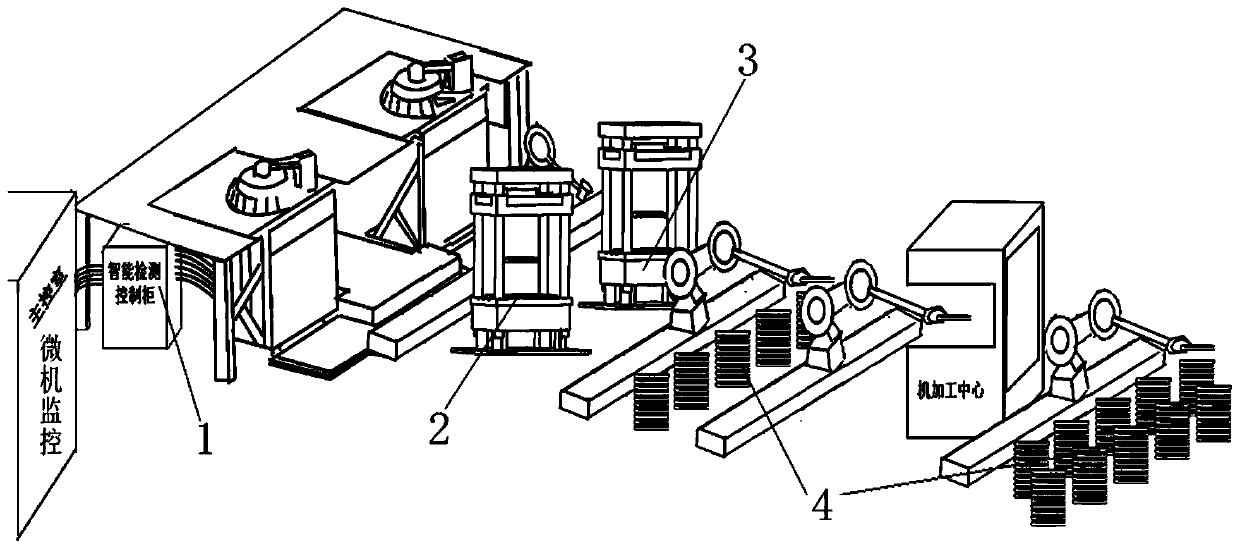

Semi-solid short-flow intelligent manufacturing system and method for steel flat flanges

A steel flat flange, short process technology, applied in the field of steel flat flange semi-solid short process intelligent manufacturing system, can solve the problem of low utilization rate of flange material blanking process, easy deformation of flange plate, easy occurrence of cracks, etc. problems, to ensure the compactness of the product, the production process is controllable and easy to adjust, and the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] The mass ratio of the alloy composition is B: 1.0%, C: 0.3%, Si: 0.5%, Mn: 0.5%, Cr: 1.0%, Ti: 0.2%, Cu: 0.5%, and the rest elements are Fe and some unavoidable impurities element.

[0067] The production parameters of high boron steel flat flange are: semi-solid preparation process parameters: chute angle—30°, chute length—450mm, chute temperature—25°C

[0068] Extrusion process parameters: mold temperature—300°C, pouring temperature—1470°C, specific pressure—100MPa, holding time—60s, extrusion speed—6~10mm / s.

[0069] Organizational Analysis:

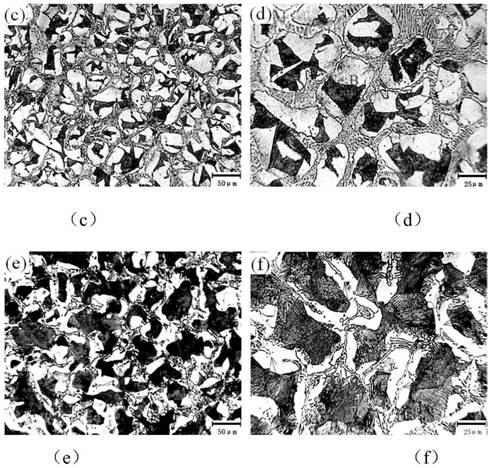

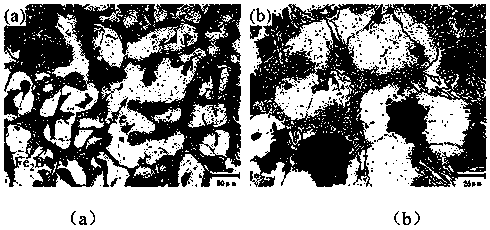

[0070] see Figure 7 , α-Fe in the as-cast structure is distributed in developed dendrites, and the dendrite arms are 50-80 μm; the eutectic Fe2B network between dendrites is relatively developed, mostly fishbone, and its width is about 20 μm. After semi-solid casting, α-Fe is obviously refined, but the Fe2B network is still very developed, such as Figure 7 (c), (d). Figure 7 (e)-(f) are the extruded microstructures at d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com