Communication cable

A technology for communication cables and sheath tubes, which is applied in the manufacture of communication cables, insulated cables, and cables/conductors. It can solve the problems of performance degradation, inability to isolate cables from high temperature, and accelerated aging. It achieves soft performance and enhanced heat insulation effects. , good heat sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

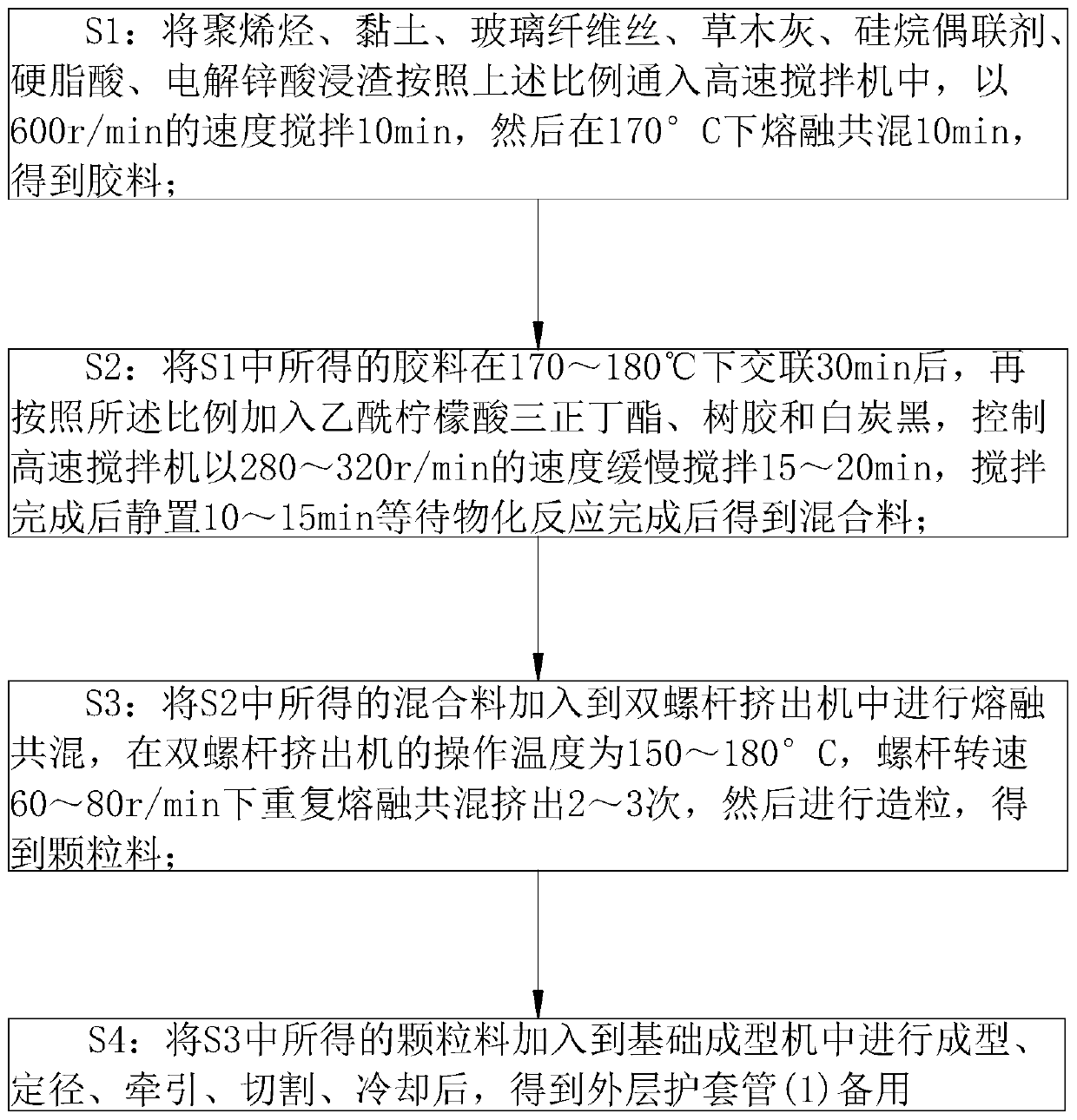

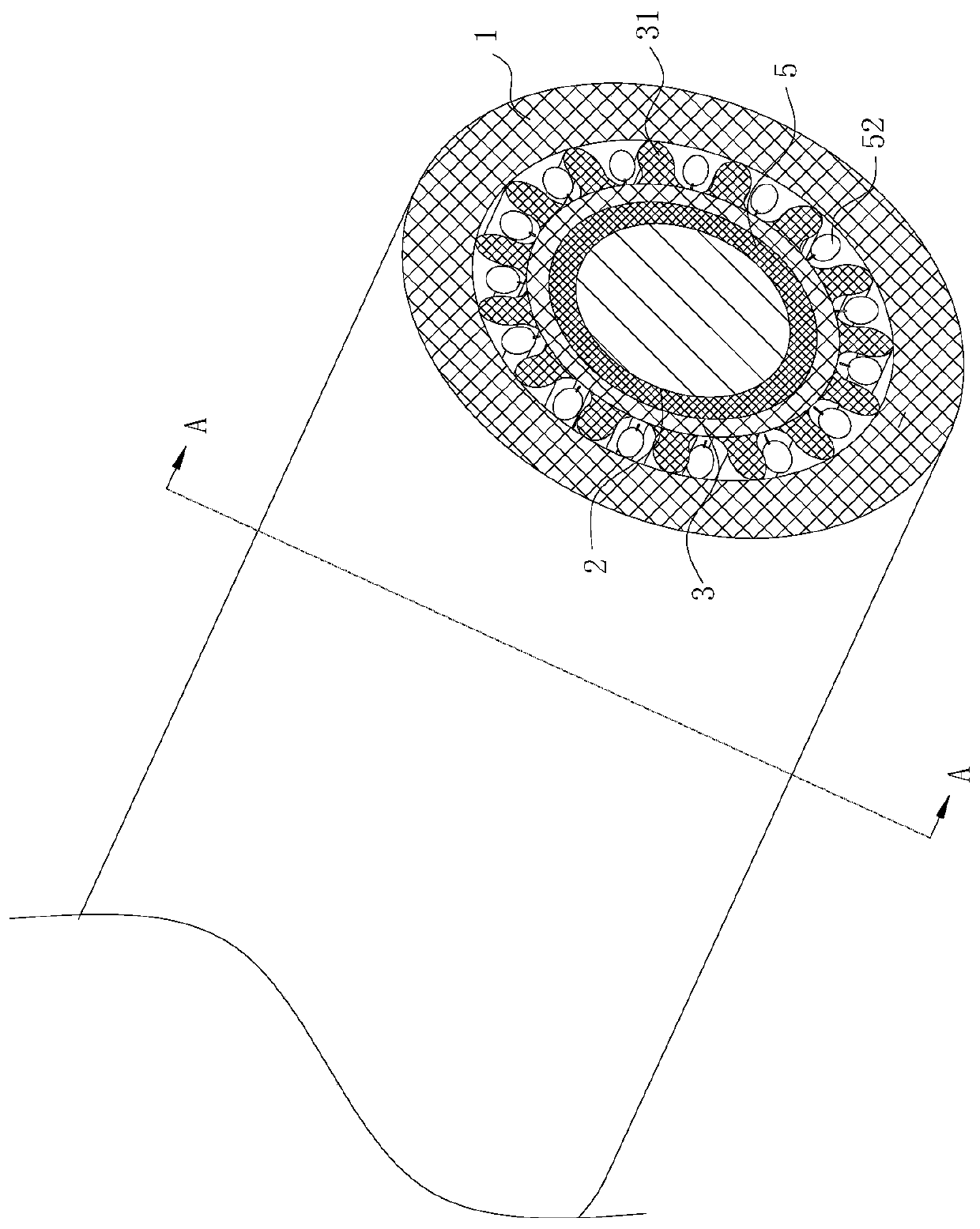

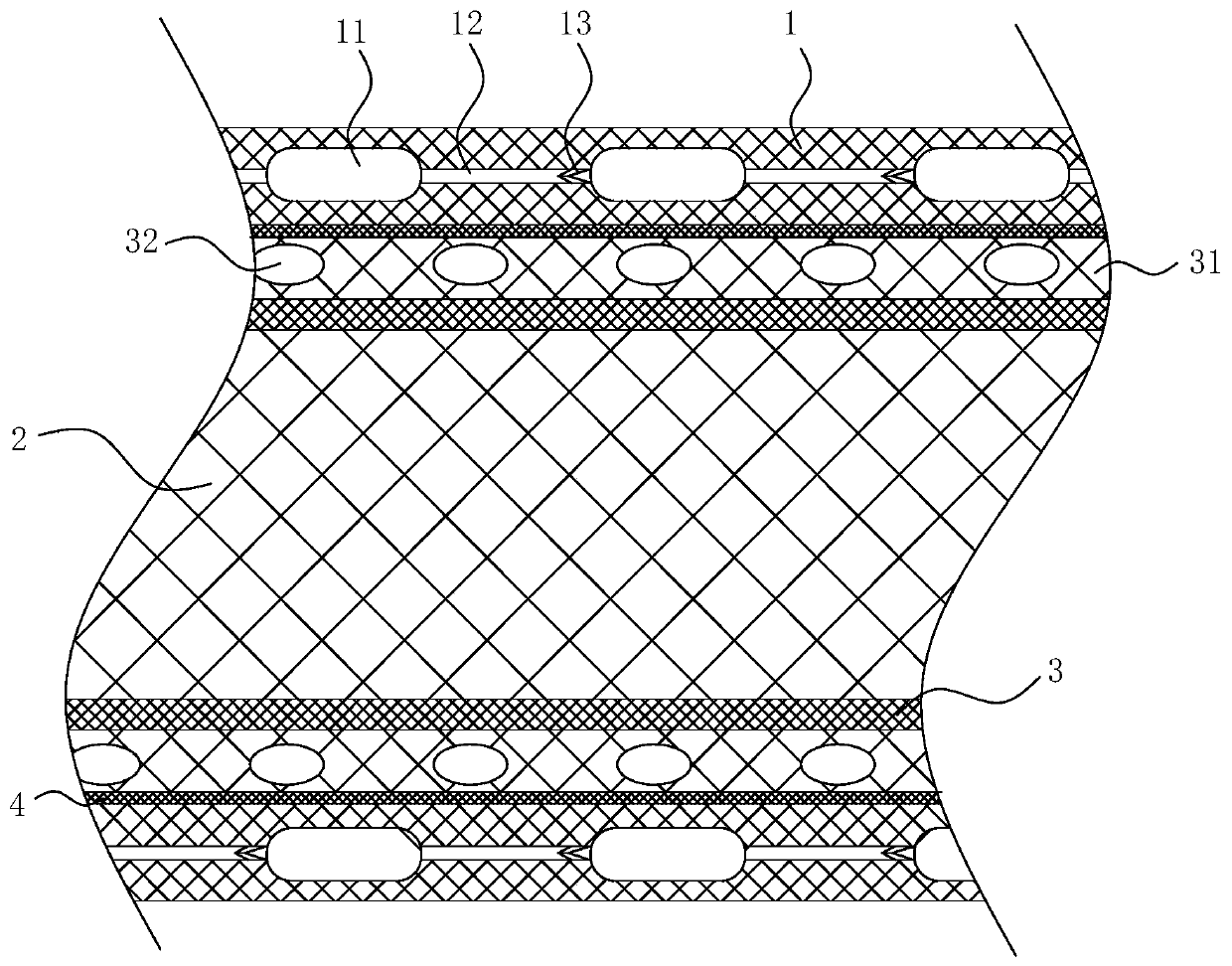

[0032] Such as Figure 1 to Figure 4 As shown, a communication cable according to the present invention includes an outer sheath tube; the outer sheath tube 1 is made of the following raw materials:

[0033] 85-90 parts by weight of polyolefin; 5-8 parts by weight of glass fiber; 6-10 parts by weight of clay; 3-4 parts by weight of plant ash; 2-3 parts by weight of acetyl tri-n-butyl citrate; 2-4 parts by weight of gum ; 0.6-1 parts by weight of silane coupling agent; 1.5-2 parts by weight of stearic acid; 0.7-0.9 parts by weight of white carbon black; 4-5 parts by weight of electrolytic zinc acid leaching residue;

[0034] The polyolefin is ethylene-1-octene copolymer; the gum is gum arabic;

[0035] The preparation method of the outer sheath p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com