Alpha,beta-unsaturated aldehyde ketone selective hydrogenation platinum-based catalyst, and preparation method and application thereof

A catalyst and unsaturated technology, applied in the α field, can solve problems such as high temperature, and achieve high activity, good application value and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

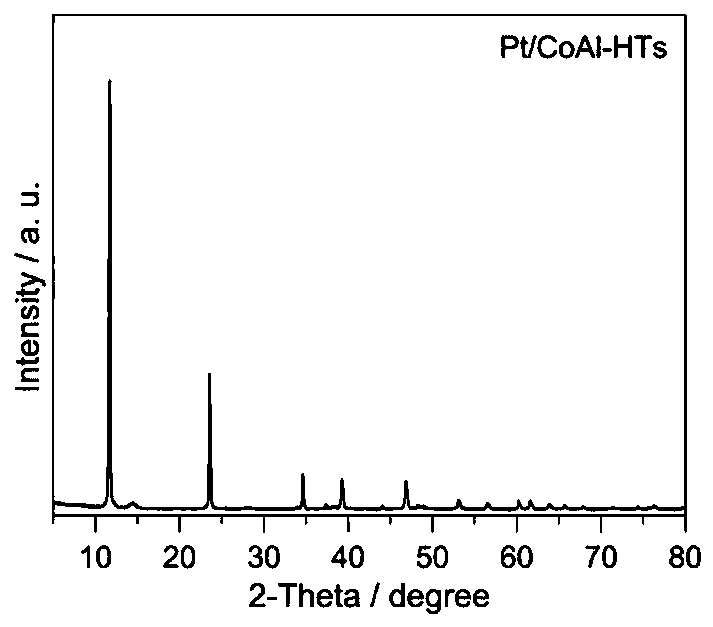

[0028] Add 40mL of benzyl alcohol into a 100mL round bottom flask, 33.3mg of Pt(acac) 2 Dissolve in benzyl alcohol and stir for 15 minutes until the solution is clear. The hydrotalcite carrier CoAl-HTs (Co:Al=2:1, 1:1) was uniformly dispersed in the above clear solution, and 1 atm CO gas was introduced under the condition of stirring, and heated at 180°C for 3h. Cool to room temperature, add 50mL of ethanol, wash with ethanol several times, dry at 70°C for 8h, and grind to obtain a supported monometallic Pt / CoAl-HTs catalyst. The loading amount of Pt is 0.1-6.0%, and the rest is carrier.

Embodiment 2

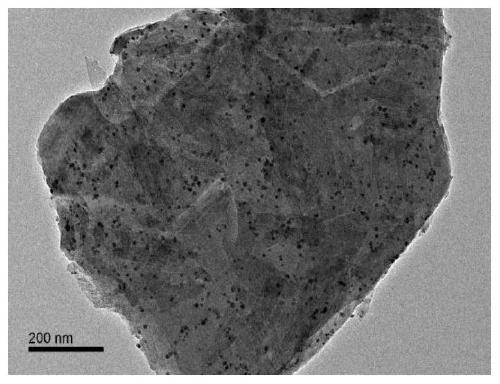

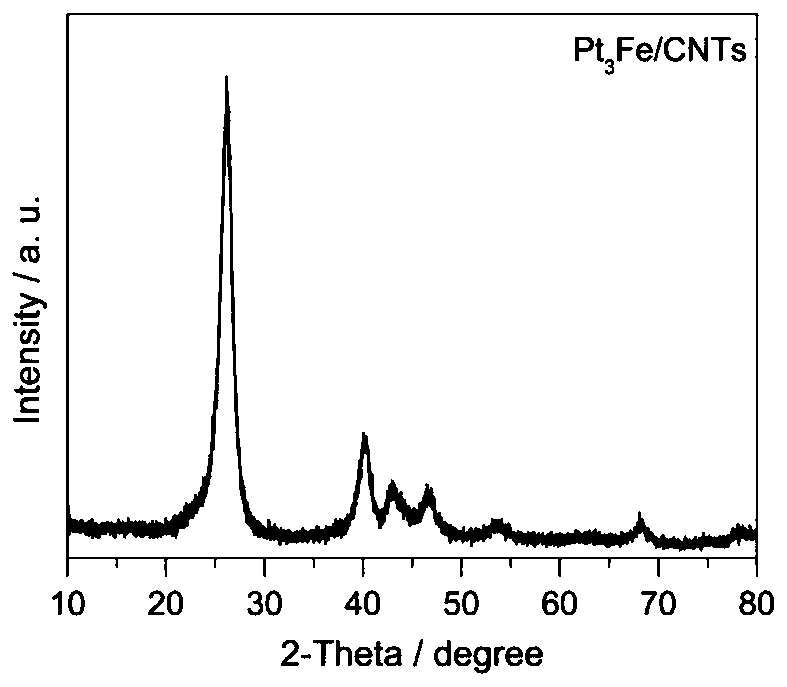

[0030] Add 40mL of benzyl alcohol into a 100mL round bottom flask, 33.3mg of Pt(acac) 2 and 10mg Fe(acac) 3 Dissolve in benzyl alcohol and stir for 15 min until the solution is clear. The multi-walled carbon nanotube carrier was uniformly dispersed in the above clear solution, and 1 atm CO gas was introduced under stirring, heated at 190°C for 2h, cooled to room temperature, washed several times with ethanol, and dried at 70°C for 13h to obtain the supported bimetallic Pt 3 Fe / CNTs catalyst. The loading amount of Pt is 0.1-6.0%, the content molar ratio of Fe and Pt is 0.01-1, and the rest is carrier.

Embodiment 3

[0032] Add 40mL of benzyl alcohol into a 100mL round bottom flask, 33.3mg of Pt(acac) 2 and 10mg Fe(acac) 3 Dissolve in benzyl alcohol and stir for 15 min until the solution is clear. Carrier CeO 2 or TiO 2 Disperse evenly in the above clear solution, pass 2atm CO gas under stirring, heat at 200°C for 5h, cool to room temperature, wash with ethanol several times, and dry at 70°C for 21h to obtain supported bimetallic Pt 3 Fe / CeO 2 catalyst. The loading amount of Pt is 0.1-6.0%, the content molar ratio of Fe and Pt is 0.01-1, and the rest is carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com