Anti-cracking gypsum-based light material

A lightweight material, gypsum-based technology, applied in the field of building insulation materials, can solve the problems of general toughening and crack resistance, weakening of fiber bridging, fiber agglomeration, etc., to reduce the area of weak areas, increase crack resistance, reduce Effect of small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

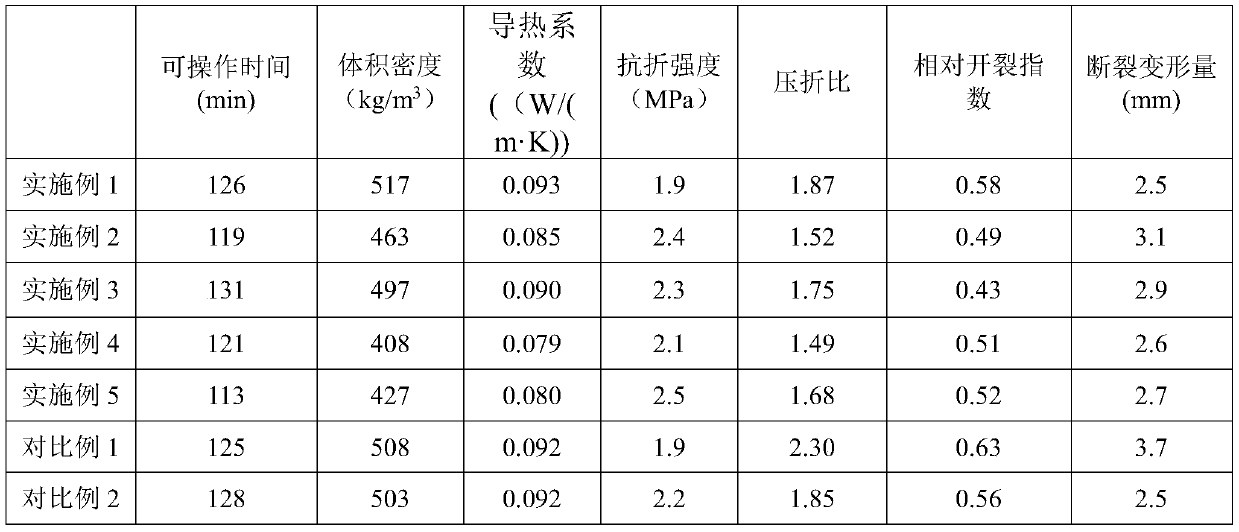

Examples

Embodiment 1

[0025] Taking the 100kg of building gypsum used to prepare the anti-crack type gypsum-based lightweight material of the present invention as an example, other raw materials used and their quality are as follows:

[0026] Construction plaster 100kg

[0027] water 91kg

[0028] Vitrified beads 45kg

[0029] Polyvinyl alcohol fiber 0.3kg

[0030] Rubber granules 10kg

[0031] Silane coupling agent 0.3kg

[0032] Adhesive 0.3kg

[0033] Water retaining agent 0.2kg

[0034] Water reducer 0.2kg

[0035] Retarder 0.2kg;

[0036] The preparation method of anti-crack type gypsum-based lightweight material, the specific steps are:

[0037] 1) Dry-mix the vitrified microspheres, rubber particles, and polyvinyl alcohol fibers for 1-5 minutes;

[0038] 2) Dry-mix building gypsum, silane coupling agent, adhesive, water retaining agent, water reducer and retarder for 1-5 minutes;

[0039] 3) Then dry mix the two mixtures together for 3-10 minutes; just add water and stir when using...

Embodiment 2

[0043] Taking the 100kg of building gypsum used to prepare the anti-crack type gypsum-based lightweight material of the present invention as an example, other raw materials used and their quality are as follows:

[0044] Construction plaster 100kg

[0045] water 86kg

[0046] Vitrified beads 55kg

[0047] Polyvinyl alcohol fiber 0.5kg

[0048] Rubber granules 10kg

[0049] Silane coupling agent 0.3kg

[0050] Adhesive 0.5kg

[0051] Water retaining agent 0.4kg

[0052] Water reducer 0.2kg

[0053] Retarder 0.3kg

[0054] The specification and preparation method of the above-mentioned raw materials are the same as in Example 1.

Embodiment 3

[0056] Taking the 100kg of building gypsum used to prepare the anti-crack type gypsum-based lightweight material of the present invention as an example, other raw materials used and their quality are as follows:

[0057] Construction plaster 100kg

[0058] water 78kg

[0059] Vitrified beads 50kg

[0060] Polyvinyl alcohol fiber 0.3kg

[0061] Rubber granules 15kg

[0062] Silane coupling agent 0.5kg

[0063] Adhesive 0.4kg

[0064] Water retaining agent 0.3kg

[0065] Water reducer 0.3kg

[0066] Retarder 0.2kg

[0067] The specification and preparation method of the above-mentioned raw materials are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com