Industrial boiler water quality online detection method

A detection method and technology of industrial boilers, applied in the direction of measuring devices, preparation of test samples, sampling, etc., can solve the problem of difficulty in obtaining boiler water samples, inaccurate test results, and easy misleading water quality adjustment methods (dosing or sewage discharge, etc.) problems, to achieve the effect of excellent water quality, shorten cooling time, and speed up cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

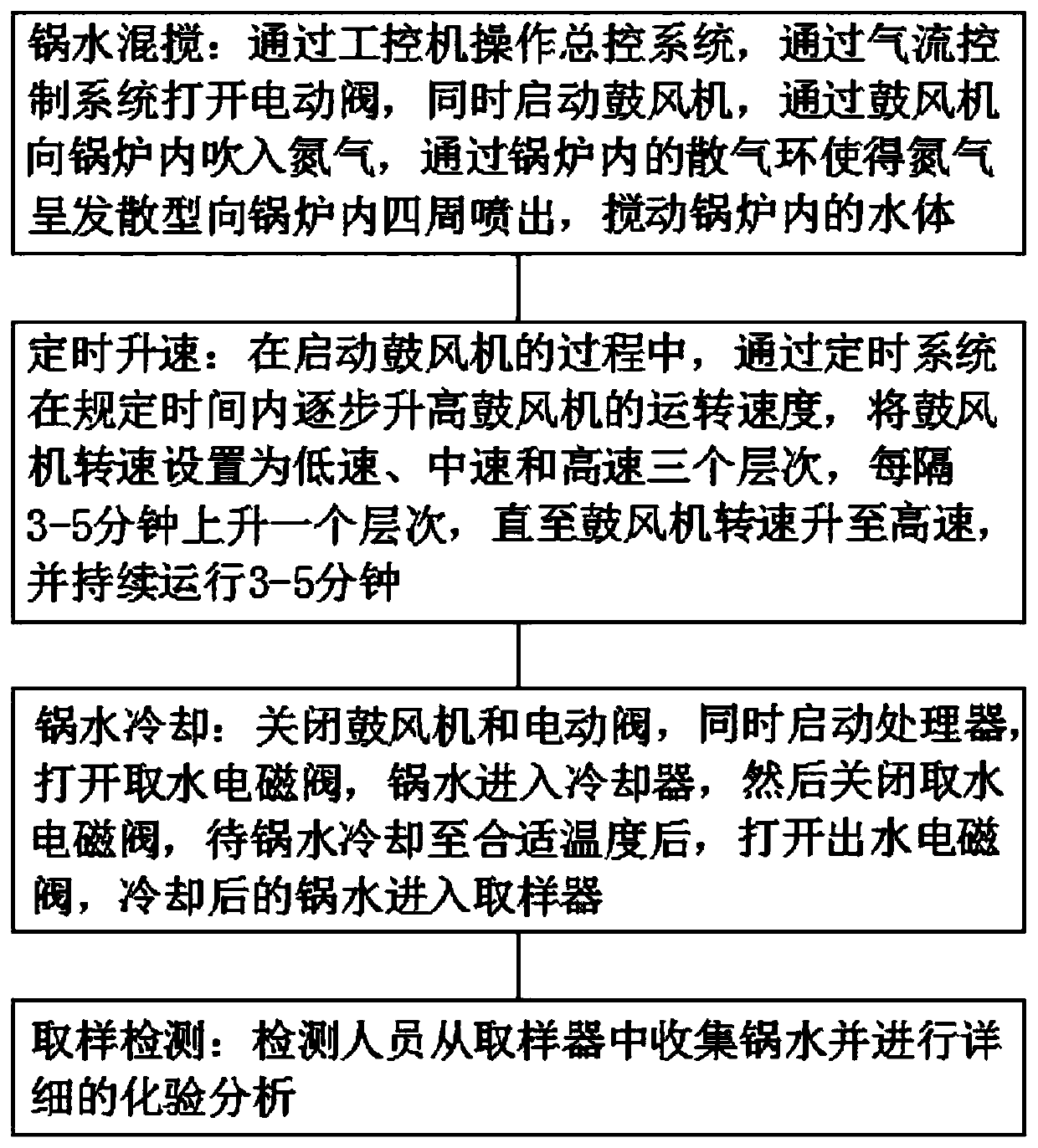

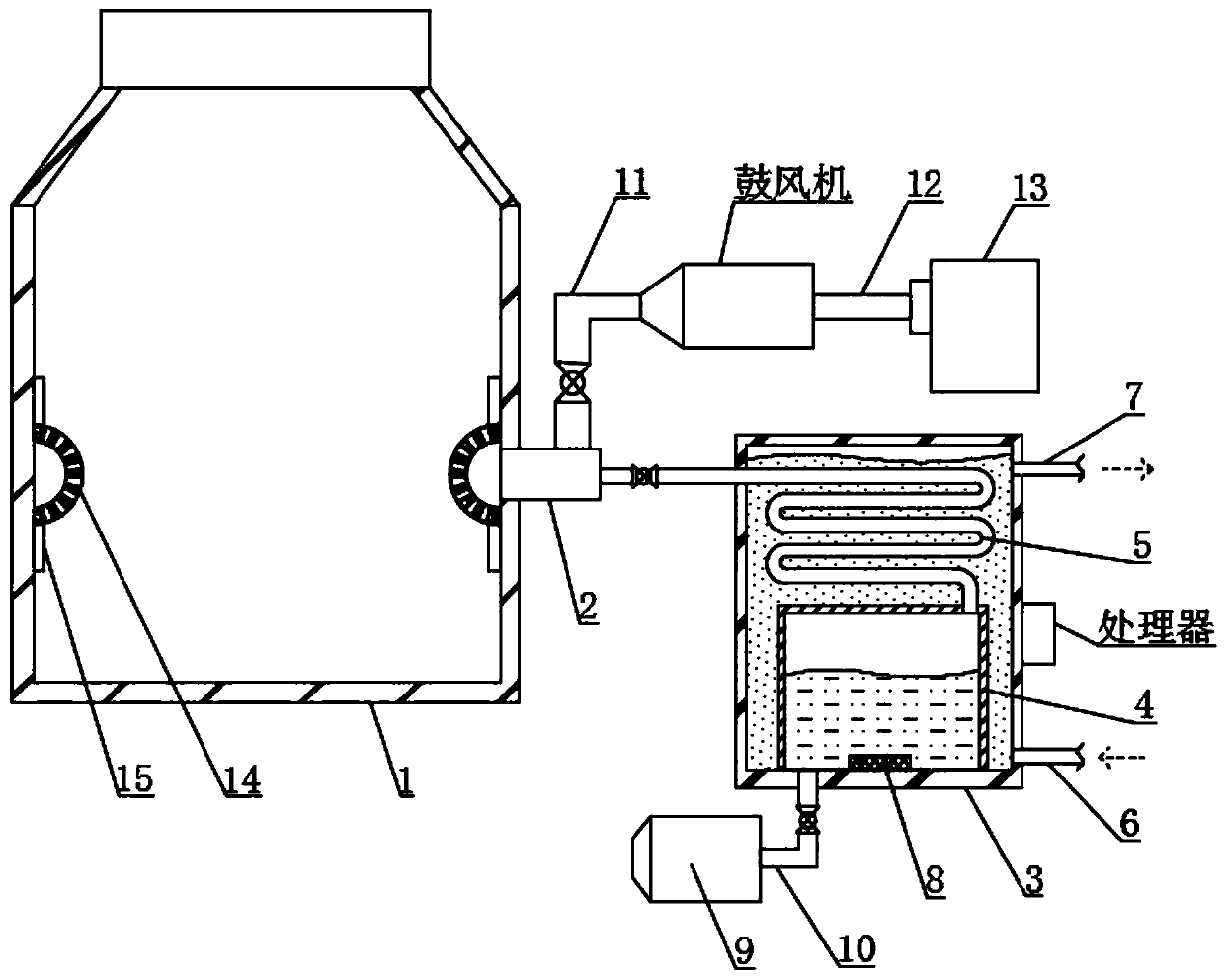

[0035] as attached Figure 1-4 The shown a kind of industrial boiler water quality on-line detection method of the present invention comprises the following steps:

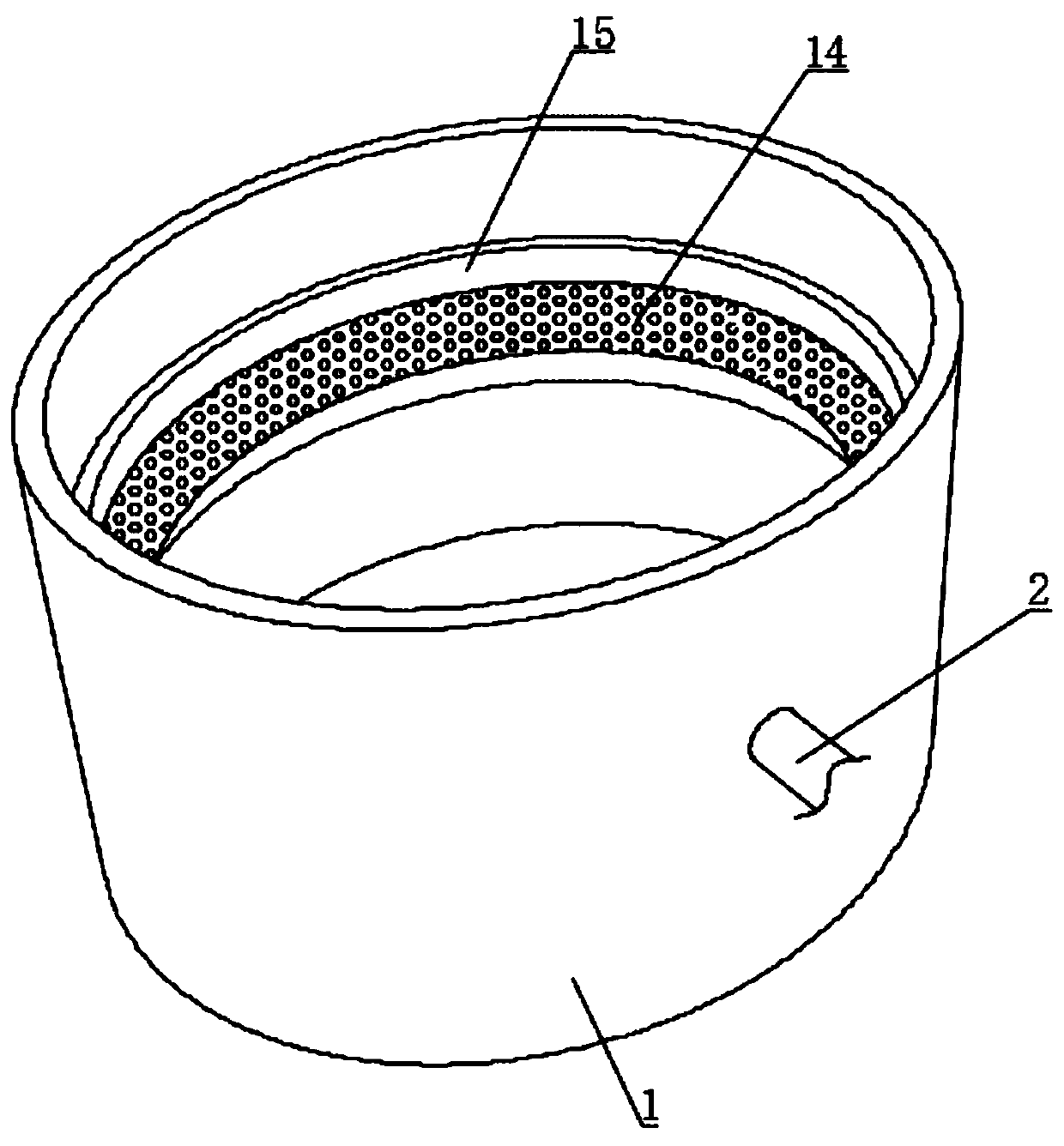

[0036] S1. Boiler water mixing: operate the main control system through the industrial computer, open the electric valve through the air flow control system, and start the blower at the same time, blow nitrogen into the boiler through the blower, and make the nitrogen diverge into the boiler through the gas diffuser ring in the boiler Spray around the inside and stir the water in the boiler;

[0037] S2. Timing speed up: In the process of starting the blower, gradually increase the speed of the blower within the specified time through the timing system, set the speed of the blower to three levels of low speed, medium speed and high speed, and increase one level every 3 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com