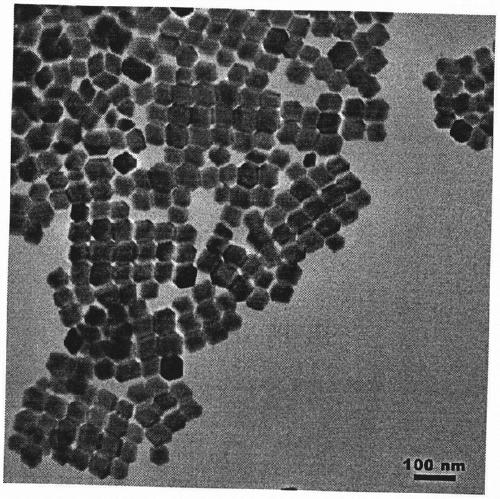

Embodiment 3

[0029] (1) Add 0.25g cesium carbonate, 15ml octadecene, and 1.5ml oleic acid into a 50ml round-bottomed flask, heat up to 150°C under nitrogen protection, stir to make all dissolves clear and transparent, and set aside;

[0030] (2) Add 0.3g of lead bromide, 20ml of octadecene, 3ml of oleylamine, and 1.5ml of 5-hexynoic acid into a 50ml round bottom flask, raise the temperature to 120°C under the protection of nitrogen, and keep stirring for 40min to ensure that the solid The drug is completely dissolved, and then continue to heat up to 170°C, take 1.2ml of the solution obtained in step (1) and quickly inject it into it, stir and react for 5 seconds, and then cool to room temperature with an ice-water bath;

[0031] (3) Add the cooled stock solution into a 50ml centrifuge tube, add 20ml of absolute ethanol to it for washing and ultrasonication for 3 minutes to make the solution uniform, then put it in a centrifuge and centrifuge at 8000 rpm for 5 minutes, discard the supernatan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com