Antibacterial finishing agent as well as antibacterial all-cotton spunlace non-woven fabric and product thereof

A technology of antibacterial finishing agent and spunlace non-woven fabric, applied in the field of antibacterial finishing agent, antibacterial cotton spunlace non-woven fabric and its products, can solve the problems of increasing the probability of external harmful bacteria, and achieve good hydrophilic performance, Good biodegradability and the effect of improving water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] An antibacterial finishing agent comprises a silicone quaternary ammonium salt antibacterial agent and a penetrating agent.

[0061] Wherein, the weight ratio of the organosilicon quaternary ammonium salt to the penetrating agent is 1:1.

[0062] Wherein, the penetrant is a polyethylene glycol ether derivative, specifically, the polyethylene glycol ether derivative is a polyethylene glycol ether derivative penetrant produced by ARCHROMA IP GMBH.

[0063] Wherein, the structural formula of the organosilicon quaternary ammonium salt is:

[0064]

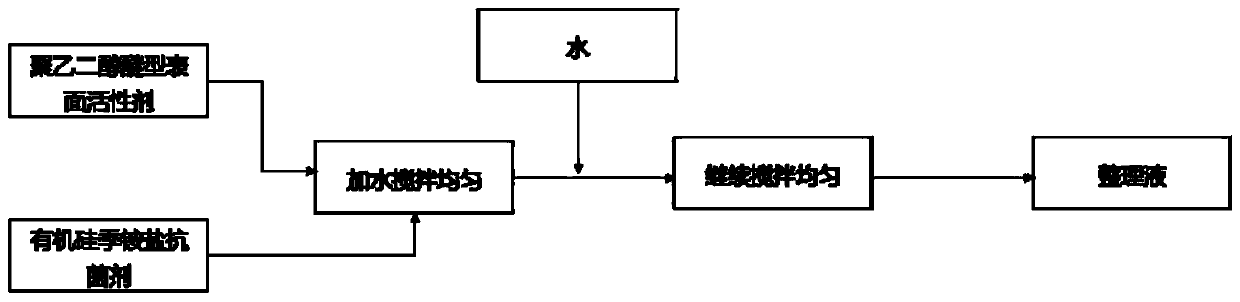

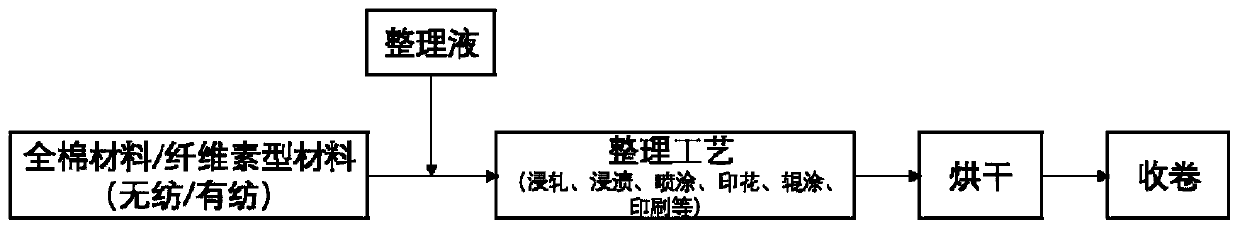

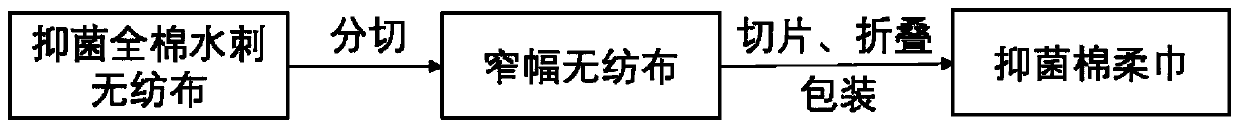

[0065] A kind of antibacterial all-cotton spunlace nonwoven fabric, described antibacterial all-cotton spunlace nonwoven fabric adopts above-mentioned antibacterial finishing agent to make, as figure 1 and 2 Shown, specifically comprise the following preparation steps:

[0066] Step 1, mixing and stirring the above-mentioned antibacterial finishing agent with water to obtain an antibacterial finishing solution;

[0067] T...

Embodiment 2

[0071] An antibacterial finishing agent, the difference between the antibacterial finishing agent in Example 2 and Example 1 is that the weight ratio of the organosilicon quaternary ammonium salt and the penetrating agent in Example 2 is 3:1.

[0072] An antibacterial all-cotton spunlace non-woven fabric, the antibacterial all-cotton spunlace non-woven fabric is prepared by using the above-mentioned antibacterial finishing agent, specifically comprising the following preparation steps:

[0073] Step 1, mixing and stirring the above-mentioned antibacterial finishing agent with water to obtain an antibacterial finishing solution;

[0074] The specific operation is: add 50L pure water into the mixing tank, then pour the penetrant of the antibacterial finishing agent into the mixing tank and stir evenly, then pour the organic silicon quaternary ammonium salt of the antibacterial finishing agent into the mixing tank, and inject pure Water to 100L, continue to stir to make the liqui...

Embodiment 3

[0078] An antibacterial finishing agent, the difference between the antibacterial finishing agent in Example 3 and Example 1 is that the weight ratio of the organosilicon quaternary ammonium salt and the penetrating agent in Example 3 is 5:1.

[0079] An antibacterial all-cotton spunlace non-woven fabric, the antibacterial all-cotton spunlace non-woven fabric is prepared by using the above-mentioned antibacterial finishing agent, specifically comprising the following preparation steps:

[0080] Step 1, mixing and stirring the above-mentioned antibacterial finishing agent with water to obtain an antibacterial finishing solution;

[0081] The specific operation is: add 50L pure water into the mixing tank, then pour the penetrant of the antibacterial finishing agent into the mixing tank and stir evenly, then pour the organic silicon quaternary ammonium salt of the antibacterial finishing agent into the mixing tank, and inject pure Water to 100L, continue to stir to make the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com