Alkaline hydrogen peroxide mechanical pulping method based on mild pretreatment and disc milling chemical treatment

A chemical treatment, hydrogen peroxide technology, applied in chemical/chemical mechanical pulp, water/steam pretreatment, pretreatment with alkaline compounds, etc., can solve the problems of poor pulp quality and poor stability, achieve low production cost, The effect of fine process, improved bulk and optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The alkaline hydrogen peroxide mechanical pulping method of the present invention's mild pretreatment and disc grinding chemical treatment, flow is specifically implemented according to the following steps:

[0043] Step 1. Pretreat the hardwood log chips with biological enzymes, then wash them, pre-steam the washed chips at normal pressure, and finally decompose the steamed wood chips in the first stage of double-screw extrusion, and remove the The air, excess moisture and resin are squeezed out, and the wood chips are crushed;

[0044] The biological enzyme selected in step 1 is the sum of laccase, HBT mediator, and pectinase, that is, first add the HBT mediator with a mass fraction of 0.5%, then add 10IU / g of laccase, and finally add 8IU / g of pectinase Gluease, pretreatment time 110min, pH=4, temperature 50°C, pretreatment concentration 10% by mass.

[0045] The temperature of the water during washing in step 1 is 60° C., the washing time is 15 minutes, the temperat...

Embodiment 2

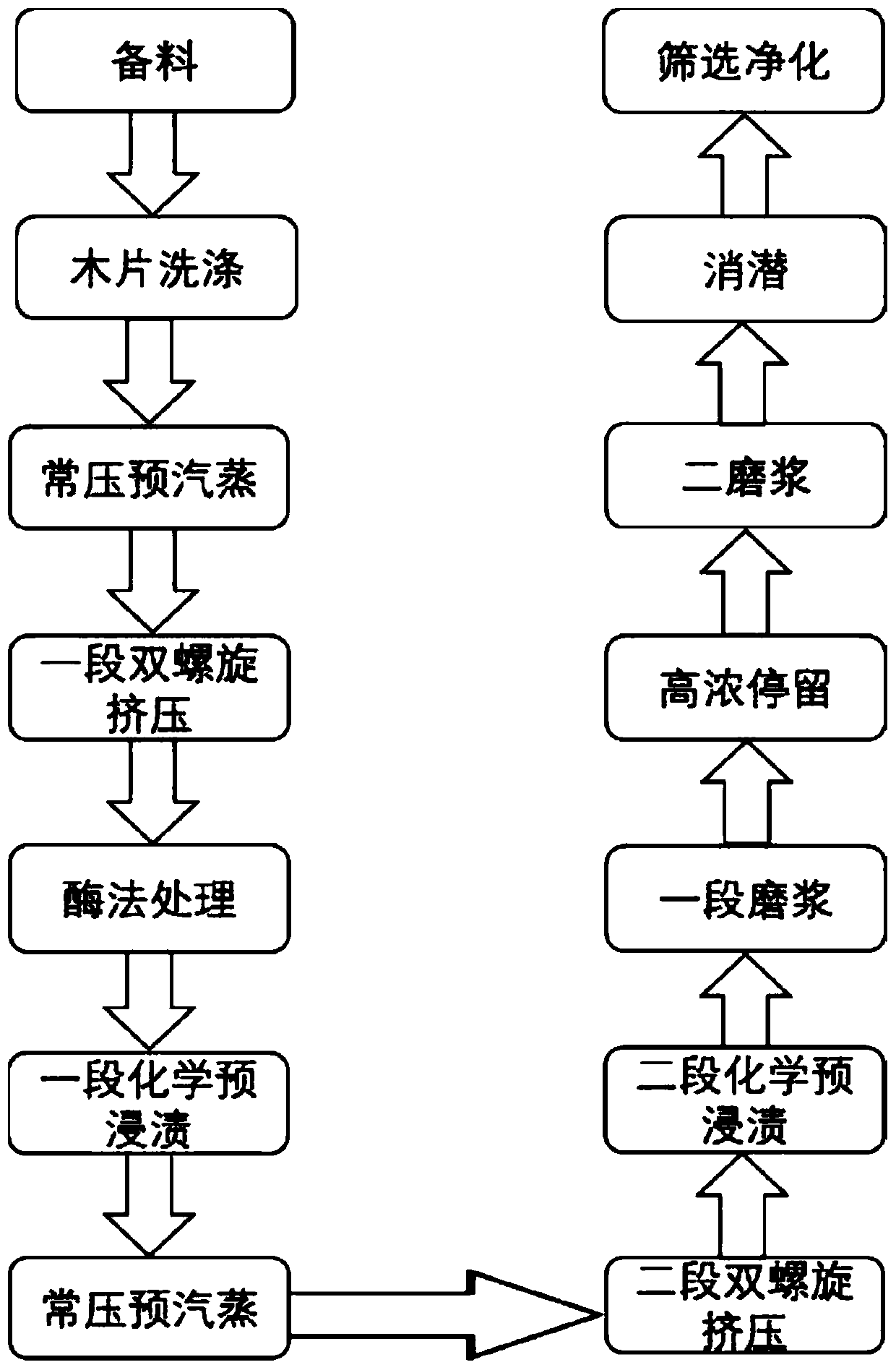

[0059] The alkaline hydrogen peroxide mechanical pulping method of mild pretreatment and disc grinding chemical treatment of the present invention, flow chart is as figure 1 As shown, the specific steps are as follows:

[0060] Step 1. Pretreat the hardwood log chips with biological enzymes, then wash them, pre-steam the washed chips at normal pressure, and finally decompose the steamed wood chips in the first stage of double-screw extrusion, and remove the The air, excess moisture and resin are squeezed out, and the wood chips are crushed;

[0061] The biological enzyme selected in step 1 is the sum of laccase, HBT mediator and pectinase, that is, firstly add the HBT mediator with a mass fraction of 0.5%, then add 12IU / g of laccase, and finally add 10IU / g of pectinase Gluease, pretreatment time 110min, pH=6, temperature 55°C, pretreatment concentration 10% by mass.

[0062] The temperature of the water during washing in step 1 is 70° C., the washing time is 20 minutes, the ...

Embodiment 3

[0076] The alkaline hydrogen peroxide mechanical pulping method of mild pretreatment and disc grinding chemical treatment of the present invention, flow chart is as figure 1 As shown, the specific steps are as follows:

[0077] Step 1. Pretreat the hardwood log chips with biological enzymes, then wash them, pre-steam the washed chips at normal pressure, and finally decompose the steamed wood chips in the first stage of double-screw extrusion, and remove the The air, excess moisture and resin are squeezed out, and the wood chips are crushed;

[0078] The biological enzyme selected in step 1 is the sum of laccase, HBT mediator and pectinase, that is, first add the HBT mediator with a mass fraction of 0.5%, then add 11IU / g of laccase, and finally add 9IU / g of pectinase Gluease, pretreatment time 120min, pH=5, temperature 53°C, pretreatment concentration 13% by mass.

[0079] In step 1, the temperature of the water during washing is 65° C., the washing time is 18 minutes, the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com