Magnetofluid external wall structure

A magnetic fluid, exterior wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of not being able to form a systematic energy-saving design, not paying attention to energy reuse, and not achieving low consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of magnetic fluid containing nanomaterials

[0028] 1) Weigh ferric oxide (Shanghai Chaowei Nano Technology Co., Ltd., 100 to 400nm), porous alumina powder (Shanghai Chaowei Nano Technology Co., Ltd., 500nm), floating beads (Shanghai Chaowei Nano Technology Co., Ltd., 500nm ) and added to deionized water to obtain a mixed solution. The mixed solution was magnetically stirred at a constant temperature of 50°C, and the constant temperature magnetic stirring speed was 1200r / min to form a reddish-brown solution. During the continuous constant temperature stirring process, acetic acid aqueous solution (mass fraction 10.4%) was added, and after mixing Adjust the pH value to 10-11, adjust the speed to 1200r / min and continue stirring for 30 minutes, then cool to room temperature naturally, remove the supernatant, and wash the precipitate with deionized water by centrifugation at a speed of 8000r / min, and wash by centrifugation for 10 minutes , then ultraso...

Embodiment 2

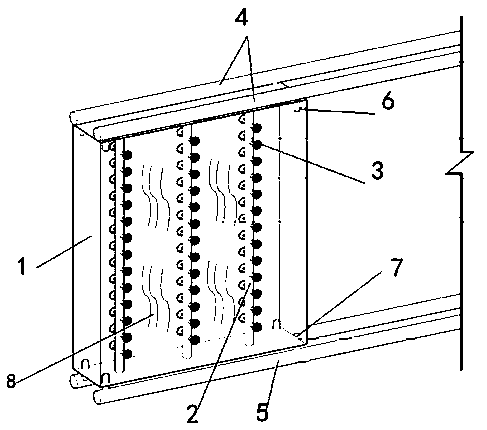

[0031] Embodiment 2 Magnetic Fluid Exterior Wall Structure

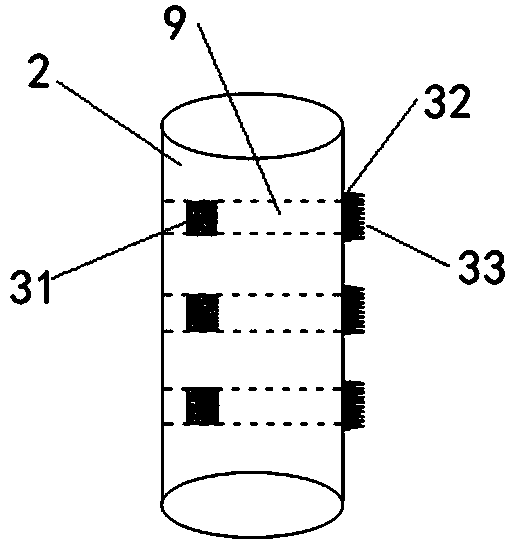

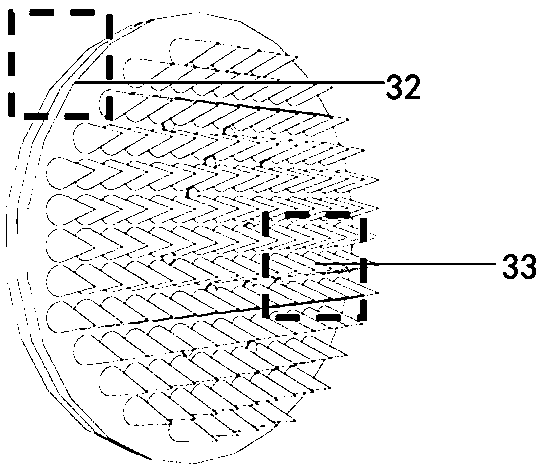

[0032] As shown in the figure, the magnetic fluid exterior wall structure is composed of several wall modules 1 that can be spliced. The wall module 1 is a cubic structure, the top of which is connected to the upper diversion pipe 4 through the upper fluid inlet and outlet 6, and the bottom is connected to the lower fluid inlet and outlet. 7 is connected to the lower diversion pipe 5, the rotatable rod 2 is vertically connected to the top and bottom of the wall module 1, and the magnet assembly 3 is arranged on the rotatable rod. Such as figure 2 and 3As shown, the magnet assembly 3 includes a first permanent magnet 31, a second permanent magnet 32 and a magnetic fluid 33. There are several grooves 9 on the rotatable rod 2, and the grooves are spaced at 15-25 cm apart. The central axis is perpendicular to the rotatable rod, a first permanent magnet 31 is arranged in the groove, a second permanent magnet 32 is ...

Embodiment 3

[0034] Example 3 Principles of use in summer working conditions;

[0035] In summer, the distance between the first permanent magnet 31 and the second permanent magnet 32 is controlled at 1 cm so that the magnetic field generated by the permanent magnet is close to the magnetic fluid. At this time, the magnetic field force is relatively large, and the magnetic field intensity is relatively high. Ferrofluid surrounds magnetic materials. The magnetic lines of force are relatively dense, forming dense sharp hills, which make them not match the wavelength of sunlight and improve the reflectivity of light and heat. At the same time, medium water 8 is inserted into the wall module 1 . When direct sunlight in summer, the sunlight passes through the medium water 8 to form a "primary reflection" to reflect most of the light. The remaining solar rays refracted by the medium water 8 are "secondarily reflected" by the magnetic fluid. The heat generated during the reflection process,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com