Modified polypropylene foamed bead reaction kettle

A technology of foaming beads and polypropylene, applied in chemical/physical/physicochemical stationary reactors, detailed information of chemical/physical/physicochemical reactors, climate sustainability, etc., can solve the failure of particle foaming , non-uniform particle foaming, slow stirring speed and other problems, to achieve good high temperature and high pressure sealing performance, uniform material temperature distribution, good temperature and pressure control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

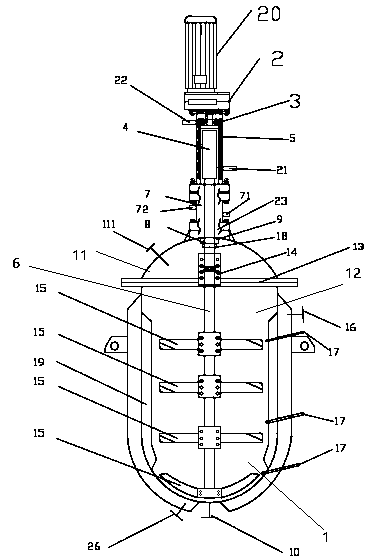

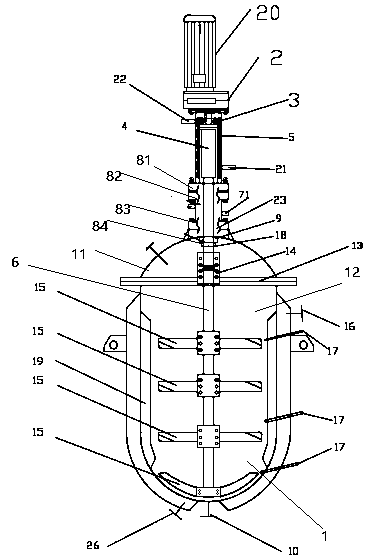

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0053] Such as Figure 1-3 As shown, the modified polypropylene foamed bead reactor includes a reactor body 1, and a frequency conversion motor 20 is arranged above the reactor body 1, and the frequency conversion motor 20 is connected with a reducer 2, and the reducer 2 is connected with a motor driven by the motor 20 to rotate. The outer permanent magnet 3 is provided with an inner permanent magnet 4 that rotates under the magnetic force of the outer permanent magnet 3, and a first sealed cavity 5 is arranged between the outer permanent magnet 3 and the inner permanent magnet 4; A stirring shaft 6 located at its longitudinal central axis and extending from the bottom of the reactor body 1 to the top of the reactor body 1 is provided; the outer surface of a section of the stirring shaft 6 from the top of the reactor body 1 to the bottom of the first sealed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com