Preparation method of Si-based substrate heterogeneous integrated graphene

A technology of graphene and graphene layers, applied in the direction of graphene, nano-carbon, etc., can solve the problems of incompatibility of substrate materials with common processes, difficulty in controlling the size of graphene films, etc., and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Such as Figure 1 to Figure 7 As shown, the present embodiment provides a method for fabricating a Si-based substrate heterogeneously integrated graphene film, comprising steps:

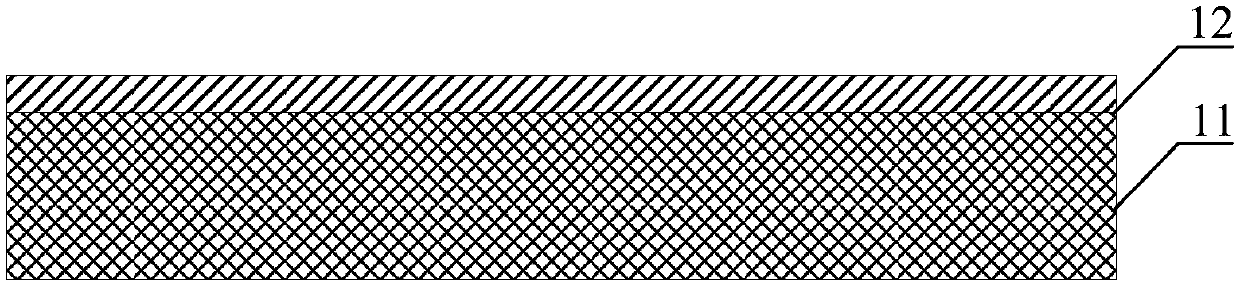

[0079] Such as figure 1 As shown, step 1) is performed to provide a Si-based substrate 11, and a dielectric layer 12 is formed on the upper surface of the Si-based substrate.

[0080] Optionally, the material of the dielectric layer 12 includes but not limited to silicon oxide, aluminum oxide, and silicon nitride.

[0081] As an example, silicon oxide is selected as the dielectric layer in step 1).

[0082] Optionally, the thickness of the dielectric layer 12 is greater than 0 nm and less than or equal to 1 μm.

[0083] Optionally, the growth method of the dielectric layer 12 includes but not limited to thermal oxidation method and vapor phase deposition method.

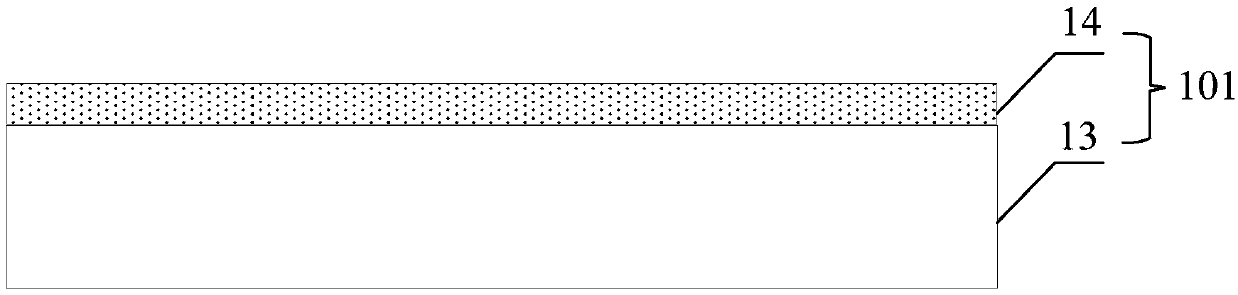

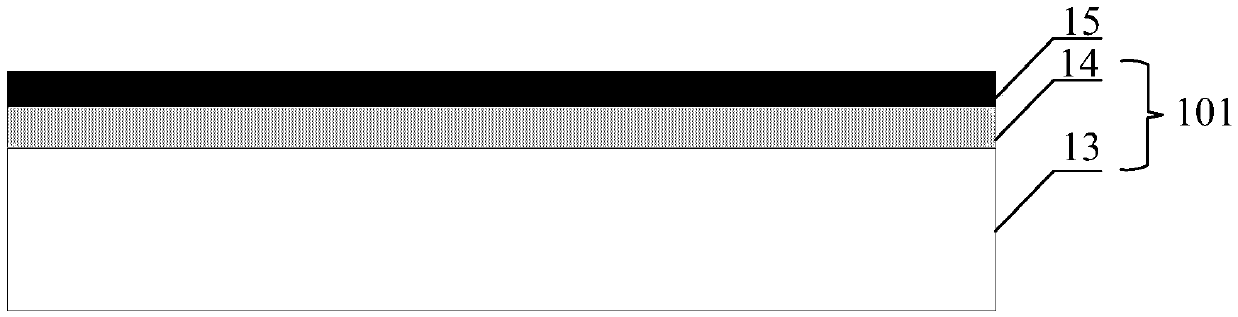

[0084] Such as figure 2 As shown, step 2) is performed to provide a composite structure 101, the composite structure 101 incl...

Embodiment 2

[0113] Such as Figure 8 ~ Figure 14 As shown, the present embodiment provides a method for fabricating a Si-based substrate heterogeneously integrated graphene film, comprising steps:

[0114] Such as Figure 8 As shown, step 1) is performed to provide a Si-based substrate 21, and a dielectric layer 22 is formed on the upper surface of the Si-based substrate.

[0115] Optionally, the material of the dielectric layer 22 includes but not limited to silicon oxide, aluminum oxide, and silicon nitride.

[0116] Optionally, the thickness of the dielectric layer 22 is greater than 0 nm and less than or equal to 1 μm.

[0117] Optionally, the growth method of the dielectric layer 22 includes but not limited to thermal oxidation method and vapor phase deposition method.

[0118] Such as Figure 9 As shown, step 2) is performed to provide a composite structure 201, the composite structure 201 includes a sacrificial substrate 23 and a metal layer 24 covering the surface of the sacri...

Embodiment 3

[0144] Such as Figure 15 ~ Figure 20 As shown, the present embodiment provides a method for fabricating a Si-based substrate heterogeneously integrated graphene film, comprising steps:

[0145] Such as Figure 15 As shown, step 1) is performed to provide a Si-based substrate 31, and a dielectric layer 32 is formed on the upper surface of the Si-based substrate.

[0146] Optionally, the material of the dielectric layer 32 includes but not limited to silicon oxide, aluminum oxide, and silicon nitride.

[0147] Optionally, the thickness of the dielectric layer 32 is greater than 0 nm and less than or equal to 1 μm.

[0148] Optionally, step 1) further includes planarizing the Si-based substrate dielectric layer 32 .

[0149] As an example, the Si-based substrate dielectric layer 32 is planarized so that the surface of the dielectric layer is atomically flat.

[0150] Optionally, the planarization method includes but not limited to chemical mechanical polishing and ion beam p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com