Culture tail water treatment system

A technology for treating system and tail water, applied in the field of aquaculture, can solve the problems of difficult to achieve treatment effect, discharge of external water pollution, increase of nitrogen and phosphorus content in water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

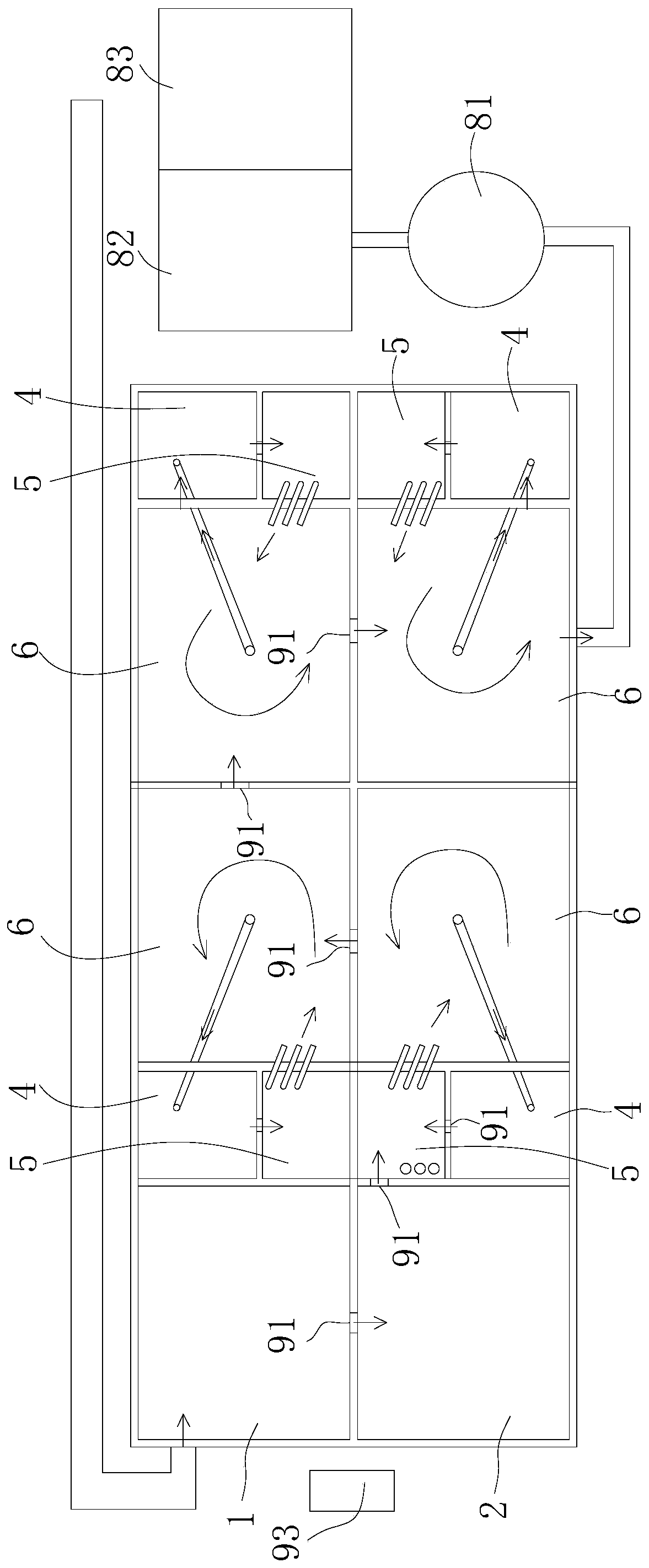

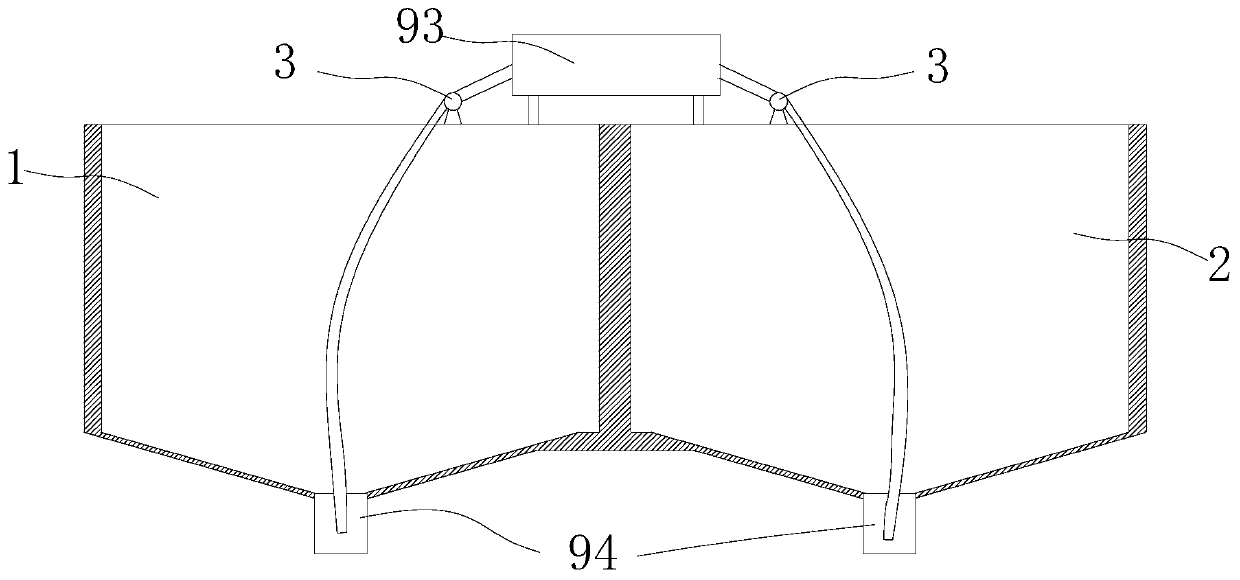

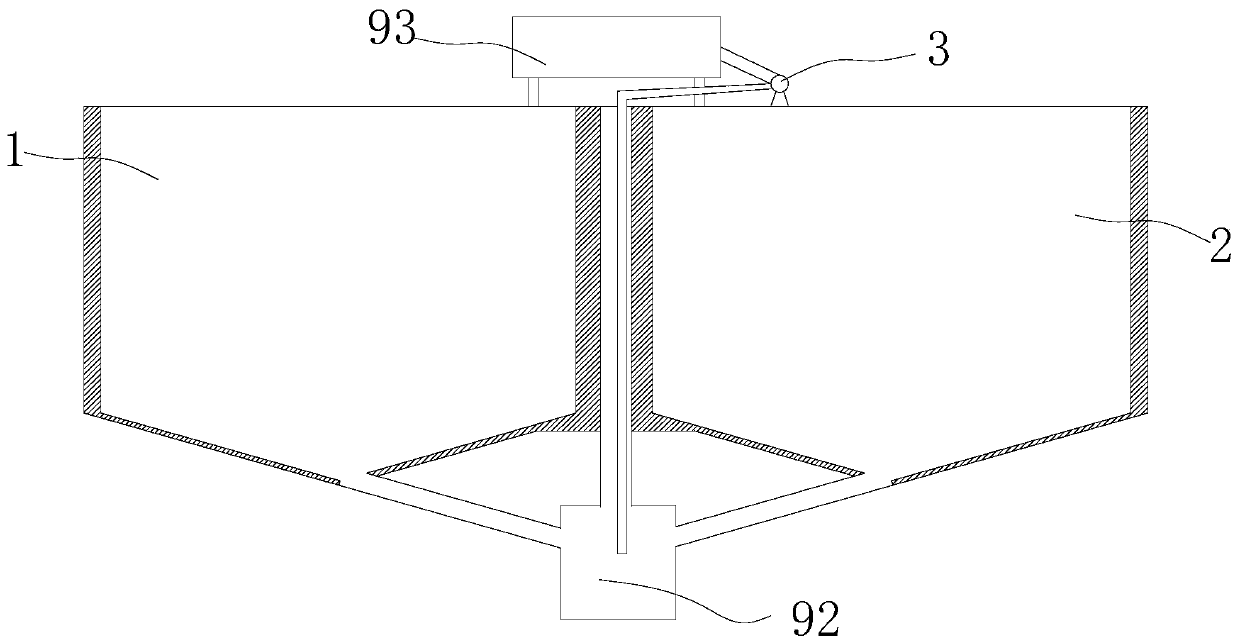

[0036] The present invention is described in detail below in conjunction with accompanying drawing description:

[0037] Such as Figure 1-6 Shown, the present invention is a kind of aquaculture tail water treatment system, comprises

[0038] The main sedimentation tank 1 is used to receive the tail water transported from the culture tank, and the bottom surface of the main sedimentation tank 1 is a slope or a funnel-shaped bottom surface;

[0039] The auxiliary sedimentation tank 2 is adjacent to the main sedimentation tank 1, and the bottom surface of the auxiliary sedimentation tank 2 is a slope or a funnel-shaped bottom surface; when the tail water in the main sedimentation tank 1 exceeds the threshold, the tail water in the main sedimentation tank 1 flows into the auxiliary sedimentation tank 2;

[0040] Here, the upper part of the junction of the main sedimentation tank and the auxiliary sedimentation tank is provided with a gap 91 or an opening or a channel pipe. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com