Sodium alginate solution capable of effectively improving viscosity and thickening property as well as preparation method and application thereof

A technology of sodium alginate and calcium alginate, which is applied in dyeing, textiles and papermaking, etc., can solve problems such as unevenness, and achieve the effect of improving viscosity and thickening properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Weigh 1.5g and 0.03g of sodium alginate (raw material) and calcium alginate powder respectively, pour 98.47g of deionized water into it at room temperature, and mix quickly and evenly.

[0026] 2) Set the mechanical stirring speed to 200r / min, and stir for 30min to obtain a mixed solution of sodium alginate (raw material) and calcium alginate.

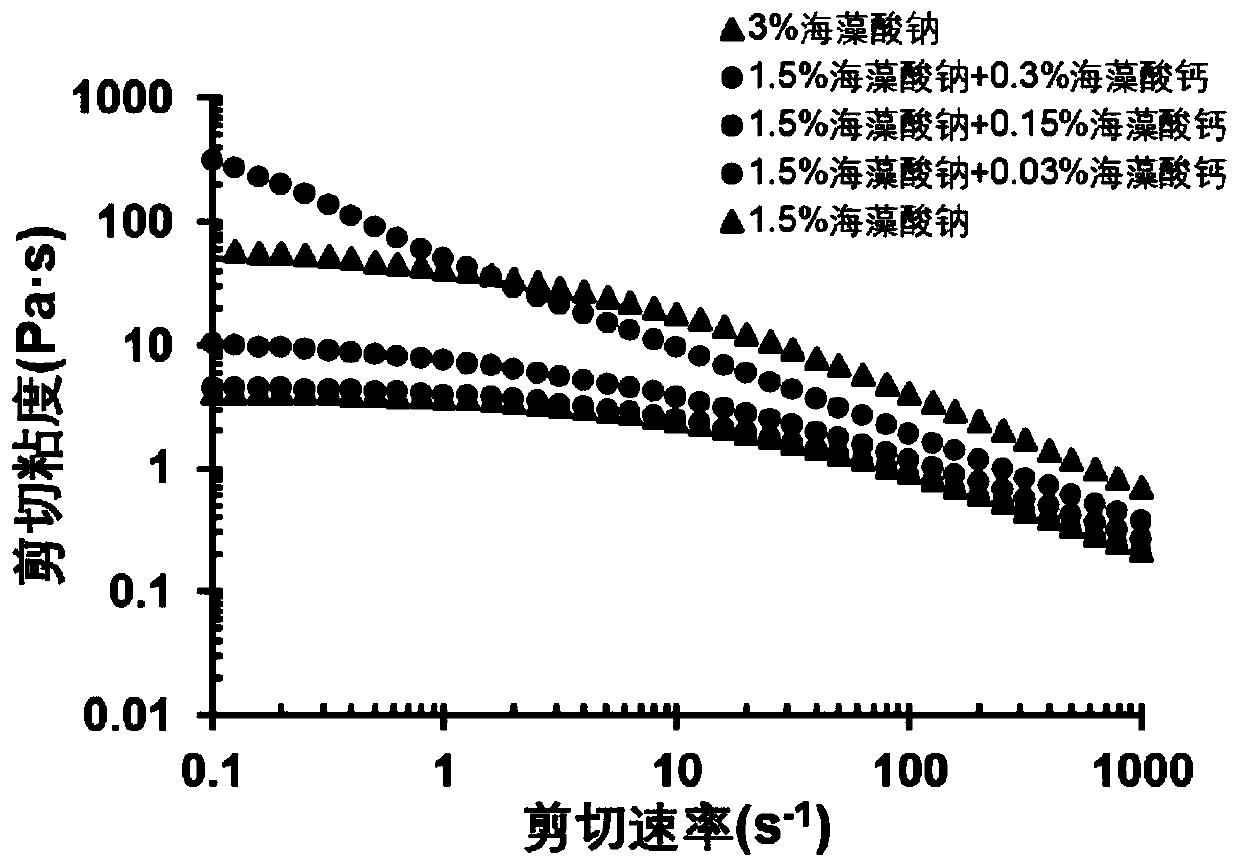

[0027] 3) Stand still for 12 hours to obtain a sodium alginate solution that effectively improves viscosity and thickening properties. The sodium alginate solution includes the following components in mass percentage: sodium alginate (raw material) 1.5% (w / w), calcium alginate 0.03%, deionized water 98.47%, and its shear viscosity is shown in figure 1 .

Embodiment 2

[0029] 1) Weigh 1.5g and 0.15g of sodium alginate (raw material) and calcium alginate powder respectively, pour 98.35g of deionized water into it at room temperature, and mix quickly and evenly.

[0030] 2) Set the mechanical stirring speed to 200r / min, and stir for 30min to obtain a mixed solution of sodium alginate (raw material) and calcium alginate.

[0031] 3) Stand still for 12 hours to obtain a sodium alginate solution that effectively improves viscosity and thickening properties. The sodium alginate solution includes the following components in mass percentage: sodium alginate (raw material) 1.5% (w / w), calcium alginate 0.15%, deionized water 98.35%, and its shear viscosity is shown in figure 1 .

Embodiment 3

[0033]1) Weigh 1.5g and 0.3g of sodium alginate (raw material) and calcium alginate powder respectively, pour 98.2g of deionized water into it at room temperature, and mix quickly and evenly.

[0034] 2) Set the mechanical stirring speed to 200r / min, and stir for 30min to obtain a mixed solution of sodium alginate (raw material) and calcium alginate.

[0035] 3) Stand still for 12 hours to obtain a sodium alginate solution that effectively improves viscosity and thickening properties. The sodium alginate solution includes the following components in mass percentage: sodium alginate (raw material) 1.5% (w / w), calcium alginate 0.3%, deionized water 98.2%, and its shear viscosity is shown in figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com