Zinc sulfide@carbon composite microsphere and preparation method and application thereof

A technology of carbon composite and zinc sulfide, applied in chemical instruments and methods, manufacturing of hybrid/electric double-layer capacitors, electrochemical generators, etc., can solve problems such as poor cycle stability, and achieve strong conductivity, uniform appearance, and structural firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

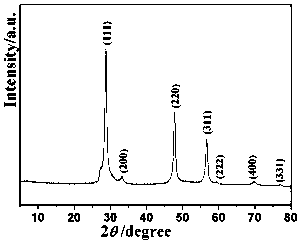

Image

Examples

Embodiment 1

[0037] Under stirring, 4 mmol of zinc gluconate and 12 mmol of thiourea were dissolved in 60 mL of water to form a transparent solution. The concentration of zinc gluconate in the solution was 0.067 mol / L, and the molar ratio of zinc gluconate to thiourea was 1:3. This solution was transferred to a 100 mL stainless steel reactor lined with polytetrafluoroethylene. Place in a dry box and react at 200°C for 24 hours. Then it was naturally cooled to room temperature, and the resulting brown-black precipitate was rinsed three times with deionized water and absolute ethanol, separated by centrifugation and vacuum-dried at 60° C. for 12 hours. The obtained solid product was heat-treated at 500° C. for 2 hours in an argon atmosphere to obtain the product.

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is that the concentration of zinc gluconate in this embodiment is 0.1mol / L, the molar ratio of zinc gluconate and thiourea is 1: 2.7, and the temperature of hydrothermal reaction is 220 ℃;

[0040] Other conditions and operation steps are identical with embodiment 1.

Embodiment 3

[0042] The difference between this embodiment and Example 1 is that the concentration of zinc gluconate in this embodiment is 0.03mol / L, the molar ratio of zinc gluconate and thiourea is 1: 2.5, and the temperature of the hydrothermal reaction is 180°C;

[0043] Other conditions and operation steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com