Loaded NiOOH electrode material, preparation method thereof and application of electrode material

An electrode material, nickel foam technology, applied in the field of supported NiOOH electrode material and its preparation, can solve the problems such as the activity of pure NiOOHOER that are rarely reported, and achieve a suitable for large-scale industrial production, large specific surface area, mild and controllable reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In the preparation method according to the present invention, the molar ratio of nickel (II) to dimethylglyoxime is 1:0.5 to 1:8, preferably 1:1 to 1:4, more preferably 1:1.5 to 1:3, The most preferred ratio is 1:2. When the molar ratio of nickel (II) to dimethylglyoxime is greater than 1:0.5, that is, the divalent nickel is excessive, it is easier to form nano-disc nickel on the surface of the foamed nickel, and it is stacked irregularly to cover the surface of the foamed nickel; When the molar ratio of nickel(II) to dimethylglyoxime is less than 1:8, that is, divalent nickel is insufficient, it is difficult to form regular nickel nanosheets. Considering the properties of nickel foam as the substrate, the molar ratio of nickel (II) to dimethylglyoxime is preferably 1:1.5 to 1:3, most preferably 1:2.

[0031] Hereinafter, the present invention will be described in detail. Before proceeding with the description, it should be understood that the terms used in this speci...

Embodiment 1

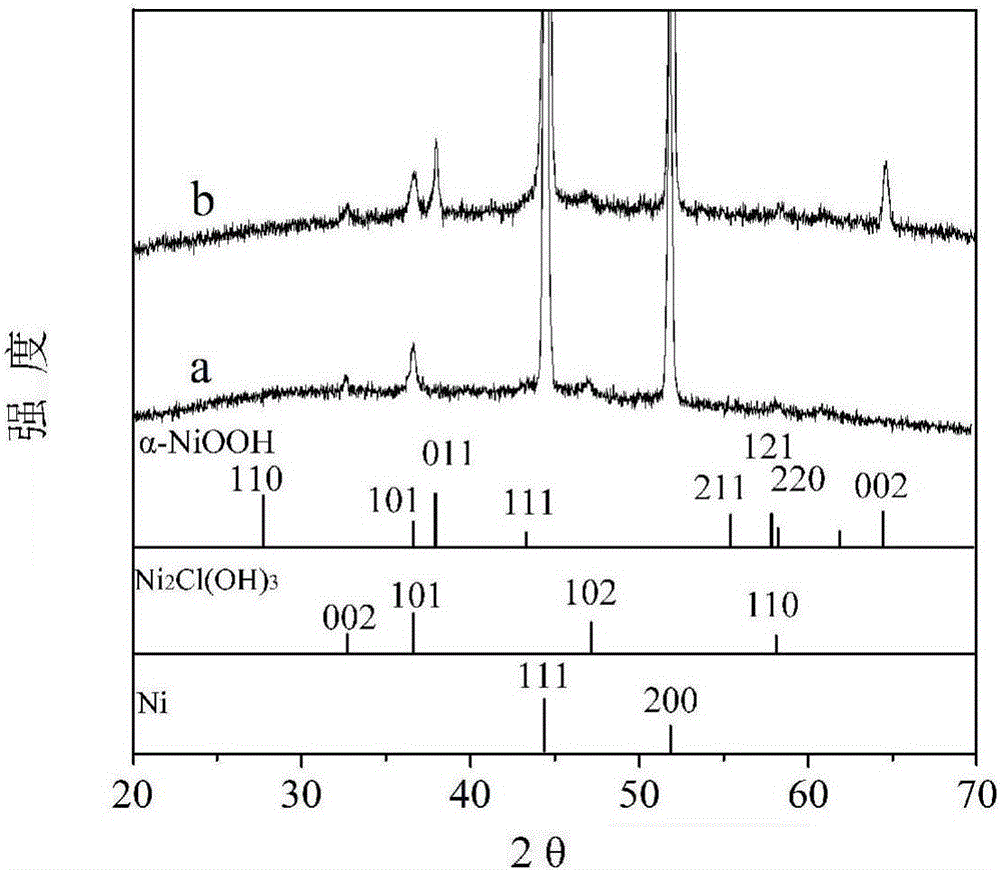

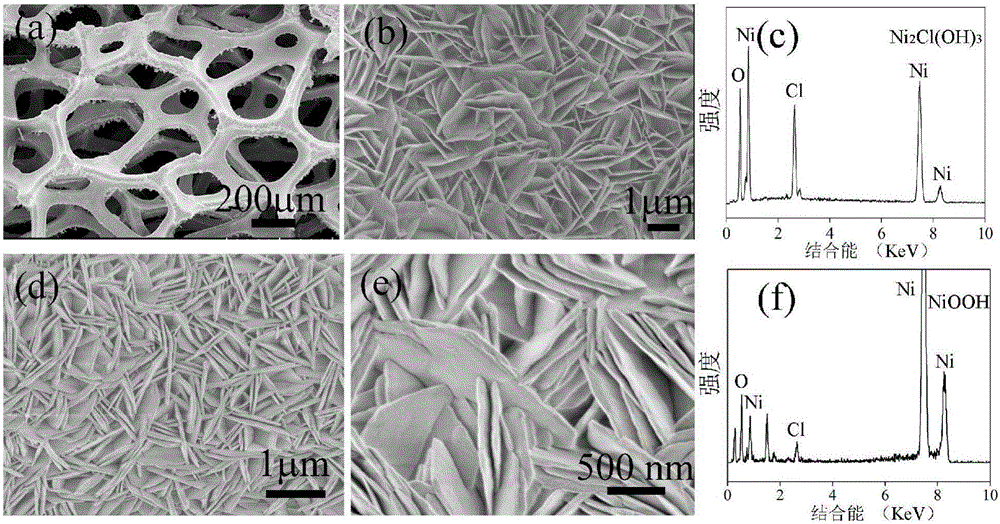

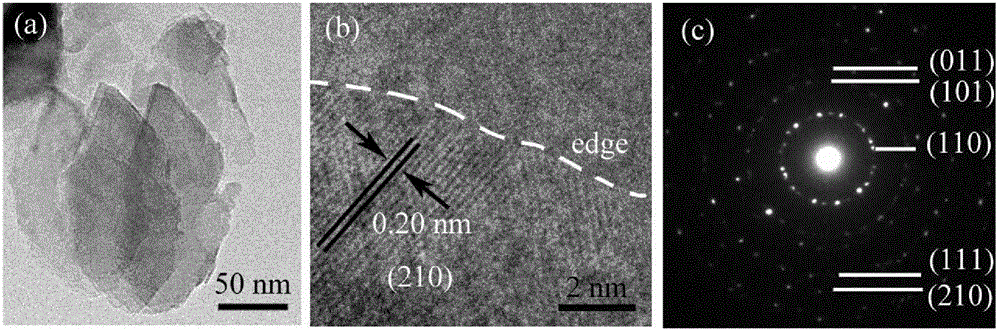

[0033] Embodiment 1: the preparation of the α-NiOOH nano sheet of nickel foam support

[0034]1) Pretreatment of nickel foam: at room temperature, ultrasonically ultrasonicate 1cm×3cm nickel foam in 3.0M HCl solution for 15min, then wash it several times with deionized water and absolute ethanol, and place it in the air for later use.

[0035] 2) Preparation of nickel (II) solution: weigh 0.5 mmol of NiCl 2 ·6H 2 O solid, dissolved in 20 mL deionized water.

[0036] 3) Preparation of dimethylglyoxime alcohol solution: Weigh 1 mmol of dimethylglyoxime solid and dissolve it in 20 mL of absolute ethanol.

[0037] 4) Take 8 mL of the solutions in the above steps 2) and 3) and add them to the polytetrafluoroethylene lining of the reaction kettle in turn. After stirring for 10 minutes, immerse the pretreated foamed nickel in it vertically, tighten the lid of the kettle, and put the reaction kettle Put it into an electric blast drying oven at 200°C and keep it for 6h.

[0038] 5)...

experiment Embodiment 1

[0063] Various electrical properties of the samples were measured using an electrochemical workstation (CHI 660D) from Beijing Huake Putian Technology Co., Ltd. In the three-electrode system, the prepared sample was used as the working electrode for linear sweep voltammetry, Tafel curve measurement, impedance spectrum measurement, active area measurement and stability measurement of the oxygen evolution reaction.

[0064] Electrochemical tests were performed using a three-electrode system, wherein the prepared sample was used as a working electrode, Hg / HgO was used as a reference electrode, Pt sheet was used as a counter electrode, and the electrolyte solution was 1.0M potassium hydroxide (pH=13.6).

[0065] According to the Nernst equation: E RHE =E Hg / HgO +0.098+0.059×pH (standard potential of mercury / mercury oxide electrode at 25°C: 0.098V)E RHE =E Hg / HgO +0.098+0.059×13.6=E Hg / HgO +0.9004

[0066] Linear sweep voltammetry (LSV) means that the potential applied to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com