Display panel and preparation method thereof

A technology for display panels and substrates, used in static indicators, instruments, electrical components, etc., can solve the problem of inability to guarantee the high-quality display quality of display panels, and achieve the effects of avoiding poor display, accurate control, and reducing dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

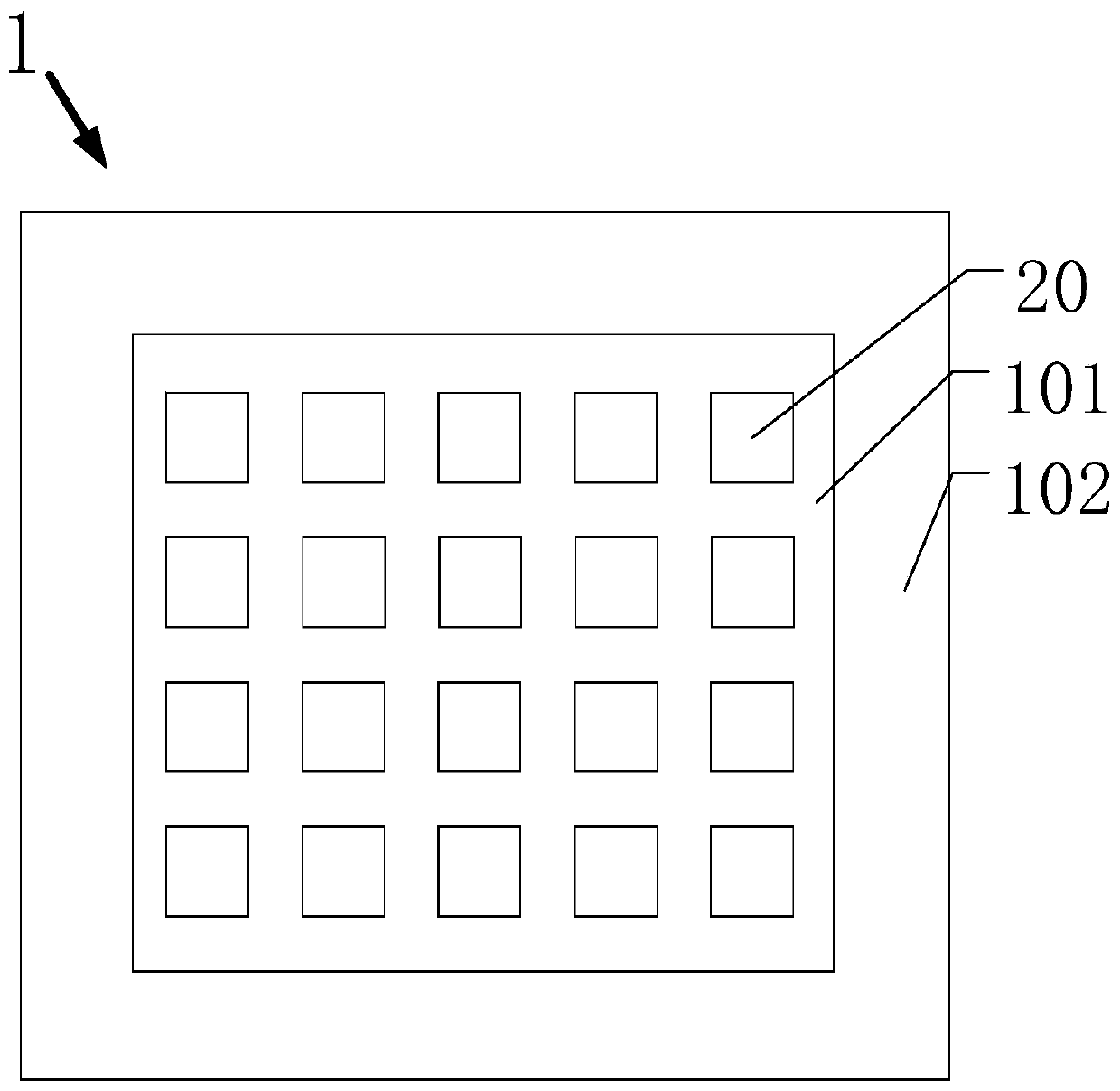

[0040] Such as figure 1 with Figure 8 As shown, in this embodiment, the display panel 1 of the present invention includes a first substrate 10 , LED chips 20 , a protective layer 30 and a reflective layer 40 .

[0041] The display panel 1 further includes a light emitting area 101 and a non-light emitting area 102 surrounding the light emitting area 101;

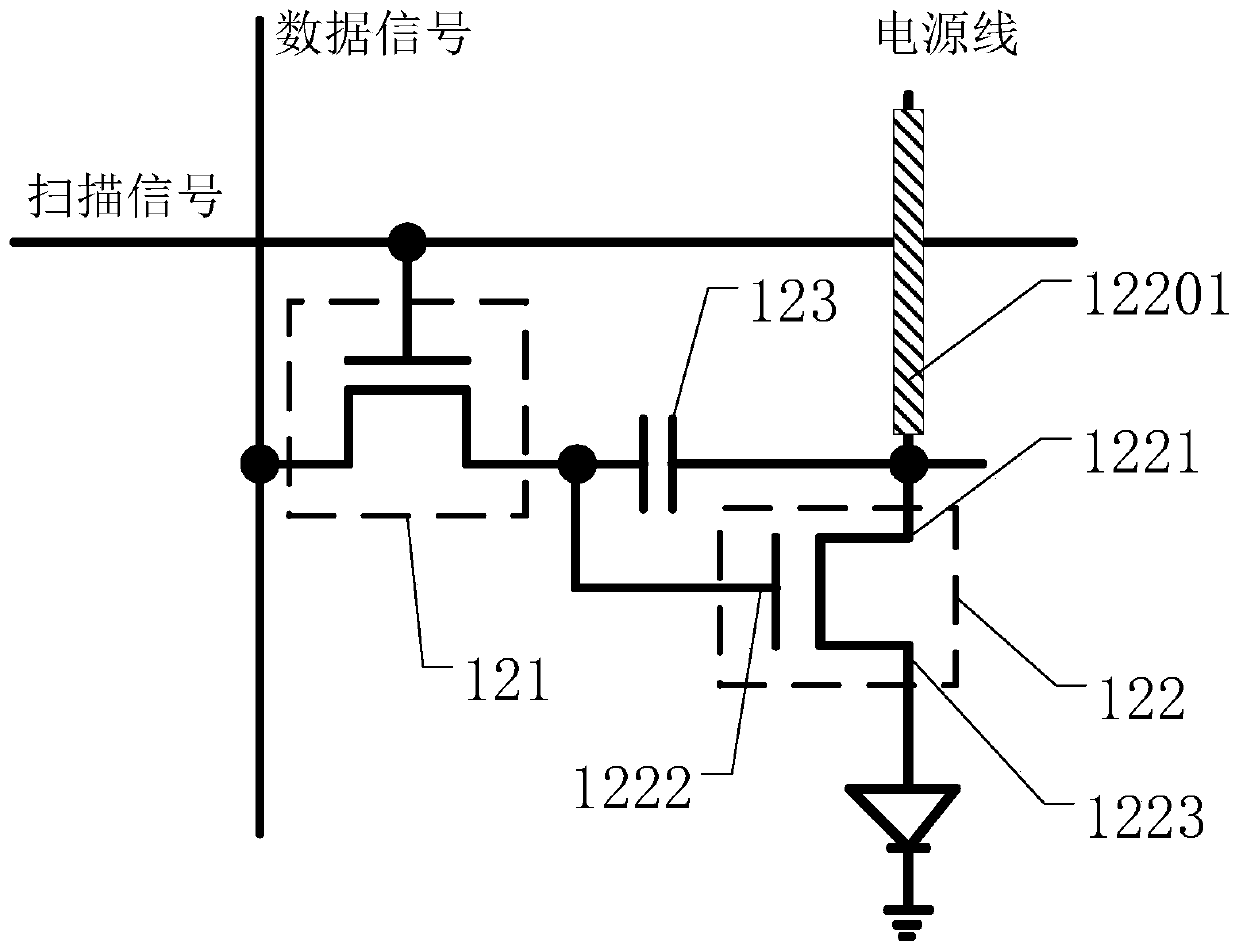

[0042] Such as Figure 5 As shown, the first substrate 10 includes a substrate 110 , a thin film transistor unit 120 , a data line 130 , a power line 140 and a GOA circuit 150 .

[0043] The LED chips 20 on the display panel 1 are individually controlled by the corresponding thin film transistor unit 120, so that the display panel 1 can realize partitioned display, thereby making the display picture more delicate and improving the display quality.

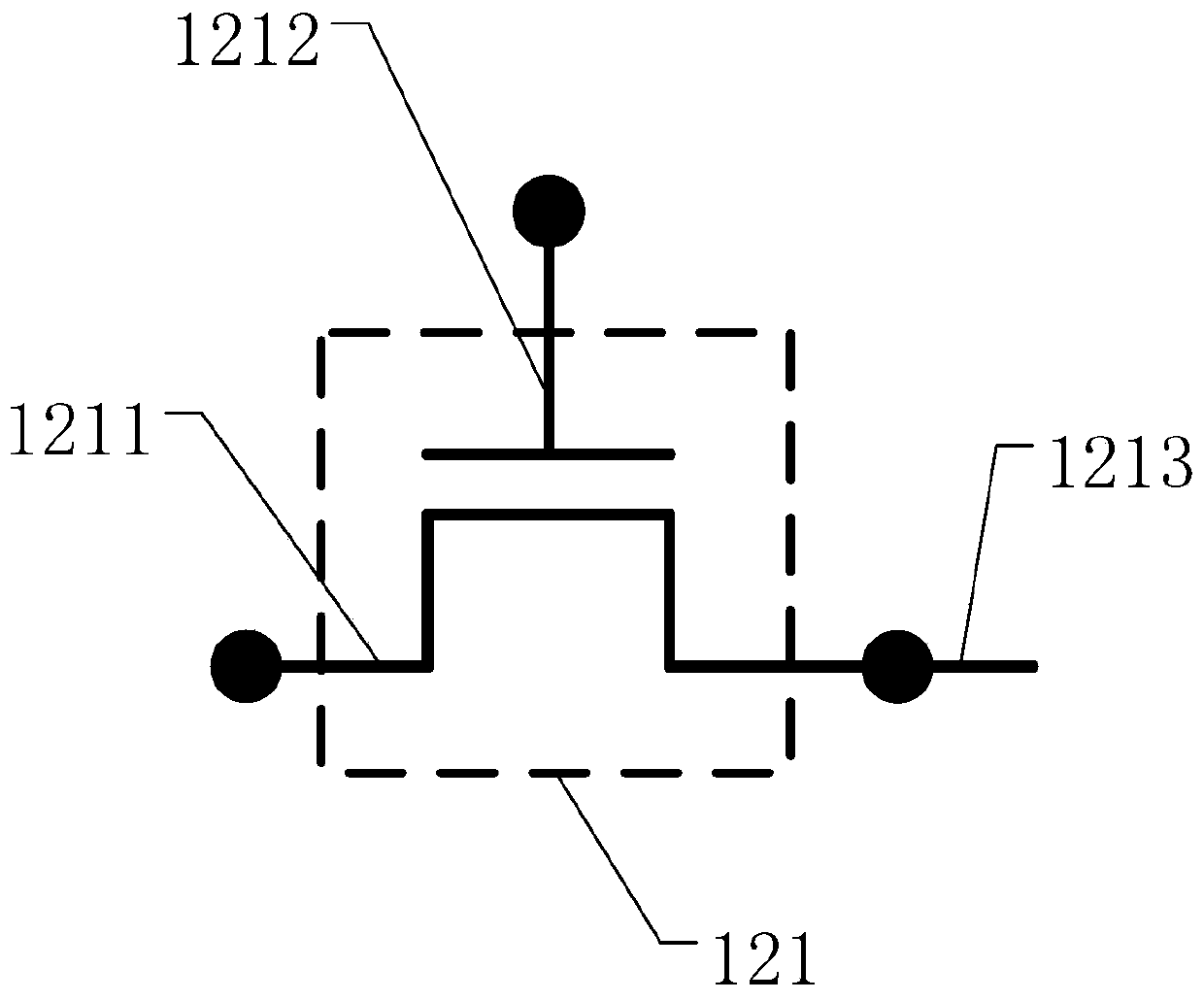

[0044] Such as figure 2 with image 3 As shown, specifically, a plurality of thin film transistor units 120 are arranged on the first substrate 10, and each thin film tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com