A kind of hot-rolled pickled steel strip for 450mpa grade oil well pipe and its manufacturing method

A technology of hot-rolled pickling and manufacturing methods, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve problems affecting production line production efficiency, reduce production control difficulty, stabilize performance, improve surface finish and Effect of Thickness Dimensional Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

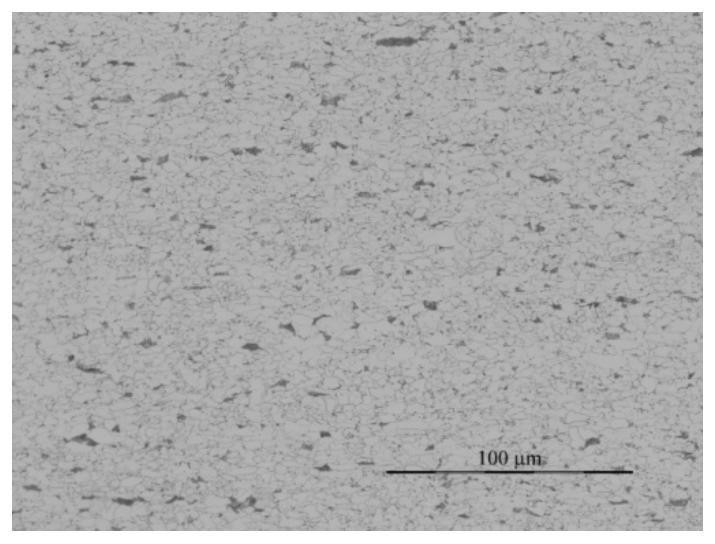

Image

Examples

Embodiment 1

[0037] A method for manufacturing hot-rolled pickled steel strip for 450MPa grade oil well pipes, including slab production, hot rolling and pickling production processes, specifically: converter smelting, LF furnace refining, RH vacuum degassing, continuous casting, heating, high pressure Water descaling, rolling, laminar cooling, coiling, coil uncoiling, welding, loop storage, tension levelling, continuous pickling, rinsing, drying, skin-leveling, trimming, oiling and coiling.

[0038] Among them, the RH vacuum degassing, the end target [H] ≤ 2ppm, the static cycle time ≥ 6min, open the ladle bottom blowing argon for weak stirring after breaking the air, the weak stirring argon flow rate is 10-30NL / min, the weak stirring holding time ≥10min;

[0039]In the continuous casting, the temperature of the tundish is controlled at 15-30° C. above the liquidus line, and the process of light reduction and electromagnetic stirring is adopted. Among them, the reduction position and red...

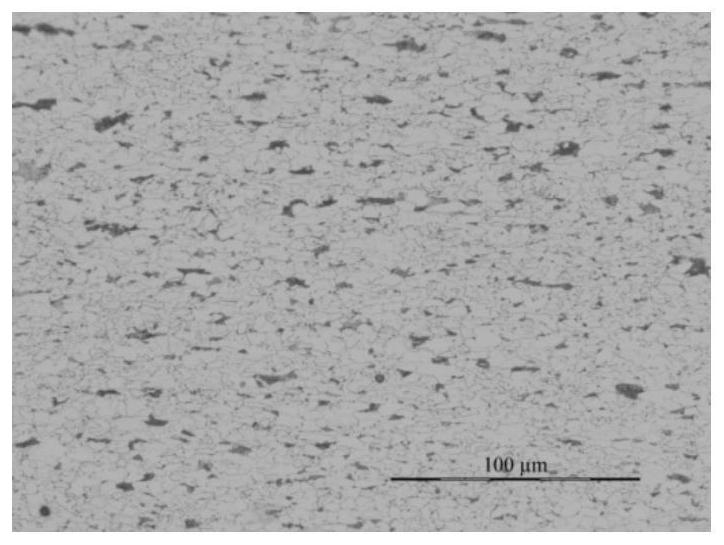

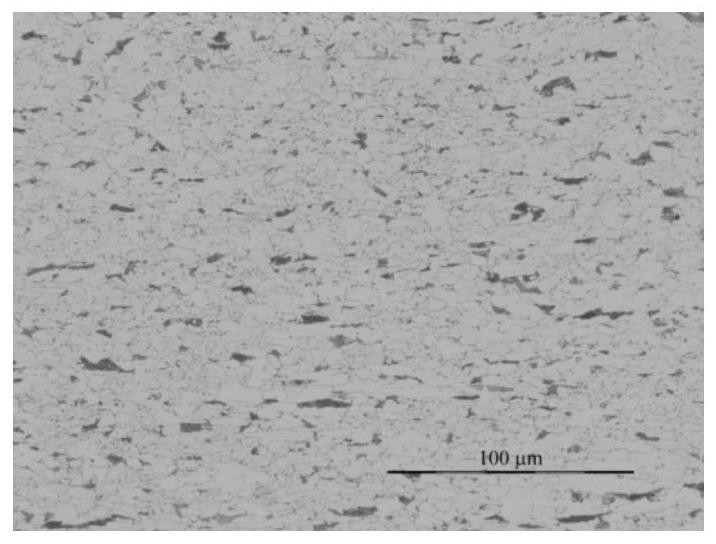

Embodiment 2- Embodiment 4

[0047] A method for manufacturing a hot-rolled pickled steel strip for 450MPa oil well pipes, except that the process parameters listed in Table 3 and Table 4 are different from those in Example 1, and the rest of the process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com