Constant-temperature structure for high-performance gas detection device and preparation method

A gas detection, high-performance technology, applied in the field of sensors, can solve the problems of affecting the degree of sensitivity and the sensitivity of sensing signals, changes in electrical and physical properties, and small gas sensing area, so as to facilitate miniaturization, improve sensitivity, and detect sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

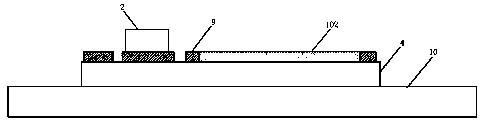

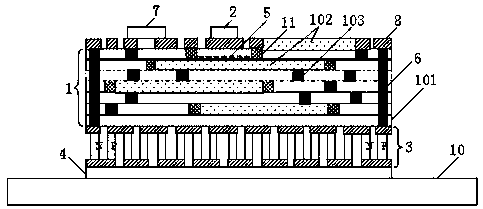

[0029] Example. A constant temperature structure for a high-performance gas detection device, consisting of figure 2 shown, including top Al 3 N 4 Substrate unit 1, top layer Al 3 N 4 The lower surface of the substrate unit 1 is integrated with the TEC unit 3, and the lower surface of the TEC unit 3 is integrated with the underlying Al 3 N 4 Substrate 4; The top layer Al 3 N 4 The substrate unit 1 consists of more than one layer of perforated Al 3 N 4 The substrates 101 are stacked in the vertical direction, and each layer is perforated with Al 3 N 4 Thin-film gas-sensitive resistors 102 are integrated on the substrate 101, and each layer is perforated with Al 3 N 4 The via holes of the substrate 101 are all filled with fillers 103; 3 N 4 The second layer from the top layer of substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com