Magnesium-based composite material with titanium or titanium alloy as skeleton enhancer and preparation method of magnesium-based composite material

A composite material and reinforcement technology, applied in the field of magnesium-based composite materials and preparation, can solve the problems of reducing damping performance, the mechanical properties of magnesium-based composite materials cannot be effectively regulated, and the material density is not significantly improved, and achieves improved strength and design. The effect of strong stability and controllability, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

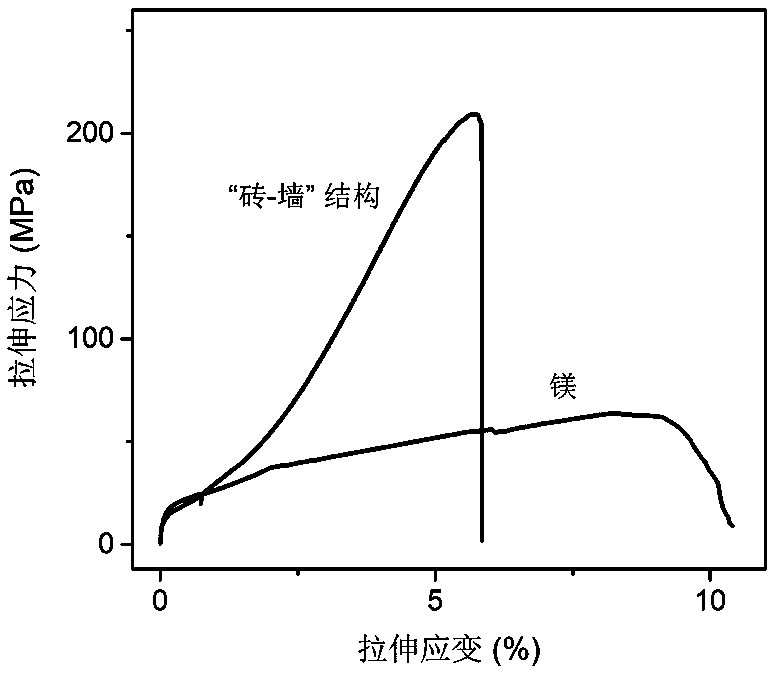

[0064] In this example, a TC4 titanium alloy reinforced magnesium-based composite material with a brick-wall structure imitating abalone shell nacre was prepared. The raw materials used include titanium-aluminum-vanadium alloy powder (average particle size is 80μm, aluminum is 5.5-6.75%, vanadium is 3.4-4.5%, and the rest is titanium), metal magnesium block. Concrete preparation process is as follows:

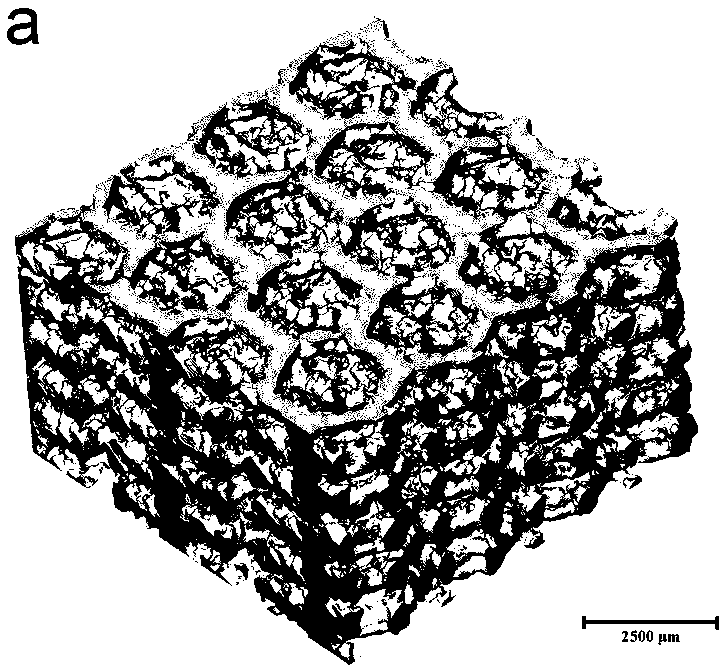

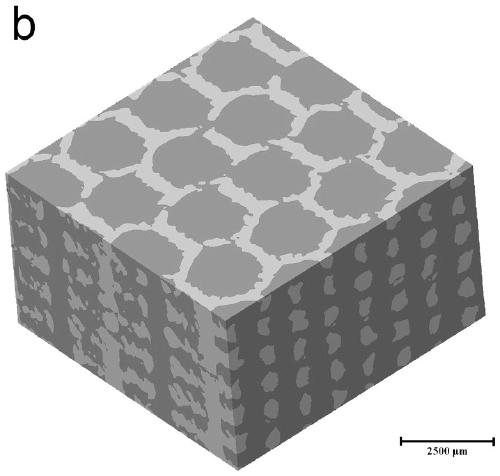

[0065] 1) Use the 3D visualization solid simulation software Autodesk Inventor Professional (AIP2019) to design and establish a 3D model of the TC4 titanium alloy reinforcement skeleton with a brick-wall structure. like figure 1 As shown, the bionic structure of the model is established based on the design principles of the brick-wall structure represented by the abalone shell nacre. The model was imported into the Realizer SLM 100 metal 3D printer formed by laser selective melting technology. Under the protection of argon, the titanium-aluminum-vanadium alloy powder was prep...

Embodiment 2

[0070] In this example, a TC4 titanium alloy skeleton reinforced AZ91D magnesium alloy-based composite material with a cross-laminated structure imitating the clam was prepared. The raw materials used include titanium-aluminum-vanadium alloy powder (average particle size is 80μm, aluminum 5.5-6.75%, vanadium 3.4-4.5%, the rest is titanium), AZ91D magnesium alloy block. Concrete preparation process is as follows:

[0071] 1) This step is similar to step 1) in Example 1, the difference is that the bionic structure of the 3D printed TC4 titanium alloy skeleton is established based on the design principle of the cross lamination structure represented by the clam shell ,like Figure 4 As shown, the printed TC4 titanium alloy skeleton is shown in Figure 5a , the dimensions of the skeleton are 90×50×5 mm 3 , the porosity is 47.16%;

[0072] 2) This step is similar to step 2) in Example 1, except that the metal used to infiltrate the TC4 titanium alloy skeleton is AZ91D magnesium a...

Embodiment 3

[0076] In this example, a titanium-skeleton-reinforced magnesium-based composite material with a helical braided structure imitating an arthropod exoskeleton was prepared. The raw materials used include titanium powder (average particle size is 15μm), metal magnesium block. Concrete preparation process is as follows:

[0077] 1) This step is similar to step 1) in Example 1, the difference is that the bionic structure of the 3D printed titanium skeleton is established based on the design principles of the helical braided structure represented by the arthropod exoskeleton, such as Image 6 As shown, the printed titanium skeleton is shown in Figure 7a , the size of the skeleton is 90×50×5mm 3 , the porosity is 65.30%;

[0078] 2) This step is similar to step 2) in Example 1, the difference is that the metal magnesium is impregnated with a titanium skeleton, and the impregnation temperature is 850°C;

[0079] 3) This step is similar to step 3) in Example 1, the difference is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com