Method for preparing ultralow-temperature lithium ion battery cathode slurry

A lithium-ion battery, cathode slurry technology, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve the problems of low cycle times, material cycle stability degradation, short service life, etc., to reduce electrode polarization , stable electrochemical performance, make up for the effect of poor safety and overshoot resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

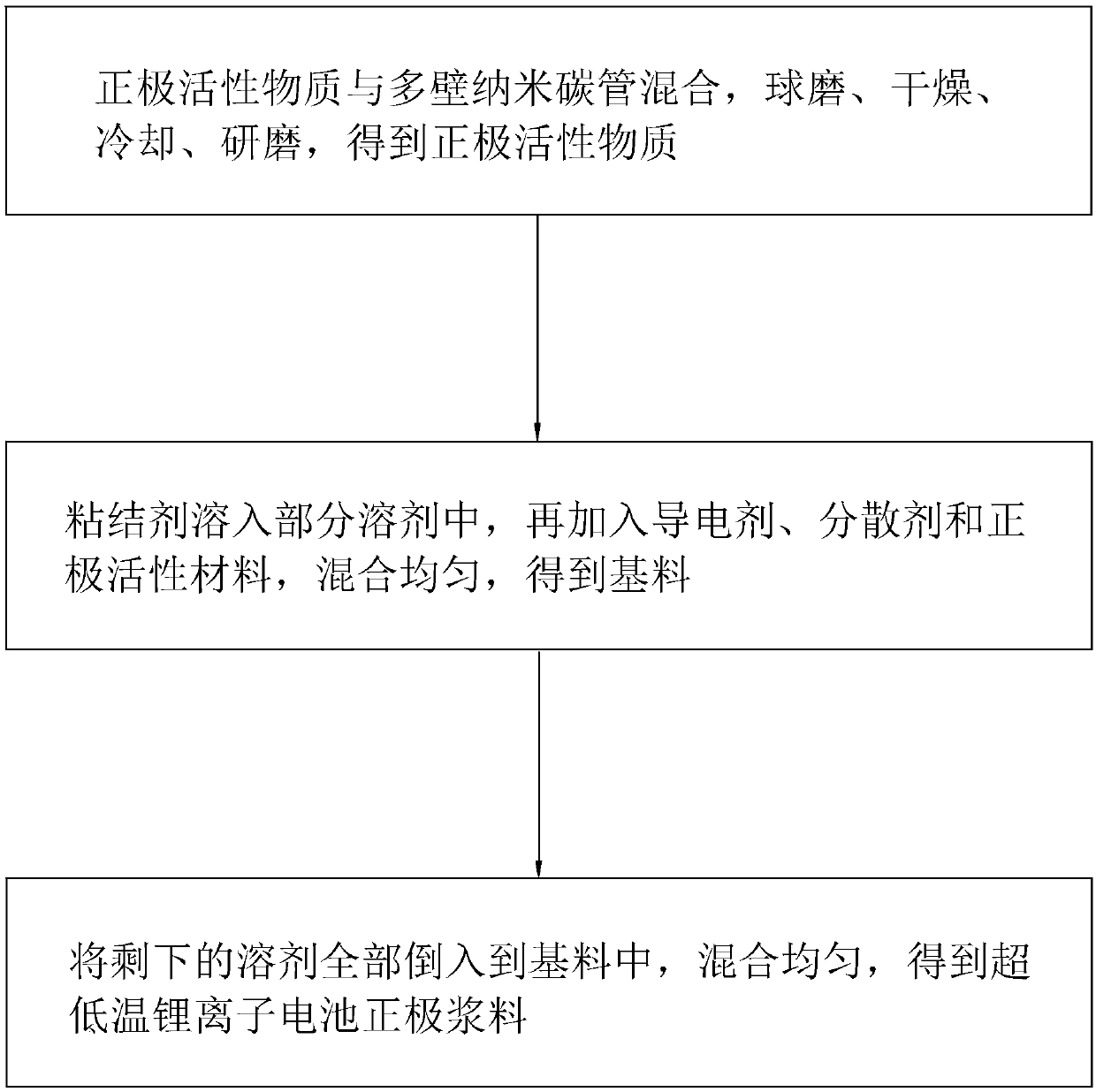

[0030] Embodiment 1: a kind of method of ultra-low temperature lithium-ion battery positive electrode slurry batching, comprises the following steps:

[0031] (a) Mix positive electrode active material and multi-walled carbon nanotubes, put into a ball mill and carry out ball milling at a speed of 300r / min for 3h, wherein the ball-to-material ratio is 8:1, and then place the ball-milled mixture in a vacuum drying oven Drying for 12 hours, fully grinding for 1 hour after cooling, to obtain the positive electrode active material;

[0032] (b) dissolving the binder in one-third of the solvent, then adding a conductive agent, a dispersant and a positive electrode active material, stirring at a speed of 30 r / min for 2 hours, and mixing evenly to obtain a base material;

[0033] (c) Add the remaining two-thirds of the solvent into the base material, stir at a speed of 30 r / min for 2 hours, and mix evenly to obtain a cathode slurry for an ultra-low temperature lithium ion battery.

...

Embodiment 2

[0037] Embodiment 2: a kind of method of ultra-low temperature lithium-ion battery positive electrode slurry batching, and the difference of embodiment 1 is:

[0038] The mass ratio among the positive electrode active material, the binder, the solvent, the conductive agent and the dispersant is 93:3:255:0.75:0.07.

[0039] LiCoPO 2 、LiFePO 4 The mass ratio between carbon nanotubes and multi-walled carbon nanotubes is 46.5:46.5:5.17.

Embodiment 3

[0040] Embodiment 3: a kind of method of ultra-low temperature lithium-ion battery positive electrode slurry batching, and the difference of embodiment 1 is:

[0041] The mass ratio among the positive electrode active material, the binder, the solvent, the conductive agent and the dispersant is 94:4:280:1:0.1.

[0042] LiCoPO 2 、LiFePO 4 The mass ratio between and multi-walled carbon nanotubes is 47:47:4.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com