Biodegradable fully mechanized mining support electrohydraulic control concentrated solution and hydraulic fluid containing same

A fully mechanized mining support and biodegradable technology, applied in the field of hydraulic fluid, can solve the problems of low biodegradability and poor environmental protection of hydraulic fluid, and achieve the effect of low cost and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

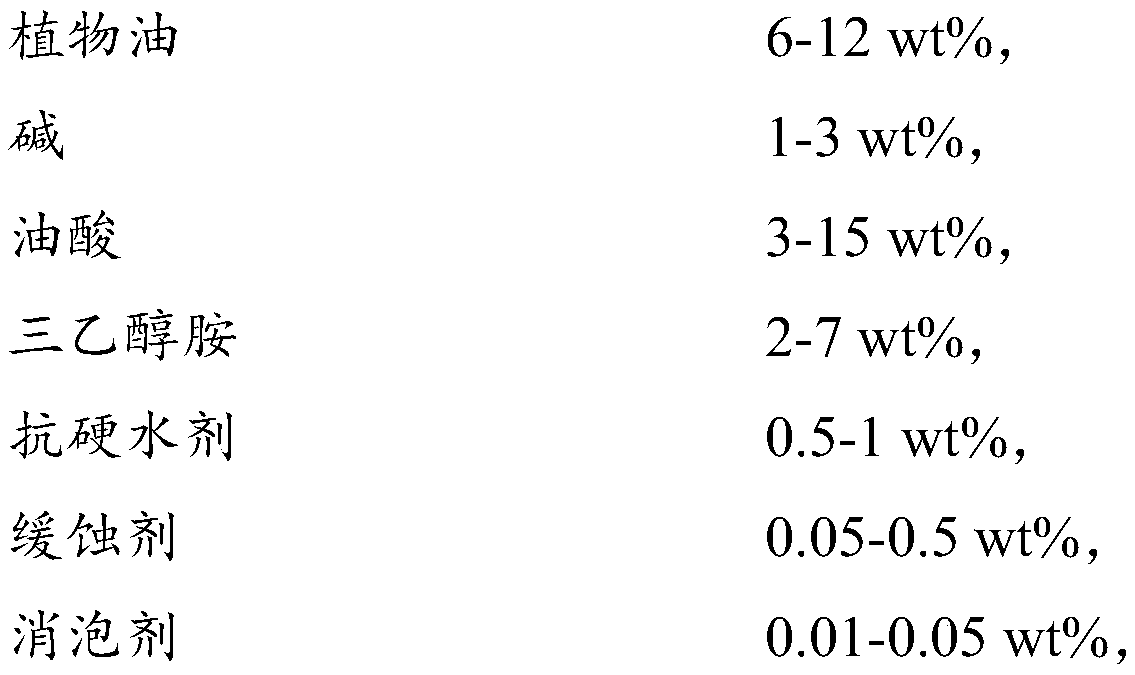

[0058] The content of each raw material component of the biodegradable fully mechanized support electro-hydraulic control concentrate is as follows:

[0059]

[0060] And the remaining water, based on the total mass of each raw material component of the concentrate.

[0061] The preparation method of described concentrated solution is: (1) in the first reactor, add 50kg castor oil, 15Kg potassium hydroxide and 85Kg deionized water, mix and be warming up to 80 ℃, carry out saponification reaction. Stirring reaction 8 hours, obtain potassium ricinoleate soap; (2) add 50kg oleic acid, 25kg triethanolamine and 85kg deionized water in the second reactor, mix and be warming up to 140 ℃, carry out saponification reaction. The reaction was stirred for 6 hours to obtain the triethanolamine oleic acid soap; (3) at a temperature of 50°C, the potassium ricinoleic acid soap obtained in (1) was mixed with the triethanolamine oleic acid soap obtained in (2), and press Add the ether carbo...

Embodiment 2

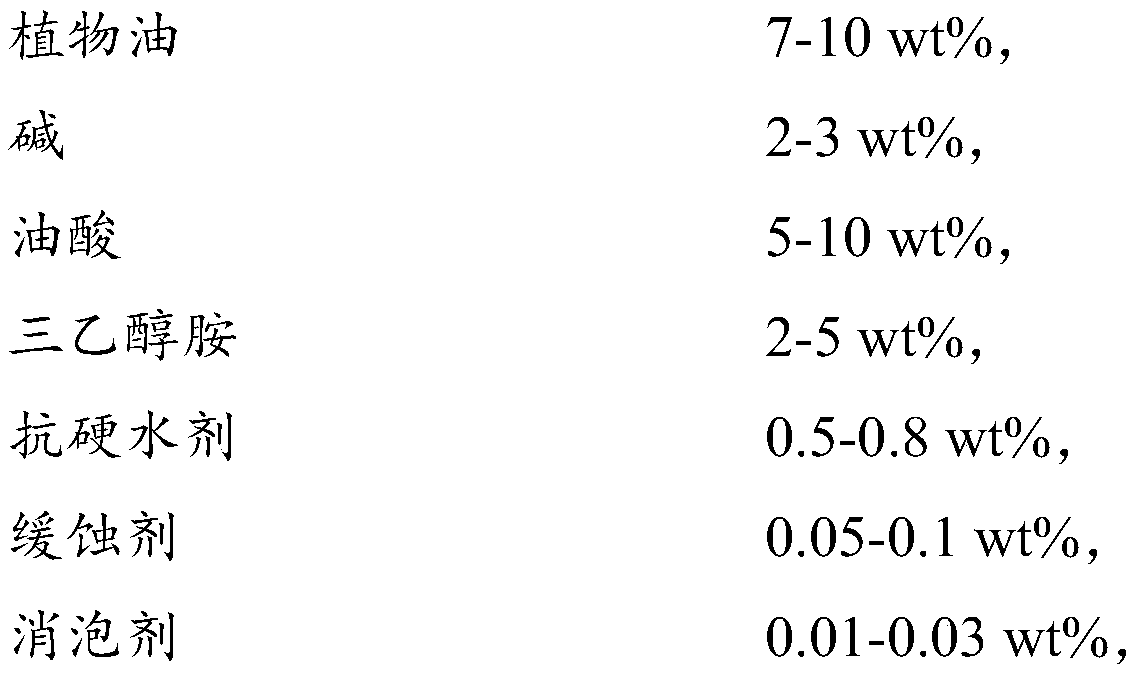

[0066] The content of each raw material component of the biodegradable fully mechanized support electro-hydraulic control concentrate is as follows:

[0067]

[0068] And the remaining water, based on the total mass of each raw material component of the concentrate.

[0069] The preparation method of described concentrated solution is: (1) in the first reactor, add 50kg castor oil, 15Kg potassium hydroxide and 85Kg deionized water, mix and be warming up to 80 ℃, carry out saponification reaction. Stirring reaction 8 hours, obtain potassium ricinoleate soap; (2) add 50kg oleic acid, 25kg triethanolamine and 85kg deionized water in the second reactor, mix and be warming up to 140 ℃, carry out saponification reaction. The reaction was stirred for 6 hours to obtain the triethanolamine oleic acid soap; (3) at a temperature of 50°C, the potassium ricinoleic acid soap obtained in (1) was mixed with the triethanolamine oleic acid soap obtained in (2), and press Add the ether carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com