Low-pressure high-flux hydrophilic ultrafiltration membrane and preparation method thereof

A hydrophilic, low-pressure and high-pressure technology, applied in the field of membrane separation, can solve problems such as limitations, achieve the effects of reducing application costs, high-purity water flux, and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

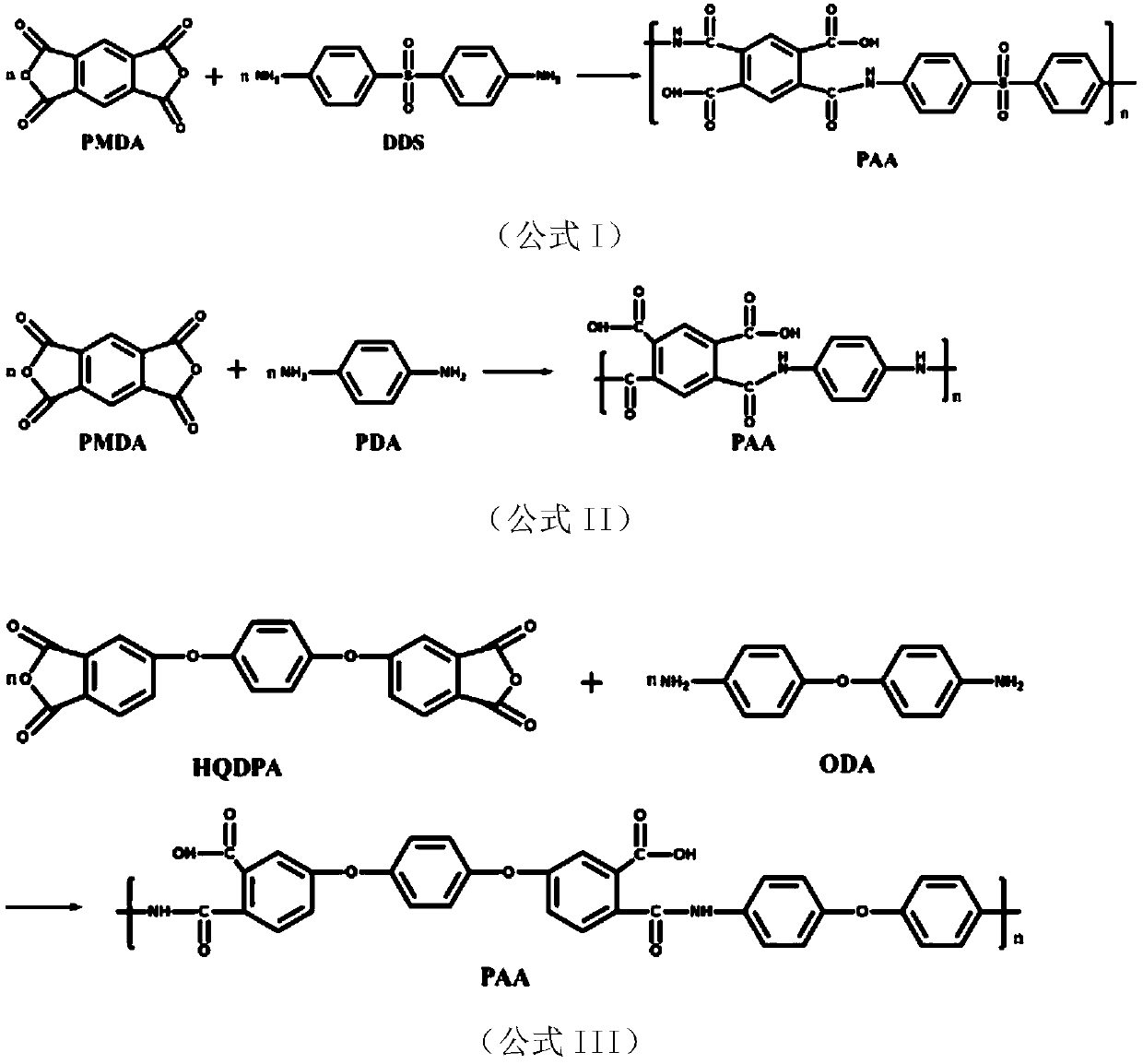

Method used

Image

Examples

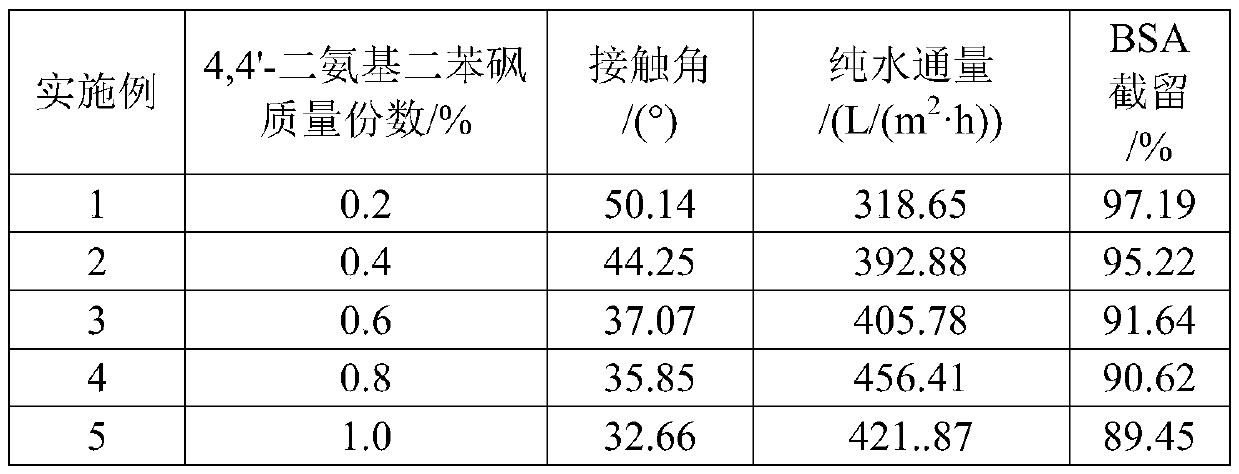

Embodiment 1-5

[0024] Hydrophilicity and bovine serum albumin (BSA) cut-off performance test of modified membrane

[0025] At 80°C, 15 parts by mass of polyethersulfone was dissolved in N,N-dimethylformamide (DMF) with mechanical stirring, and after obtaining the preliminary casting solution, cooled to room temperature, and then added by mass parts of 0 to 1.0 parts of monomer 4,4'-diaminodiphenylsulfone (DDS), and continue stirring with a stirrer to dissolve and mix evenly, then add the corresponding parts by mass of DDS (molar ratio is 1:1.02) Monomer pyromellitic dianhydride (PMDA), continue to use a stirrer to stir for 4h to make the two monomers react to obtain a mixed solution, then leave it to stand for degassing for 12h under a vacuum of 0.05MPa, and finally obtain a clear and transparent solution; The clear and transparent solution was placed on a glass plate to scrape the membrane, and then placed in deionized water at 20°C for coagulation to obtain an ultrafiltration membrane.

...

Embodiment 6-10

[0030] Pure water low pressure high flux test of modified membrane

[0031] As in the above example, at 80°C, 15 parts by mass of polyethersulfone was dissolved in N,N-dimethylformamide (DMF) with mechanical stirring, and after obtaining the preliminary casting solution, cooled to room temperature, Then add 0.8 parts by mass of monomer 4,4'-diaminodiphenylsulfone (DDS), and continue stirring with a stirrer to dissolve and mix evenly, then add the corresponding DDS (molar ratio is 1:1.02) The mass parts of the monomer pyromellitic dianhydride (PMDA), continue to use the stirrer to stir for 4h to make the two monomers react to obtain a mixed solution, and then stand for defoaming for 12h under a vacuum of 0.05MPa, and finally obtain a clear and transparent solution; the clear and transparent solution was placed on a glass plate to scrape the film, and then placed in deionized water at 20°C for coagulation to obtain an ultrafiltration membrane.

[0032] Under the operating press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com