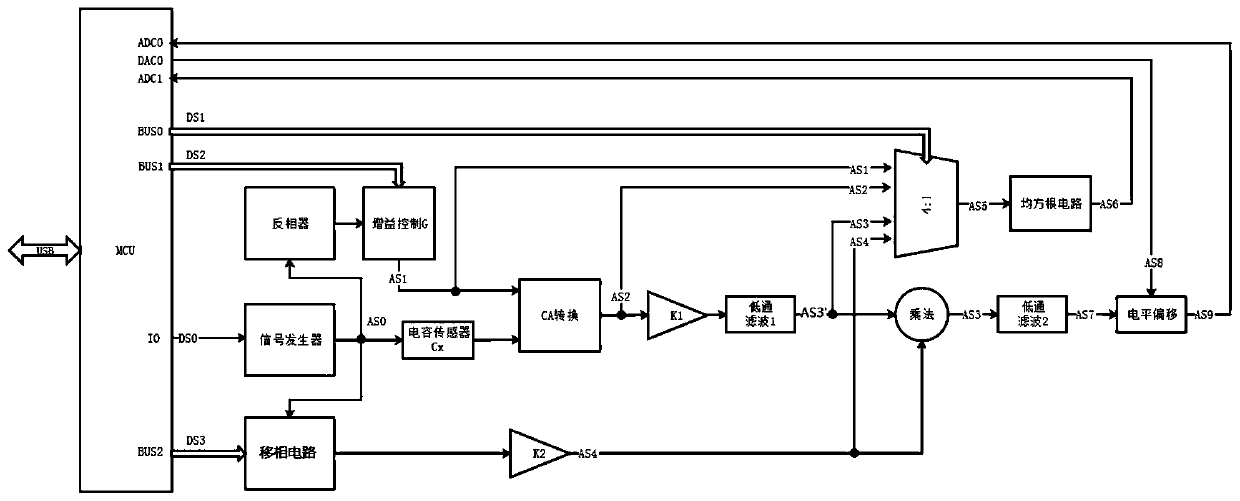

Weak capacitance change measuring circuit of capacitance sensor

A capacitive sensor and weak capacitance technology, applied in the field of sensor measurement, can solve problems such as many constraints, and achieve the effects of strong adaptability, fast speed and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

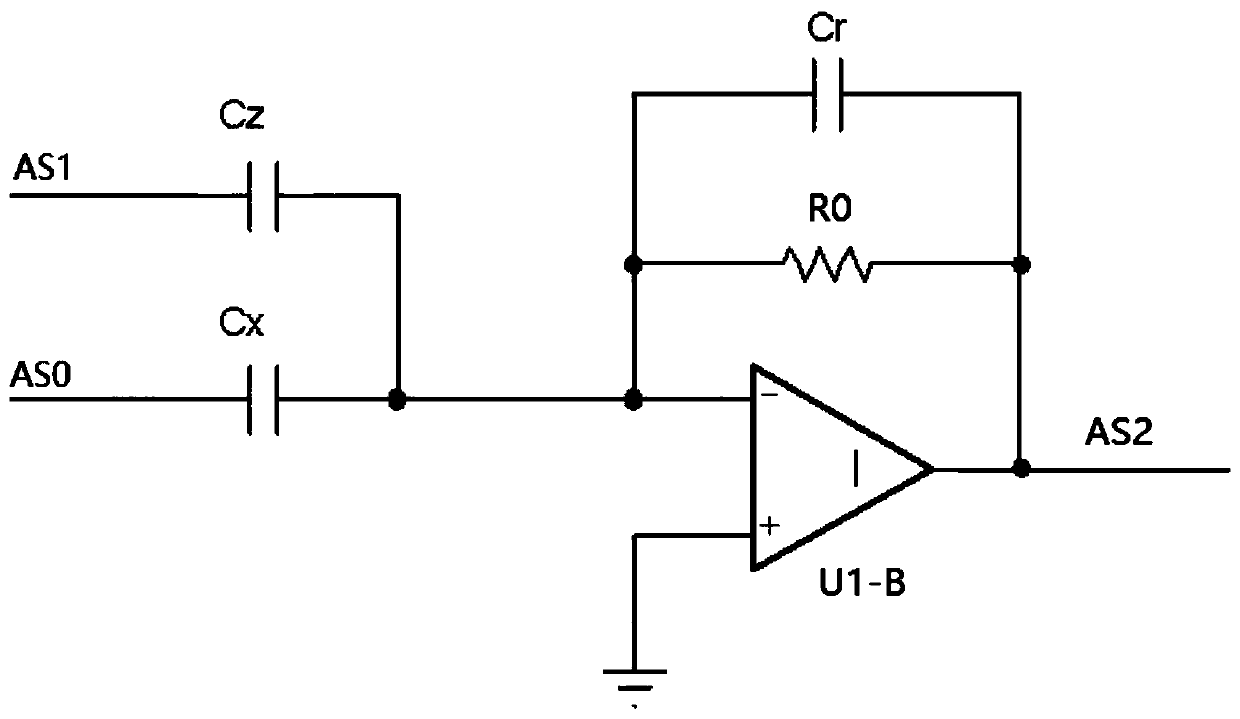

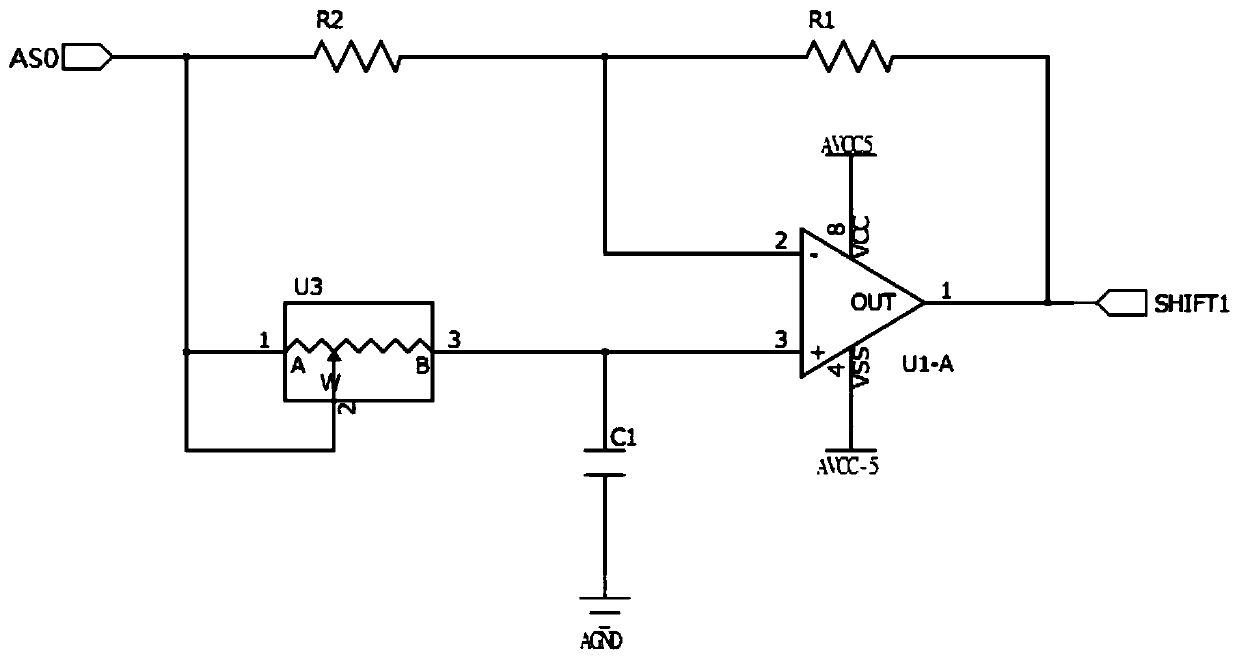

[0025] The capacitance-voltage conversion method used in the present invention is based on the AC negative feedback method of capacitance measurement, and a large number of improvements are made on this basis, so that the circuit directly outputs a DC voltage signal proportional to the relative change rate of capacitance. First, the capacitance change of the capacitive sensor (the change relative to the initial capacitance value) is transformed into the amplitude of a sine wave (excitation signal), which is proportional to the relative change rate of the capacitance of the capacitive sensor. After canceling the effect of the static capacitance of the capacitance sensor, the output of the CA conversion circuit only includes the capacitance variation of the capacitance sensor. The capacitance change is detected by an analog multiplier, and finally passes through a low-pass filter to output a DC signal proportional to the relative change rate of the sensor's capacitance. This cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com