Elastic coupler for supporting propeller thrust direct transmission

An elastic coupling and propeller technology, applied in the direction of elastic coupling, coupling, propulsion power transmission, etc., can solve the damage to the health and comfort of the crew, affect the normal operation of the equipment and instruments on the ship, and the hull of the ship. Structural fatigue damage and other problems, to achieve the effect of wide applicability, strong installation adaptability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

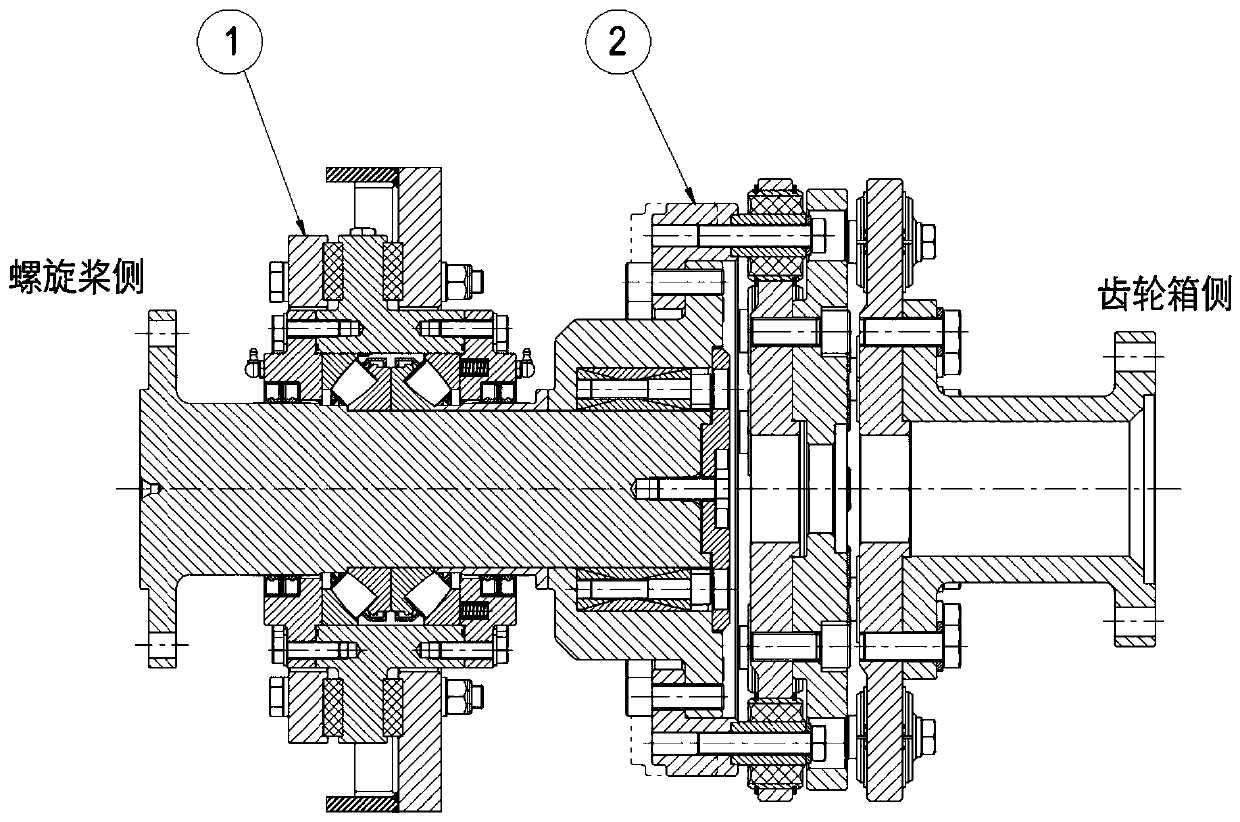

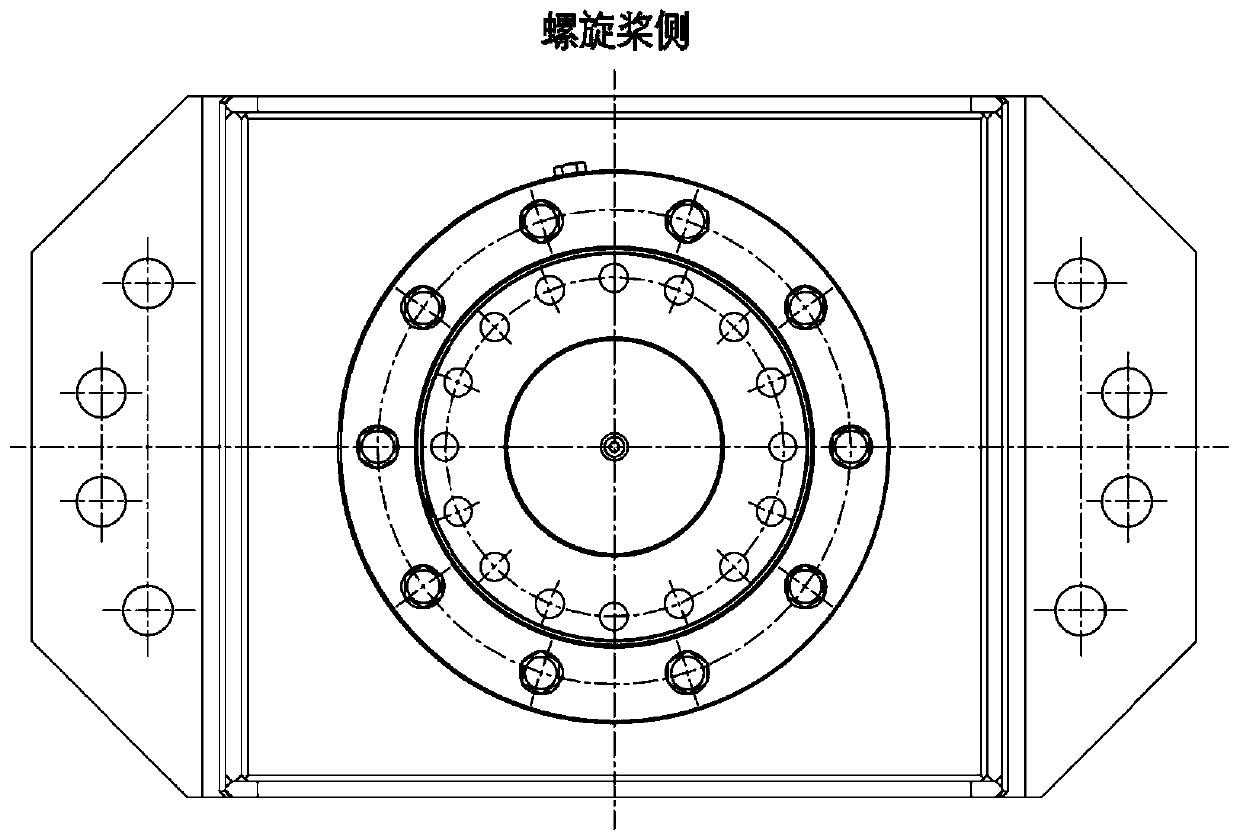

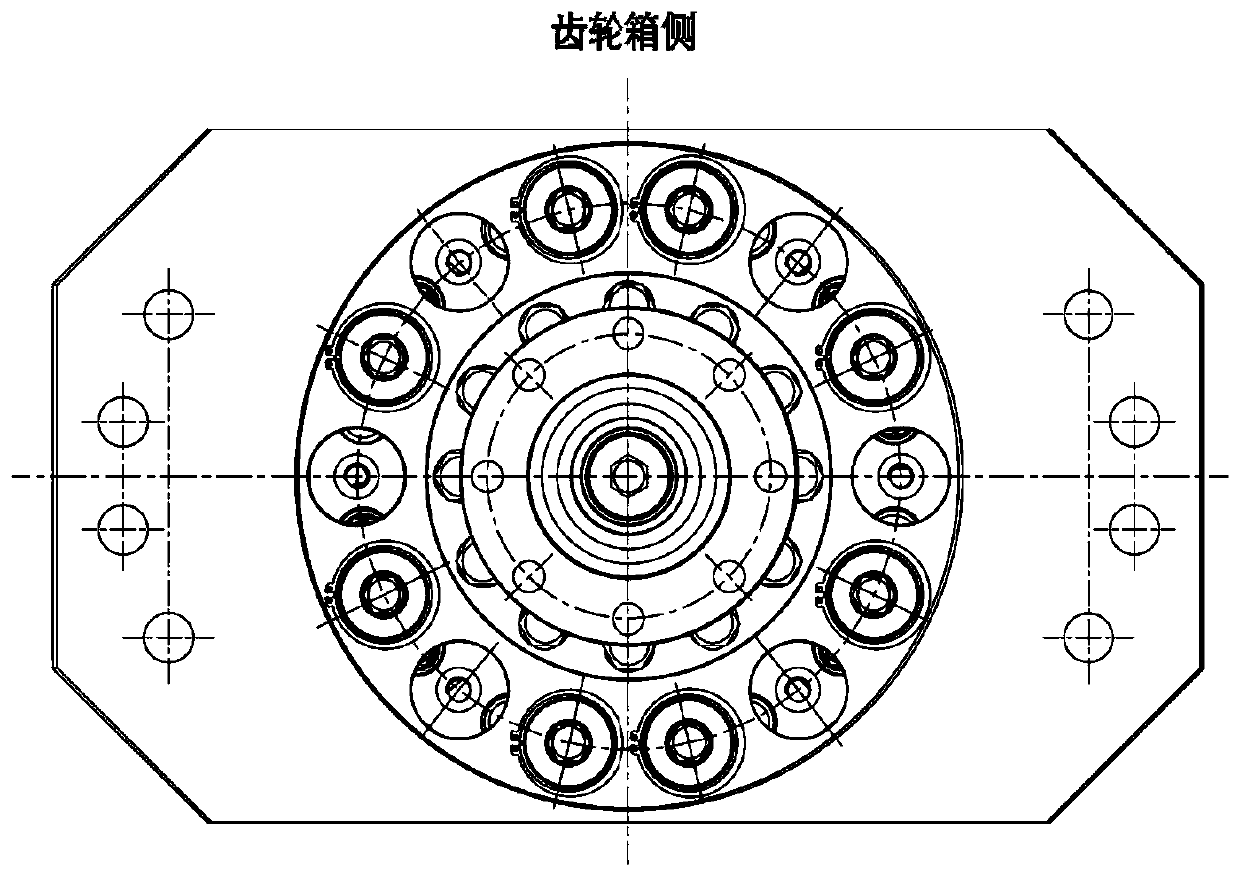

[0033] Such as figure 1 As shown, an elastic coupling supporting propeller thrust direct transmission includes a thrust bearing assembly 1 connected to the propeller, and an elastic coupling assembly 2 connected to the gearbox, the thrust bearing assembly 1 and the elastic coupling assembly 2 connected in series, wherein the main function of the thrust bearing assembly 1 is to carry the thrust on the hull formed by the propeller of the stern shaft and the water flow, as figure 2 As shown, the stern shaft is conventionally connected to the thrust bearing assembly 1 in the form of flange connection. Such as image 3 As shown, the main function of the elastic coupling assembly 2 is to efficiently transmit the torque on the power output shaft of the gearbox to the stern shaft, and it has torsional vibration isolation, axial displacement, radial displacement, and angular displacement compensation capabilities. It is usually connected to the output power shaft of the gearbox in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com