Method for preparing isooctyl nitrate by catalyzing nitration of isooctyl alcohol

A technology of isooctyl nitrate and isooctyl alcohol, which is applied in the field of catalytic nitration to prepare isooctyl nitrate, can solve the problems of large consumption of sulfuric acid and difficult treatment, and achieve the effects of less waste, environmental friendliness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

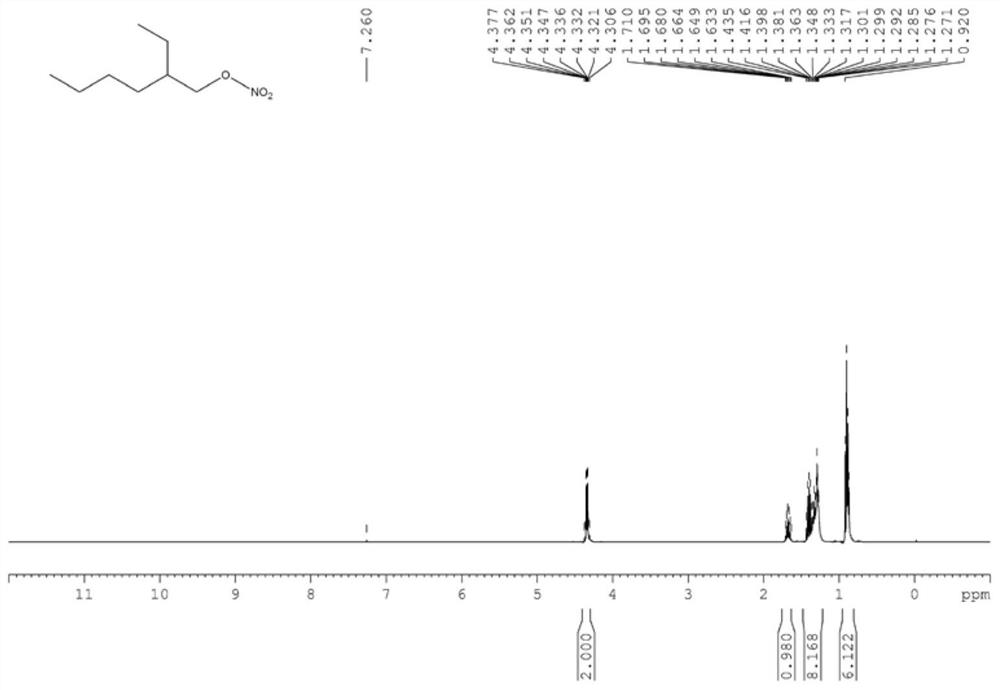

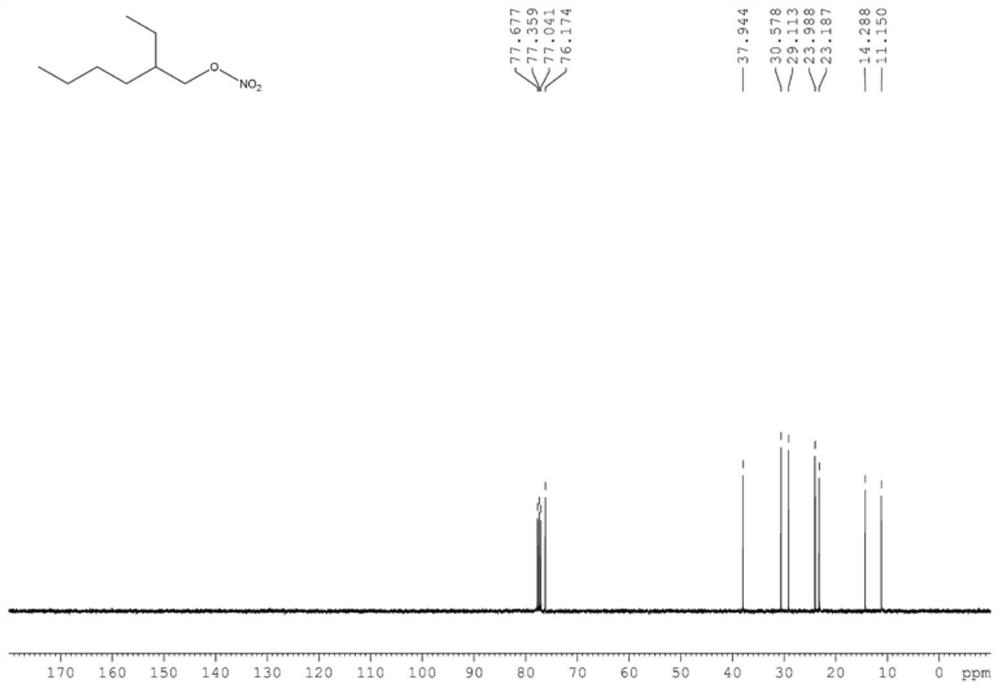

[0023] In a 250 mL reaction flask, put 20 mL (0.128 mol) isooctanol, 10.6 mL (0.154 mol) nitric acid (65%), 644 mg (1 mol%) iron triflate, 92 mg (1 mol%) ) urea and 80 mL of dichloromethane; heated up to 40°C with stirring, stopped the reaction after 18 hours, cooled to room temperature, washed the organic layer with 3 × 15 mL of water, evaporated to remove dichloromethane, and distilled the remaining liquid under reduced pressure to get no Color liquid 21.06 g, the product is determined by methods such as NMR (see accompanying drawing), MS that the structure is isooctyl nitrate, the yield is 94%, and the gas chromatograph analysis product purity is 99%.

Embodiment 2

[0025] In a 250 mL reaction flask, put 20 mL (0.128 mol) isooctanol, 8.9 mL (0.128 mol) nitric acid (65%), 393 mg erbium triflate, 231 mg copper triflate, 230 mg urea and 20 mL petroleum ether; heated and heated to 40°C with stirring, the reaction was stopped after 18 hours, cooled to room temperature, the organic layer was washed with 3 × 15 mL of water, the dichloromethane was removed by rotary evaporation, and the remaining liquid was distilled under reduced pressure to obtain a colorless Liquid isooctyl nitrate 21.75 g, yield is 97%, gas chromatograph analysis product purity is 99%.

[0026] Synthesize isooctyl nitrate in the same manner as in Example 1, and its various reaction conditions and reaction results are shown in Table 1.

[0027] Table 1 Preparation of isooctyl nitrate under different conditions 0.01-10 mol%.

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com