Novel high-salt mercury-containing wastewater concentration method

A technology of wastewater concentration and high salt, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc. Operation cost, realization of evaporative crystallization, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A treatment method for high-salt mercury-containing wastewater, the specific steps are:

[0045] Step 1: the COD concentration is 322mg / L, PH is 7.6, mercury ion content 7ppb, chloride ion content 22323mg / L, sulfate ion content 65300mg / L high-salt mercury-containing waste water is injected in stock solution feeding tank 8, simultaneously The light brine after electrolysis of saturated brine, the specific NaCl content is 193-202g / L, and the pH is 8-11 is injected into the draw liquid feed tank;

[0046] Step 2: Use the raw liquid feed pump 9 to transport high-salt mercury-containing waste water, pass through the raw liquid filter 10, and then enter the inner wall side of the forward osmosis membrane module 4. After the liquid filter 3, enter the outer wall side of the forward osmosis membrane module 4;

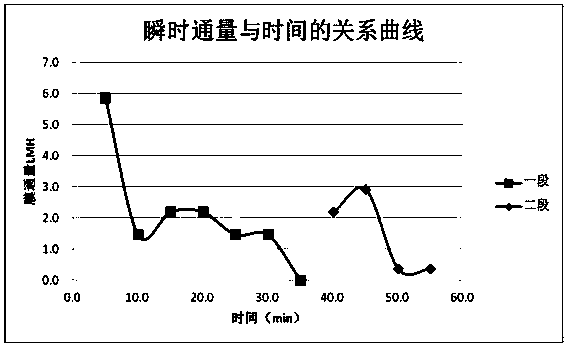

[0047] Step 3: After the draw solution passes through the forward osmosis membrane module, the solution will be diluted, and the osmotic pressure will tend to be consis...

Embodiment 2

[0053] A treatment method for high-salt mercury-containing wastewater, the steps of which are:

[0054] Step 1, the COD concentration is 322mg / L, PH is 7.6, mercury ion content 7ppb, chloride ion content 22323mg / L, the high-salt mercury-containing waste water of sulfate ion content 65300mg / L injects in the stoste feeding tank 8, simultaneously The light brine after electrolysis of saturated brine, with NaCl content of 182-191g / L and pH of 8-11, is injected into the draw liquid feeding tank;

[0055] Step 2, use the raw liquid feed pump 9 to transport high-salt mercury-containing wastewater into the raw liquid filter 10 and filter it, then enter the inner wall side of the forward osmosis membrane module 4, and use the draw liquid feed pump 2 to transport the light brine of the draw liquid through After the draw liquid filter 3, enter the outer wall side of the forward osmosis membrane module 4;

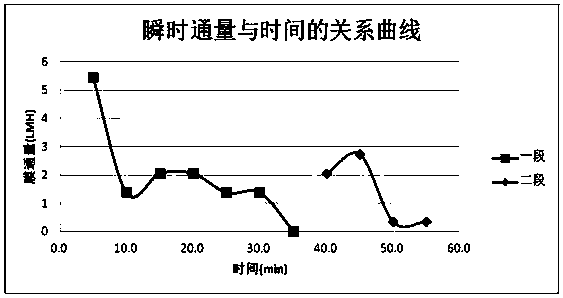

[0056] Step 3, after the draw solution passes through the forward osmosis membran...

Embodiment 3

[0062] A treatment method for high-salt mercury-containing wastewater, the steps of which are:

[0063] Step 1, the COD concentration is 322mg / L, PH is 7.6, mercury ion content 7ppb, chloride ion content 22323mg / L, sulfate ion content 65300mg / L high-salt mercury-containing waste water is injected in 8-stock solution feeding tank 8, At the same time, the refined brine of saturated saline, with a NaCl content of 240-248g / L and a pH of 7, is injected into the drawing liquid feeding tank;

[0064] Step 2, use the raw liquid feed pump 9 to transport the high-salt mercury-containing waste water through the raw liquid filter 10 to filter, then enter the inner wall side of the forward osmosis membrane module 4, and use the draw liquid feed pump 2 to transport the draw liquid fine brine through After the draw liquid filter 3, enter the outer wall side of the forward osmosis membrane module 4;

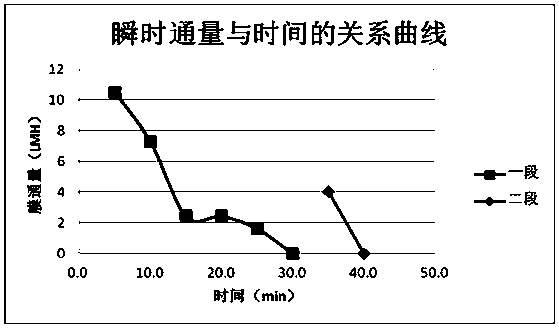

[0065] Step 3, after the draw solution passes through the forward osmosis membrane module, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com