Wellhead repairing method for petroleum industry

一种修复方法、石油工业的技术,应用在土方钻采、井眼/井部件等方向,能够解决地层能量不确定、油气井的地层能量高、操作中毒等问题,达到出液量或出气量提升、避免自喷或溢出、避免安全事故的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

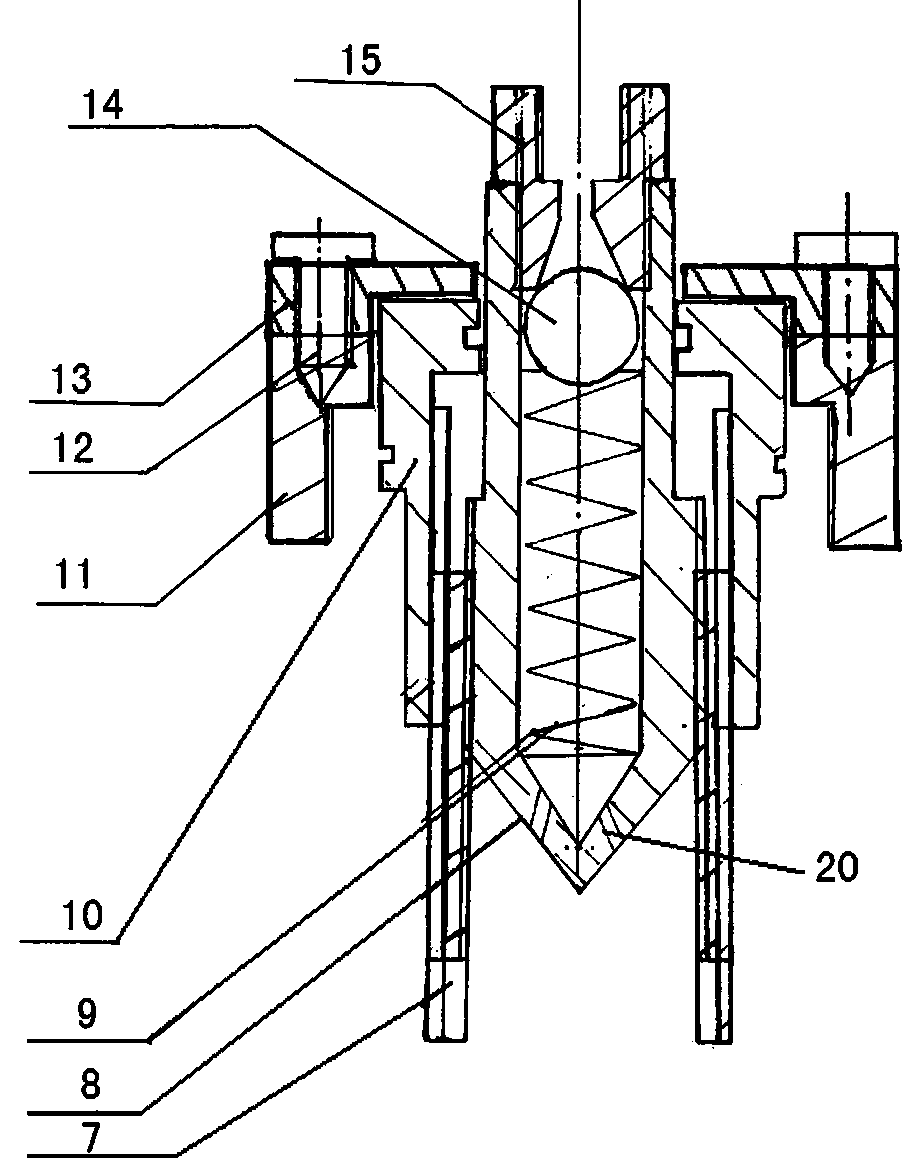

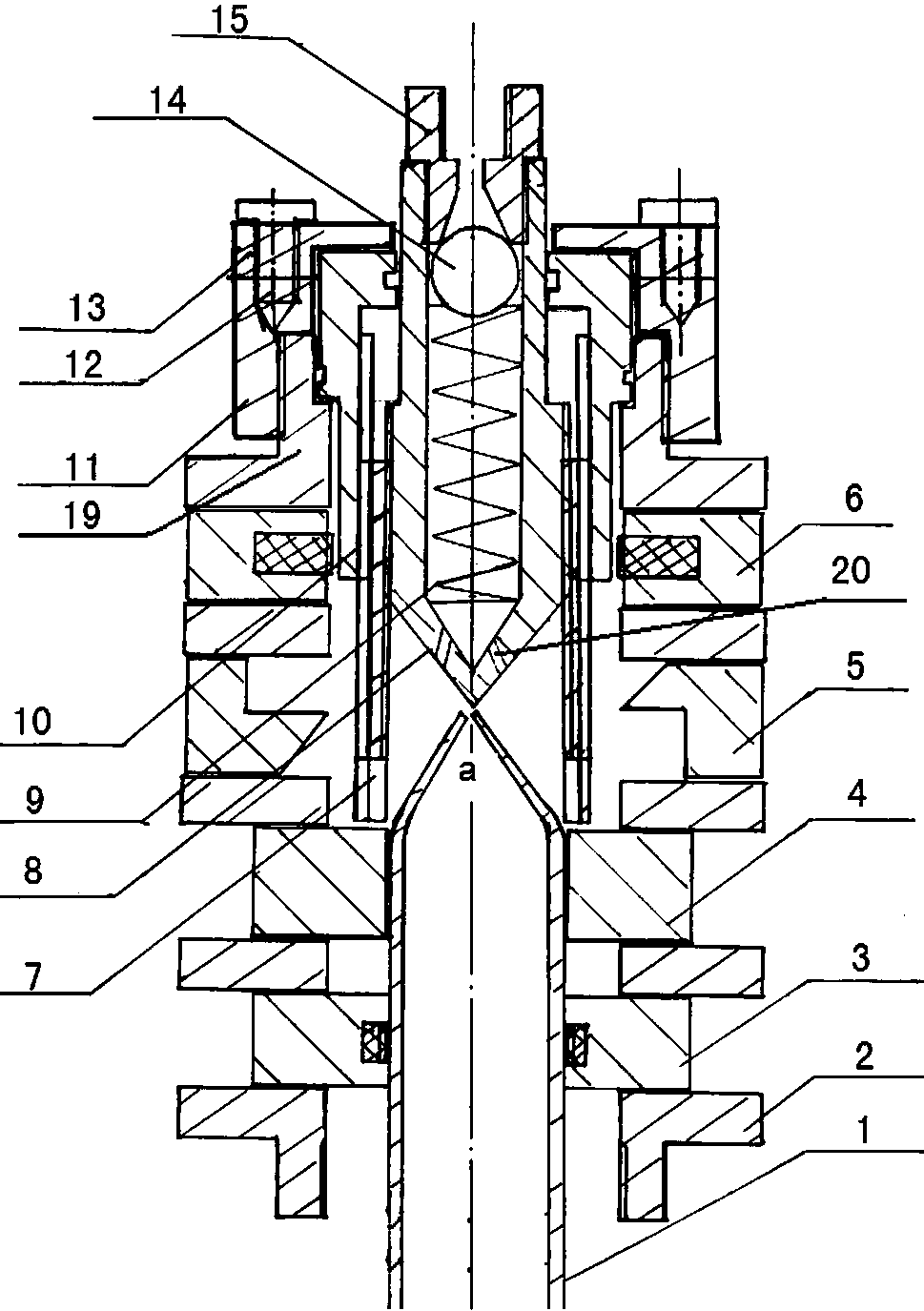

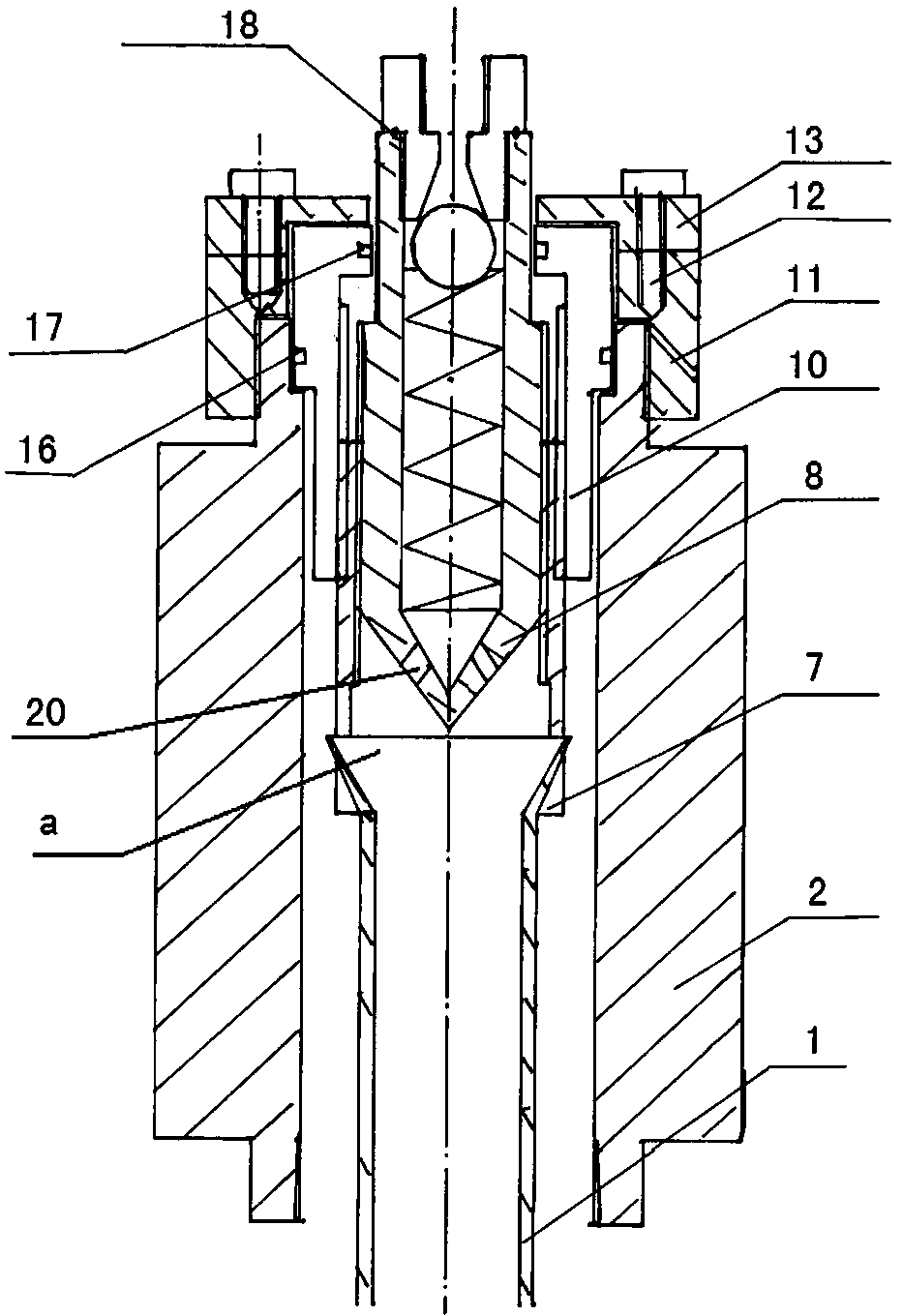

[0034] Embodiment 1, with reference to attached Figure 1-3 , a coiled tubing incision recovery repair device mentioned in the present invention, its technical solution is: including the repair port outer jacket 7, repair port inner mold 8, support spring 9, key sleeve 10, transition connection sleeve 11, connecting bolt 12, upper pressure Cap 13, single-flow valve sealing steel ball 14, single-flow valve inlet ball seat 15, wherein the four-ram packer includes four-ram BOP body 2, half-sealed ram 3, suspension ram 4, shear The ram 5 and the fully-sealed ram 6 are provided with a coiled tubing 1 in the oil well, and the end is a straight cut a cut by the shear ram 5 . The transition connecting sleeve 11 is connected with the upper joint 19 of the four-ram blowout preventer through an internal thread, the upper part of the transition connecting sleeve 11 is connected to the upper pressing cap 13 through the connecting bolt 12, and the key sleeve 10 is placed under the upper pre...

Embodiment 2

[0048] Embodiment 2, the difference between the present invention and Embodiment 1 is that the bottom of the repair mouth cover 7 can be provided with an L-shaped groove, and the two extruding ends of the incision can still be grasped, and then lifted, and at the same time pass Reaming extrusion of the notch by the conical structure.

Embodiment 3

[0049] Embodiment 3, with reference to attached Figure 10 The difference between the present invention and Embodiment 1 is: a bearing 21 can be provided between the repair port outer cover 7 and the repair port inner mold 8 of the present invention, so that the rotation is easier and the operation is more labor-saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com