LPSO-phase strengthened degradable high-temperature magnesium alloy and preparation method thereof

A magnesium alloy, high temperature technology, applied in the field of magnesium alloys, can solve the problems of high temperature mechanical properties and unsatisfactory degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

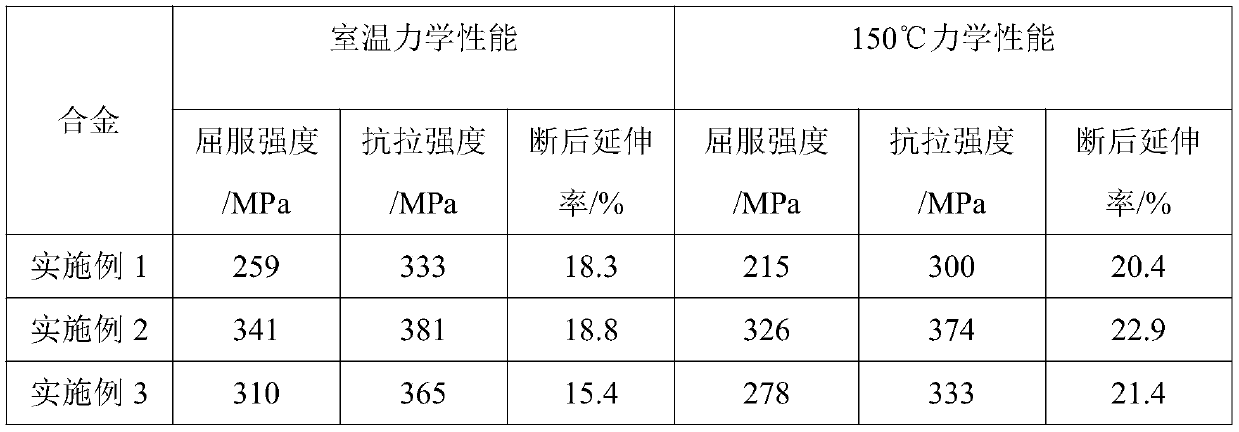

Embodiment 1

[0031] The chemical composition of the magnesium alloy in this embodiment is: Gd 8wt%, Ho 4wt%, Cu 0.86wt%, Ni 0.43%, Zn 0.215wt%, Zr 0.2wt%, and the balance is Mg.

[0032] The invention discloses a preparation method of an LPSO phase-strengthened degradable high-temperature magnesium alloy, which comprises the following steps:

[0033]Step 1: Pure magnesium ingot (>99.99wt%), pure gadolinium ingot (>99.99wt%), pure holmium ingot (>99.99wt%), pure copper ingot (>99.99wt%), pure nickel ingot (>99.99wt%) %), zinc ingot (>99.99wt%) and magnesium-30wt% zirconium master alloy as raw materials, the total amount of raw materials is 5kg;

[0034] Step 2: Preheat and dry the raw materials in step 1 at 200°C, then place the magnesium ingot in a low-carbon steel crucible in a resistance furnace and heat it to 750°C to melt and form magnesium liquid, then sequentially place the preheated gadolinium ingot, Add holmium ingots, copper ingots, nickel ingots, zinc ingots, and magnesium-zirco...

Embodiment 2

[0037] The chemical composition of the magnesium alloy in this embodiment is: Gd 10wt%, Ho 5wt%, Cu 2.4wt%, Ni 1.2%, Zn 0.6wt%, Zr 0.5wt%, and the balance is Mg.

[0038] The invention discloses a preparation method of an LPSO phase-strengthened degradable high-temperature magnesium alloy, which comprises the following steps:

[0039] Step 1: Pure magnesium ingot (>99.99wt%), pure gadolinium ingot (>99.99wt%), pure holmium ingot (>99.99wt%), pure copper ingot (>99.99wt%), pure nickel ingot (>99.99wt%) %), zinc ingot (>99.99wt%) and magnesium-30wt% zirconium master alloy as raw materials, the total amount of raw materials is 5kg;

[0040] Step 2: Preheat and dry the raw materials in step 1 at 200°C, then place the magnesium ingot in a low-carbon steel crucible in a resistance furnace and heat it to 750°C to melt and form magnesium liquid, then sequentially place the preheated gadolinium ingot, Add holmium ingots, copper ingots, nickel ingots, zinc ingots, and magnesium-zirconi...

Embodiment 3

[0043] The chemical composition of the magnesium alloy in this embodiment is: Gd 12wt%, Ho 6wt%, Cu 3.2wt%, Ni 1.6%, Zn 0.8wt%, Zr 0.8wt%, and the balance is Mg.

[0044] The invention discloses a preparation method of an LPSO phase-strengthened degradable high-temperature magnesium alloy, which comprises the following steps:

[0045] Step 1: Pure magnesium ingot (>99.99wt%), pure gadolinium ingot (>99.99wt%), pure holmium ingot (>99.99wt%), pure copper ingot (>99.99wt%), pure nickel ingot (>99.99wt%) %), zinc ingot (>99.99wt%) and magnesium-30wt% zirconium master alloy as raw materials, the total amount of raw materials is 5kg;

[0046] Step 2: Preheat and dry the raw materials in step 1 at 200°C, then place the magnesium ingot in a low-carbon steel crucible in a resistance furnace and heat it to 750°C to melt and form magnesium liquid, then sequentially place the preheated gadolinium ingot, Add holmium ingots, copper ingots, nickel ingots, zinc ingots, and magnesium-zirconi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com