Nanobubble hydrogen-water-gas mixing device for high-pressure jet cutting

A nano-bubble, high-pressure jet technology, applied in gas/vapor and liquid mixing, mixers, mixing methods, etc., can solve the problems of high cost, prolonged storage time, and the inability of ordinary manufacturers to produce, and achieve good crushing effect and preservation. Long-lasting, easy-to-achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

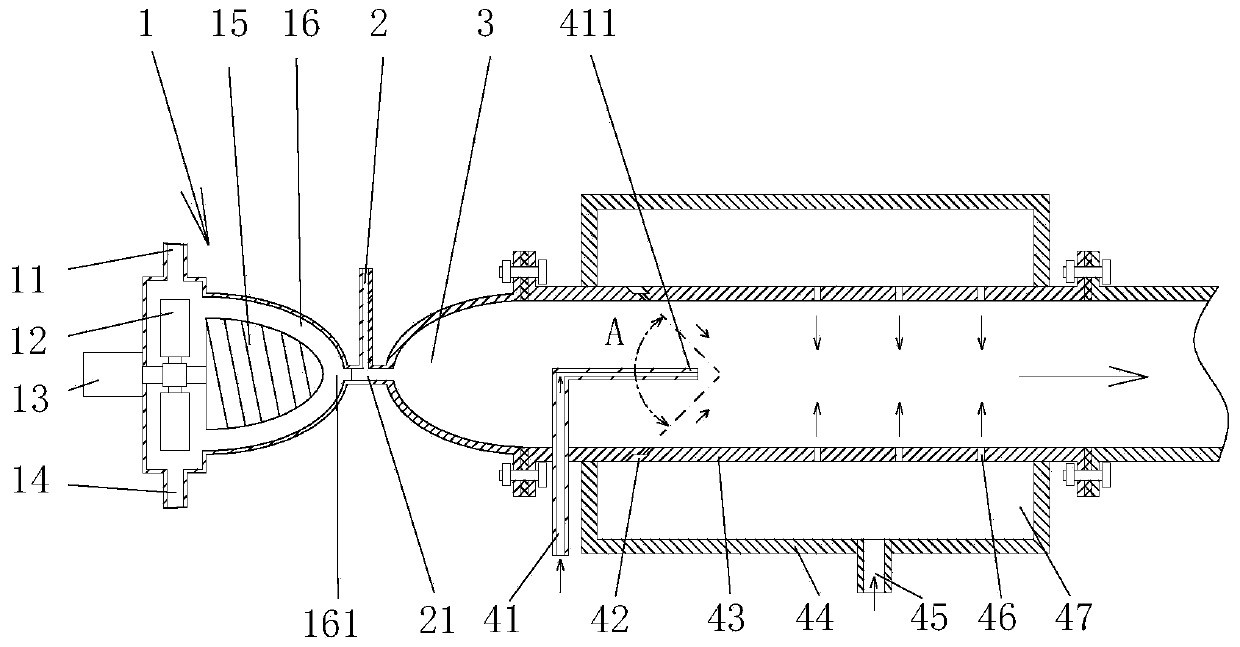

[0025] Example 1, such as figure 1 Shown:

[0026] A nano-bubble hydrogen-water gas mixing device for high-pressure jet cutting, comprising:

[0027] A hydrogen-water mixing component capable of outputting hydrogen water;

[0028] Inner pipe 43, its input port communicates with the output end of the hydrogen-water mixing assembly;

[0029] Hydrogen pipe 41, which penetrates the inner pipe 43, the input port of the hydrogen pipe 41 communicates with the hydrogen generator, and the output port 411 is located in the inner pipe 43;

[0030] The outer tube 44 is set outside the inner tube 43. The two ends of the outer tube are provided with closed end faces. The outer tube 44, the inner tube 43 and the two closed end faces form an airtight water cavity 47. The outer tube 44 or the closed end faces are provided with a high pressure inlet. The water inlet 45 and the high-pressure water inlet 45 are connected to the water source through the pipeline through the high-pressure water ...

Embodiment 2

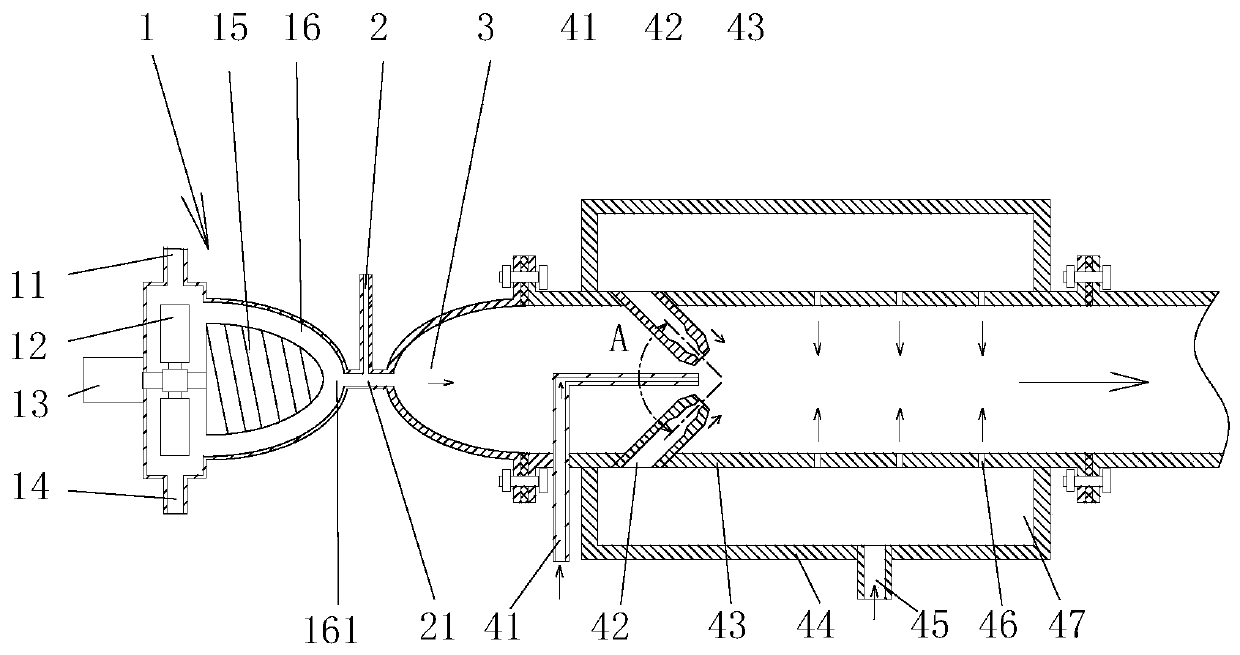

[0036] Example 2, such as figure 1 Shown:

[0037] On the basis of Embodiment 1, the output port 411 of the hydrogen pipe 41 is located on the center line of the inner pipe 43, and a plurality of water nozzles are arranged symmetrically with respect to the center line, and the angle A formed by more than one pair of inclined water nozzles 42 is 70° -150 degrees, preferably 90 degrees, every other pair of water nozzles is a radial water nozzle 46, and the jet flow directions oppose each other.

[0038] The angle A formed by more than one pair of oblique water nozzles 42 is 70-150 degrees, which can satisfy the cutting and crushing of hydrogen gas, and at the same time, the resultant force formed by them can push the hydrogen water forward; the radial water nozzles 46 can be set inside On the pipe 43, it should be noted that the multiple pairs of radial faucets 46 opposed to each other may not be on the same plane, such as figure 1 , figure 2 and Figure 5 As shown, it shou...

Embodiment 3

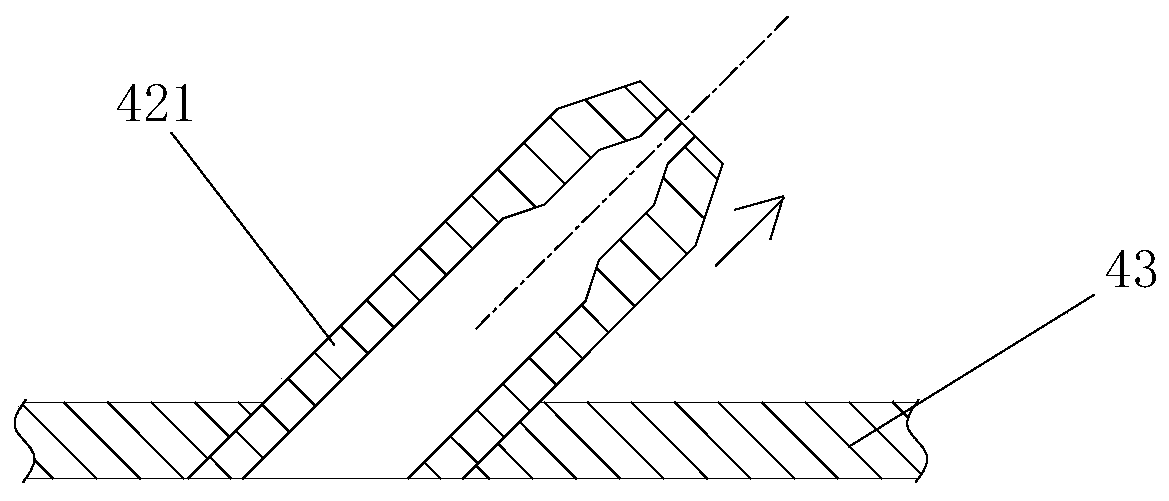

[0040] Example 3, such as figure 2 and 3 Shown:

[0041] On the basis of Embodiment 1 and Embodiment 2, the inclined water nozzle 42 is provided with an inner extension 421 , and the water outlet of the inner extension 421 is close to the outlet 411 of the hydrogen gas pipe 41 .

[0042] This embodiment can be applicable to the quarter pipe with inner pipe diameter close to 15mm, and can also be applied to the relatively thick structure of inner pipe diameter. The outlet mouth of the water nozzle is close to the output port 411 of the hydrogen pipe 41, which shortens the jetting path and can improve the cutting and crushing efficiency of the hydrogen by the water jet formed by the high-pressure jet. The advantage of this embodiment is that it can be applied to large-scale production.

[0043] In the above three embodiments, preferably, the shape of the nozzle of the faucet is a thin cylinder or a flat shape, and this technical solution can further improve the efficiency of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com