High-strength chitosan filament and interfacial photopolymerization preparation method and device thereof

A technology of chitosan and photopolymerization, which is applied in the fields of filament/thread forming, chemical instruments and methods, and complete sets of equipment for the production of artificial threads, etc., can solve the problems to be studied and the limited effect of improving the strength of chitosan filaments. , to achieve the effect of good uniformity and continuity, high strength, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing high-strength chitosan filament by interfacial photopolymerization. The method for preparing high-strength chitosan filament by interfacial photopolymerization is prepared by using the above-mentioned interfacial photopolymerization preparation device for high-strength chitosan filament. Including the following steps:

[0037] S1. Preparation of maleylated chitosan;

[0038] S2. The maleylated chitosan prepared in step S1 is used as the water-phase solute, and the maleylated chitosan is dissolved in deionized water according to a preset mass-volume ratio, and a predetermined amount of photoinitiator is added , Formulated into an aqueous phase solution and injected into the first reaction phase storage tank 1;

[0039] S3. Using a binary or polybasic acid chloride compound as the oil phase solute, prepare an oil phase solution of the oil phase solute and the organic solvent according to a preset mass-volume ratio, and ...

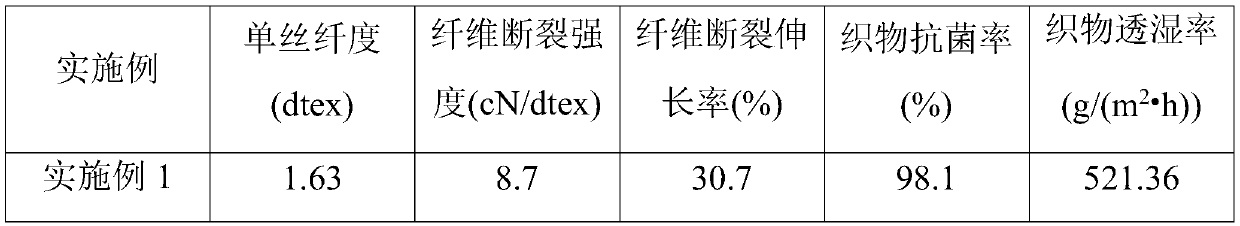

Embodiment 1

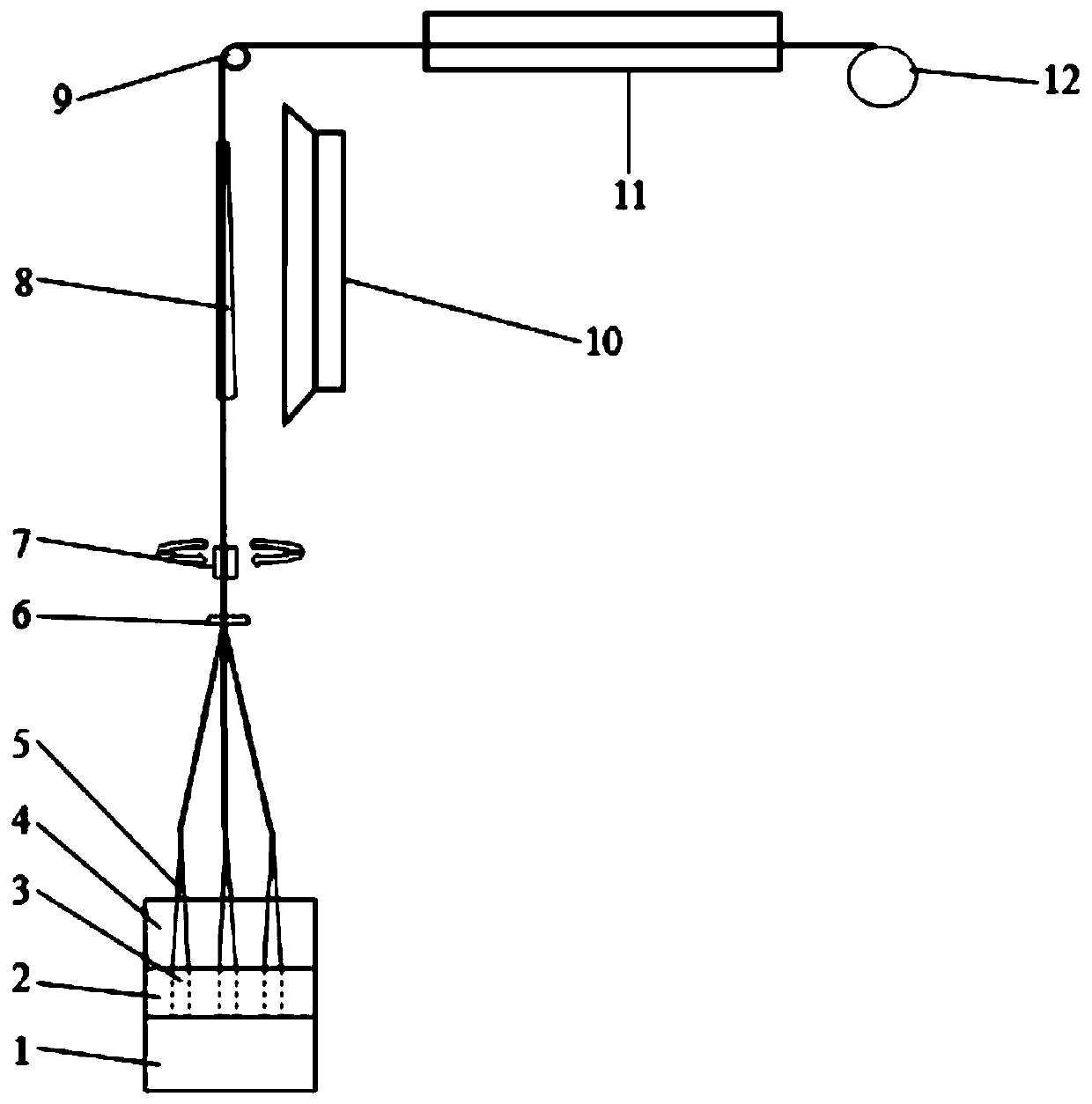

[0055] See figure 1 This embodiment provides a high-strength chitosan filament interfacial photopolymerization preparation device, which includes a spinning solution storage unit, a spinning unit, and a spinning collection unit; the spinning solution storage unit includes the first spinning solution storage unit from bottom to top. A reaction phase storage box 1 and a second reaction phase storage box 4; the spinning unit includes a film-forming orifice 2, a gathering hole 6, a twister 7, a transparent inclination tube 8 and a UV lamp 10, the UV lamp 10 It is arranged opposite to the transparent inclination tube 8; the spinning collection unit includes a guide wheel 9, a blow dryer 11, and a winding drum 12 in the horizontal direction; the film forming orifice 2 is arranged in the first reaction Between the phase storage tank 1 and the second reaction phase storage tank 4, the film-forming orifice plate 2 is provided with a plurality of film-forming holes 3 vertically penetrati...

Embodiment 2~8

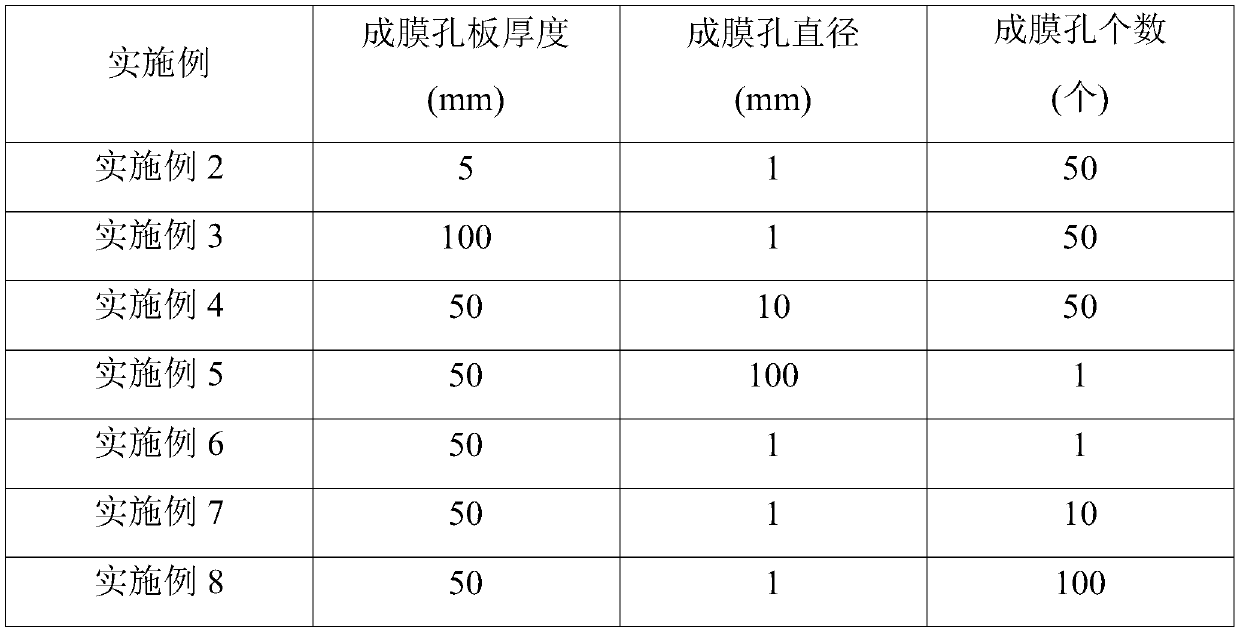

[0071] Examples 2-8 respectively provide a high-strength chitosan filament interfacial photopolymerization preparation device. Compared with Example 1, the difference lies in that the thickness of the film-forming orifice 2 and the diameter or the diameter of the film-forming hole 3 are changed. The number of film holes 3, other structures and parameters are the same as those in Embodiment 1, and will not be repeated here. The corresponding parameters of the film-forming orifice 2 and the film-forming hole 3 corresponding to each embodiment are shown in Table 2.

[0072] Table 2 Corresponding parameters of film-forming orifice plates and film-forming holes in Examples 2-8

[0073]

[0074] According to the same preparation method as in Example 1, the high-strength chitosan filaments were prepared by using the interfacial photopolymerization preparation device of high-strength chitosan filaments provided in Examples 2-8. The performance of the sugar filament was tested, and the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Fiber breaking strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com