Glutathione-protected strong-fluorescence-emission gold-platinum alloy nano-cluster and controllable preparation method thereof

A glutathione, fluorescence emission technology, applied in nanotechnology, nano-optics, nanotechnology and other directions, can solve the problem of limited reports of near-infrared fluorescence emission nanoclusters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

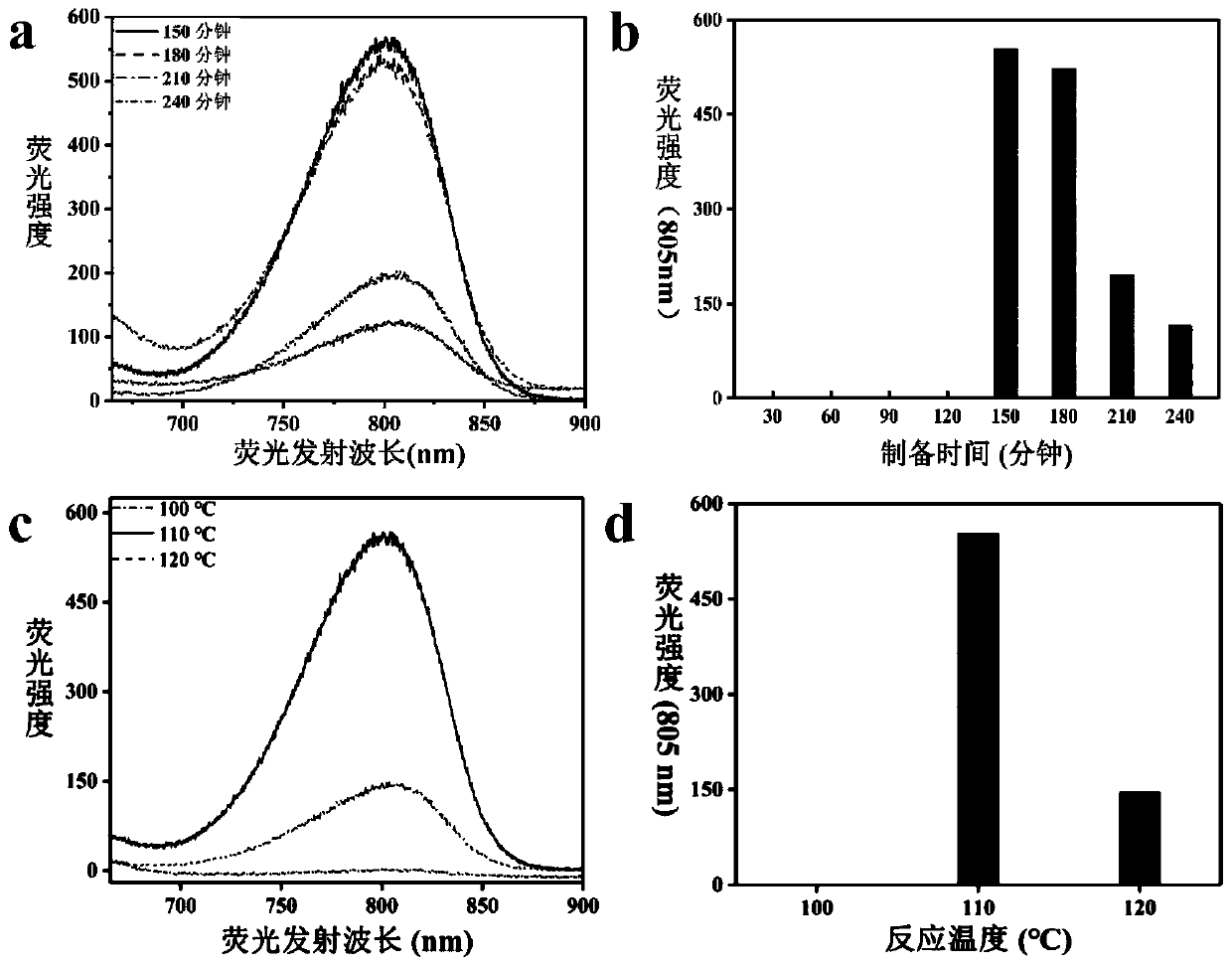

[0025] In this example, the effect of different reaction times on the fluorescence intensity of the nanoclusters is mainly explored. Add 800 microliters and 100 microliters of chloroauric acid trihydrate aqueous solution and chloroplatinic acid hexahydrate aqueous solution with a concentration of 10 mmol / ml into the polytetrafluoroethylene lining of the stainless steel reaction kettle, stir well, and then add a concentration of 100 microliters. 360 microliters of glutathione aqueous solution in millimolar / milliliter, and then add 400 microliters, 500 millimoles / ml of sodium citrate (CA) aqueous solution. Finally, deionized water was added to make the volume of the solution 10 ml. After stirring evenly, the polytetrafluoroethylene lining was transferred to a stainless steel reaction kettle, which was placed in an oven whose temperature was set at 110°C for hydrothermal reaction. Then take out the reaction kettle after 30, 60, 90, 120, 150, 180, 210 and 240 minutes respectively,...

Embodiment 2

[0028] In this example, the effect of different reaction temperatures on the fluorescence intensity of the nanoclusters was mainly explored. Add 800 microliters and 100 microliters of chloroauric acid trihydrate aqueous solution and chloroplatinic acid hexahydrate aqueous solution with a concentration of 10 mmol / ml into the polytetrafluoroethylene liner, stir well, and then add a concentration of 100 millimolar 360 microliters of glutathione aqueous solution per milliliter, and then add 400 microliters, 500 mmol / ml of sodium citrate (CA) aqueous solution. Finally, deionized water was added to make the volume of the solution 10 ml. After stirring evenly, the polytetrafluoroethylene lining was transferred to a stainless steel reaction kettle. The stainless steel reaction kettle was placed in an oven. Thermal reaction, the reaction time is 150 minutes. After the reaction, the reactor was taken out and cooled to room temperature to obtain Au-PtNCs@GSH prepared under different rea...

Embodiment 3

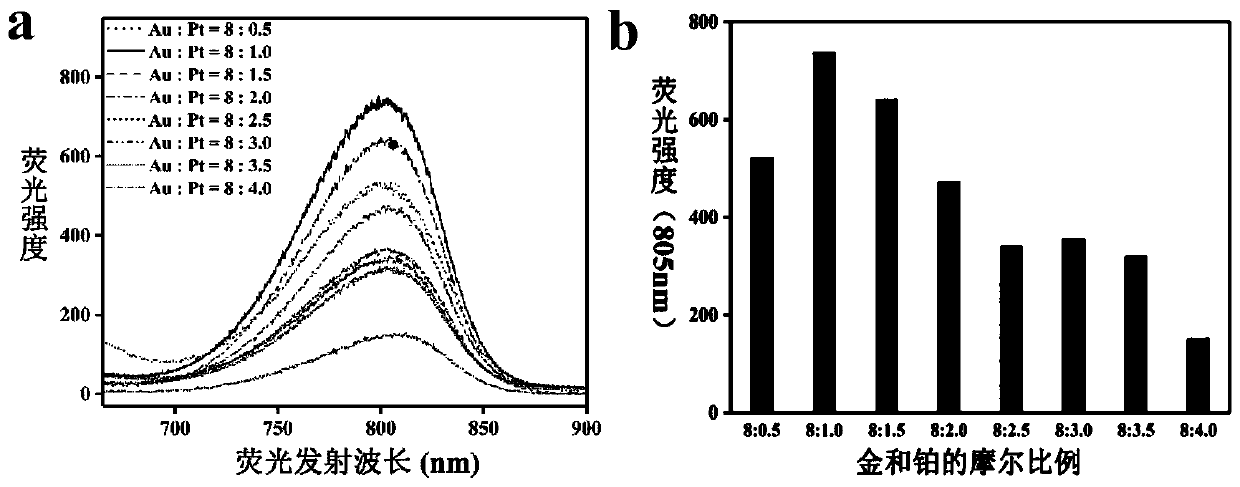

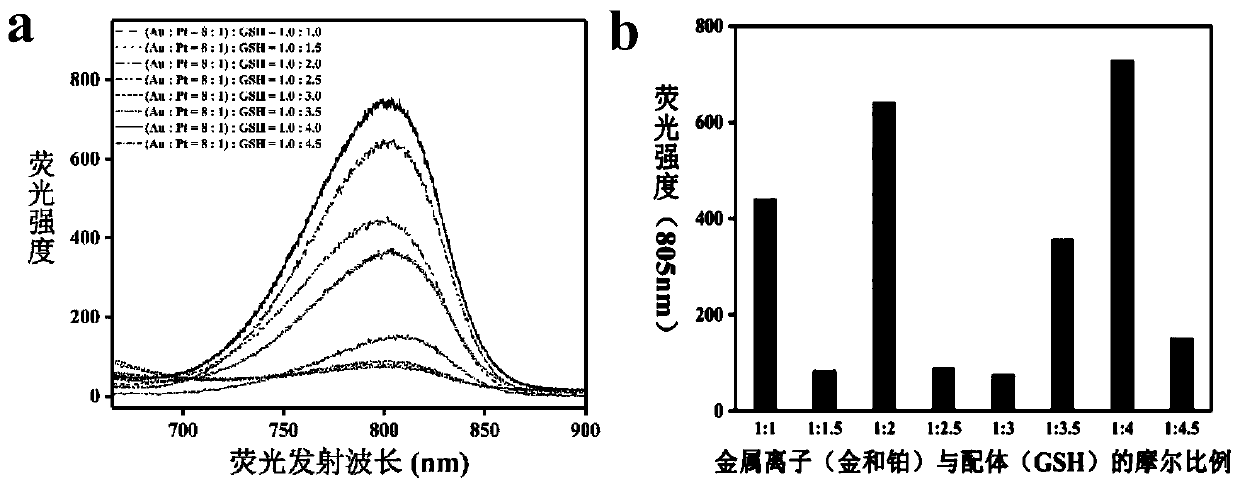

[0031] In this example, the effect of different molar ratios of chloroauric acid to chloroplatinic acid on the fluorescence intensity of the nanoclusters is mainly explored. In the polytetrafluoroethylene liner, adding concentration is 800 microliters of chloroauric acid trihydrate aqueous solution of 10 mmol / ml, and then respectively adding 50, 100, 200, 100, 200, After stirring 300 and 400 microliters evenly, add 100 mmol / ml glutathione (GSH) aqueous solution 340, 360, 400, 440 and 480 microliters respectively, and then add 400 microliters, 500 mmol / ml Sodium citrate (CA) aqueous solution. Finally, deionized water was added to make the volume of the solution 10 ml. After stirring evenly, the polytetrafluoroethylene lining was transferred to a stainless steel reaction kettle. The stainless steel reaction kettle was placed in an oven, and the temperature of the oven was set at 110°C for hydrothermal reaction for 150 minutes. After the reaction, it was cooled to room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com