Method for improving photoelectric efficiency of organic polymer solar cell

A technology for solar cells and photoelectric efficiency, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of limited improvement of photoelectric efficiency of organic polymer solar cells, achieve superior wettability and permeability, and reduce hole transport The effect of speed attenuation and photoelectric efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for improving the photoelectric efficiency of organic polymer solar cells includes the following steps:

[0034] S1. Physically blend 2g of donor material and 2g of acceptor material in 10ml of toluene to form a precursor,

[0035] S2. Add 0.5wt% of polyethylene glycol of the precursor to the above precursor, and use the method of magnetic stirring to mix uniformly at room temperature to form a blended material.

[0036] S3. Using the above blended material as the active layer, spin-coated on the anode substrate in the organic polymer solar cell;

[0037] Among them, the thickness of the active layer is 20 nm.

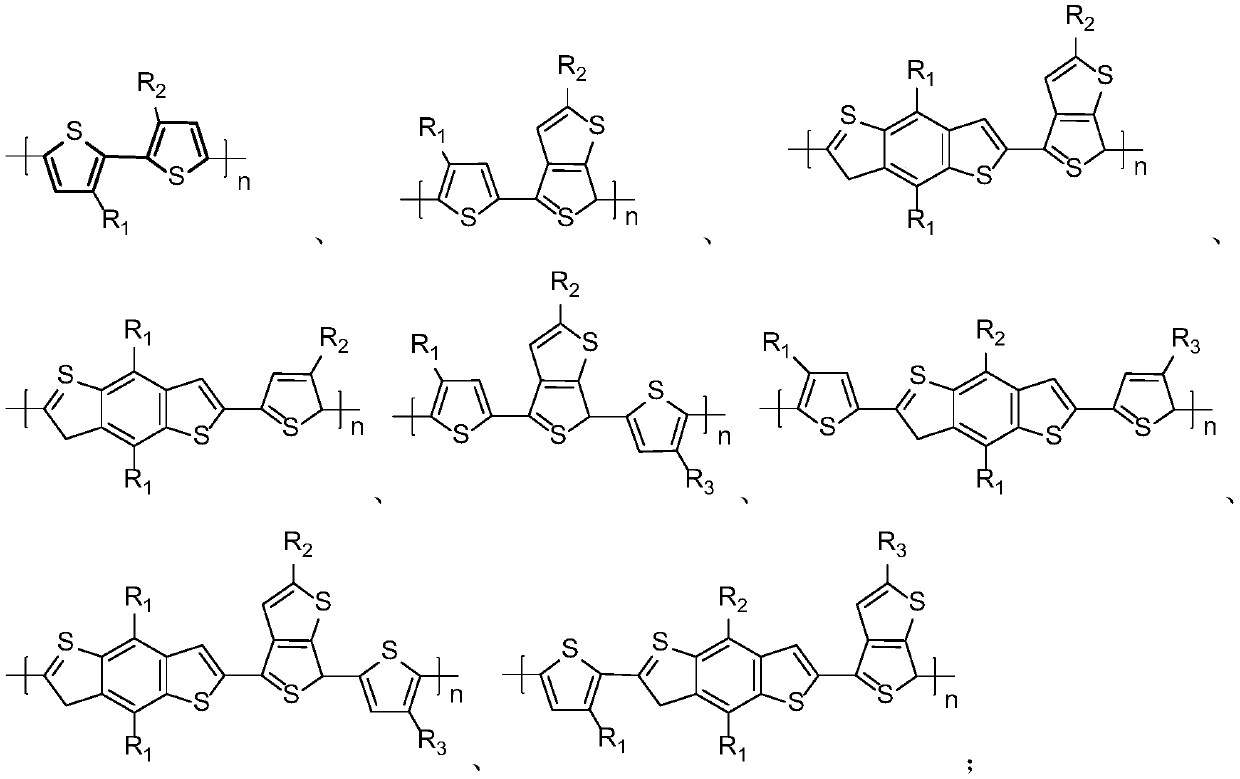

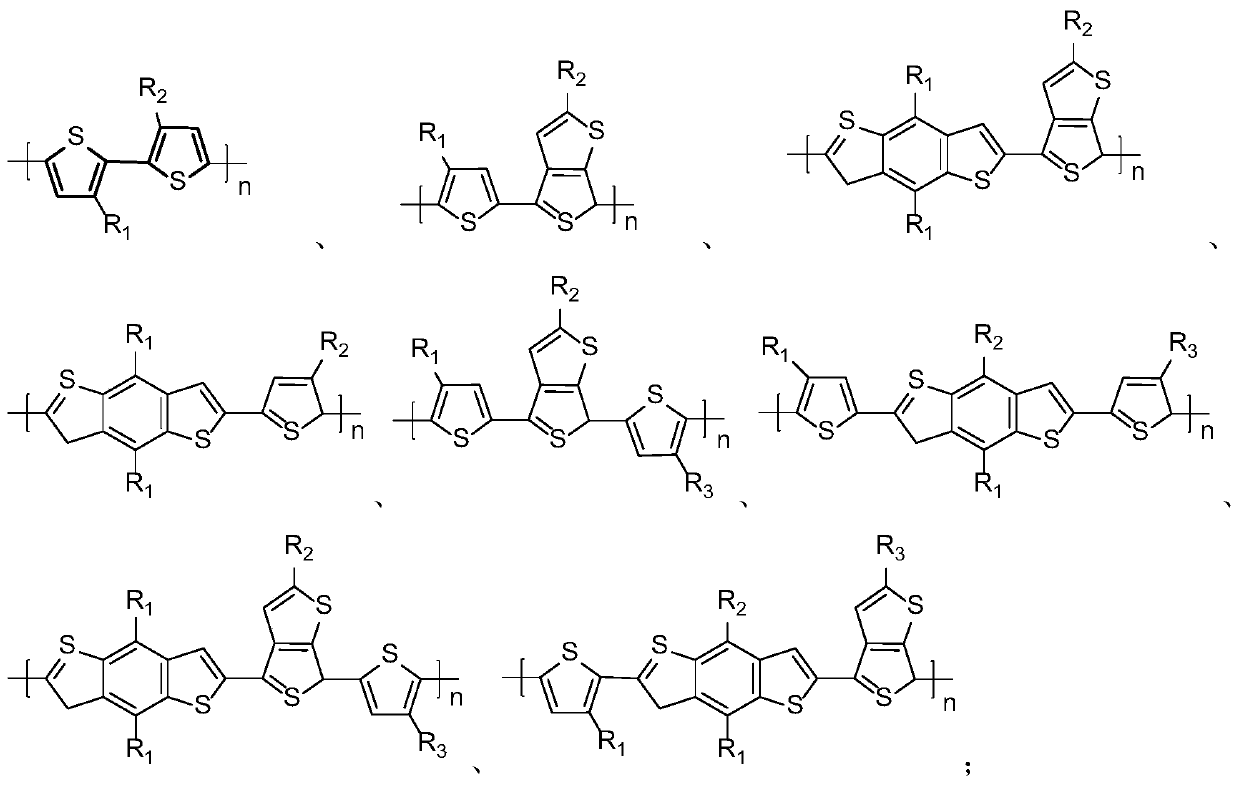

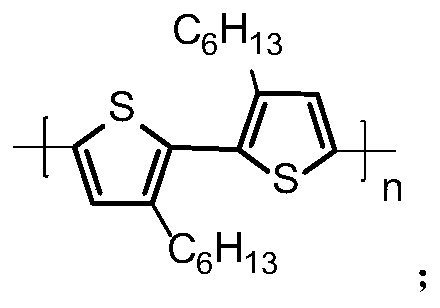

[0038] The chemical structure of the donor material is as follows:

[0039]

[0040] The molecular weight of the donor material is 23000 Da, PDI = 2.12;

[0041] Acceptor material selected from PC 61 BM;

[0042] The number average molecular weight of polyethylene glycol is 600.

[0043] The polyethylene glycol is pretreated before use, and the steps include:

[0044]...

Embodiment 2

[0050] A method for improving the photoelectric efficiency of organic polymer solar cells includes the following steps:

[0051] S1. Physically blend 8g of donor material and 2g of acceptor material in 14ml of toluene to form a precursor,

[0052] S2. Add the polyethylene glycol of the precursor with a mass of 1 wt% to the precursor, and use the method of magnetic stirring to mix uniformly at room temperature to form a blended material,

[0053] S3. Using the above blended material as the active layer, spin-coated on the anode substrate in the organic polymer solar cell;

[0054] Among them, the thickness of the active layer is 100 nm.

[0055] The chemical structure of the donor material is as follows:

[0056]

[0057] The molecular weight of the donor material is 15500 Da, PDI=1.82;

[0058] Acceptor material selected from PC 71 BM;

[0059] The number average molecular weight of polyethylene glycol is 2,000.

[0060] The polyethylene glycol is pretreated before use, and the steps includ...

Embodiment 3

[0067] A method for improving the photoelectric efficiency of organic polymer solar cells includes the following steps:

[0068] S1. Physically blend 4g of donor material and 2g of acceptor material in 12ml of toluene to form a precursor,

[0069] S2. Add 0.75wt% of polyethylene glycol of the precursor to the aforementioned precursor, and use a magnetic stirring method to mix uniformly at room temperature to form a blended material.

[0070] S3. Using the above blended material as the active layer, spin-coated on the anode substrate in the organic polymer solar cell;

[0071] Among them, the thickness of the active layer is 80 nm.

[0072] The chemical structure of the donor material is as follows:

[0073]

[0074] The molecular weight of the donor material is 14,500 Da, PDI=1.98;

[0075] Acceptor material selected from PC 71 BM;

[0076] The number average molecular weight of polyethylene glycol is 1,500.

[0077] The polyethylene glycol is pretreated before use, and the steps include:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com