Supercritical hydrothermal combustion device with residue self-separation function and method

A supercritical water and combustion device technology, applied in combustion methods, separation methods, filtration and separation, etc., can solve problems such as affecting normal operation, blocking follow-up devices, and blocking salt deposition, and achieves easy and low-cost capture, process extension, The effect of burning embers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

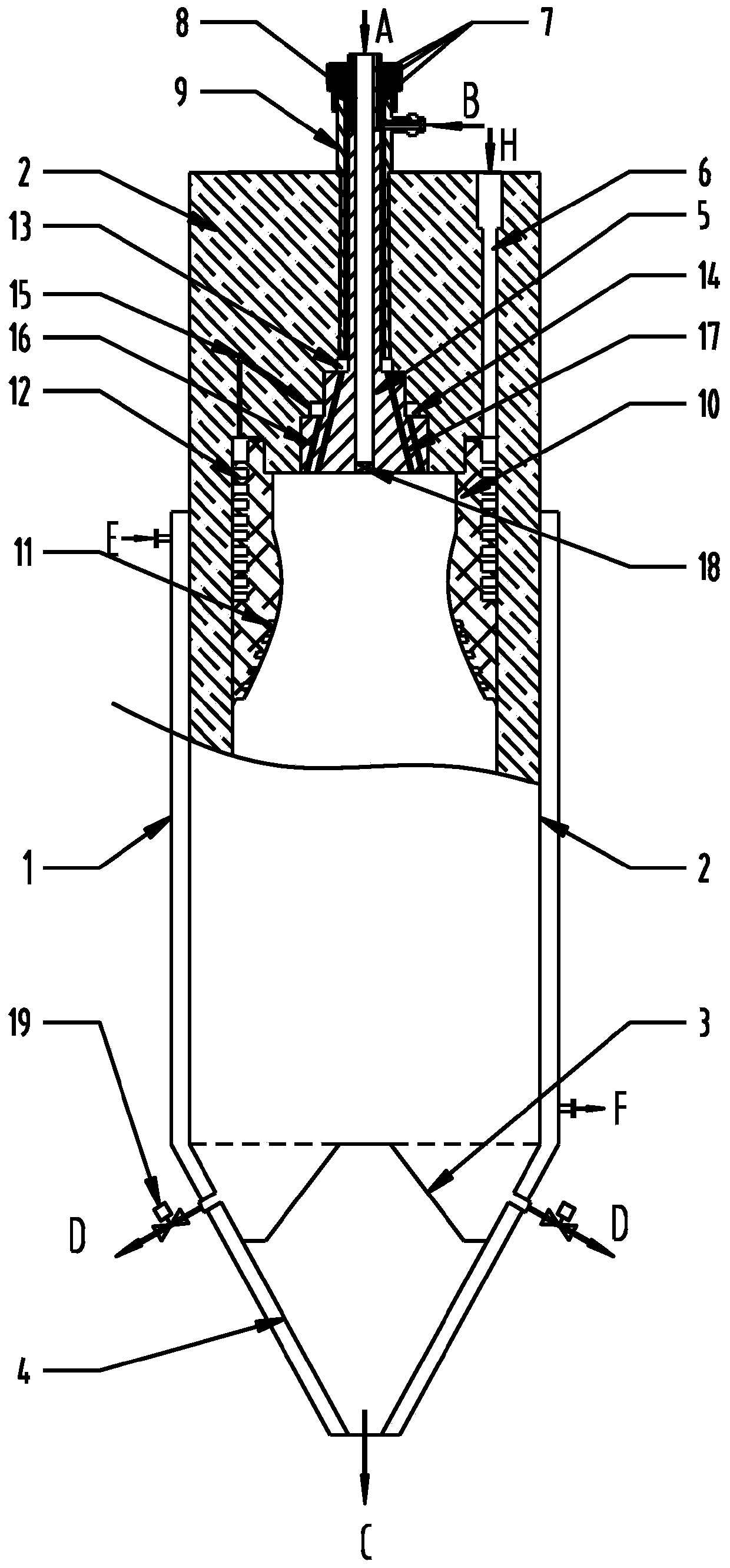

[0025] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0026] Such as figure 1 As shown, a supercritical hydrothermal combustion device with residue self-separation function of the present invention is a swirling supercritical hydrothermal combustion device compatible with water and fire, which includes a device main body 2, which is efficiently cooled by a cooling jacket 1 package, high-efficiency cooling jacket 1 is a jacket structure or a single-layer / multi-layer spiral channel structure, the coolant can be water, air, heat transfer oil, organic slurry or oxidant, etc., the cooling water in the cooling jacket 1 is formed by the cooling water at the top Inlet E enters and flows out through cooling water outlet F.

[0027] in:

[0028]A hydrothermal flame generator 5 is arranged in the center of the upper part of the device main body 2. In this embodiment, the hydrothermal flame generator 5 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com